Stack binding machine and control method thereof

A strapping machine and small-bundle technology, which is applied in stacking receiving devices, separating objects, sending objects, etc., can solve the problems of not being able to stack work, bumping into fences, etc., and achieve the effect of prolonging the temporary stop time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

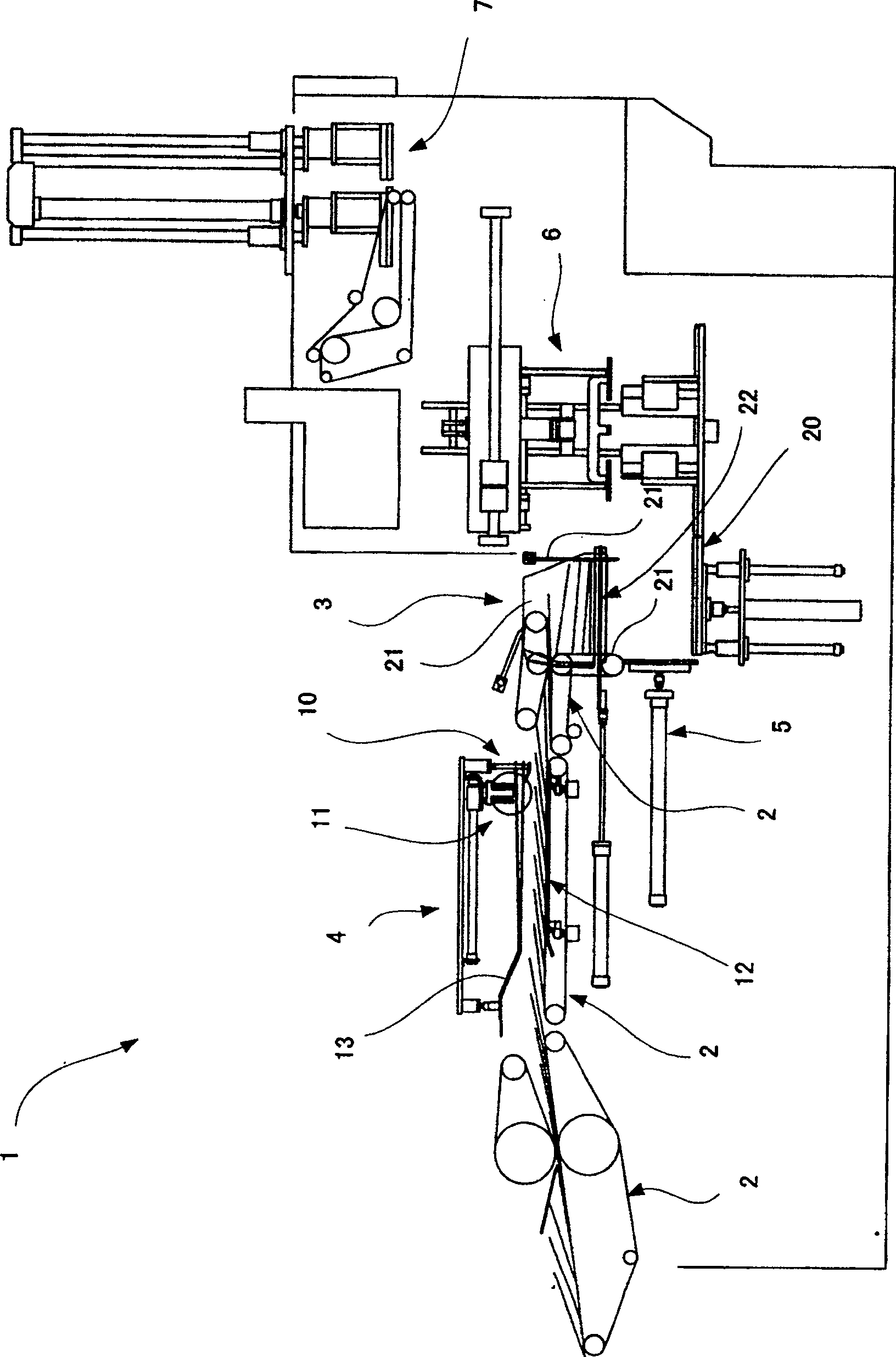

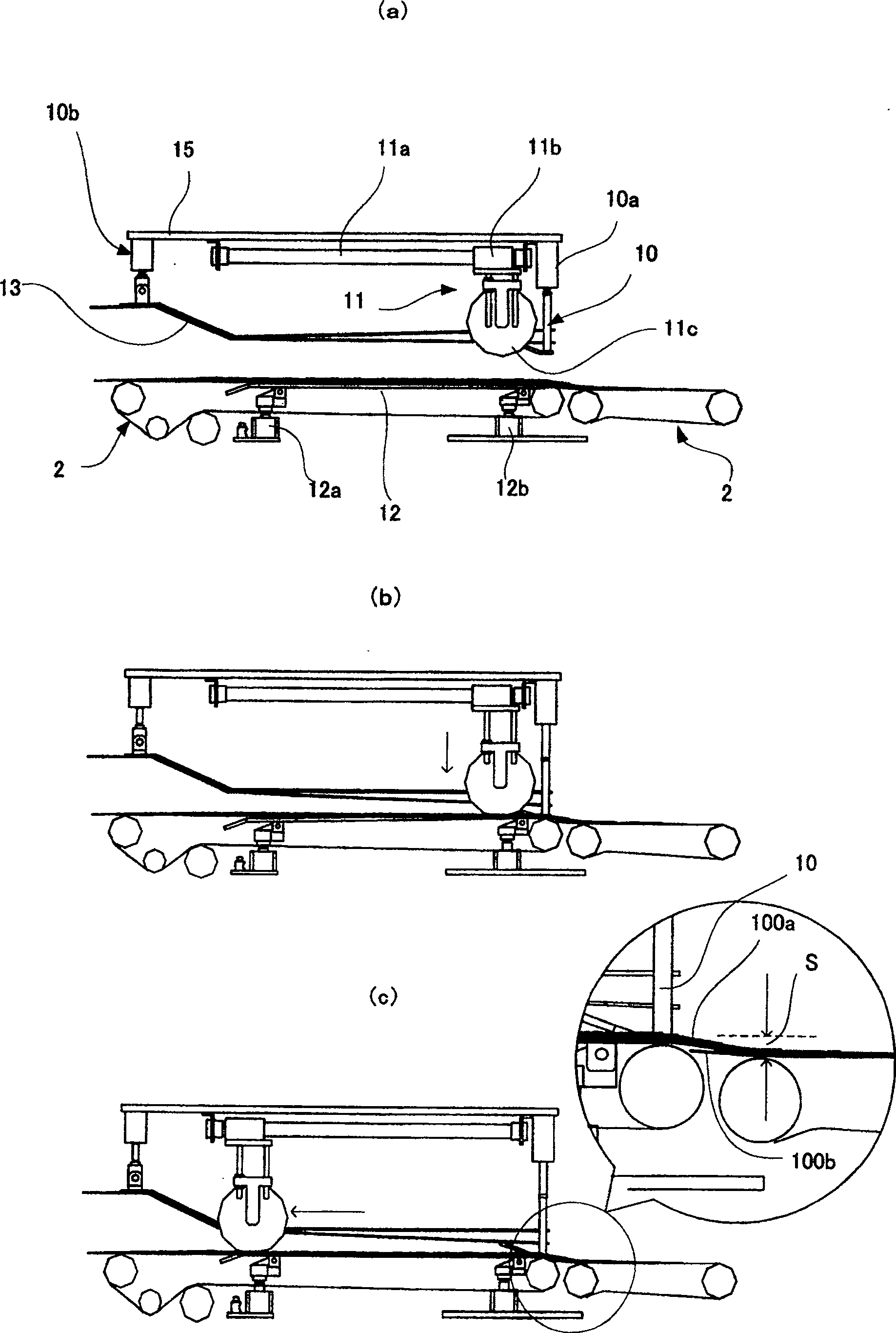

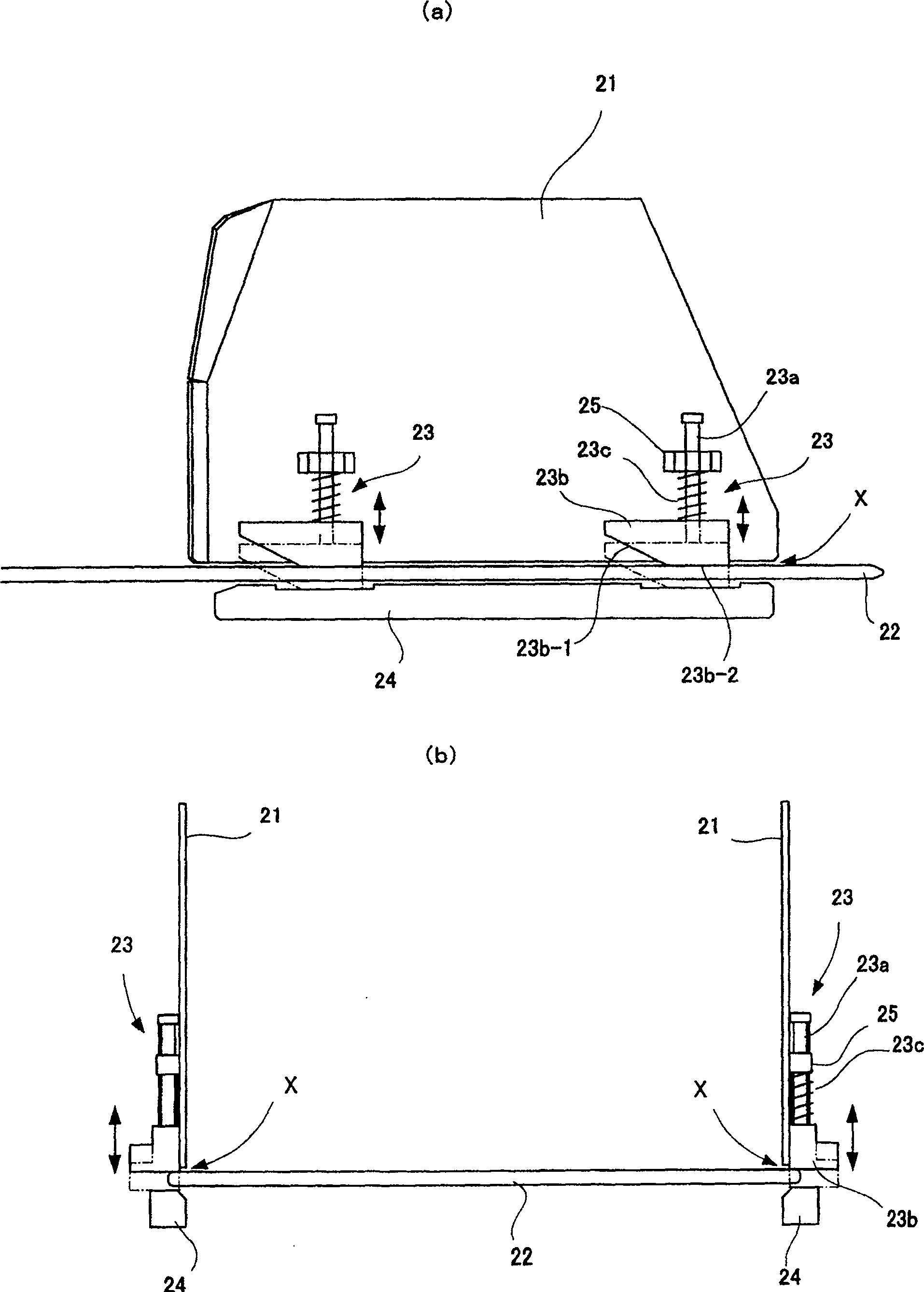

[0029] Refer below Figure 1 ~ Figure 4 , a preferred embodiment of the stacking and binding machine of the present invention will be described.

[0030] Stacking and binding machine 1 such as figure 1 It is shown that there are: a conveyor belt 2 that conveys a stack of papers in a staggered and overlapping state, a small bundle accumulating device 3 that accumulates a stack of papers that have fallen freely from the end of the conveyor belt 2 and forms small bundles, and a device that temporarily blocks a stack of papers on the conveyor belt 2 The cut-off device 4 of paper flow, the pusher 5 that pushes out the small bundle to the downstream side or the front during the flow of a bundle of paper is blocked by the cut-off device 4, and the large pusher that accumulates the small bundle into a large bundle again. A bundle making part 6 and a bundling part 7 for bundling large bundles.

[0031] The conveyor belt 2 is constituted by winding a plurality of endless ropes in para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com