Gas blowing type negative pressure air-suction device

A gas injection and air suction device technology, which is applied to jet pumps, non-displacement pumps, machines/engines, etc., can solve problems such as difficulty in noise production process, and achieve the effects of facilitating product process production, reducing process costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

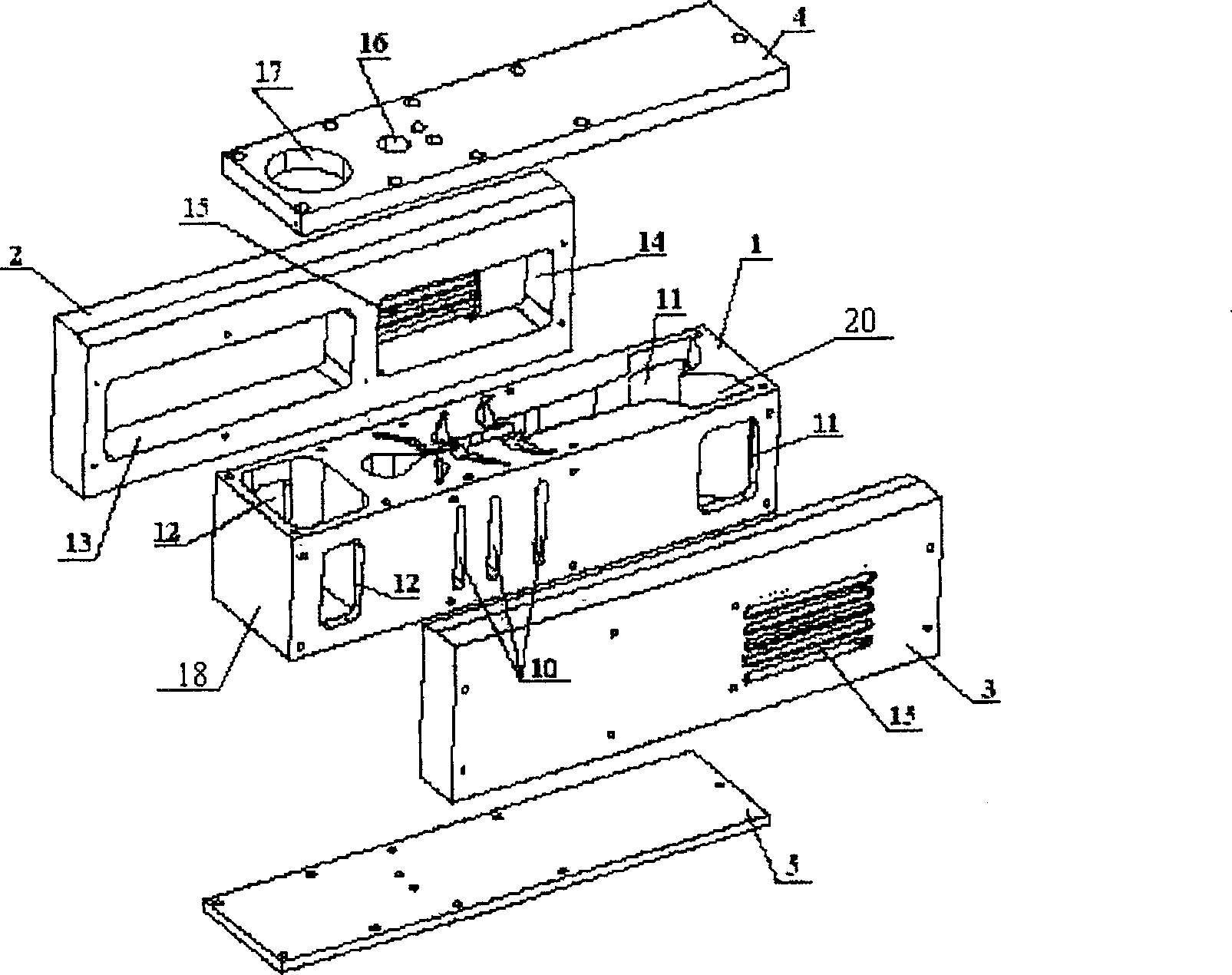

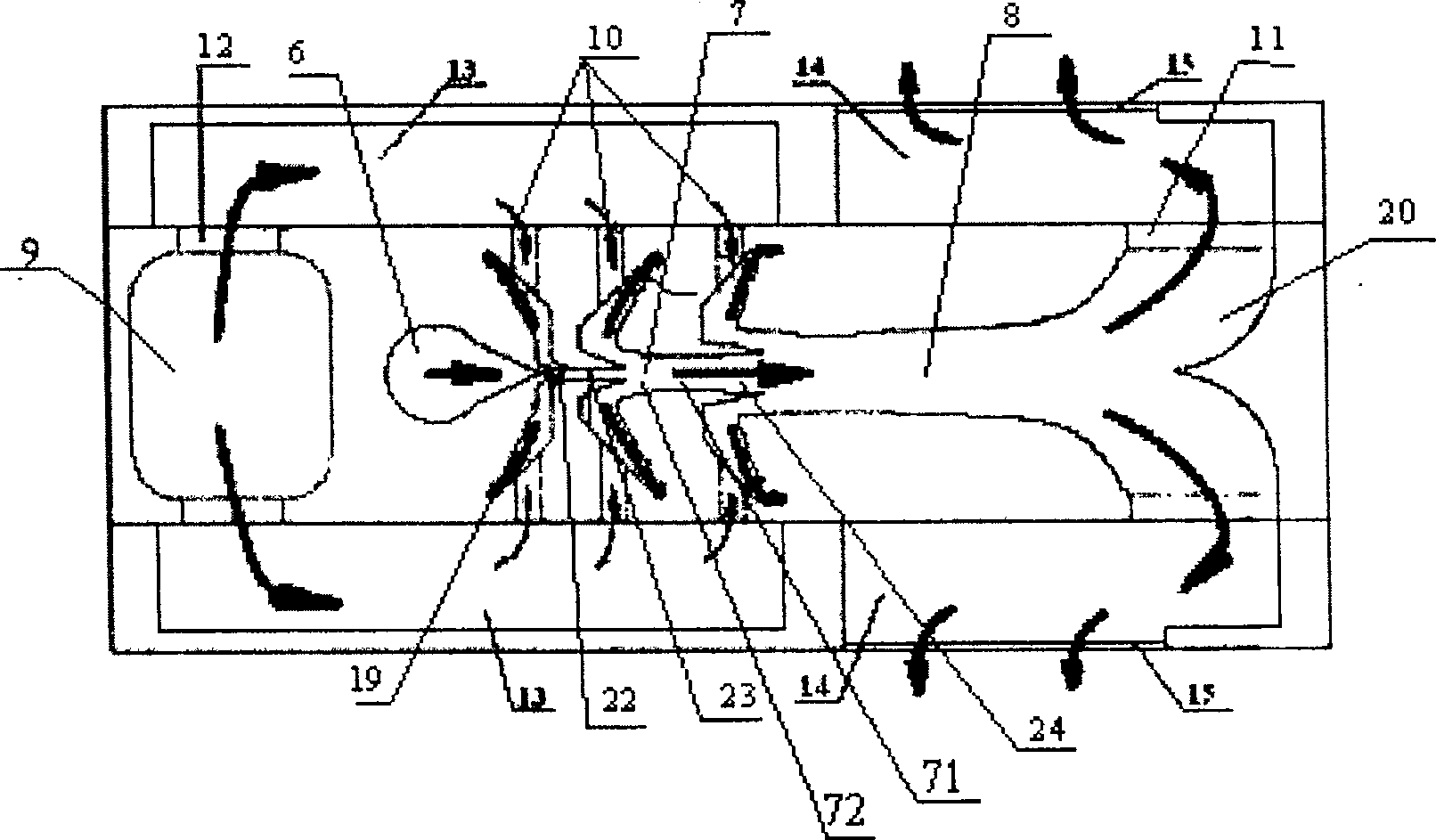

[0020] Embodiment 1, a kind of gas injection type negative pressure suction device, such as figure 1 with figure 2 As shown, it includes: spray plate seat 1, left side plate 2, right side plate 3, upper cover plate 4 and lower cover plate 5. Among them, the gas injection type negative pressure suction device is based on the injection plate base 1, and the left side plate 2, the right side plate 3, the upper cover plate 4, and the lower cover plate 5 are all fixed on the injection plate base 1 by screws. The joint surfaces of plate 2, right side plate 3, upper cover plate 4, lower cover plate 5 and spray plate seat 1 are provided with gaskets or coated with sealant to ensure better sealing effect.

[0021] combine figure 1 with figure 2 , A vacuum chamber 9 , a pressure chamber 6 , an injection channel 7 , an exhaust channel 8 and an exhaust chamber 20 are provided in sequence from back to front on the injection plate base 1 . A partition is provided between the vacuum ch...

Embodiment 2

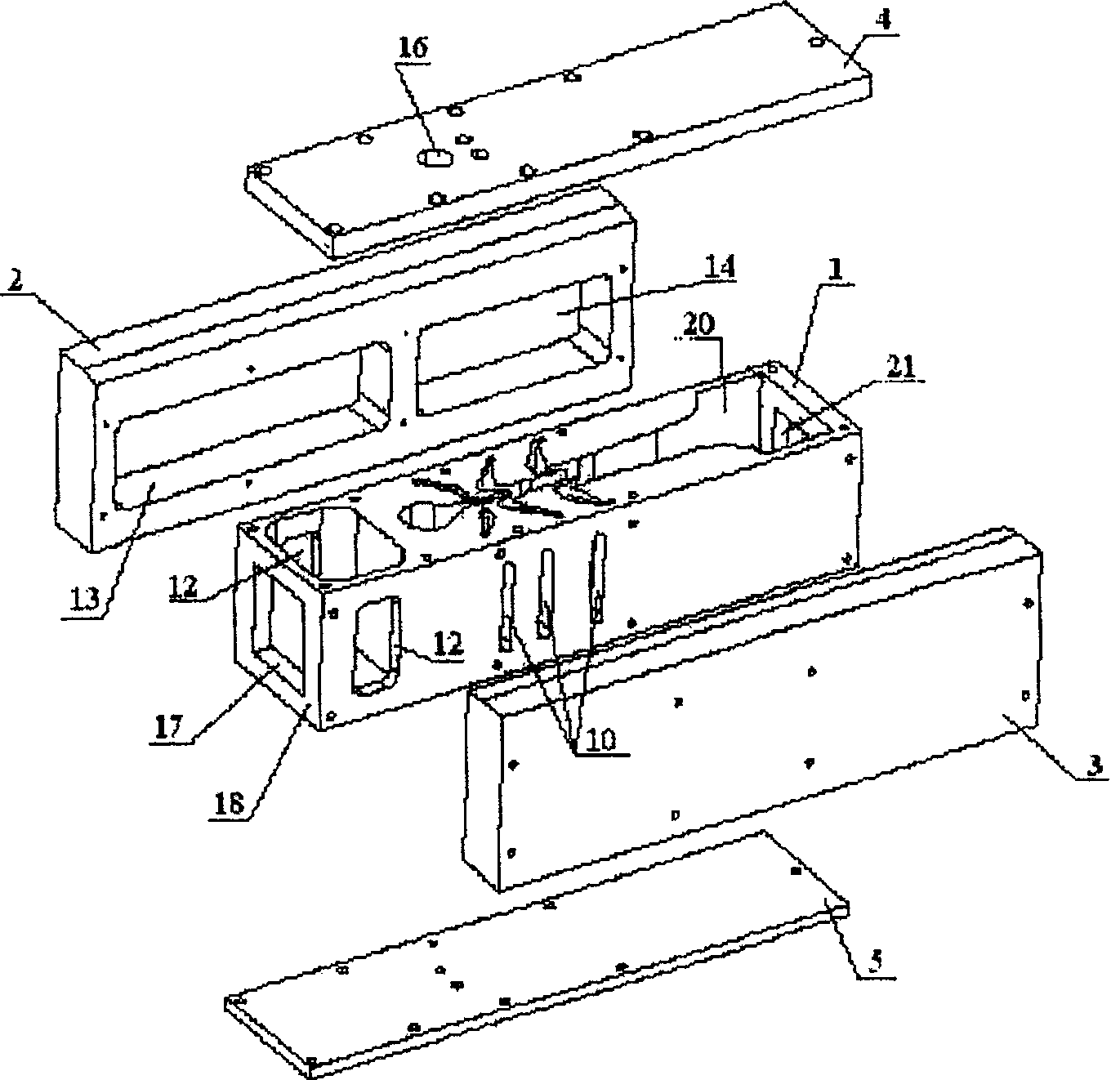

[0024] Embodiment 2, another kind of gas injection type negative pressure suction device, such as image 3 with Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the external vacuum port 17 is moved from the upper cover plate 4 to the injection plate seat 1, and no external exhaust is provided on the left side plate 2 and the right side plate 3. Port 15, but directly on the front end injection plate seat 1 of the expanded exhaust chamber 20, exhaust hole 21 is set (certainly, also can offer external exhaust port 15 on left side plate 2 and right side plate 3 simultaneously. ). Of course, other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com