Portalachse

A portal axle and axle technology, which is applied to vehicle components, control devices, transportation and packaging, etc., can solve the problems of increasing the diameter of the intermediate gear, the door distance cannot be further increased, and the spring support connection cannot be performed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

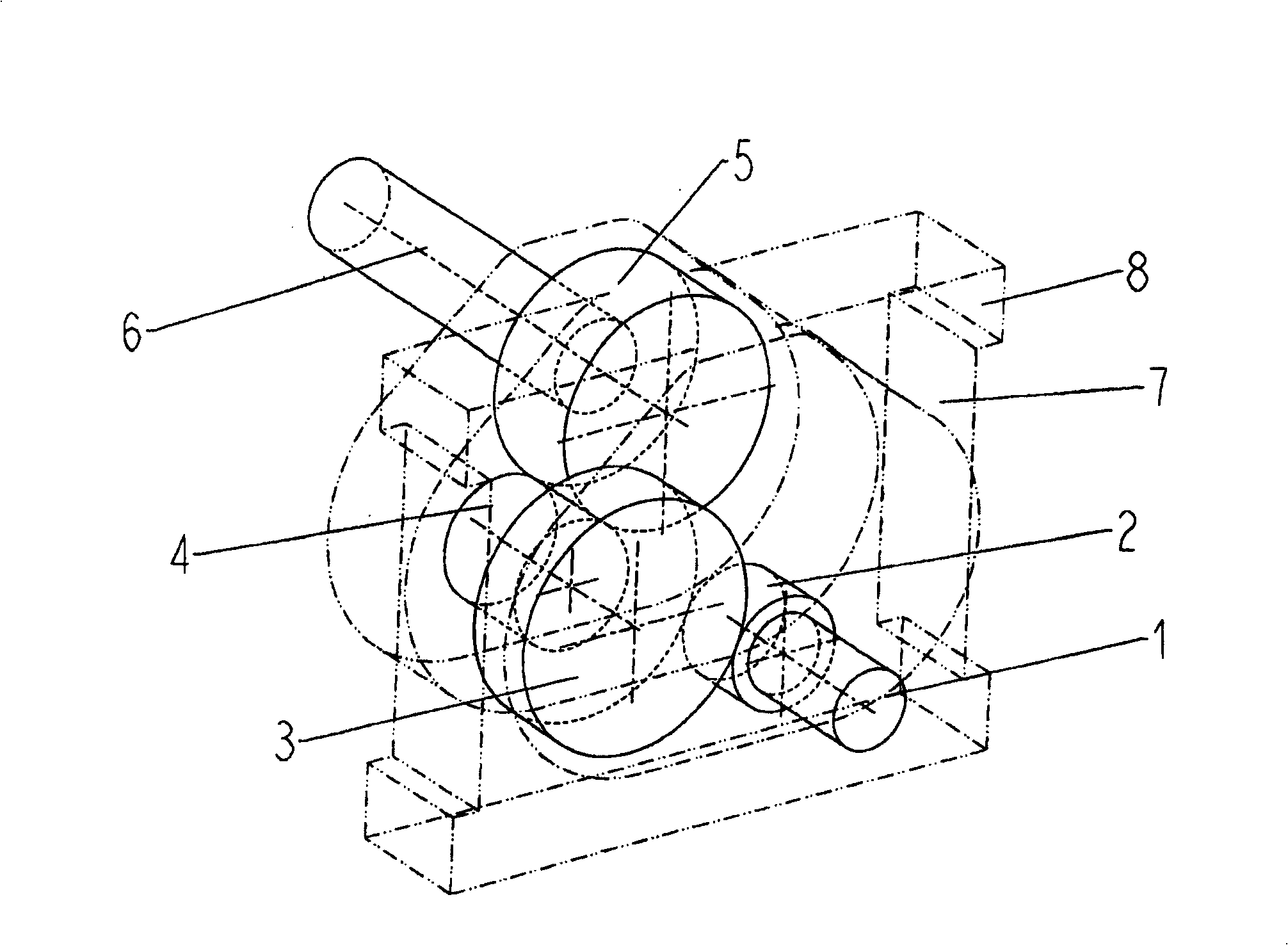

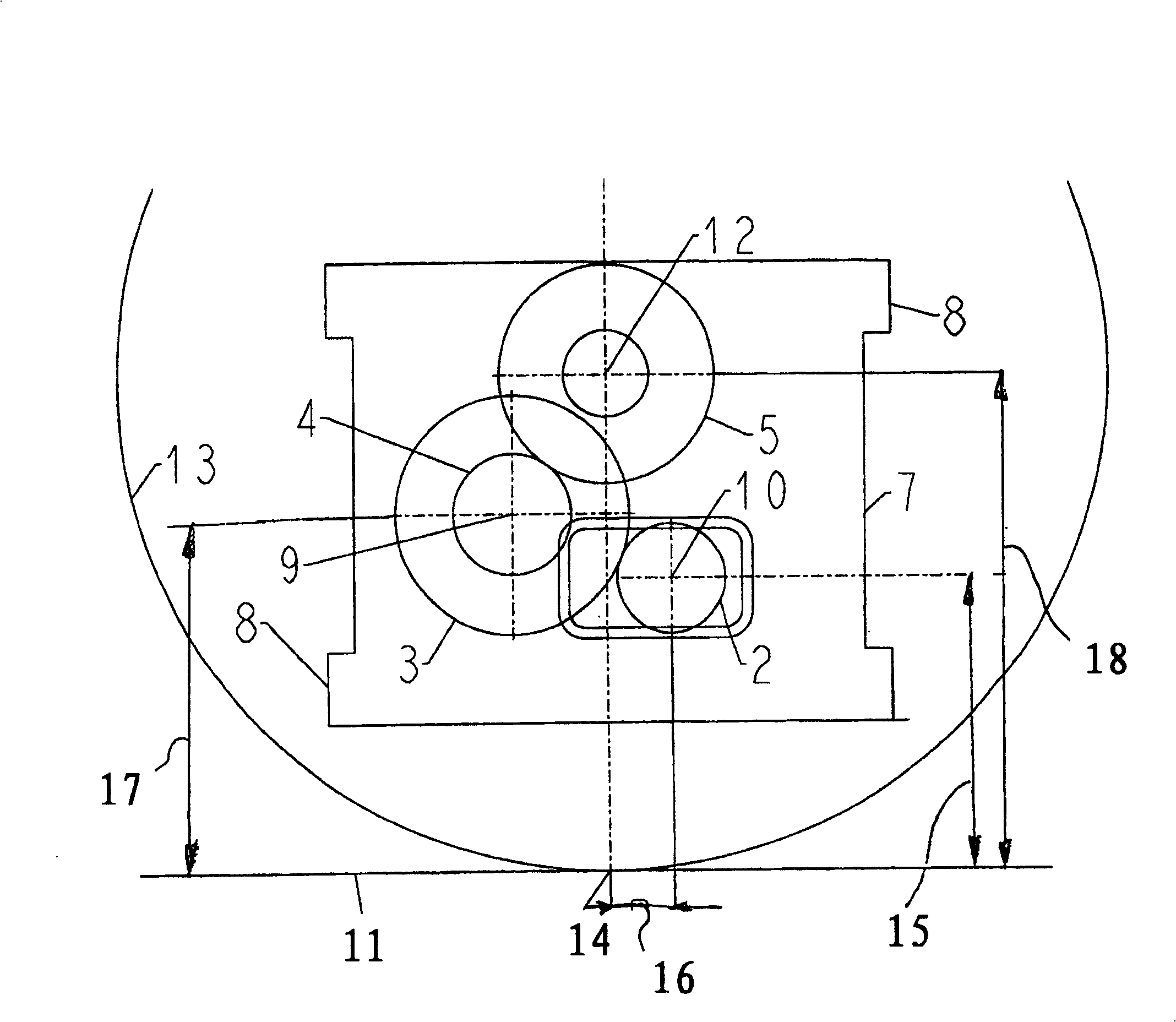

[0012] about figure 1 :

[0013] The basic structure of a portal axle for low-frame vehicles is known from DE 196 04 730 A1, and the invention is to include its features in its entirety except for the wheel-side reduction.

[0014] A differential (not shown) drives an axle 1 , which is connected in a rotationally fixed manner to a drive spur gear 2 . The drive spur gear 2 is operatively connected to a first countershaft spur gear 3 , which is connected in a rotationally fixed manner to a second countershaft spur gear 4 , or is formed in one piece with this countershaft spur gear. The second countershaft spur gear 4 is operatively connected to an output spur gear 5 which drives a not shown vehicle wheel via an output shaft 6 . The wheel gear reducer housing 7 surrounds the wheel gear reducer and has connecting points 8 to which spring bearings (not shown) can be connected, which connect the vehicle axle to the vehicle chassis. The axle 1 is arranged in the upper region of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com