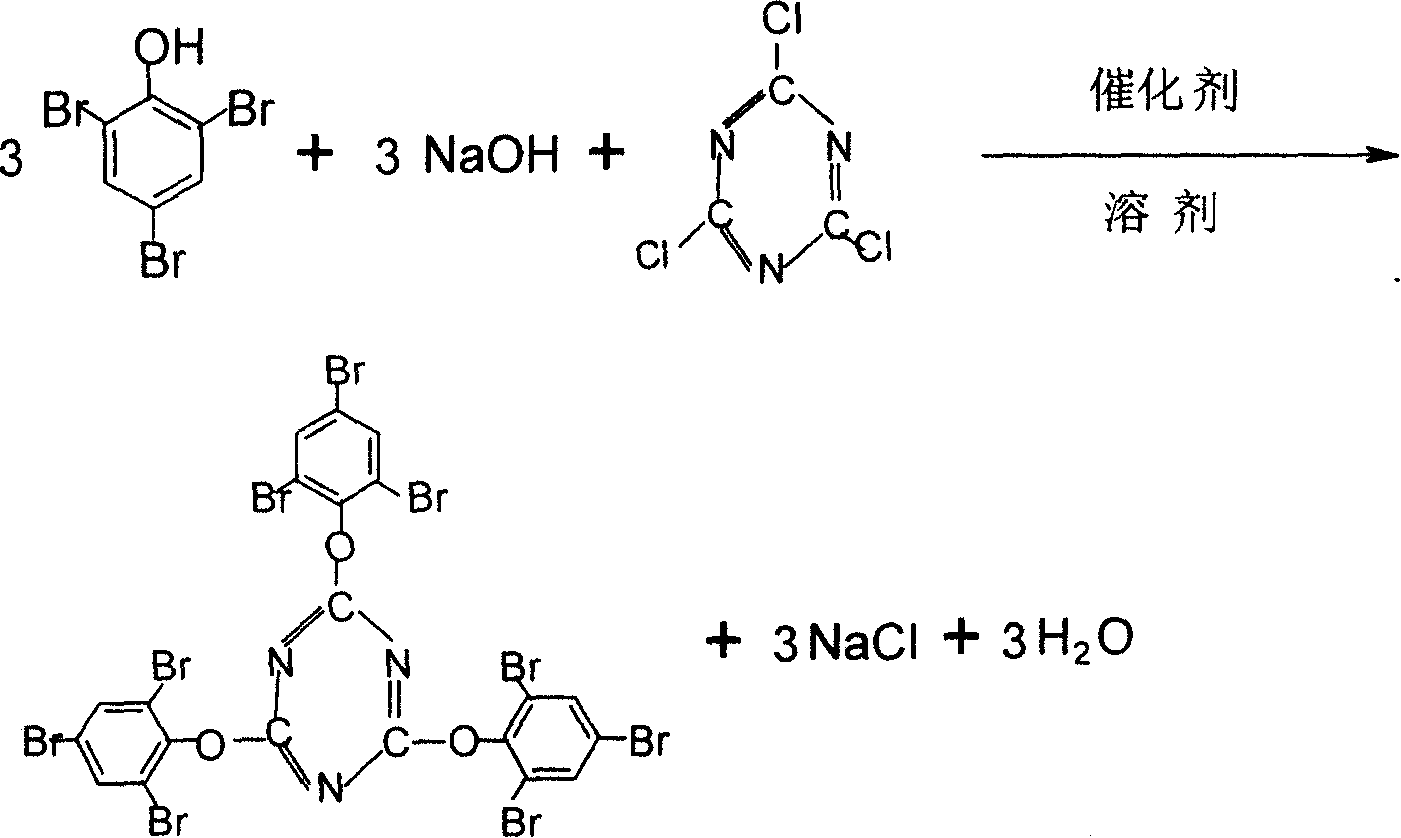

Synthesis of fire retardant tri (bromophenoxy) cyanurate

A technology of bromophenoxy and cyanurate, applied in the direction of organic chemistry, can solve the problems of large environmental pollution, high cost, and large amount of solvents, and achieve the effect of high safety factor and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1 is equipped with agitator, reflux condenser, thermometer, in the reaction flask of constant pressure dropping funnel, add 19.92g tribromophenol, 2.7g sodium hydroxide, 0.5g n-tetrabutylammonium bromide, 52gH 2 O, stir. Dissolve 3.7g of cyanuric chloride in 30ml of chloroform, add the cyanuric chloride chloroform solution dropwise at 20°C to 35°C, and continue the reaction at 40°C to 55°C for 60 minutes after the dropwise addition is completed. Then the solvent was distilled off. Filter, wash with water twice, filter and dry to obtain a white product. The yield is 95%.

Embodiment 2

[0018] Embodiment 2 In the reaction flask that stirrer, reflux condenser, thermometer are housed, constant pressure dropping funnel, add 15.16g dibromophenol, 2.7g sodium hydroxide, 0.5g triethyl benzyl ammonium chloride, 52gH 2 O, stir. Dissolve 3.7g of cyanuric chloride in 25ml of chloroform, add the cyanuric chloride chloroform solution dropwise at 20°C to 35°C, and continue the reaction for 60min after the dropwise addition is completed. Then the solvent was distilled off. Filter, wash with water twice, filter and dry to obtain a white product. The yield is 95%.

Embodiment 3

[0019] Embodiment 3 In the reaction flask equipped with stirrer, reflux condenser, thermometer, and constant pressure dropping funnel, add 10.38g monobromophenol, 2.7g sodium hydroxide, 0.3g triphenylethylphosphonium bromide, 52gH 2 O, stir. Dissolve 3.7g of cyanuric chloride in 20ml of chloroform, add the cyanuric chloride chloroform solution dropwise at 20°C to 35°C, and continue the reaction for 60min after the dropwise addition is completed. Then the solvent was distilled off. Filter, wash with water twice, filter and dry to obtain a white product. The yield is 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com