Needle protector for cylindrical sewing machine

A sewing machine, straight cylinder type technology, applied in the direction of needle holders for sewing machines, sewing machine components, sewing equipment, etc., can solve problems such as failure to improve production efficiency, shaking of sewing needles, broken needles or skipped stitches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

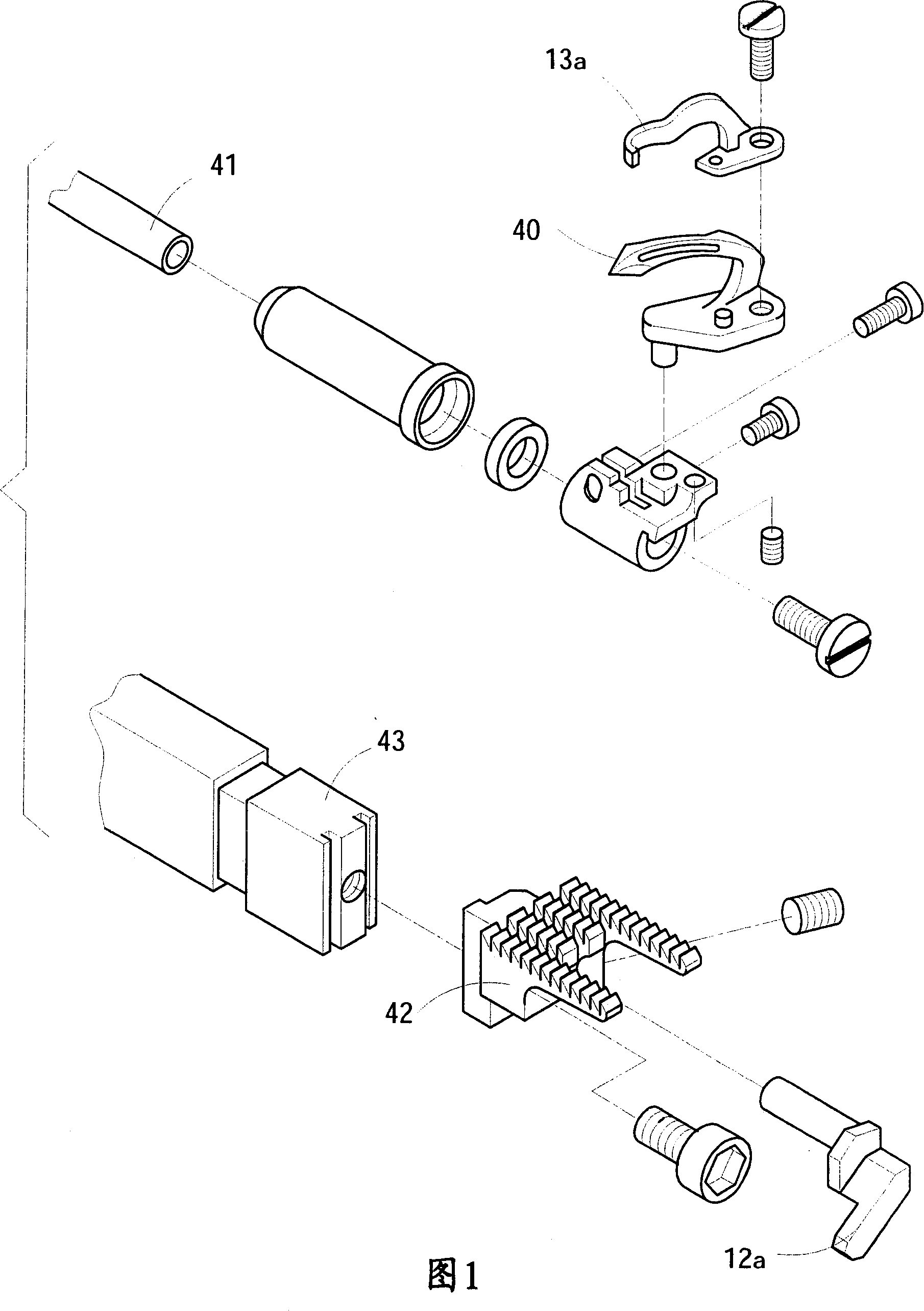

[0017] Relevant detailed description and technical contents of the present invention are as follows now in conjunction with the accompanying drawings:

[0018] Please refer to Figures 2 and 7, the needle stop mechanism is placed inside the sewing table of the sewing machine 1. When the sewing needle 30 goes down to the sewing table, the needle stop mechanism can stabilize the shaking machine due to high-speed movement. The sewing needle 30 includes a needle stopper 10 and a transmission mechanism 20. The needle stopper 10 includes a movable body 11, a rear stopper 12, and a front stopper 13. The rear stopper 12 is connected to the top of the movable body 11, and The front pin 13 straddles the front end of the top of the movable body 11, and can do reciprocating swinging motion; and the transmission mechanism 20 includes a rotating main shaft 21, a steering mechanism 22, and a linkage mechanism 23, and the rotating main shaft 21 provides a rotational force, and It is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com