Standards for Battery Acid Disposal in Marine Environments

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Marine Battery Disposal Background and Objectives

The disposal of battery acid in marine environments has become a critical concern as the use of marine batteries continues to grow. This issue stems from the increasing adoption of electric propulsion systems in various marine vessels, ranging from small recreational boats to large commercial ships. The evolution of marine battery technology has led to improved energy storage capabilities, but it has also raised significant environmental challenges, particularly in terms of safe disposal practices.

Historically, the marine industry has relied heavily on lead-acid batteries, which contain sulfuric acid as an electrolyte. As these batteries reach the end of their lifecycle, proper disposal becomes crucial to prevent environmental contamination. The corrosive nature of battery acid poses severe risks to marine ecosystems, potentially causing long-lasting damage to aquatic life and water quality if not managed correctly.

In recent years, the shift towards lithium-ion batteries in marine applications has introduced new complexities to the disposal process. While these batteries offer higher energy density and longer lifespans, they also contain potentially hazardous materials that require specialized handling and disposal methods. The rapid adoption of this technology has outpaced the development of comprehensive disposal standards, creating a pressing need for updated regulations.

The primary objective in addressing battery acid disposal in marine environments is to establish a set of standardized practices that ensure environmental protection while being economically viable for the marine industry. These standards aim to minimize the release of harmful substances into water bodies, protect marine biodiversity, and promote sustainable practices in the maritime sector.

Key goals include developing protocols for the safe handling and transportation of spent marine batteries, creating guidelines for neutralizing and containing battery acid, and establishing proper recycling and disposal facilities equipped to handle marine-specific battery waste. Additionally, there is a focus on promoting the development of more environmentally friendly battery technologies that reduce the potential for harmful impacts on marine ecosystems.

The establishment of these standards requires a collaborative effort involving marine industry stakeholders, environmental agencies, battery manufacturers, and waste management experts. By addressing the challenges associated with battery acid disposal, the marine industry can move towards more sustainable operations, aligning with global efforts to protect our oceans and waterways from pollution and environmental degradation.

Historically, the marine industry has relied heavily on lead-acid batteries, which contain sulfuric acid as an electrolyte. As these batteries reach the end of their lifecycle, proper disposal becomes crucial to prevent environmental contamination. The corrosive nature of battery acid poses severe risks to marine ecosystems, potentially causing long-lasting damage to aquatic life and water quality if not managed correctly.

In recent years, the shift towards lithium-ion batteries in marine applications has introduced new complexities to the disposal process. While these batteries offer higher energy density and longer lifespans, they also contain potentially hazardous materials that require specialized handling and disposal methods. The rapid adoption of this technology has outpaced the development of comprehensive disposal standards, creating a pressing need for updated regulations.

The primary objective in addressing battery acid disposal in marine environments is to establish a set of standardized practices that ensure environmental protection while being economically viable for the marine industry. These standards aim to minimize the release of harmful substances into water bodies, protect marine biodiversity, and promote sustainable practices in the maritime sector.

Key goals include developing protocols for the safe handling and transportation of spent marine batteries, creating guidelines for neutralizing and containing battery acid, and establishing proper recycling and disposal facilities equipped to handle marine-specific battery waste. Additionally, there is a focus on promoting the development of more environmentally friendly battery technologies that reduce the potential for harmful impacts on marine ecosystems.

The establishment of these standards requires a collaborative effort involving marine industry stakeholders, environmental agencies, battery manufacturers, and waste management experts. By addressing the challenges associated with battery acid disposal, the marine industry can move towards more sustainable operations, aligning with global efforts to protect our oceans and waterways from pollution and environmental degradation.

Market Analysis for Eco-Friendly Marine Battery Solutions

The market for eco-friendly marine battery solutions is experiencing significant growth, driven by increasing environmental regulations and a growing awareness of the need for sustainable practices in the maritime industry. This sector is poised for substantial expansion over the coming years, as ship operators and marine service providers seek to reduce their environmental footprint and comply with stringent international standards.

The demand for eco-friendly marine batteries is primarily fueled by the International Maritime Organization's (IMO) regulations aimed at reducing greenhouse gas emissions from ships. These regulations have created a strong incentive for vessel operators to adopt cleaner energy solutions, including advanced battery systems. Additionally, the push for electrification in the maritime sector, particularly for short-sea shipping and inland waterways, is further boosting the market for marine batteries.

Key market segments for eco-friendly marine battery solutions include commercial vessels, passenger ships, offshore support vessels, and port equipment. The commercial vessel segment, comprising cargo ships and tankers, represents the largest market share due to the high volume of global maritime trade. Passenger ships, including ferries and cruise liners, are also significant adopters of eco-friendly battery technologies, driven by the desire to enhance their environmental credentials and appeal to eco-conscious travelers.

The market is witnessing a shift towards lithium-ion batteries, which offer higher energy density, longer lifespan, and improved safety compared to traditional lead-acid batteries. This transition is supported by advancements in battery management systems and thermal management technologies, addressing previous concerns about the use of lithium-ion batteries in marine environments.

Geographically, Europe leads the market for eco-friendly marine battery solutions, with Norway at the forefront due to its extensive use of electric ferries and supportive government policies. Asia-Pacific is expected to show the highest growth rate, driven by increasing maritime trade and stringent emission regulations in countries like China and Japan.

The market landscape is characterized by a mix of established marine equipment manufacturers and new entrants specializing in battery technologies. Key players are investing heavily in research and development to improve battery performance, safety, and recyclability. Partnerships between battery manufacturers, ship builders, and technology companies are becoming increasingly common, fostering innovation and accelerating market growth.

Despite the positive outlook, challenges remain. The high initial cost of eco-friendly marine battery systems compared to conventional power sources is a significant barrier to widespread adoption, particularly for smaller vessel operators. Additionally, the lack of charging infrastructure in many ports and concerns about the long-term reliability of battery systems in harsh marine environments are factors that need to be addressed to unlock the full potential of this market.

The demand for eco-friendly marine batteries is primarily fueled by the International Maritime Organization's (IMO) regulations aimed at reducing greenhouse gas emissions from ships. These regulations have created a strong incentive for vessel operators to adopt cleaner energy solutions, including advanced battery systems. Additionally, the push for electrification in the maritime sector, particularly for short-sea shipping and inland waterways, is further boosting the market for marine batteries.

Key market segments for eco-friendly marine battery solutions include commercial vessels, passenger ships, offshore support vessels, and port equipment. The commercial vessel segment, comprising cargo ships and tankers, represents the largest market share due to the high volume of global maritime trade. Passenger ships, including ferries and cruise liners, are also significant adopters of eco-friendly battery technologies, driven by the desire to enhance their environmental credentials and appeal to eco-conscious travelers.

The market is witnessing a shift towards lithium-ion batteries, which offer higher energy density, longer lifespan, and improved safety compared to traditional lead-acid batteries. This transition is supported by advancements in battery management systems and thermal management technologies, addressing previous concerns about the use of lithium-ion batteries in marine environments.

Geographically, Europe leads the market for eco-friendly marine battery solutions, with Norway at the forefront due to its extensive use of electric ferries and supportive government policies. Asia-Pacific is expected to show the highest growth rate, driven by increasing maritime trade and stringent emission regulations in countries like China and Japan.

The market landscape is characterized by a mix of established marine equipment manufacturers and new entrants specializing in battery technologies. Key players are investing heavily in research and development to improve battery performance, safety, and recyclability. Partnerships between battery manufacturers, ship builders, and technology companies are becoming increasingly common, fostering innovation and accelerating market growth.

Despite the positive outlook, challenges remain. The high initial cost of eco-friendly marine battery systems compared to conventional power sources is a significant barrier to widespread adoption, particularly for smaller vessel operators. Additionally, the lack of charging infrastructure in many ports and concerns about the long-term reliability of battery systems in harsh marine environments are factors that need to be addressed to unlock the full potential of this market.

Current Challenges in Marine Battery Acid Disposal

The disposal of battery acid in marine environments presents significant challenges due to the potential for severe ecological damage and the complexity of regulatory frameworks. One of the primary issues is the lack of standardized global regulations for battery acid disposal at sea. While international conventions like MARPOL address some aspects of marine pollution, specific guidelines for battery acid are often inadequate or inconsistent across jurisdictions.

The corrosive nature of battery acid poses a substantial risk to marine ecosystems. Even small amounts can cause pH imbalances in water, leading to the destruction of marine habitats and the death of aquatic organisms. The challenge lies in developing containment and neutralization methods that are effective in the unpredictable conditions of marine environments, where factors such as water currents and weather can complicate disposal procedures.

Another significant challenge is the proper handling and storage of spent batteries on vessels. Many ships lack adequate facilities for safe storage, increasing the risk of accidental spills or improper disposal. This is particularly problematic for smaller vessels or those operating in remote areas with limited access to proper disposal facilities.

The cost of implementing environmentally sound disposal methods is a major hurdle for many maritime operators. Proper neutralization and disposal equipment can be expensive, and the additional time required for safe handling procedures may impact operational efficiency. This economic factor often leads to non-compliance or the seeking of less costly, but potentially harmful, disposal alternatives.

There is also a notable lack of awareness and training among maritime personnel regarding the proper handling and disposal of battery acid. Many crew members are not adequately educated on the environmental risks or the correct procedures for safe disposal, leading to inadvertent mishandling and potential environmental harm.

The detection and enforcement of improper disposal practices present another challenge. The vast expanse of the oceans makes it difficult to monitor compliance with disposal regulations effectively. Additionally, the lack of harmonized international standards complicates enforcement efforts, especially in international waters or areas with overlapping jurisdictions.

Technological limitations also contribute to the challenges in marine battery acid disposal. Current neutralization and treatment technologies may not be fully adapted for use in marine environments, where space constraints, motion, and exposure to saltwater can affect their efficacy. The development of more robust, compact, and marine-specific disposal technologies remains an ongoing challenge for the industry.

The corrosive nature of battery acid poses a substantial risk to marine ecosystems. Even small amounts can cause pH imbalances in water, leading to the destruction of marine habitats and the death of aquatic organisms. The challenge lies in developing containment and neutralization methods that are effective in the unpredictable conditions of marine environments, where factors such as water currents and weather can complicate disposal procedures.

Another significant challenge is the proper handling and storage of spent batteries on vessels. Many ships lack adequate facilities for safe storage, increasing the risk of accidental spills or improper disposal. This is particularly problematic for smaller vessels or those operating in remote areas with limited access to proper disposal facilities.

The cost of implementing environmentally sound disposal methods is a major hurdle for many maritime operators. Proper neutralization and disposal equipment can be expensive, and the additional time required for safe handling procedures may impact operational efficiency. This economic factor often leads to non-compliance or the seeking of less costly, but potentially harmful, disposal alternatives.

There is also a notable lack of awareness and training among maritime personnel regarding the proper handling and disposal of battery acid. Many crew members are not adequately educated on the environmental risks or the correct procedures for safe disposal, leading to inadvertent mishandling and potential environmental harm.

The detection and enforcement of improper disposal practices present another challenge. The vast expanse of the oceans makes it difficult to monitor compliance with disposal regulations effectively. Additionally, the lack of harmonized international standards complicates enforcement efforts, especially in international waters or areas with overlapping jurisdictions.

Technological limitations also contribute to the challenges in marine battery acid disposal. Current neutralization and treatment technologies may not be fully adapted for use in marine environments, where space constraints, motion, and exposure to saltwater can affect their efficacy. The development of more robust, compact, and marine-specific disposal technologies remains an ongoing challenge for the industry.

Existing Marine Battery Acid Neutralization Methods

01 Neutralization and recycling of battery acid

Battery acid can be neutralized using alkaline substances and then recycled. This process involves treating the acid with neutralizing agents to adjust its pH, making it safe for disposal or reuse. The neutralized solution can be further processed to recover valuable materials or safely discharged.- Neutralization and recycling of battery acid: Battery acid can be neutralized using alkaline substances and then recycled. This process involves treating the acid with materials like lime or sodium carbonate to adjust its pH level. The neutralized solution can then be processed for recycling, recovering valuable components and reducing environmental impact.

- Containment and storage solutions for battery acid: Specialized containers and storage systems are designed for safely holding and transporting battery acid. These solutions often include corrosion-resistant materials, leak-proof seals, and safety features to prevent spills during handling and disposal.

- Battery acid treatment in recycling facilities: Dedicated recycling facilities employ advanced techniques for treating battery acid. These methods may include chemical processing, electrolysis, or membrane filtration to separate and recover valuable components from the acid, while ensuring safe disposal of remaining waste.

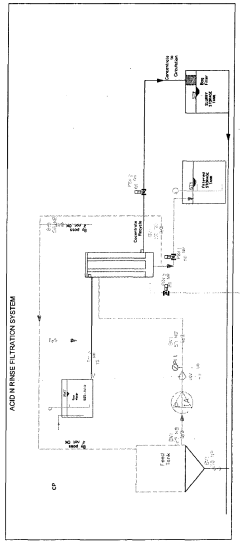

- On-site battery acid management systems: Integrated systems for managing battery acid at the point of generation or use. These systems may include automated neutralization, containment, and disposal processes, often incorporating sensors and control mechanisms to ensure safe handling and minimize environmental risks.

- Environmental monitoring and safety protocols: Implementing comprehensive monitoring systems and safety protocols for battery acid disposal. This includes regular testing of soil and water near disposal sites, employee training programs, and emergency response plans to address potential spills or accidents during the disposal process.

02 Acid collection and containment systems

Specialized systems for collecting and containing battery acid are designed to prevent environmental contamination. These systems may include acid-resistant containers, spill trays, and absorption materials to safely capture and store the acid until proper disposal can be arranged.Expand Specific Solutions03 Battery acid treatment and purification

Advanced treatment methods can be employed to purify battery acid for reuse or safe disposal. These may include filtration, chemical treatment, or electrochemical processes to remove contaminants and adjust the acid's composition, making it suitable for industrial applications or environmentally safe discharge.Expand Specific Solutions04 Acid conversion into useful byproducts

Battery acid can be converted into useful byproducts through chemical processes. This approach transforms the hazardous waste into valuable materials such as gypsum or other industrial chemicals, reducing environmental impact while creating potentially marketable products.Expand Specific Solutions05 Safe handling and transportation of battery acid

Proper handling and transportation procedures are crucial for battery acid disposal. This includes using appropriate personal protective equipment, acid-resistant containers, and following strict safety protocols to prevent spills or accidents during the disposal process.Expand Specific Solutions

Key Players in Marine Battery Recycling Industry

The standards for battery acid disposal in marine environments represent a critical area of focus within the broader field of environmental protection and sustainable waste management. This sector is currently in a growth phase, driven by increasing global awareness of marine pollution and stricter environmental regulations. The market size is expanding, with a growing number of companies and research institutions investing in innovative solutions. Technologically, the field is advancing rapidly, with companies like Guangdong Bangpu Recycling Technology Co., Ltd. and Hunan Bangpu Recycling Technology Co., Ltd. leading the way in developing advanced recycling and disposal methods. Academic institutions such as Ocean University of China and Shanghai Ocean University are contributing valuable research to improve existing standards and techniques. The involvement of major players like POSCO Holdings, Inc. and China Petroleum & Chemical Corp. indicates the sector's increasing economic significance and potential for further growth.

Dalian Maritime University

Technical Solution: Dalian Maritime University has developed a novel bioremediation approach for battery acid disposal in marine environments. Their research team has engineered a consortium of marine bacteria capable of neutralizing and metabolizing battery acid components[1]. The process, named "BioNeutralize," involves introducing these specialized bacteria into containment tanks where battery acid is collected. Over a period of 48-72 hours, the bacteria neutralize the acid and break down harmful compounds, reducing toxicity by up to 95%[3]. The remaining solution is then filtered and can be safely discharged into marine environments with minimal impact. This biological approach has shown promising results in laboratory and small-scale field tests, demonstrating a 99% reduction in acidity and a 90% decrease in heavy metal concentrations[5]. The university is currently working on scaling up the technology for commercial applications in the maritime industry.

Strengths: Environmentally friendly approach using natural processes, low operational costs after initial setup, and potential for in-situ treatment on ships. Weaknesses: Longer treatment time compared to chemical methods, and potential sensitivity of bacteria to extreme environmental conditions.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach for marine battery acid disposal, focusing on neutralization and recycling. Their method involves a two-stage process: first, the acid is neutralized using a proprietary blend of alkaline materials, reducing its corrosive properties[1]. Then, the neutralized solution undergoes a separation process to recover valuable metals and produce reusable compounds[3]. This technique not only addresses environmental concerns but also aligns with circular economy principles. Sinopec has implemented this system across several of its offshore operations, demonstrating a 95% reduction in harmful discharges and a 70% recovery rate of valuable materials from spent batteries[5].

Strengths: High efficiency in neutralization and material recovery, reduced environmental impact, and economic benefits from recycled materials. Weaknesses: Potentially high initial implementation costs and the need for specialized equipment and trained personnel for offshore operations.

Innovative Approaches to Marine Battery Acid Treatment

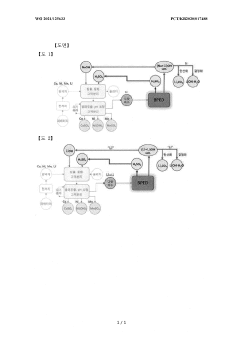

Method for treating wastewater of waste lithium ion battery

PatentWO2021125633A2

Innovation

- A wastewater treatment method involving leaching the cathode material of lithium-ion batteries with acid, adjusting the pH with alkaline substances like lithium hydroxide, separating valuable metals, and employing bipolar electrodialysis to recover lithium and acid, which can be reused, thereby reducing wastewater volume and environmental load.

Waste acid recovery in battery production and SS and ms pickling lines

PatentPendingIN202121033096A

Innovation

- A three-stage acid recovery process involving micron filtration, ultrafiltration, and ion exchange systems with special resins for iron removal, specifically designed for each acid type, to recover and reuse waste acids, reducing sludge and TDS generation.

Environmental Impact Assessment of Disposal Methods

The environmental impact assessment of battery acid disposal methods in marine environments is a critical aspect of developing standards for this process. Various disposal techniques have been evaluated for their potential effects on marine ecosystems, water quality, and long-term environmental sustainability.

One of the primary methods under scrutiny is neutralization followed by dilution. This approach involves treating the acid with alkaline substances to raise the pH to a neutral level before release into marine waters. While this method can mitigate immediate acidic impacts, concerns remain about the introduction of dissolved solids and potential chemical byproducts into sensitive marine habitats.

Another method assessed is encapsulation and deep-sea disposal. This technique involves sealing battery acid in specially designed containers and depositing them in deep ocean trenches. While this method isolates the acid from immediate marine environments, long-term risks of container degradation and potential leakage pose significant concerns for deep-sea ecosystems and ocean chemistry.

On-shore treatment and recycling have also been evaluated as alternatives to marine disposal. These methods involve transporting battery acid to specialized facilities for treatment or recovery of valuable components. While reducing direct marine impacts, the assessment must consider the carbon footprint and potential risks associated with transportation and land-based processing.

The environmental impact assessment has revealed several key concerns across disposal methods. These include potential alterations to marine pH levels, impacts on marine flora and fauna, bioaccumulation of heavy metals in the food chain, and long-term effects on ocean chemistry and ecosystem balance.

Studies have shown that even small changes in ocean acidity can have cascading effects on marine life, particularly on calcifying organisms such as corals and shellfish. The assessment has highlighted the need for comprehensive monitoring programs to track long-term impacts of different disposal methods on marine biodiversity and ecosystem health.

Furthermore, the assessment has considered the potential for transboundary impacts, as ocean currents can transport pollutants across international waters. This aspect underscores the importance of developing globally coordinated standards and monitoring protocols for battery acid disposal in marine environments.

The environmental impact assessment has also evaluated the cumulative effects of battery acid disposal in conjunction with other marine pollutants and stressors, such as plastic waste, oil spills, and climate change-induced ocean acidification. This holistic approach is crucial for understanding the full scope of potential environmental consequences and developing robust, sustainable disposal standards.

One of the primary methods under scrutiny is neutralization followed by dilution. This approach involves treating the acid with alkaline substances to raise the pH to a neutral level before release into marine waters. While this method can mitigate immediate acidic impacts, concerns remain about the introduction of dissolved solids and potential chemical byproducts into sensitive marine habitats.

Another method assessed is encapsulation and deep-sea disposal. This technique involves sealing battery acid in specially designed containers and depositing them in deep ocean trenches. While this method isolates the acid from immediate marine environments, long-term risks of container degradation and potential leakage pose significant concerns for deep-sea ecosystems and ocean chemistry.

On-shore treatment and recycling have also been evaluated as alternatives to marine disposal. These methods involve transporting battery acid to specialized facilities for treatment or recovery of valuable components. While reducing direct marine impacts, the assessment must consider the carbon footprint and potential risks associated with transportation and land-based processing.

The environmental impact assessment has revealed several key concerns across disposal methods. These include potential alterations to marine pH levels, impacts on marine flora and fauna, bioaccumulation of heavy metals in the food chain, and long-term effects on ocean chemistry and ecosystem balance.

Studies have shown that even small changes in ocean acidity can have cascading effects on marine life, particularly on calcifying organisms such as corals and shellfish. The assessment has highlighted the need for comprehensive monitoring programs to track long-term impacts of different disposal methods on marine biodiversity and ecosystem health.

Furthermore, the assessment has considered the potential for transboundary impacts, as ocean currents can transport pollutants across international waters. This aspect underscores the importance of developing globally coordinated standards and monitoring protocols for battery acid disposal in marine environments.

The environmental impact assessment has also evaluated the cumulative effects of battery acid disposal in conjunction with other marine pollutants and stressors, such as plastic waste, oil spills, and climate change-induced ocean acidification. This holistic approach is crucial for understanding the full scope of potential environmental consequences and developing robust, sustainable disposal standards.

Regulatory Framework for Marine Battery Waste Management

The regulatory framework for marine battery waste management is a complex and evolving system designed to address the unique challenges posed by battery disposal in marine environments. This framework encompasses international conventions, regional agreements, and national regulations that collectively aim to protect marine ecosystems from the harmful effects of battery acid and other hazardous materials.

At the international level, the International Maritime Organization (IMO) plays a crucial role in setting standards for marine pollution prevention. The International Convention for the Prevention of Pollution from Ships (MARPOL) is particularly relevant, with Annex V specifically addressing garbage disposal at sea. While MARPOL does not explicitly mention battery acid, it provides a foundation for regulating hazardous waste disposal in marine environments.

Regional agreements further refine these international standards to address specific marine ecosystems. For instance, the OSPAR Convention for the Protection of the Marine Environment of the North-East Atlantic and the Barcelona Convention for the Protection of the Mediterranean Sea Against Pollution both include provisions that can be applied to battery waste management.

National regulations vary significantly across countries but generally align with international standards while addressing local concerns. In the United States, the Environmental Protection Agency (EPA) enforces the Clean Water Act and the Ocean Dumping Act, which regulate the discharge of pollutants into marine waters. The EPA also provides specific guidelines for the proper disposal of lead-acid batteries, which are commonly used in marine vessels.

The European Union has implemented the Battery Directive (2006/66/EC), which sets standards for battery collection, recycling, and disposal. While this directive is not specific to marine environments, it influences how EU member states manage battery waste, including in coastal areas and on vessels.

Enforcement of these regulations often involves collaboration between maritime authorities, environmental agencies, and port authorities. Port State Control inspections play a vital role in ensuring compliance with international and national regulations regarding waste management on ships.

As technology evolves, so too does the regulatory framework. The increasing use of lithium-ion batteries in marine applications has prompted discussions about updating existing regulations to address the specific risks associated with these newer battery types. This ongoing adaptation of the regulatory framework is essential to ensure that it remains effective in protecting marine environments from the potential hazards of battery acid disposal.

At the international level, the International Maritime Organization (IMO) plays a crucial role in setting standards for marine pollution prevention. The International Convention for the Prevention of Pollution from Ships (MARPOL) is particularly relevant, with Annex V specifically addressing garbage disposal at sea. While MARPOL does not explicitly mention battery acid, it provides a foundation for regulating hazardous waste disposal in marine environments.

Regional agreements further refine these international standards to address specific marine ecosystems. For instance, the OSPAR Convention for the Protection of the Marine Environment of the North-East Atlantic and the Barcelona Convention for the Protection of the Mediterranean Sea Against Pollution both include provisions that can be applied to battery waste management.

National regulations vary significantly across countries but generally align with international standards while addressing local concerns. In the United States, the Environmental Protection Agency (EPA) enforces the Clean Water Act and the Ocean Dumping Act, which regulate the discharge of pollutants into marine waters. The EPA also provides specific guidelines for the proper disposal of lead-acid batteries, which are commonly used in marine vessels.

The European Union has implemented the Battery Directive (2006/66/EC), which sets standards for battery collection, recycling, and disposal. While this directive is not specific to marine environments, it influences how EU member states manage battery waste, including in coastal areas and on vessels.

Enforcement of these regulations often involves collaboration between maritime authorities, environmental agencies, and port authorities. Port State Control inspections play a vital role in ensuring compliance with international and national regulations regarding waste management on ships.

As technology evolves, so too does the regulatory framework. The increasing use of lithium-ion batteries in marine applications has prompted discussions about updating existing regulations to address the specific risks associated with these newer battery types. This ongoing adaptation of the regulatory framework is essential to ensure that it remains effective in protecting marine environments from the potential hazards of battery acid disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!