Impact of Humidity on Battery Acid Performance Metrics

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Evolution

The evolution of battery acid technology has been a crucial factor in the development and improvement of battery performance over the years. Initially, lead-acid batteries used a simple sulfuric acid electrolyte, which was effective but had limitations in terms of energy density and cycle life. As research progressed, the focus shifted towards optimizing the acid composition to enhance battery performance and longevity.

In the early stages of battery acid evolution, efforts were primarily directed at adjusting the concentration of sulfuric acid to balance power output and battery life. Scientists discovered that higher acid concentrations could increase initial power output but often led to faster electrode degradation. This led to the development of more sophisticated electrolyte formulations that incorporated additives to mitigate these negative effects.

The introduction of gel electrolytes marked a significant milestone in battery acid evolution. These semi-solid electrolytes, created by adding silica to the sulfuric acid, reduced acid stratification and improved the battery's resistance to vibration and shock. This innovation paved the way for valve-regulated lead-acid (VRLA) batteries, which offered improved safety and reduced maintenance requirements.

Further advancements in battery acid technology focused on addressing the impact of humidity on battery performance. Researchers found that high humidity levels could lead to increased water loss in batteries, affecting acid concentration and overall performance. This led to the development of advanced electrolyte formulations with reduced water loss characteristics and improved stability under varying environmental conditions.

The advent of absorbent glass mat (AGM) technology represented another significant step in battery acid evolution. AGM batteries use a highly absorbent separator to hold the electrolyte in place, reducing the risk of acid spills and allowing for more efficient gas recombination. This technology not only improved safety but also enhanced the battery's ability to withstand extreme temperatures and humidity levels.

Recent developments in battery acid technology have focused on nano-enhanced electrolytes. These advanced formulations incorporate nanoparticles that can modify the electrolyte's properties, leading to improved conductivity, reduced corrosion, and enhanced overall battery performance. Researchers are exploring various nanomaterials, such as carbon nanotubes and graphene, to further optimize electrolyte characteristics and mitigate the negative effects of humidity on battery acid performance metrics.

As the demand for more efficient and environmentally friendly energy storage solutions continues to grow, the evolution of battery acid technology remains an active area of research. Scientists are now investigating bio-based electrolytes and ionic liquids as potential alternatives to traditional sulfuric acid electrolytes, aiming to develop batteries with improved performance, safety, and sustainability profiles.

In the early stages of battery acid evolution, efforts were primarily directed at adjusting the concentration of sulfuric acid to balance power output and battery life. Scientists discovered that higher acid concentrations could increase initial power output but often led to faster electrode degradation. This led to the development of more sophisticated electrolyte formulations that incorporated additives to mitigate these negative effects.

The introduction of gel electrolytes marked a significant milestone in battery acid evolution. These semi-solid electrolytes, created by adding silica to the sulfuric acid, reduced acid stratification and improved the battery's resistance to vibration and shock. This innovation paved the way for valve-regulated lead-acid (VRLA) batteries, which offered improved safety and reduced maintenance requirements.

Further advancements in battery acid technology focused on addressing the impact of humidity on battery performance. Researchers found that high humidity levels could lead to increased water loss in batteries, affecting acid concentration and overall performance. This led to the development of advanced electrolyte formulations with reduced water loss characteristics and improved stability under varying environmental conditions.

The advent of absorbent glass mat (AGM) technology represented another significant step in battery acid evolution. AGM batteries use a highly absorbent separator to hold the electrolyte in place, reducing the risk of acid spills and allowing for more efficient gas recombination. This technology not only improved safety but also enhanced the battery's ability to withstand extreme temperatures and humidity levels.

Recent developments in battery acid technology have focused on nano-enhanced electrolytes. These advanced formulations incorporate nanoparticles that can modify the electrolyte's properties, leading to improved conductivity, reduced corrosion, and enhanced overall battery performance. Researchers are exploring various nanomaterials, such as carbon nanotubes and graphene, to further optimize electrolyte characteristics and mitigate the negative effects of humidity on battery acid performance metrics.

As the demand for more efficient and environmentally friendly energy storage solutions continues to grow, the evolution of battery acid technology remains an active area of research. Scientists are now investigating bio-based electrolytes and ionic liquids as potential alternatives to traditional sulfuric acid electrolytes, aiming to develop batteries with improved performance, safety, and sustainability profiles.

Humidity Market Demand

The market demand for humidity control solutions in battery manufacturing and storage has seen significant growth in recent years. This surge is primarily driven by the increasing awareness of humidity's critical impact on battery acid performance metrics. As the global battery market continues to expand, particularly in the electric vehicle and renewable energy storage sectors, the need for effective humidity management has become paramount.

Battery manufacturers and users are increasingly recognizing that uncontrolled humidity levels can lead to a range of issues affecting battery performance and longevity. High humidity environments can accelerate the self-discharge rate of batteries, reduce their capacity, and shorten their overall lifespan. Conversely, excessively low humidity can cause electrolyte evaporation, leading to increased internal resistance and reduced power output.

The automotive industry, especially the electric vehicle segment, has emerged as a key driver of demand for humidity control solutions. As electric vehicles gain market share, manufacturers are investing heavily in advanced battery technologies and seeking ways to optimize battery performance and durability. This has led to a growing market for specialized humidity control systems in battery production facilities and vehicle assembly plants.

The renewable energy sector is another significant contributor to the humidity control market demand. As large-scale energy storage systems become more prevalent in solar and wind power installations, the need for maintaining optimal environmental conditions for batteries has increased. Grid-scale battery storage facilities are implementing sophisticated humidity management systems to ensure the longevity and efficiency of their energy storage assets.

The telecommunications industry also represents a substantial market for humidity control solutions in battery applications. With the ongoing expansion of 5G networks and the increasing reliance on backup power systems, telecom companies are investing in advanced climate control technologies to protect their battery installations from humidity-related degradation.

In response to this growing demand, the market has seen an influx of innovative humidity control products and services. These range from advanced desiccant systems and chemical dehumidifiers to smart, IoT-enabled environmental monitoring and control systems. Manufacturers are developing solutions that not only manage humidity levels but also integrate with broader battery management systems to provide comprehensive performance optimization.

The market demand for humidity control in battery applications extends beyond manufacturing and extends to transportation and storage. As global supply chains for batteries become more complex, there is an increasing need for humidity-controlled shipping containers and warehousing facilities to maintain battery quality during transit and storage.

Battery manufacturers and users are increasingly recognizing that uncontrolled humidity levels can lead to a range of issues affecting battery performance and longevity. High humidity environments can accelerate the self-discharge rate of batteries, reduce their capacity, and shorten their overall lifespan. Conversely, excessively low humidity can cause electrolyte evaporation, leading to increased internal resistance and reduced power output.

The automotive industry, especially the electric vehicle segment, has emerged as a key driver of demand for humidity control solutions. As electric vehicles gain market share, manufacturers are investing heavily in advanced battery technologies and seeking ways to optimize battery performance and durability. This has led to a growing market for specialized humidity control systems in battery production facilities and vehicle assembly plants.

The renewable energy sector is another significant contributor to the humidity control market demand. As large-scale energy storage systems become more prevalent in solar and wind power installations, the need for maintaining optimal environmental conditions for batteries has increased. Grid-scale battery storage facilities are implementing sophisticated humidity management systems to ensure the longevity and efficiency of their energy storage assets.

The telecommunications industry also represents a substantial market for humidity control solutions in battery applications. With the ongoing expansion of 5G networks and the increasing reliance on backup power systems, telecom companies are investing in advanced climate control technologies to protect their battery installations from humidity-related degradation.

In response to this growing demand, the market has seen an influx of innovative humidity control products and services. These range from advanced desiccant systems and chemical dehumidifiers to smart, IoT-enabled environmental monitoring and control systems. Manufacturers are developing solutions that not only manage humidity levels but also integrate with broader battery management systems to provide comprehensive performance optimization.

The market demand for humidity control in battery applications extends beyond manufacturing and extends to transportation and storage. As global supply chains for batteries become more complex, there is an increasing need for humidity-controlled shipping containers and warehousing facilities to maintain battery quality during transit and storage.

Humidity Challenges

Humidity poses significant challenges to battery acid performance, affecting various aspects of battery operation and longevity. One of the primary concerns is the acceleration of corrosion processes within the battery. Increased humidity levels can lead to faster oxidation of metal components, particularly the lead plates and connectors, compromising the battery's structural integrity and electrical conductivity.

The presence of excess moisture in the battery environment can also result in electrolyte dilution. As water vapor enters the battery casing, it may condense and mix with the sulfuric acid electrolyte, altering its concentration. This dilution can reduce the battery's capacity and efficiency, as the chemical reactions necessary for energy storage and release become less effective in a more diluted solution.

Furthermore, high humidity can impact the self-discharge rate of batteries. Moisture on the battery's surface can create conductive paths between terminals, leading to increased self-discharge and a gradual loss of stored energy over time. This phenomenon is particularly problematic for batteries in standby or storage conditions, where maintaining charge levels is crucial for long-term reliability.

Temperature fluctuations associated with changing humidity levels can also affect battery performance. As humidity rises and falls, it can cause expansion and contraction of battery components, potentially leading to mechanical stress and premature aging of materials. This thermal cycling, exacerbated by humidity, may result in reduced battery life and decreased overall performance.

The formation of condensation on battery surfaces in high-humidity environments presents another challenge. Water droplets can accumulate on terminals and connectors, increasing the risk of short circuits and electrical malfunctions. Additionally, this moisture can seep into small cracks or imperfections in the battery casing, potentially compromising the seal and allowing contaminants to enter the internal components.

Humidity also affects the charging process of batteries. In high-humidity conditions, the charging efficiency may decrease due to increased resistance and altered electrochemical reactions. This can lead to longer charging times, incomplete charging, and potential overheating issues, all of which can negatively impact battery performance and lifespan.

Lastly, the interaction between humidity and battery acid can create corrosive byproducts and gases. These substances may accumulate within the battery, leading to increased internal pressure and potential leakage. The release of such corrosive materials can pose safety risks and further degrade battery performance over time.

The presence of excess moisture in the battery environment can also result in electrolyte dilution. As water vapor enters the battery casing, it may condense and mix with the sulfuric acid electrolyte, altering its concentration. This dilution can reduce the battery's capacity and efficiency, as the chemical reactions necessary for energy storage and release become less effective in a more diluted solution.

Furthermore, high humidity can impact the self-discharge rate of batteries. Moisture on the battery's surface can create conductive paths between terminals, leading to increased self-discharge and a gradual loss of stored energy over time. This phenomenon is particularly problematic for batteries in standby or storage conditions, where maintaining charge levels is crucial for long-term reliability.

Temperature fluctuations associated with changing humidity levels can also affect battery performance. As humidity rises and falls, it can cause expansion and contraction of battery components, potentially leading to mechanical stress and premature aging of materials. This thermal cycling, exacerbated by humidity, may result in reduced battery life and decreased overall performance.

The formation of condensation on battery surfaces in high-humidity environments presents another challenge. Water droplets can accumulate on terminals and connectors, increasing the risk of short circuits and electrical malfunctions. Additionally, this moisture can seep into small cracks or imperfections in the battery casing, potentially compromising the seal and allowing contaminants to enter the internal components.

Humidity also affects the charging process of batteries. In high-humidity conditions, the charging efficiency may decrease due to increased resistance and altered electrochemical reactions. This can lead to longer charging times, incomplete charging, and potential overheating issues, all of which can negatively impact battery performance and lifespan.

Lastly, the interaction between humidity and battery acid can create corrosive byproducts and gases. These substances may accumulate within the battery, leading to increased internal pressure and potential leakage. The release of such corrosive materials can pose safety risks and further degrade battery performance over time.

Current Solutions

01 Battery performance monitoring and analysis

Systems and methods for monitoring and analyzing battery performance metrics, including acid levels, voltage, and capacity. These solutions involve data collection, real-time monitoring, and predictive analytics to optimize battery life and efficiency.- Battery performance monitoring and analysis: Systems and methods for monitoring and analyzing battery performance metrics, including acid levels, voltage, and capacity. These solutions involve data collection, real-time monitoring, and predictive analytics to assess battery health and optimize performance.

- Battery acid management systems: Innovative approaches to managing battery acid, including automated systems for maintaining optimal acid levels, detecting leaks, and ensuring proper electrolyte balance. These systems aim to extend battery life and improve overall performance.

- Performance metrics visualization and reporting: Tools and techniques for visualizing and reporting battery acid performance metrics, enabling easier interpretation of data and facilitating informed decision-making for maintenance and replacement strategies.

- Machine learning for battery performance prediction: Application of machine learning algorithms to analyze historical battery acid performance data and predict future performance, enabling proactive maintenance and optimized battery management strategies.

- Integration of battery metrics with broader systems: Methods for integrating battery acid performance metrics into larger operational systems, such as fleet management or energy management platforms, to provide a holistic view of system performance and enable more efficient resource allocation.

02 Battery acid quality assessment

Techniques for assessing and measuring the quality of battery acid, including its concentration, specific gravity, and purity. These methods help in maintaining optimal battery performance and preventing degradation due to acid-related issues.Expand Specific Solutions03 Battery health prediction and maintenance

Algorithms and systems for predicting battery health based on acid performance metrics and other factors. These solutions enable proactive maintenance scheduling and optimization of battery replacement strategies.Expand Specific Solutions04 Battery acid performance data management

Data management systems and methods for collecting, storing, and analyzing battery acid performance metrics. These solutions facilitate efficient data handling, trend analysis, and reporting of battery acid-related information.Expand Specific Solutions05 Battery acid performance optimization

Techniques and systems for optimizing battery acid performance through intelligent charging algorithms, temperature control, and electrolyte management. These solutions aim to extend battery life and improve overall efficiency.Expand Specific Solutions

Key Industry Players

The impact of humidity on battery acid performance metrics is a critical area of research in the advanced battery technology sector. This field is currently in a growth phase, with increasing market size driven by the expanding electric vehicle and renewable energy storage industries. The technology maturity varies across different aspects, with established players like GS Yuasa, Toyota, and Nissan leading in traditional lead-acid batteries, while companies such as LG Energy Solution and Contemporary Amperex Technology are pushing boundaries in lithium-ion technology. Research institutions like CSIRO and Beijing University of Technology are contributing to fundamental understanding, while specialized firms like Daramic and Microporous focus on separator technologies, crucial for managing humidity effects on battery performance.

Robert Bosch GmbH

Technical Solution: Bosch has developed comprehensive solutions to mitigate the impact of humidity on battery acid performance. Their approach includes the implementation of advanced moisture-resistant coatings for battery components, reducing the risk of water absorption and corrosion[13]. The company has also introduced innovative battery case designs with improved sealing techniques to minimize humidity ingress. Bosch's research has led to the development of sophisticated electrolyte formulations that maintain stable performance across a wide range of humidity conditions[14]. Additionally, they have implemented advanced battery management systems that can detect and compensate for humidity-induced changes in battery behavior, optimizing charging and discharging processes accordingly[15]. Bosch has also explored the use of passive and active humidity control systems within battery enclosures to maintain optimal internal conditions.

Strengths: Comprehensive approach combining hardware and software solutions, extensive automotive industry experience. Weaknesses: Potential higher costs associated with implementing multiple advanced technologies.

Panasonic Holdings Corp.

Technical Solution: Panasonic has developed a range of solutions to address the impact of humidity on battery acid performance. Their approach includes the use of advanced hydrophobic coatings on battery components to repel moisture and prevent water absorption[4]. The company has also implemented sophisticated battery management systems that can detect and compensate for humidity-induced changes in battery performance[5]. Panasonic's research has led to the development of novel electrolyte additives that maintain stable acid concentrations even in high humidity environments, ensuring consistent battery performance across various climatic conditions[6]. Furthermore, they have introduced improved venting systems that regulate internal pressure and moisture levels, minimizing the impact of external humidity on battery acid metrics.

Strengths: Cutting-edge research in electrolyte additives and battery management systems. Weaknesses: Potential complexity in manufacturing processes and higher costs associated with advanced technologies.

Core Humidity Research

Laminated oxidation protected separator

PatentWO2014138509A1

Innovation

- A battery separator comprising a microporous membrane laminated with a diffusive mat that has superior wicking properties and includes rubber to prevent acid stratification and oxidation, made from synthetic, glass, or natural fibers, and silica, which enhances diffusion and protects against water loss and contaminants.

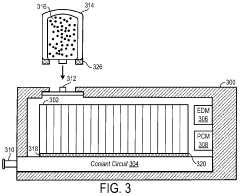

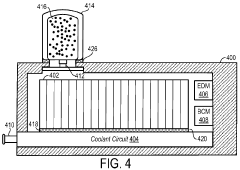

System and method for controlling humidity in a battery module

PatentWO2012082116A1

Innovation

- A system for controlling humidity within battery enclosures using a removably attached desiccant device or a Peltier device to extract water vapor, with the desiccant attracting moisture and the Peltier device condensing it, thereby reducing degradation and extending battery life.

Environmental Factors

Environmental factors play a crucial role in determining the performance and longevity of battery acid, with humidity being a particularly significant factor. The impact of humidity on battery acid performance metrics is multifaceted and can lead to various chemical and physical changes within the battery system.

High humidity levels can cause increased water absorption by the battery acid, leading to dilution of the electrolyte solution. This dilution effect can result in reduced specific gravity of the acid, which directly affects the battery's capacity and overall performance. As the concentration of sulfuric acid decreases due to water absorption, the chemical reactions within the battery become less efficient, potentially leading to a decrease in voltage output and reduced energy storage capabilities.

Furthermore, elevated humidity can accelerate the corrosion of battery components, particularly the metal terminals and internal connectors. This corrosion process can create resistance points within the battery, impeding the flow of electrical current and reducing the overall efficiency of the system. In extreme cases, severe corrosion may lead to physical damage of battery components, compromising the structural integrity of the battery and potentially causing leaks or short circuits.

The presence of excess moisture in the battery environment can also promote the growth of fungi and other microorganisms on the battery surface and within its casing. These biological contaminants can contribute to the degradation of battery materials and may interfere with proper ventilation, potentially leading to the accumulation of harmful gases within the battery enclosure.

Temperature fluctuations often accompany changes in humidity levels, and this interplay between temperature and humidity can have compounding effects on battery acid performance. Higher temperatures typically associated with humid conditions can accelerate chemical reactions within the battery, potentially leading to increased self-discharge rates and reduced overall lifespan of the battery.

To mitigate the negative impacts of humidity on battery acid performance, various strategies can be employed. These may include the use of sealed or maintenance-free battery designs, implementation of proper ventilation systems in battery storage areas, and the application of protective coatings or enclosures to minimize moisture exposure. Regular monitoring of battery acid specific gravity and timely maintenance can also help identify and address humidity-related issues before they significantly impact battery performance.

Understanding the complex relationship between humidity and battery acid performance is essential for optimizing battery systems across various applications, from automotive and industrial uses to renewable energy storage solutions. By considering the environmental factors that influence battery acid behavior, engineers and researchers can develop more robust and efficient battery technologies capable of withstanding diverse environmental conditions.

High humidity levels can cause increased water absorption by the battery acid, leading to dilution of the electrolyte solution. This dilution effect can result in reduced specific gravity of the acid, which directly affects the battery's capacity and overall performance. As the concentration of sulfuric acid decreases due to water absorption, the chemical reactions within the battery become less efficient, potentially leading to a decrease in voltage output and reduced energy storage capabilities.

Furthermore, elevated humidity can accelerate the corrosion of battery components, particularly the metal terminals and internal connectors. This corrosion process can create resistance points within the battery, impeding the flow of electrical current and reducing the overall efficiency of the system. In extreme cases, severe corrosion may lead to physical damage of battery components, compromising the structural integrity of the battery and potentially causing leaks or short circuits.

The presence of excess moisture in the battery environment can also promote the growth of fungi and other microorganisms on the battery surface and within its casing. These biological contaminants can contribute to the degradation of battery materials and may interfere with proper ventilation, potentially leading to the accumulation of harmful gases within the battery enclosure.

Temperature fluctuations often accompany changes in humidity levels, and this interplay between temperature and humidity can have compounding effects on battery acid performance. Higher temperatures typically associated with humid conditions can accelerate chemical reactions within the battery, potentially leading to increased self-discharge rates and reduced overall lifespan of the battery.

To mitigate the negative impacts of humidity on battery acid performance, various strategies can be employed. These may include the use of sealed or maintenance-free battery designs, implementation of proper ventilation systems in battery storage areas, and the application of protective coatings or enclosures to minimize moisture exposure. Regular monitoring of battery acid specific gravity and timely maintenance can also help identify and address humidity-related issues before they significantly impact battery performance.

Understanding the complex relationship between humidity and battery acid performance is essential for optimizing battery systems across various applications, from automotive and industrial uses to renewable energy storage solutions. By considering the environmental factors that influence battery acid behavior, engineers and researchers can develop more robust and efficient battery technologies capable of withstanding diverse environmental conditions.

Safety Regulations

Safety regulations play a crucial role in managing the impact of humidity on battery acid performance metrics. These regulations are designed to protect workers, consumers, and the environment from potential hazards associated with battery acid exposure and degradation due to humidity.

The Occupational Safety and Health Administration (OSHA) in the United States has established specific guidelines for handling and storing battery acid in humid environments. These regulations require proper ventilation systems to control humidity levels in battery storage areas, as excessive moisture can lead to increased corrosion and potential leaks. OSHA also mandates the use of personal protective equipment (PPE) for workers handling battery acid, including acid-resistant gloves, face shields, and aprons.

The International Electrotechnical Commission (IEC) has developed standards for battery safety, including IEC 62133, which addresses safety requirements for portable sealed secondary cells and batteries. This standard includes provisions for testing battery performance under various environmental conditions, including high humidity. Manufacturers must demonstrate compliance with these standards to ensure their products can withstand humid conditions without compromising safety or performance.

The United Nations (UN) has established regulations for the transportation of dangerous goods, including battery acid. These regulations specify packaging requirements and labeling standards to prevent accidents during shipping, particularly in regions with high humidity. The UN recommendations are often adopted by national regulatory bodies and incorporated into local transportation laws.

Environmental protection agencies worldwide have implemented regulations to address the potential environmental impact of battery acid disposal. These regulations often require proper containment and neutralization of battery acid before disposal, taking into account the increased risk of leakage and contamination in humid environments.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation includes specific provisions for battery acid and its components. Manufacturers and importers must register substances used in battery production and provide safety data sheets that account for the effects of humidity on battery acid performance and safety.

In the automotive industry, regulations such as the United Nations Economic Commission for Europe (UNECE) Regulation No. 100 set safety requirements for electric vehicle batteries. These regulations include provisions for testing battery systems under various environmental conditions, including high humidity, to ensure safety and performance in diverse climates.

As the impact of humidity on battery acid performance becomes better understood, regulatory bodies continue to update and refine safety regulations. This ongoing process involves collaboration between industry experts, researchers, and policymakers to develop comprehensive guidelines that address the complex interplay between humidity, battery acid, and safety considerations.

The Occupational Safety and Health Administration (OSHA) in the United States has established specific guidelines for handling and storing battery acid in humid environments. These regulations require proper ventilation systems to control humidity levels in battery storage areas, as excessive moisture can lead to increased corrosion and potential leaks. OSHA also mandates the use of personal protective equipment (PPE) for workers handling battery acid, including acid-resistant gloves, face shields, and aprons.

The International Electrotechnical Commission (IEC) has developed standards for battery safety, including IEC 62133, which addresses safety requirements for portable sealed secondary cells and batteries. This standard includes provisions for testing battery performance under various environmental conditions, including high humidity. Manufacturers must demonstrate compliance with these standards to ensure their products can withstand humid conditions without compromising safety or performance.

The United Nations (UN) has established regulations for the transportation of dangerous goods, including battery acid. These regulations specify packaging requirements and labeling standards to prevent accidents during shipping, particularly in regions with high humidity. The UN recommendations are often adopted by national regulatory bodies and incorporated into local transportation laws.

Environmental protection agencies worldwide have implemented regulations to address the potential environmental impact of battery acid disposal. These regulations often require proper containment and neutralization of battery acid before disposal, taking into account the increased risk of leakage and contamination in humid environments.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation includes specific provisions for battery acid and its components. Manufacturers and importers must register substances used in battery production and provide safety data sheets that account for the effects of humidity on battery acid performance and safety.

In the automotive industry, regulations such as the United Nations Economic Commission for Europe (UNECE) Regulation No. 100 set safety requirements for electric vehicle batteries. These regulations include provisions for testing battery systems under various environmental conditions, including high humidity, to ensure safety and performance in diverse climates.

As the impact of humidity on battery acid performance becomes better understood, regulatory bodies continue to update and refine safety regulations. This ongoing process involves collaboration between industry experts, researchers, and policymakers to develop comprehensive guidelines that address the complex interplay between humidity, battery acid, and safety considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!