PVDF Nanofiber Membranes For Enhanced Adsorption Capacity

Technology Background and Goals

The primary objective of this research is to explore the development of polyvinylidene fluoride (PVDF) nanofiber membranes for enhanced adsorption capacity. PVDF nanofiber membranes have gained significant attention due to their high surface area, interconnected porous structure, and excellent chemical resistance.

These unique properties make them promising candidates for various adsorption applications, such as water treatment, air purification, and chemical separations. The research aims to investigate strategies for optimizing the nanofiber membrane's morphology, surface chemistry, and functionalization to enhance its adsorption performance for specific target pollutants or valuable compounds.

Market Demand Analysis

- Market Size and Growth

The market for PVDF nanofiber membranes is expected to witness significant growth due to their enhanced adsorption capacity and versatile applications in water treatment, air filtration, and biomedical fields. - Key Applications

- Water treatment: PVDF nanofiber membranes offer improved removal efficiency for contaminants, heavy metals, and organic pollutants.

- Air filtration: Their high surface area and porosity make them effective in capturing particulate matter and volatile organic compounds.

- Biomedical: Potential applications include wound dressings, tissue engineering scaffolds, and drug delivery systems.

- Driving Factors

- Stringent environmental regulations and the need for sustainable water and air treatment solutions.

- Growing demand for advanced biomedical materials with improved biocompatibility and functionality.

- Increasing awareness of the health and environmental impacts of traditional filtration methods.

- Market Challenges

- High production costs and scalability issues associated with nanofiber membrane manufacturing.

- Potential fouling and clogging issues, requiring frequent membrane replacement or cleaning.

- Competition from established filtration technologies and the need for market acceptance of nanofiber membranes.

Technology Status and Challenges

- Current Status

PVDF nanofiber membranes have gained significant attention due to their high porosity, large surface area, and good mechanical properties. Various fabrication techniques, such as electrospinning and phase inversion, have been developed to produce these membranes. - Technical Challenges

Key challenges include controlling fiber diameter and pore size distribution, improving hydrophilicity and fouling resistance, enhancing mechanical strength, and scaling up production. Addressing these issues is crucial for practical applications. - Geographical Distribution

Research on PVDF nanofiber membranes is widely distributed globally, with major contributions from countries like the United States, China, South Korea, and several European nations. Collaboration among research groups is common.

Current Technical Solutions

01 High Adsorption Capacity PVDF Nanofiber Membranes

PVDF nanofiber membranes with high adsorption capacity can be prepared by incorporating additives or modifying surface properties, exhibiting enhanced adsorption capabilities for various substances, suitable for water treatment, air purification, and chemical separations.- High Adsorption Capacity PVDF Nanofiber Membranes: PVDF nanofiber membranes with optimized fiber diameter, porosity, and surface properties exhibit excellent adsorption performance for various pollutants, making them suitable for water treatment and environmental remediation applications.

- Functionalized PVDF Nanofiber Membranes: Incorporating functional groups or nanoparticles onto the fiber surface enhances the adsorption capacity of PVDF nanofiber membranes, improving affinity and selectivity towards specific target molecules for efficient adsorption and separation processes.

- Hierarchical PVDF Nanofiber Membranes: PVDF nanofiber membranes with hierarchical structures, such as core-shell or multi-layered configurations, provide unique properties like high surface area, tunable pore sizes, and controlled surface chemistry, enabling efficient adsorption of various target molecules.

- Composite PVDF Nanofiber Membranes: Combining PVDF nanofiber membranes with materials like carbon nanotubes, graphene, or metal-organic frameworks forms composite membranes with enhanced adsorption capabilities, leveraging the synergistic effects of different materials for improved adsorption performance and selectivity.

- Tailored PVDF Nanofiber Membranes: PVDF nanofiber membranes can be tailored for specific adsorption applications, such as heavy metal removal, organic pollutant adsorption, or gas separation, by optimizing membrane properties like fiber morphology, surface chemistry, and pore structure for high adsorption efficiency and selectivity.

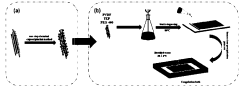

02 Fabrication Methods for PVDF Nanofiber Membranes

Various fabrication methods like electrospinning, phase inversion, and self-assembly can produce PVDF nanofiber membranes with tailored properties and adsorption capacities, allowing precise control over fiber morphology, porosity, and surface characteristics for optimized adsorption performance.Expand Specific Solutions03 Surface Modification of PVDF Nanofiber Membranes

Surface modification techniques like plasma treatment, chemical grafting, or coating with functional materials can enhance the adsorption capacity of PVDF nanofiber membranes by introducing specific functional groups or creating hydrophilic/hydrophobic surfaces, improving adsorption affinity for target substances.Expand Specific Solutions04 Composite PVDF Nanofiber Membranes

Incorporating materials like carbon nanotubes, metal-organic frameworks, or functional nanoparticles into PVDF nanofiber structures creates composite membranes exhibiting synergistic effects, leading to improved adsorption capacities and selectivities for specific target substances.Expand Specific Solutions05 Applications of High Adsorption PVDF Nanofiber Membranes

PVDF nanofiber membranes with high adsorption capacity find applications in water treatment for pollutant removal, air purification for capturing volatile organic compounds, and chemical separations for selective adsorption and recovery of valuable substances.Expand Specific Solutions

Main Player Analysis

Arkema, Inc.

Commissariat à l´énergie atomique et aux énergies Alternatives

Key Technology Interpretation

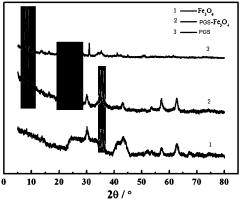

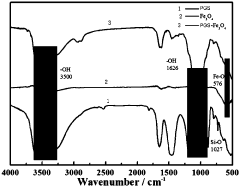

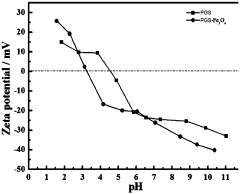

- 1. Incorporating Fe3O4 nanoparticles and attapulgite into the PVDF membrane to enhance adsorption capacity and antifouling properties.

- 2. Utilizing a phase inversion method to prepare the composite ultrafiltration membrane, allowing for better control over membrane structure and properties.

- 3. Combining the advantages of Fe3O4 nanoparticles and attapulgite, which can provide both adsorption and mechanical reinforcement properties to the membrane.