PVDF-Based Composite Adsorbents For Selective Adsorption

Technology Background And Goals

This report provides a comprehensive overview of the development history and technological evolution trends in the field of PVDF-based composite adsorbents for selective adsorption. This section will delve into the key milestones and breakthroughs that have shaped the progress of this technology, shedding light on the driving forces behind its advancements. Additionally, it will clearly define the expected technological goals and targets to be achieved through further research and development efforts in this domain.

By establishing a solid understanding of the technology's background and trajectory, this section lays the foundation for the subsequent analysis and recommendations presented in the report. It serves as a crucial starting point for exploring the market demand, current technological landscape, and potential future directions for PVDF-based composite adsorbents in selective adsorption applications.

Market Demand Analysis

- Market Size and Growth

The market for PVDF-based composite adsorbents is expected to witness significant growth due to increasing demand from various industries, such as water treatment, chemical processing, and environmental remediation. - Key Applications

PVDF-based composite adsorbents find applications in:- Water purification and desalination

- Removal of heavy metals and organic pollutants

- Recovery of valuable materials from industrial effluents

- Air purification and gas separation

- Drivers and Trends

The market growth is driven by:- Stringent environmental regulations and increasing focus on sustainability

- Rising demand for clean water and air

- Advancements in material science and nanotechnology

- Adoption of cost-effective and energy-efficient adsorption processes

- Regional Outlook

The Asia-Pacific region is expected to dominate the market due to rapid industrialization and growing environmental concerns. North America and Europe also present significant opportunities due to strict regulations and adoption of advanced technologies.

Technology Status And Challenges

- Technology Evolution

Tracing the development of PVDF-based composite adsorbents, from early research on PVDF membranes to incorporation of various fillers and modifiers to enhance adsorption performance. - Current Challenges

Identifying key challenges such as limited adsorption capacity, poor selectivity, fouling issues, and difficulties in large-scale production and regeneration. - Geographical Distribution

Highlighting major research centers and industrial hubs focused on PVDF-based composite adsorbents, with a global perspective on technology development.

Current Technical Solutions

01 Water Treatment Adsorbents

PVDF-based composite adsorbents are developed for removing various contaminants from water. They combine PVDF with materials like activated carbon, metal oxides, or polymers to enhance adsorption capacity and selectivity towards specific pollutants.- Water Treatment Adsorbents: PVDF-based composite adsorbents are developed for removing various contaminants from water. They combine PVDF with materials like activated carbon, metal oxides, or polymers to enhance adsorption capacity and selectivity towards specific pollutants.

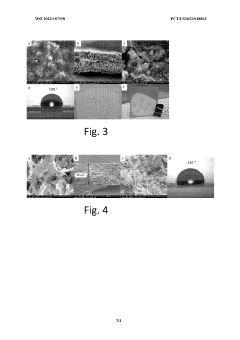

- Filtration Membranes: PVDF-based composite membranes are fabricated for filtration applications like water purification, wastewater treatment, and gas separation. They incorporate PVDF with nanoparticles, polymers, or inorganic fillers to enhance permeability, selectivity, and fouling resistance.

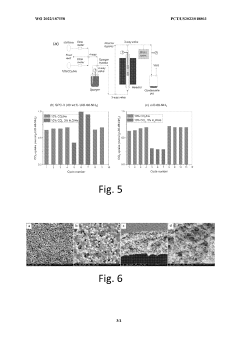

- Energy Storage Electrodes: PVDF-based composite electrodes are developed for energy storage applications like lithium-ion batteries and supercapacitors. They incorporate PVDF with conductive materials like carbon nanotubes, graphene, or metal oxides to improve electrochemical performance, conductivity, and cycle stability.

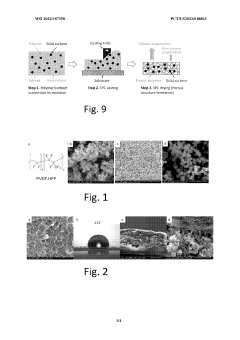

- Coatings and Films: PVDF-based composite coatings and films are developed for applications like corrosion protection, self-cleaning surfaces, and anti-fouling coatings. They combine PVDF with nanoparticles, polymers, or inorganic fillers to enhance mechanical, chemical, or surface properties.

- Tissue Engineering Scaffolds: PVDF-based composite scaffolds are developed for tissue engineering applications like bone regeneration, wound healing, and drug delivery. They incorporate PVDF with bioactive materials like hydroxyapatite, biopolymers, or growth factors to promote cell adhesion, proliferation, and tissue regeneration.

02 Filtration Membranes

PVDF-based composite membranes are fabricated for filtration applications like water purification, wastewater treatment, and gas separation. They incorporate PVDF with materials like nanoparticles, polymers, or inorganic fillers to enhance permeability, selectivity, and fouling resistance.Expand Specific Solutions03 Energy Storage Electrodes

PVDF-based composite electrodes are developed for energy storage applications like lithium-ion batteries and supercapacitors. They incorporate PVDF with conductive materials like carbon nanotubes, graphene, or metal oxides to improve electrochemical performance, conductivity, and cycle stability.Expand Specific Solutions04 Coatings and Films

PVDF-based composite coatings and films are developed for applications like corrosion protection, anti-fouling surfaces, and protective layers. They combine PVDF with fillers, nanoparticles, or other polymers to enhance mechanical, chemical, or surface properties.Expand Specific Solutions05 Tissue Engineering Scaffolds

PVDF-based composite scaffolds are developed for tissue engineering applications like bone regeneration, wound healing, and cell culture. They incorporate PVDF with bioactive materials like hydroxyapatite, bioactive glasses, or natural polymers to promote cell attachment, proliferation, and tissue integration.Expand Specific Solutions

Main Player Analysis

Arkema France SA

Fluoroware, Inc.

Key Technology Interpretation

- The use of a mixed matrix membrane combining PVDF and metal-organic frameworks (MOFs) for CO2 capture.

- The incorporation of an optional filler particle for hydrophobicity modification, improving the compatibility of the sorbent polymer composite with CO2 adsorption applications.

- The solution-casting method for preparing hydrophobic sorbent polymer composites, enabling efficient and scalable production.

PVDF-Based Composite Adsorbents Environmental Impact Assessment

The environmental impact of PVDF-based composite adsorbents is a crucial factor to consider. These materials are typically composed of polyvinylidene fluoride (PVDF) polymer and various inorganic fillers or additives. While PVDF itself is a relatively stable and chemically inert polymer, the production and disposal processes, as well as the potential leaching of fillers, can have environmental consequences.

During the manufacturing stage, the use of organic solvents, reagents, and energy consumption may contribute to air and water pollution, as well as greenhouse gas emissions. Appropriate waste management and treatment practices are essential to mitigate these impacts.

Once deployed for adsorption applications, the potential leaching of inorganic fillers or additives from the composite materials could lead to soil and water contamination, posing risks to ecosystems and human health. Careful consideration should be given to the composition and stability of these fillers to minimize leaching potential.

At the end of their service life, the disposal or recycling of spent PVDF-based composite adsorbents presents another environmental challenge. While PVDF is generally considered recyclable, the presence of inorganic fillers may complicate the recycling process and potentially lead to the generation of hazardous waste streams. Appropriate disposal methods, such as incineration or secure landfilling, may be required to prevent environmental contamination.

PVDF-Based Composite Adsorbents Regulatory And Policy Analysis

The development and application of PVDF-based composite adsorbents for selective adsorption are closely intertwined with various regulations and policies governing environmental protection, chemical safety, and industrial practices. Stringent emission standards and effluent discharge regulations have driven the demand for efficient and selective adsorption technologies to capture and remove hazardous substances from air, water, and industrial processes.

On the other hand, policies promoting the adoption of sustainable and green technologies have fostered research and development efforts in the field of PVDF-based composite adsorbents. These materials offer advantages such as high selectivity, reusability, and low environmental impact, aligning with the principles of green chemistry and circular economy.

Furthermore, regulations related to material safety and chemical handling have influenced the design and manufacturing processes of these adsorbents. Strict guidelines ensure that the materials used and the production methods employed comply with safety standards, minimizing potential risks to workers and the environment.

It is crucial to continuously monitor and adapt to evolving regulations and policies to ensure compliance and capitalize on potential incentives or funding opportunities for research and development in this field. Collaboration between regulatory bodies, academia, and industry stakeholders is essential to strike a balance between environmental protection, technological advancement, and economic viability.