Innovations in Battery Acid Encapsulation Technologies

AUG 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Encapsulation Background and Objectives

Battery acid encapsulation technology has evolved significantly over the past few decades, driven by the increasing demand for safer and more efficient energy storage solutions. This technology plays a crucial role in enhancing the performance and longevity of batteries, particularly in automotive and industrial applications. The primary objective of battery acid encapsulation is to contain the corrosive electrolyte within the battery, preventing leakage and improving overall safety.

The development of battery acid encapsulation can be traced back to the early 20th century when lead-acid batteries became widely used in automobiles. Initially, simple glass or hard rubber containers were employed to house the battery acid. However, as the automotive industry grew and safety standards became more stringent, the need for more advanced encapsulation methods became apparent.

In the 1970s and 1980s, significant advancements were made in polymer technology, leading to the introduction of more sophisticated encapsulation materials. These new materials offered improved chemical resistance, durability, and flexibility, addressing many of the limitations of earlier designs. The advent of absorbent glass mat (AGM) technology in the 1980s marked a major milestone, allowing for the development of valve-regulated lead-acid (VRLA) batteries with enhanced safety features.

The turn of the 21st century saw a renewed focus on battery technology, driven by the growing electric vehicle market and increasing concerns about environmental sustainability. This led to further innovations in acid encapsulation, including the development of advanced polymer composites and nano-engineered materials designed to improve acid retention and reduce the risk of leakage.

Current trends in battery acid encapsulation technology are focused on several key areas. These include the development of smart encapsulation systems that can monitor and respond to changes in battery conditions, the exploration of bio-based and environmentally friendly encapsulation materials, and the integration of encapsulation technology with other battery components to create more compact and efficient energy storage solutions.

Looking ahead, the objectives for future advancements in battery acid encapsulation technology are multifaceted. Researchers and engineers are working towards creating encapsulation systems that can withstand extreme temperatures and pressures, extending battery life and improving safety in harsh environments. Additionally, there is a strong emphasis on developing encapsulation technologies that are compatible with next-generation battery chemistries, such as lithium-sulfur and solid-state batteries.

Another important goal is to reduce the environmental impact of battery production and disposal. This includes developing encapsulation materials that are easier to recycle or biodegrade, as well as exploring ways to minimize the use of toxic or hazardous materials in the encapsulation process. As the global demand for energy storage continues to grow, innovations in battery acid encapsulation will play a vital role in shaping the future of sustainable and efficient power solutions.

The development of battery acid encapsulation can be traced back to the early 20th century when lead-acid batteries became widely used in automobiles. Initially, simple glass or hard rubber containers were employed to house the battery acid. However, as the automotive industry grew and safety standards became more stringent, the need for more advanced encapsulation methods became apparent.

In the 1970s and 1980s, significant advancements were made in polymer technology, leading to the introduction of more sophisticated encapsulation materials. These new materials offered improved chemical resistance, durability, and flexibility, addressing many of the limitations of earlier designs. The advent of absorbent glass mat (AGM) technology in the 1980s marked a major milestone, allowing for the development of valve-regulated lead-acid (VRLA) batteries with enhanced safety features.

The turn of the 21st century saw a renewed focus on battery technology, driven by the growing electric vehicle market and increasing concerns about environmental sustainability. This led to further innovations in acid encapsulation, including the development of advanced polymer composites and nano-engineered materials designed to improve acid retention and reduce the risk of leakage.

Current trends in battery acid encapsulation technology are focused on several key areas. These include the development of smart encapsulation systems that can monitor and respond to changes in battery conditions, the exploration of bio-based and environmentally friendly encapsulation materials, and the integration of encapsulation technology with other battery components to create more compact and efficient energy storage solutions.

Looking ahead, the objectives for future advancements in battery acid encapsulation technology are multifaceted. Researchers and engineers are working towards creating encapsulation systems that can withstand extreme temperatures and pressures, extending battery life and improving safety in harsh environments. Additionally, there is a strong emphasis on developing encapsulation technologies that are compatible with next-generation battery chemistries, such as lithium-sulfur and solid-state batteries.

Another important goal is to reduce the environmental impact of battery production and disposal. This includes developing encapsulation materials that are easier to recycle or biodegrade, as well as exploring ways to minimize the use of toxic or hazardous materials in the encapsulation process. As the global demand for energy storage continues to grow, innovations in battery acid encapsulation will play a vital role in shaping the future of sustainable and efficient power solutions.

Market Analysis for Advanced Battery Technologies

The advanced battery technology market is experiencing significant growth, driven by the increasing demand for electric vehicles, renewable energy storage, and portable electronic devices. The global market for advanced batteries is projected to reach substantial figures in the coming years, with lithium-ion batteries dominating the landscape. However, emerging technologies such as solid-state batteries, lithium-sulfur batteries, and sodium-ion batteries are gaining traction and are expected to reshape the market dynamics.

In the context of battery acid encapsulation technologies, the market shows promising potential. These innovations aim to enhance battery safety, longevity, and performance by effectively containing and managing the electrolyte within the battery cells. The automotive sector, in particular, is a key driver for this technology, as manufacturers seek to improve the safety and reliability of electric vehicle batteries.

The market for battery acid encapsulation technologies is closely tied to the broader trends in the battery industry. As electric vehicle adoption accelerates globally, the demand for safer and more efficient battery technologies is surging. This trend is further amplified by stringent safety regulations and consumer expectations for longer-lasting and faster-charging batteries.

Several factors are influencing the market growth for advanced battery technologies, including government initiatives promoting clean energy, advancements in material science, and increasing investments in research and development. The push for sustainable energy solutions is also driving the need for more efficient and environmentally friendly battery technologies, creating opportunities for innovations in acid encapsulation.

The Asia-Pacific region, particularly China, Japan, and South Korea, leads the market in advanced battery technologies, including acid encapsulation innovations. These countries have established strong manufacturing capabilities and continue to invest heavily in battery research. North America and Europe are also significant markets, with a focus on high-performance batteries for electric vehicles and grid storage applications.

Challenges in the market include the high costs associated with developing and implementing new battery technologies, as well as the need for scalable manufacturing processes. However, ongoing research and development efforts are addressing these issues, potentially leading to more cost-effective solutions in the near future.

The market for battery acid encapsulation technologies is expected to grow in tandem with the overall advanced battery market. As manufacturers strive to differentiate their products and gain a competitive edge, innovations in this area are likely to play a crucial role in shaping the future of battery technology. The integration of smart materials and nanotechnology in acid encapsulation is an emerging trend that could further enhance battery performance and safety, opening up new market opportunities.

In the context of battery acid encapsulation technologies, the market shows promising potential. These innovations aim to enhance battery safety, longevity, and performance by effectively containing and managing the electrolyte within the battery cells. The automotive sector, in particular, is a key driver for this technology, as manufacturers seek to improve the safety and reliability of electric vehicle batteries.

The market for battery acid encapsulation technologies is closely tied to the broader trends in the battery industry. As electric vehicle adoption accelerates globally, the demand for safer and more efficient battery technologies is surging. This trend is further amplified by stringent safety regulations and consumer expectations for longer-lasting and faster-charging batteries.

Several factors are influencing the market growth for advanced battery technologies, including government initiatives promoting clean energy, advancements in material science, and increasing investments in research and development. The push for sustainable energy solutions is also driving the need for more efficient and environmentally friendly battery technologies, creating opportunities for innovations in acid encapsulation.

The Asia-Pacific region, particularly China, Japan, and South Korea, leads the market in advanced battery technologies, including acid encapsulation innovations. These countries have established strong manufacturing capabilities and continue to invest heavily in battery research. North America and Europe are also significant markets, with a focus on high-performance batteries for electric vehicles and grid storage applications.

Challenges in the market include the high costs associated with developing and implementing new battery technologies, as well as the need for scalable manufacturing processes. However, ongoing research and development efforts are addressing these issues, potentially leading to more cost-effective solutions in the near future.

The market for battery acid encapsulation technologies is expected to grow in tandem with the overall advanced battery market. As manufacturers strive to differentiate their products and gain a competitive edge, innovations in this area are likely to play a crucial role in shaping the future of battery technology. The integration of smart materials and nanotechnology in acid encapsulation is an emerging trend that could further enhance battery performance and safety, opening up new market opportunities.

Current Challenges in Battery Acid Containment

Battery acid containment remains a critical challenge in the development and implementation of advanced battery technologies. The primary issue stems from the corrosive nature of battery acids, which can lead to leakage, environmental contamination, and safety hazards. Current containment methods often struggle to provide long-term protection against acid degradation, especially in high-performance batteries subjected to extreme conditions.

One of the main challenges is the development of materials that can withstand prolonged exposure to highly acidic environments while maintaining structural integrity. Traditional containment materials, such as certain plastics and metals, may degrade over time, leading to potential failures and reduced battery lifespan. This degradation is particularly problematic in applications requiring extended operational periods, such as electric vehicles and grid-scale energy storage systems.

Another significant challenge lies in balancing acid containment with optimal battery performance. Effective containment solutions must not impede the electrochemical reactions necessary for battery function, nor should they add excessive weight or volume to the battery system. This balance is crucial for maintaining high energy density and efficiency, particularly in portable electronic devices and electric vehicles where space and weight are at a premium.

The thermal management of battery systems presents an additional hurdle for acid containment. As batteries generate heat during operation, containment materials must withstand temperature fluctuations without compromising their protective properties. This challenge is exacerbated in fast-charging scenarios and high-power applications, where rapid temperature changes can stress containment systems.

Furthermore, the scalability of containment solutions poses a significant challenge. While certain advanced materials or designs may prove effective in laboratory settings, translating these innovations to mass production while maintaining cost-effectiveness and reliability remains a hurdle. This scaling issue is particularly relevant as the demand for large-scale battery systems in renewable energy storage and electric transportation continues to grow.

Environmental concerns also play a crucial role in shaping the challenges of battery acid containment. There is an increasing need for containment solutions that not only prevent leakage during operation but also facilitate safe disposal or recycling at the end of the battery's life cycle. This aspect is becoming more critical as regulations around battery disposal and recycling become more stringent globally.

Lastly, the diversity of battery chemistries and designs presents a challenge in developing universal containment solutions. Different battery types, from lead-acid to lithium-ion and emerging technologies, require tailored approaches to acid containment. This diversity necessitates ongoing research and development to create versatile or specialized containment technologies that can address the unique needs of various battery systems.

One of the main challenges is the development of materials that can withstand prolonged exposure to highly acidic environments while maintaining structural integrity. Traditional containment materials, such as certain plastics and metals, may degrade over time, leading to potential failures and reduced battery lifespan. This degradation is particularly problematic in applications requiring extended operational periods, such as electric vehicles and grid-scale energy storage systems.

Another significant challenge lies in balancing acid containment with optimal battery performance. Effective containment solutions must not impede the electrochemical reactions necessary for battery function, nor should they add excessive weight or volume to the battery system. This balance is crucial for maintaining high energy density and efficiency, particularly in portable electronic devices and electric vehicles where space and weight are at a premium.

The thermal management of battery systems presents an additional hurdle for acid containment. As batteries generate heat during operation, containment materials must withstand temperature fluctuations without compromising their protective properties. This challenge is exacerbated in fast-charging scenarios and high-power applications, where rapid temperature changes can stress containment systems.

Furthermore, the scalability of containment solutions poses a significant challenge. While certain advanced materials or designs may prove effective in laboratory settings, translating these innovations to mass production while maintaining cost-effectiveness and reliability remains a hurdle. This scaling issue is particularly relevant as the demand for large-scale battery systems in renewable energy storage and electric transportation continues to grow.

Environmental concerns also play a crucial role in shaping the challenges of battery acid containment. There is an increasing need for containment solutions that not only prevent leakage during operation but also facilitate safe disposal or recycling at the end of the battery's life cycle. This aspect is becoming more critical as regulations around battery disposal and recycling become more stringent globally.

Lastly, the diversity of battery chemistries and designs presents a challenge in developing universal containment solutions. Different battery types, from lead-acid to lithium-ion and emerging technologies, require tailored approaches to acid containment. This diversity necessitates ongoing research and development to create versatile or specialized containment technologies that can address the unique needs of various battery systems.

Existing Acid Encapsulation Solutions

01 Polymer-based encapsulation techniques

Polymer-based encapsulation techniques are used to protect battery acid and improve battery performance. These methods involve coating or encapsulating the acid with various polymeric materials, which can enhance the stability, safety, and longevity of the battery. The polymers used may include thermoplastics, thermosets, or specialized copolymers designed for acid resistance.- Polymer-based encapsulation of battery acid: This technique involves using polymer materials to encapsulate battery acid, preventing leakage and improving safety. The polymer coating forms a protective barrier around the acid, allowing for better handling and storage of batteries. This method can enhance the overall performance and lifespan of the battery while reducing environmental risks associated with acid leakage.

- Gel electrolyte encapsulation: Gel electrolyte encapsulation is a method where the battery acid is incorporated into a gel matrix. This approach reduces the risk of acid spillage and allows for more flexible battery designs. The gel electrolyte can improve the battery's resistance to vibration and shock, making it suitable for various applications, including portable electronics and electric vehicles.

- Nanoparticle-based encapsulation technologies: This innovative approach uses nanoparticles to encapsulate battery acid, offering improved control over acid distribution and release. Nanoparticle encapsulation can enhance the battery's efficiency, reduce corrosion, and potentially increase energy density. This technology also allows for better integration of additives and performance-enhancing materials within the battery structure.

- Ceramic-based encapsulation methods: Ceramic materials are used to encapsulate battery acid, providing excellent thermal stability and chemical resistance. This method can significantly improve the safety of batteries, especially in high-temperature environments. Ceramic encapsulation also offers potential benefits in terms of battery longevity and performance in extreme conditions.

- Microencapsulation techniques for battery acid: Microencapsulation involves enclosing small droplets of battery acid within microscopic capsules. This technique allows for better control of acid release and can improve the overall stability of the battery. Microencapsulation can also facilitate the incorporation of smart materials that respond to environmental changes, potentially leading to more adaptive and efficient battery systems.

02 Gel electrolyte encapsulation

Gel electrolyte encapsulation involves the use of gel-forming materials to immobilize the battery acid. This technique can reduce acid leakage, improve safety, and enhance the overall performance of the battery. The gel electrolyte can be formed using various polymers or inorganic materials that create a semi-solid matrix to contain the acid.Expand Specific Solutions03 Nanoparticle-based encapsulation

Nanoparticle-based encapsulation technologies utilize nanoscale materials to encapsulate or modify battery acid. This approach can improve the electrochemical properties of the battery, enhance acid retention, and potentially increase the energy density. Various types of nanoparticles, such as metal oxides or carbon-based materials, may be used in this technique.Expand Specific Solutions04 Microencapsulation of battery components

Microencapsulation involves enclosing small particles or droplets of battery acid within a protective coating or shell. This technique can improve the handling and safety of battery materials, reduce acid leakage, and potentially enable new battery designs. Various materials and methods can be used for microencapsulation, including spray drying, coacervation, and interfacial polymerization.Expand Specific Solutions05 Composite membrane encapsulation

Composite membrane encapsulation technologies involve the use of specialized membranes to contain and manage battery acid. These membranes can be designed to allow ion transport while preventing acid leakage, improving battery safety and performance. The membranes may be made from a combination of organic and inorganic materials, offering enhanced mechanical and chemical stability.Expand Specific Solutions

Key Players in Battery Encapsulation Industry

The battery acid encapsulation technology market is in a growth phase, driven by increasing demand for safer and more efficient battery solutions across various industries. The market size is expanding, with significant potential in electric vehicles, renewable energy storage, and consumer electronics sectors. Technological maturity varies among key players, with companies like Tesla, BYD, and GS Yuasa leading in innovation. Established firms such as Robert Bosch and Fraunhofer-Gesellschaft contribute substantial research and development efforts. Emerging players like I-TEN SA and Hyperdrive Innovation are introducing novel approaches, while traditional battery manufacturers like Tianneng Battery Group and Amara Raja Energy & Mobility are adapting to new encapsulation technologies. The competitive landscape is diverse, with a mix of global conglomerates, specialized battery manufacturers, and research institutions driving advancements in this field.

BYD Co., Ltd.

Technical Solution: BYD has pioneered the Blade Battery technology, which incorporates innovative acid encapsulation methods. The Blade Battery uses a novel cell-to-pack design that maximizes space utilization and improves thermal management[5]. BYD's encapsulation technique involves a high-temperature resistant polymer coating that effectively contains the electrolyte while allowing for efficient heat dissipation[6]. They have also developed a smart electrolyte circulation system that reduces acid stratification and extends battery life[7]. BYD's batteries feature advanced pressure relief mechanisms to prevent acid leakage in case of overcharging or physical damage[8].

Strengths: High energy density, improved safety, and efficient thermal management. Weaknesses: Relatively new technology with limited long-term performance data in real-world applications.

Tesla, Inc.

Technical Solution: Tesla has developed advanced battery acid encapsulation technologies for their electric vehicles. They use a proprietary electrolyte additive package that forms a protective layer on the electrode surface, reducing acid-induced corrosion and extending battery life[1]. Tesla's innovation includes a nano-engineered separator material that enhances acid containment while allowing efficient ion transfer[2]. Their batteries also feature a multi-layer pouch design with acid-resistant polymers, effectively preventing electrolyte leakage and improving safety[3]. Tesla's battery management system continuously monitors acid levels and adjusts charging parameters to optimize performance and longevity[4].

Strengths: Extended battery life, improved safety, and optimized performance. Weaknesses: Proprietary technology may increase production costs and limit compatibility with other systems.

Innovative Encapsulation Materials and Methods

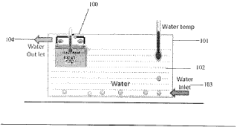

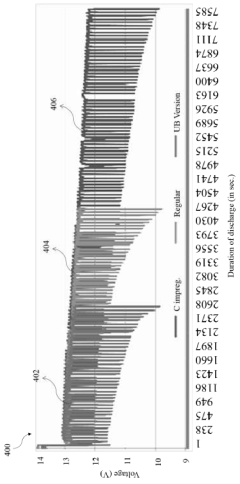

In-situ process to reduce the formation cycle time in flooded lead acid battery manufacturing process

PatentInactiveIN4815CHE2015A

Innovation

- An in-situ process is introduced where a combination of sodium bicarbonate and citric acid is added to the formation tub water to induce an endothermic reaction, enhancing heat transfer from the electrolyte to surrounding water, thereby maintaining electrolyte temperature and reducing the formation cycle time.

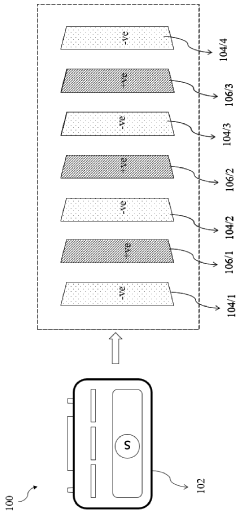

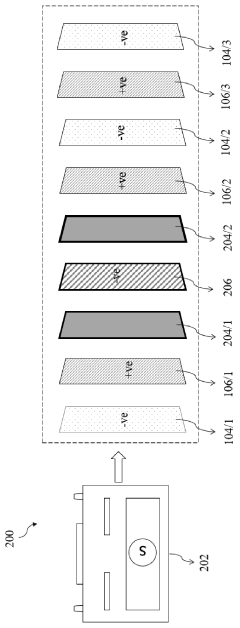

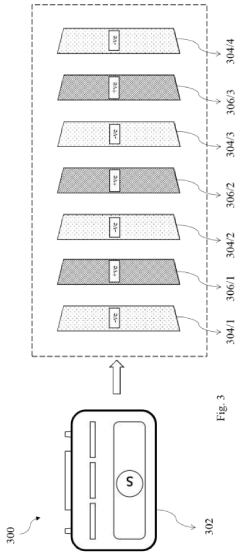

System and method for improving charge-discharge rates and cycle life of a battery

PatentInactiveIN202041004010A

Innovation

- Incorporating processed activated carbon into the negative electrode material of lead acid batteries to reduce sulfation rates, enhance charge-discharge rates, and improve battery capacity, while maintaining the battery's structural integrity.

Environmental Impact of Encapsulation Technologies

Battery acid encapsulation technologies have significant environmental implications that extend beyond their primary function of improving battery performance and safety. These technologies aim to contain and manage the corrosive electrolytes used in batteries, particularly lead-acid batteries, which are widely used in automotive and industrial applications.

One of the primary environmental benefits of advanced encapsulation technologies is the reduction of acid leakage risks. Traditional batteries are prone to leaks, which can result in soil and water contamination. Improved encapsulation methods, such as gel electrolytes and absorbent glass mat (AGM) designs, significantly minimize the risk of acid spills, thereby protecting ecosystems and reducing the potential for environmental hazards.

Furthermore, encapsulation technologies contribute to the extension of battery life cycles. By preventing electrolyte evaporation and maintaining optimal acid concentration, these innovations help batteries last longer. This increased longevity directly translates to reduced waste generation, as fewer batteries need to be replaced over time. Consequently, the demand for raw materials used in battery production decreases, leading to a reduction in mining activities and their associated environmental impacts.

The environmental benefits of encapsulation technologies also extend to the recycling process. Batteries with advanced encapsulation are often easier and safer to recycle, as the contained acid is less likely to leak during transportation and processing. This improvement in recyclability not only enhances worker safety but also increases the efficiency of recycling operations, allowing for higher recovery rates of valuable materials such as lead and plastic.

However, it is important to consider the potential environmental trade-offs associated with these technologies. Some encapsulation methods may introduce new materials or chemicals that could pose their own environmental challenges. For instance, certain polymer-based encapsulants might not be as easily recyclable as traditional battery components, potentially creating new waste streams.

Additionally, the production processes for advanced encapsulation technologies may require more energy or resources compared to conventional battery manufacturing. This increased production complexity could lead to a higher carbon footprint in the short term, although the long-term benefits of extended battery life and improved recyclability may offset these initial environmental costs.

In conclusion, while battery acid encapsulation technologies offer significant environmental advantages in terms of reduced leakage risks, extended battery life, and improved recyclability, a comprehensive life cycle assessment is necessary to fully understand their net environmental impact. As these technologies continue to evolve, ongoing research and development efforts should focus on optimizing both performance and environmental sustainability to ensure that the benefits outweigh any potential drawbacks.

One of the primary environmental benefits of advanced encapsulation technologies is the reduction of acid leakage risks. Traditional batteries are prone to leaks, which can result in soil and water contamination. Improved encapsulation methods, such as gel electrolytes and absorbent glass mat (AGM) designs, significantly minimize the risk of acid spills, thereby protecting ecosystems and reducing the potential for environmental hazards.

Furthermore, encapsulation technologies contribute to the extension of battery life cycles. By preventing electrolyte evaporation and maintaining optimal acid concentration, these innovations help batteries last longer. This increased longevity directly translates to reduced waste generation, as fewer batteries need to be replaced over time. Consequently, the demand for raw materials used in battery production decreases, leading to a reduction in mining activities and their associated environmental impacts.

The environmental benefits of encapsulation technologies also extend to the recycling process. Batteries with advanced encapsulation are often easier and safer to recycle, as the contained acid is less likely to leak during transportation and processing. This improvement in recyclability not only enhances worker safety but also increases the efficiency of recycling operations, allowing for higher recovery rates of valuable materials such as lead and plastic.

However, it is important to consider the potential environmental trade-offs associated with these technologies. Some encapsulation methods may introduce new materials or chemicals that could pose their own environmental challenges. For instance, certain polymer-based encapsulants might not be as easily recyclable as traditional battery components, potentially creating new waste streams.

Additionally, the production processes for advanced encapsulation technologies may require more energy or resources compared to conventional battery manufacturing. This increased production complexity could lead to a higher carbon footprint in the short term, although the long-term benefits of extended battery life and improved recyclability may offset these initial environmental costs.

In conclusion, while battery acid encapsulation technologies offer significant environmental advantages in terms of reduced leakage risks, extended battery life, and improved recyclability, a comprehensive life cycle assessment is necessary to fully understand their net environmental impact. As these technologies continue to evolve, ongoing research and development efforts should focus on optimizing both performance and environmental sustainability to ensure that the benefits outweigh any potential drawbacks.

Safety Regulations for Battery Acid Handling

Safety regulations for battery acid handling have become increasingly stringent in recent years, reflecting the growing awareness of the potential hazards associated with these corrosive substances. Regulatory bodies worldwide have implemented comprehensive guidelines to ensure the safe management of battery acid throughout its lifecycle, from production and transportation to storage and disposal.

One of the primary focuses of these regulations is the proper containment of battery acid. Manufacturers are required to use high-quality, acid-resistant materials for containers and enclosures. These materials must undergo rigorous testing to ensure their ability to withstand prolonged exposure to acidic substances without degradation or leakage. Additionally, regulations mandate the use of secondary containment systems to prevent spills from spreading in case of primary container failure.

Personal protective equipment (PPE) requirements have also been significantly enhanced. Workers handling battery acid must wear appropriate acid-resistant gloves, face shields, and protective clothing. Employers are obligated to provide comprehensive training on the proper use of PPE and emergency response procedures in case of accidental exposure or spills.

Transportation of battery acid is subject to strict regulations, including specific packaging requirements and labeling standards. Vehicles transporting these materials must be equipped with spill containment kits and follow designated routes to minimize potential risks to populated areas. Drivers transporting battery acid are required to undergo specialized training in hazardous materials handling and emergency response procedures.

Storage facilities for battery acid must adhere to specific design criteria, including proper ventilation systems, acid-resistant flooring, and designated neutralization areas. Regular inspections and maintenance of storage areas are mandated to ensure ongoing compliance with safety standards. Emergency response plans must be in place, including procedures for containment, neutralization, and disposal of spilled acid.

Environmental regulations have also been tightened, focusing on the prevention of soil and water contamination. Facilities handling battery acid are required to implement comprehensive waste management plans, including proper neutralization and disposal procedures for spent acid. Regular environmental impact assessments are mandated to monitor and mitigate potential long-term effects on surrounding ecosystems.

Occupational health and safety regulations have evolved to include more frequent medical monitoring for workers regularly exposed to battery acid. This includes periodic health check-ups and maintaining detailed exposure records. Employers are required to implement engineering controls to minimize worker exposure, such as automated handling systems and enclosed processing areas.

As innovations in battery acid encapsulation technologies continue to advance, regulatory frameworks are expected to evolve accordingly. Future regulations may focus on promoting the adoption of safer, more environmentally friendly alternatives to traditional lead-acid batteries, as well as encouraging the development of more advanced containment and neutralization technologies.

One of the primary focuses of these regulations is the proper containment of battery acid. Manufacturers are required to use high-quality, acid-resistant materials for containers and enclosures. These materials must undergo rigorous testing to ensure their ability to withstand prolonged exposure to acidic substances without degradation or leakage. Additionally, regulations mandate the use of secondary containment systems to prevent spills from spreading in case of primary container failure.

Personal protective equipment (PPE) requirements have also been significantly enhanced. Workers handling battery acid must wear appropriate acid-resistant gloves, face shields, and protective clothing. Employers are obligated to provide comprehensive training on the proper use of PPE and emergency response procedures in case of accidental exposure or spills.

Transportation of battery acid is subject to strict regulations, including specific packaging requirements and labeling standards. Vehicles transporting these materials must be equipped with spill containment kits and follow designated routes to minimize potential risks to populated areas. Drivers transporting battery acid are required to undergo specialized training in hazardous materials handling and emergency response procedures.

Storage facilities for battery acid must adhere to specific design criteria, including proper ventilation systems, acid-resistant flooring, and designated neutralization areas. Regular inspections and maintenance of storage areas are mandated to ensure ongoing compliance with safety standards. Emergency response plans must be in place, including procedures for containment, neutralization, and disposal of spilled acid.

Environmental regulations have also been tightened, focusing on the prevention of soil and water contamination. Facilities handling battery acid are required to implement comprehensive waste management plans, including proper neutralization and disposal procedures for spent acid. Regular environmental impact assessments are mandated to monitor and mitigate potential long-term effects on surrounding ecosystems.

Occupational health and safety regulations have evolved to include more frequent medical monitoring for workers regularly exposed to battery acid. This includes periodic health check-ups and maintaining detailed exposure records. Employers are required to implement engineering controls to minimize worker exposure, such as automated handling systems and enclosed processing areas.

As innovations in battery acid encapsulation technologies continue to advance, regulatory frameworks are expected to evolve accordingly. Future regulations may focus on promoting the adoption of safer, more environmentally friendly alternatives to traditional lead-acid batteries, as well as encouraging the development of more advanced containment and neutralization technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!