How Butane Affects the Octane Rating of Fuel Blends

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane and Octane Rating: Background and Objectives

The octane rating of fuel blends is a critical factor in determining the performance and efficiency of internal combustion engines. This technical research report aims to explore the impact of butane on the octane rating of fuel blends, providing a comprehensive overview of the historical development, current trends, and future objectives in this field.

Butane, a hydrocarbon compound with the formula C4H10, has been a subject of interest in the fuel industry for decades. Its inclusion in fuel blends has significant implications for octane ratings, which measure a fuel's resistance to knock or pre-ignition in spark-ignition engines. The relationship between butane and octane ratings has evolved alongside advancements in engine technology and environmental regulations.

Historically, the use of butane in fuel blends gained prominence in the mid-20th century as refiners sought cost-effective ways to boost octane ratings. The volatility of butane made it an attractive additive, particularly for winter-grade fuels. However, as environmental concerns grew, regulations began to limit the amount of butane that could be blended into gasoline, especially during summer months when its high vapor pressure contributes to increased emissions.

The technical evolution of fuel blending has led to a more nuanced understanding of how butane affects octane ratings. Modern research focuses on optimizing the balance between octane enhancement and environmental impact. This includes studying the interaction of butane with other fuel components and its behavior under various engine operating conditions.

Current trends in the field involve the development of advanced blending techniques that maximize the octane-boosting properties of butane while minimizing its negative effects. This includes exploring synergistic effects with other additives and investigating the potential of butane isomers with more favorable characteristics.

The primary objective of this research is to provide a comprehensive analysis of butane's role in determining the octane rating of fuel blends. This involves examining the chemical and physical properties of butane that contribute to its octane-enhancing capabilities, as well as its limitations and potential drawbacks.

Furthermore, this report aims to explore the regulatory landscape surrounding butane use in fuel blends, considering both current standards and potential future changes. Understanding these regulations is crucial for predicting the long-term viability of butane as an octane booster and for guiding future research and development efforts in the field.

Ultimately, this technical research seeks to contribute to the ongoing efforts to improve fuel efficiency, reduce emissions, and enhance engine performance through optimized fuel blending strategies. By thoroughly examining the relationship between butane and octane ratings, we aim to identify promising avenues for innovation and provide valuable insights for the fuel industry and automotive sector.

Butane, a hydrocarbon compound with the formula C4H10, has been a subject of interest in the fuel industry for decades. Its inclusion in fuel blends has significant implications for octane ratings, which measure a fuel's resistance to knock or pre-ignition in spark-ignition engines. The relationship between butane and octane ratings has evolved alongside advancements in engine technology and environmental regulations.

Historically, the use of butane in fuel blends gained prominence in the mid-20th century as refiners sought cost-effective ways to boost octane ratings. The volatility of butane made it an attractive additive, particularly for winter-grade fuels. However, as environmental concerns grew, regulations began to limit the amount of butane that could be blended into gasoline, especially during summer months when its high vapor pressure contributes to increased emissions.

The technical evolution of fuel blending has led to a more nuanced understanding of how butane affects octane ratings. Modern research focuses on optimizing the balance between octane enhancement and environmental impact. This includes studying the interaction of butane with other fuel components and its behavior under various engine operating conditions.

Current trends in the field involve the development of advanced blending techniques that maximize the octane-boosting properties of butane while minimizing its negative effects. This includes exploring synergistic effects with other additives and investigating the potential of butane isomers with more favorable characteristics.

The primary objective of this research is to provide a comprehensive analysis of butane's role in determining the octane rating of fuel blends. This involves examining the chemical and physical properties of butane that contribute to its octane-enhancing capabilities, as well as its limitations and potential drawbacks.

Furthermore, this report aims to explore the regulatory landscape surrounding butane use in fuel blends, considering both current standards and potential future changes. Understanding these regulations is crucial for predicting the long-term viability of butane as an octane booster and for guiding future research and development efforts in the field.

Ultimately, this technical research seeks to contribute to the ongoing efforts to improve fuel efficiency, reduce emissions, and enhance engine performance through optimized fuel blending strategies. By thoroughly examining the relationship between butane and octane ratings, we aim to identify promising avenues for innovation and provide valuable insights for the fuel industry and automotive sector.

Market Analysis of High-Octane Fuel Blends

The high-octane fuel blend market has experienced significant growth in recent years, driven by increasing demand for improved engine performance and fuel efficiency. This segment of the fuel market caters to premium vehicles, high-performance engines, and consumers seeking enhanced driving experiences. The global market for high-octane fuel blends is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) exceeding the overall fuel market average.

Several factors contribute to the expanding market for high-octane fuel blends. Stringent environmental regulations and the push for reduced emissions have led automakers to develop more efficient engines that require higher octane fuels. Additionally, the growing popularity of turbocharged engines, which benefit from higher octane ratings, has further boosted demand for premium fuel blends.

Consumer preferences also play a crucial role in market growth. As disposable incomes rise in emerging economies, there is an increasing willingness to pay for premium fuels perceived to offer better performance and engine protection. This trend is particularly evident in countries with rapidly growing middle-class populations and expanding automotive markets.

The market landscape for high-octane fuel blends varies geographically. North America and Europe have well-established markets, with a significant portion of consumers opting for premium fuels. In contrast, developing regions such as Asia-Pacific and Latin America present substantial growth opportunities as vehicle ownership increases and consumer awareness of fuel quality grows.

Major oil companies and fuel retailers have recognized the potential of the high-octane fuel blend market, leading to increased investment in product development and marketing. Many have introduced proprietary premium fuel formulations, often incorporating additives that claim to provide additional benefits beyond octane enhancement.

Competition in this market segment is intense, with companies differentiating their products through branding, performance claims, and loyalty programs. Some retailers have partnered with automakers to develop co-branded fuels specifically formulated for certain vehicle models, further segmenting the market.

The future outlook for high-octane fuel blends remains positive, despite the gradual shift towards electric vehicles. In the medium term, hybrid vehicles and advanced internal combustion engines will continue to drive demand for high-octane fuels. However, market players must remain adaptable to evolving technologies and changing consumer preferences to maintain their competitive edge in this dynamic sector.

Several factors contribute to the expanding market for high-octane fuel blends. Stringent environmental regulations and the push for reduced emissions have led automakers to develop more efficient engines that require higher octane fuels. Additionally, the growing popularity of turbocharged engines, which benefit from higher octane ratings, has further boosted demand for premium fuel blends.

Consumer preferences also play a crucial role in market growth. As disposable incomes rise in emerging economies, there is an increasing willingness to pay for premium fuels perceived to offer better performance and engine protection. This trend is particularly evident in countries with rapidly growing middle-class populations and expanding automotive markets.

The market landscape for high-octane fuel blends varies geographically. North America and Europe have well-established markets, with a significant portion of consumers opting for premium fuels. In contrast, developing regions such as Asia-Pacific and Latin America present substantial growth opportunities as vehicle ownership increases and consumer awareness of fuel quality grows.

Major oil companies and fuel retailers have recognized the potential of the high-octane fuel blend market, leading to increased investment in product development and marketing. Many have introduced proprietary premium fuel formulations, often incorporating additives that claim to provide additional benefits beyond octane enhancement.

Competition in this market segment is intense, with companies differentiating their products through branding, performance claims, and loyalty programs. Some retailers have partnered with automakers to develop co-branded fuels specifically formulated for certain vehicle models, further segmenting the market.

The future outlook for high-octane fuel blends remains positive, despite the gradual shift towards electric vehicles. In the medium term, hybrid vehicles and advanced internal combustion engines will continue to drive demand for high-octane fuels. However, market players must remain adaptable to evolving technologies and changing consumer preferences to maintain their competitive edge in this dynamic sector.

Current Challenges in Fuel Blending Technologies

The fuel blending industry faces several significant challenges in maintaining and improving the octane rating of fuel blends, particularly when incorporating butane. One of the primary issues is the volatility of butane, which can lead to vapor lock in engines and increased evaporative emissions. This volatility becomes especially problematic in warmer climates or during summer months, necessitating careful adjustment of blend compositions based on seasonal variations.

Another challenge lies in the precise control of butane content in fuel blends. Butane is an attractive blending component due to its high octane rating and lower cost compared to other hydrocarbons. However, excessive butane can lead to reduced fuel economy and potential engine performance issues. Achieving the optimal balance between octane enhancement and overall fuel quality requires sophisticated blending technologies and real-time monitoring systems.

The inconsistency in butane quality from different sources also presents a significant hurdle. Variations in impurities and composition can affect the final octane rating of the fuel blend, making it difficult to maintain consistent product quality. This necessitates rigorous quality control measures and potentially costly purification processes.

Environmental regulations pose another challenge to fuel blenders. Stricter emissions standards and limitations on volatile organic compounds (VOCs) restrict the amount of butane that can be used in fuel blends, particularly in regions with air quality concerns. Balancing regulatory compliance with octane requirements often requires innovative blending strategies and the use of alternative octane boosters.

The dynamic nature of crude oil feedstocks further complicates the blending process. As refineries process different types of crude oil, the base gasoline components can vary significantly in composition and octane rating. This variability requires constant adjustment of blending recipes to maintain consistent octane levels in the final product, adding complexity to the production process.

Lastly, the fuel blending industry faces challenges in accurately predicting and measuring the octane rating of complex fuel blends. Traditional laboratory testing methods can be time-consuming and may not fully capture the synergistic effects of different blend components. Developing rapid, accurate, and cost-effective methods for octane prediction and measurement remains an ongoing challenge for fuel blenders seeking to optimize their products and processes.

Another challenge lies in the precise control of butane content in fuel blends. Butane is an attractive blending component due to its high octane rating and lower cost compared to other hydrocarbons. However, excessive butane can lead to reduced fuel economy and potential engine performance issues. Achieving the optimal balance between octane enhancement and overall fuel quality requires sophisticated blending technologies and real-time monitoring systems.

The inconsistency in butane quality from different sources also presents a significant hurdle. Variations in impurities and composition can affect the final octane rating of the fuel blend, making it difficult to maintain consistent product quality. This necessitates rigorous quality control measures and potentially costly purification processes.

Environmental regulations pose another challenge to fuel blenders. Stricter emissions standards and limitations on volatile organic compounds (VOCs) restrict the amount of butane that can be used in fuel blends, particularly in regions with air quality concerns. Balancing regulatory compliance with octane requirements often requires innovative blending strategies and the use of alternative octane boosters.

The dynamic nature of crude oil feedstocks further complicates the blending process. As refineries process different types of crude oil, the base gasoline components can vary significantly in composition and octane rating. This variability requires constant adjustment of blending recipes to maintain consistent octane levels in the final product, adding complexity to the production process.

Lastly, the fuel blending industry faces challenges in accurately predicting and measuring the octane rating of complex fuel blends. Traditional laboratory testing methods can be time-consuming and may not fully capture the synergistic effects of different blend components. Developing rapid, accurate, and cost-effective methods for octane prediction and measurement remains an ongoing challenge for fuel blenders seeking to optimize their products and processes.

Existing Butane Blending Methodologies

01 Octane rating measurement for butane

Methods and apparatus for measuring the octane rating of butane. This involves specialized equipment and techniques to determine the anti-knock properties of butane fuel, which is crucial for assessing its performance in internal combustion engines.- Octane rating measurement for butane: Methods and apparatus for determining the octane rating of butane and other hydrocarbon fuels. This involves analyzing the fuel composition, combustion characteristics, and performance in test engines to assess its knock resistance and overall quality.

- Butane blending for octane enhancement: Techniques for blending butane with other hydrocarbons to improve the overall octane rating of fuel mixtures. This process involves careful control of blend ratios and consideration of seasonal variations to meet regulatory requirements and optimize fuel performance.

- Catalytic processes affecting butane octane rating: Catalytic conversion processes that can modify the molecular structure of butane and related hydrocarbons to enhance their octane rating. These processes may include isomerization, reforming, or other chemical transformations to produce higher-octane fuel components.

- Butane purification for octane improvement: Methods for purifying butane to remove impurities that may negatively affect its octane rating. This can involve distillation, adsorption, or other separation techniques to produce a higher-quality butane stream suitable for high-octane fuel applications.

- Octane rating prediction and modeling for butane-containing fuels: Computational methods and models for predicting the octane rating of butane and butane-containing fuel blends. These approaches may use machine learning, statistical analysis, or thermodynamic calculations to estimate octane ratings without extensive physical testing.

02 Butane blending for octane enhancement

Processes for blending butane with other hydrocarbons to improve the overall octane rating of fuel mixtures. This includes optimizing the proportion of butane in gasoline blends to achieve desired octane levels while meeting regulatory requirements.Expand Specific Solutions03 Butane isomerization for octane improvement

Techniques for isomerizing butane to produce higher-octane isomers. This involves catalytic processes to convert normal butane into isobutane, which has a higher octane rating and is more valuable as a fuel component.Expand Specific Solutions04 Octane boosting additives for butane-based fuels

Development and use of additives to enhance the octane rating of butane-containing fuels. These additives can include oxygenates, aromatics, or other compounds that increase the anti-knock properties of the fuel mixture.Expand Specific Solutions05 Quality control and analysis of butane for octane rating

Systems and methods for monitoring and controlling the quality of butane with respect to its octane rating. This includes analytical techniques, sampling procedures, and quality assurance processes to ensure consistent octane performance in butane-based fuels.Expand Specific Solutions

Key Players in Fuel Additive Industry

The competitive landscape for "How Butane Affects the Octane Rating of Fuel Blends" is characterized by a mature industry in a growth phase, with a substantial global market size. Major players like China Petroleum & Chemical Corp., Saudi Arabian Oil Co., and ExxonMobil are at the forefront of research and development in this field. The technology's maturity is evident through the involvement of specialized research institutes such as Sinopec Research Institute of Petroleum Processing and Shanghai Petrochemical Research Institute. Emerging companies like Gevo, Inc. and Swift Fuel LLC are also contributing to innovation in fuel blending technologies, indicating a dynamic and evolving market with potential for further advancements in octane rating optimization.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive approach to optimize the octane rating of fuel blends incorporating butane. Their method involves a multi-step process that includes precise blending techniques, advanced catalytic reforming, and innovative isomerization processes. Sinopec's research has shown that controlled addition of butane can increase the octane number by up to 3-4 points without compromising fuel stability[1]. They have also implemented a real-time blending optimization system that adjusts butane content based on seasonal variations and regulatory requirements, ensuring consistent fuel quality and performance[3].

Strengths: Large-scale production capabilities, advanced research facilities, and extensive market presence. Weaknesses: Potential over-reliance on fossil fuels and challenges in adapting to stricter environmental regulations.

Saudi Arabian Oil Co.

Technical Solution: Saudi Arabian Oil Co. (Saudi Aramco) has pioneered a novel approach to managing butane's impact on octane ratings in fuel blends. Their proprietary technology, known as the Aramco Octane on Demand system, allows for dynamic adjustment of fuel octane levels by precisely controlling butane content. This system enables vehicles to operate on lower octane fuel during normal driving conditions and switch to higher octane fuel when needed for improved performance[2]. Aramco's research has demonstrated that this approach can reduce overall fuel consumption by up to 4% while maintaining engine performance[5].

Strengths: Vast oil reserves, cutting-edge research facilities, and significant financial resources for R&D. Weaknesses: Heavy dependence on oil markets and potential challenges in diversifying into renewable energy sources.

Innovative Approaches to Octane Enhancement

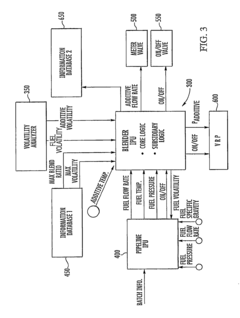

Method of monitoring and controlling activity involving a fuel composition

PatentInactiveUS20140229010A1

Innovation

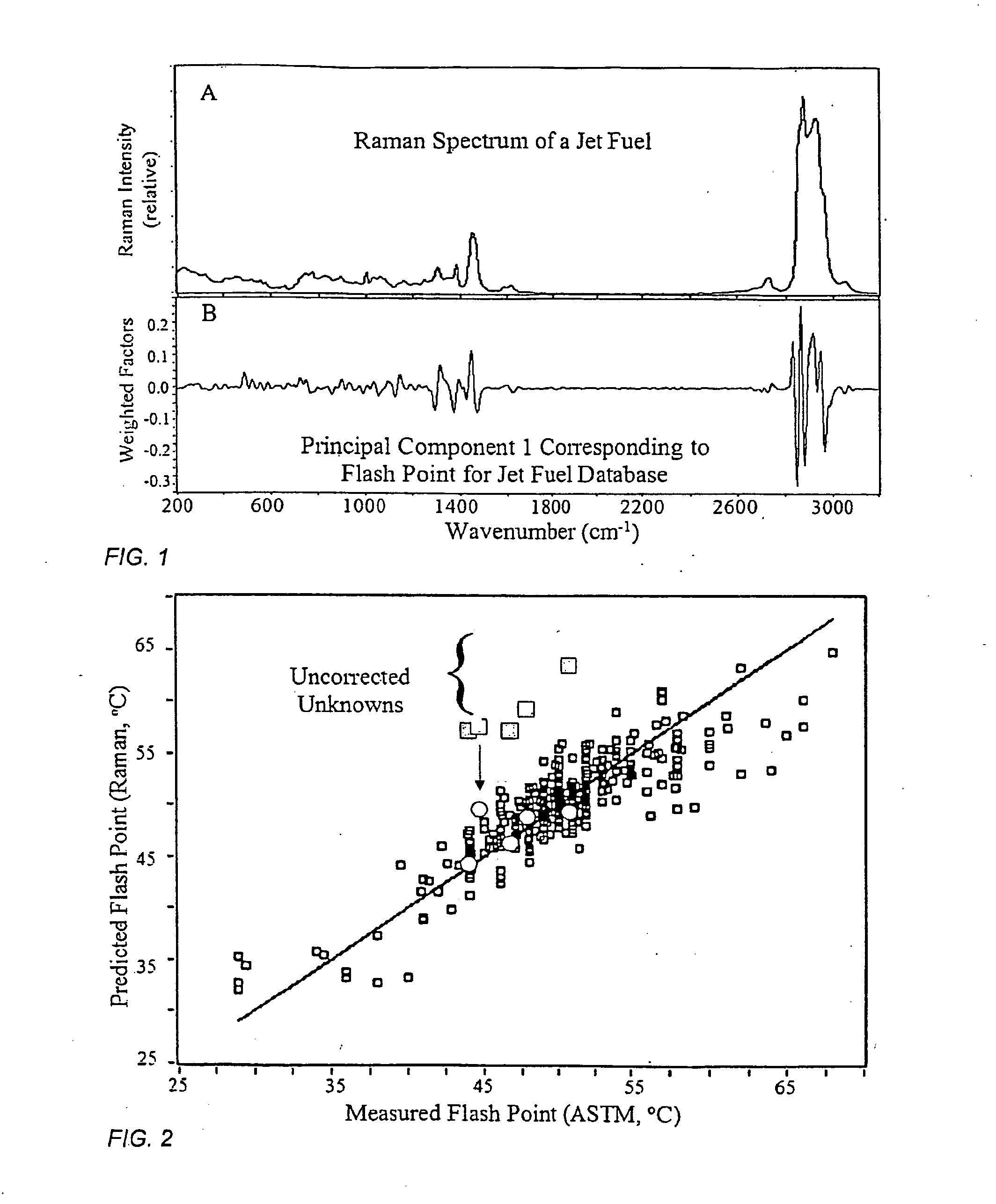

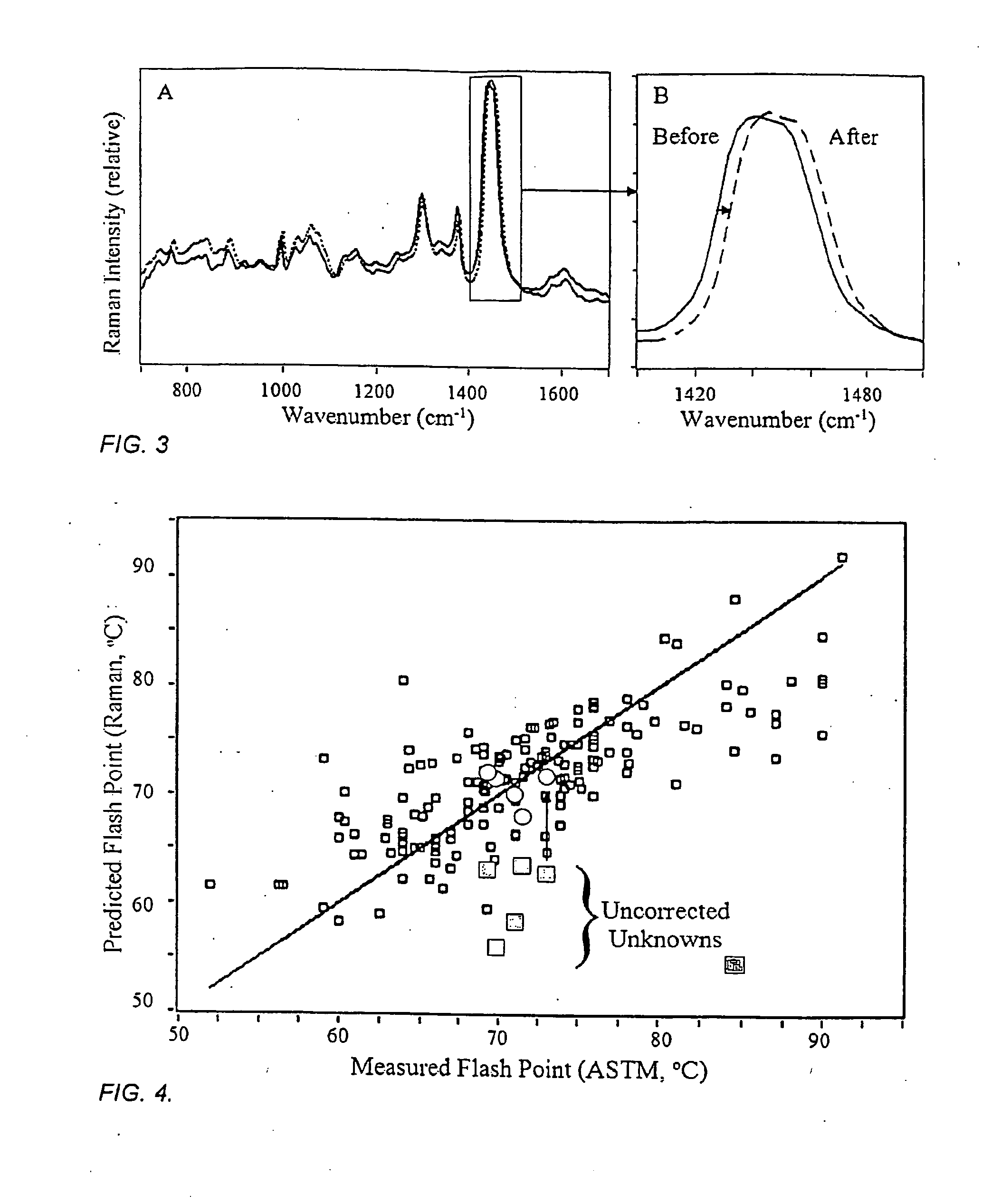

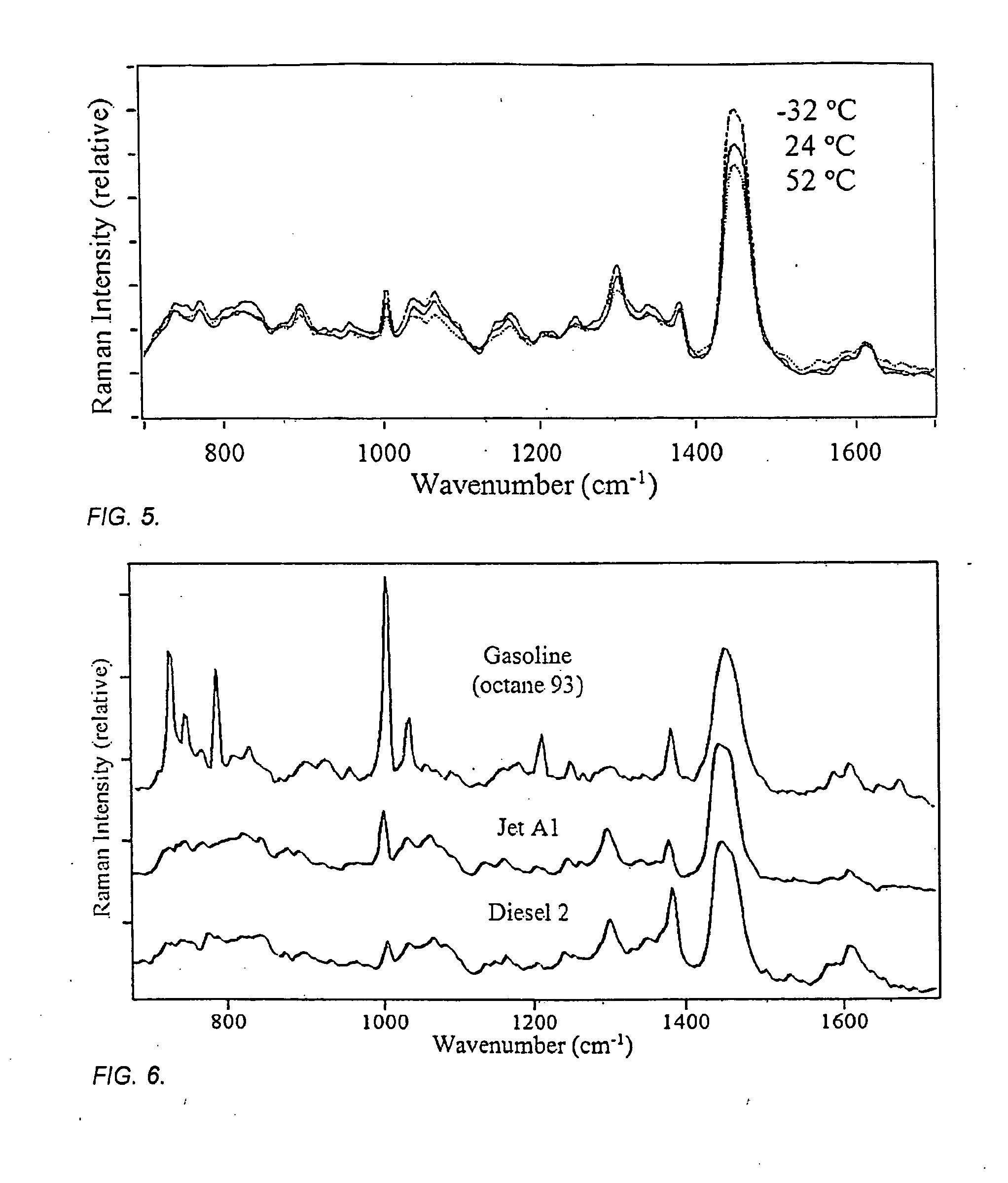

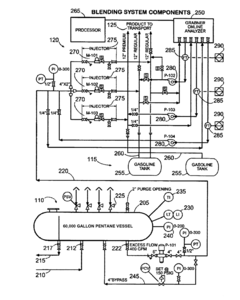

- A portable Raman analyzer uses spectral databases to correlate Raman spectra with fuel class, grade, and properties, employing chemometric models to account for temperature variations and instrument stability, allowing for quick identification and monitoring of fuel properties in various environments.

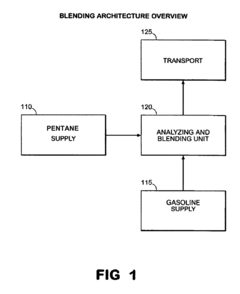

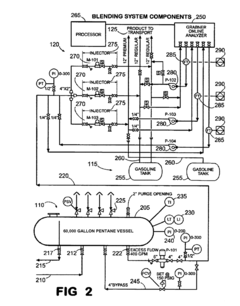

Expansion of fuel streams using mixed hydrocarbons

PatentActiveUS20140237893A1

Innovation

- The method involves blending isopentane with n-pentane to offset the negative octane depression and using ethanol to further stabilize the octane value, while controlling the volatility of the additive hydrocarbon stream to ensure consistent blending results.

Environmental Impact of Butane in Fuel Blends

The environmental impact of butane in fuel blends is a critical consideration in the ongoing efforts to balance energy efficiency with ecological responsibility. Butane, as a component in fuel blends, contributes to the overall performance of the fuel but also raises concerns about its environmental footprint.

One of the primary environmental considerations is the emission of volatile organic compounds (VOCs) associated with butane. When fuel containing butane evaporates or is incompletely combusted, it releases these compounds into the atmosphere. VOCs are precursors to ground-level ozone formation, which can lead to smog and have detrimental effects on air quality, particularly in urban areas with high traffic density.

Furthermore, the combustion of butane-containing fuel blends results in the production of carbon dioxide (CO2), a greenhouse gas that contributes to global warming. While butane itself has a lower carbon content compared to longer-chain hydrocarbons, its inclusion in fuel blends still adds to the overall carbon emissions from vehicles and other combustion engines.

The use of butane in fuel blends also impacts the fuel's vapor pressure. Higher vapor pressure can lead to increased evaporative emissions, especially in warmer climates or during hot weather conditions. This not only represents a loss of fuel but also contributes to air pollution and potential health hazards.

On the positive side, butane's high octane rating can improve engine efficiency, potentially leading to better fuel economy and reduced overall emissions per mile traveled. This efficiency gain must be weighed against the environmental costs associated with its use.

The production and transportation of butane for fuel blending purposes also carry environmental implications. The extraction process, typically associated with natural gas processing or petroleum refining, requires energy and can result in fugitive emissions. Additionally, the transportation of butane to blending facilities contributes to the overall carbon footprint of the fuel production chain.

Regulatory bodies worldwide have implemented measures to mitigate the environmental impact of fuel components, including butane. These regulations often focus on limiting the vapor pressure of fuels, especially during summer months when evaporative emissions are more problematic. Such measures aim to strike a balance between fuel performance and environmental protection.

In conclusion, while butane plays a significant role in enhancing fuel performance, its environmental impact necessitates careful consideration and ongoing research into alternative fuel compositions and emission reduction technologies. The challenge lies in optimizing fuel blends to maintain performance standards while minimizing negative environmental consequences.

One of the primary environmental considerations is the emission of volatile organic compounds (VOCs) associated with butane. When fuel containing butane evaporates or is incompletely combusted, it releases these compounds into the atmosphere. VOCs are precursors to ground-level ozone formation, which can lead to smog and have detrimental effects on air quality, particularly in urban areas with high traffic density.

Furthermore, the combustion of butane-containing fuel blends results in the production of carbon dioxide (CO2), a greenhouse gas that contributes to global warming. While butane itself has a lower carbon content compared to longer-chain hydrocarbons, its inclusion in fuel blends still adds to the overall carbon emissions from vehicles and other combustion engines.

The use of butane in fuel blends also impacts the fuel's vapor pressure. Higher vapor pressure can lead to increased evaporative emissions, especially in warmer climates or during hot weather conditions. This not only represents a loss of fuel but also contributes to air pollution and potential health hazards.

On the positive side, butane's high octane rating can improve engine efficiency, potentially leading to better fuel economy and reduced overall emissions per mile traveled. This efficiency gain must be weighed against the environmental costs associated with its use.

The production and transportation of butane for fuel blending purposes also carry environmental implications. The extraction process, typically associated with natural gas processing or petroleum refining, requires energy and can result in fugitive emissions. Additionally, the transportation of butane to blending facilities contributes to the overall carbon footprint of the fuel production chain.

Regulatory bodies worldwide have implemented measures to mitigate the environmental impact of fuel components, including butane. These regulations often focus on limiting the vapor pressure of fuels, especially during summer months when evaporative emissions are more problematic. Such measures aim to strike a balance between fuel performance and environmental protection.

In conclusion, while butane plays a significant role in enhancing fuel performance, its environmental impact necessitates careful consideration and ongoing research into alternative fuel compositions and emission reduction technologies. The challenge lies in optimizing fuel blends to maintain performance standards while minimizing negative environmental consequences.

Regulatory Framework for Fuel Composition

The regulatory framework for fuel composition plays a crucial role in ensuring the quality, safety, and environmental impact of fuel blends. In the context of how butane affects the octane rating of fuel blends, various regulatory bodies have established guidelines and standards to govern the use of butane and other components in fuel formulations.

The United States Environmental Protection Agency (EPA) has set forth regulations under the Clean Air Act that specify the allowable limits for various fuel components, including butane. These regulations aim to control emissions and maintain air quality standards. The EPA's Tier 3 Vehicle Emission and Fuel Standards Program, implemented in 2017, further tightened the requirements for fuel composition, including restrictions on the use of butane to boost octane ratings.

In the European Union, the Fuel Quality Directive (FQD) establishes standards for fuel composition, including limits on the use of butane and other light hydrocarbons. The directive sets maximum vapor pressure limits for gasoline, which indirectly affects the amount of butane that can be blended into fuel. Additionally, the EN 228 standard for unleaded petrol specifies the acceptable ranges for various fuel properties, including octane ratings and vapor pressure.

The International Organization for Standardization (ISO) has developed several standards related to fuel composition and testing methods. ISO 4259, for instance, provides guidelines for the interpretation of test results and the determination of fuel properties, which is essential when assessing the impact of butane on octane ratings.

Many countries have adopted or adapted these international standards to create their own regulatory frameworks. For example, Japan's Ministry of Economy, Trade and Industry (METI) has established fuel quality standards that regulate the composition of gasoline, including limitations on butane content to maintain appropriate octane ratings and vapor pressure.

Regulatory bodies also require fuel manufacturers and distributors to conduct regular testing and reporting to ensure compliance with composition standards. These requirements often include specific protocols for measuring octane ratings and other fuel properties affected by butane content.

As concerns about climate change and air quality continue to grow, regulatory frameworks are evolving to address new challenges. Some jurisdictions are implementing stricter limits on the use of certain fuel components, including butane, to reduce emissions and improve overall fuel efficiency. This ongoing regulatory evolution necessitates continuous adaptation by fuel producers and refiners to meet changing standards while maintaining optimal octane ratings in their fuel blends.

The United States Environmental Protection Agency (EPA) has set forth regulations under the Clean Air Act that specify the allowable limits for various fuel components, including butane. These regulations aim to control emissions and maintain air quality standards. The EPA's Tier 3 Vehicle Emission and Fuel Standards Program, implemented in 2017, further tightened the requirements for fuel composition, including restrictions on the use of butane to boost octane ratings.

In the European Union, the Fuel Quality Directive (FQD) establishes standards for fuel composition, including limits on the use of butane and other light hydrocarbons. The directive sets maximum vapor pressure limits for gasoline, which indirectly affects the amount of butane that can be blended into fuel. Additionally, the EN 228 standard for unleaded petrol specifies the acceptable ranges for various fuel properties, including octane ratings and vapor pressure.

The International Organization for Standardization (ISO) has developed several standards related to fuel composition and testing methods. ISO 4259, for instance, provides guidelines for the interpretation of test results and the determination of fuel properties, which is essential when assessing the impact of butane on octane ratings.

Many countries have adopted or adapted these international standards to create their own regulatory frameworks. For example, Japan's Ministry of Economy, Trade and Industry (METI) has established fuel quality standards that regulate the composition of gasoline, including limitations on butane content to maintain appropriate octane ratings and vapor pressure.

Regulatory bodies also require fuel manufacturers and distributors to conduct regular testing and reporting to ensure compliance with composition standards. These requirements often include specific protocols for measuring octane ratings and other fuel properties affected by butane content.

As concerns about climate change and air quality continue to grow, regulatory frameworks are evolving to address new challenges. Some jurisdictions are implementing stricter limits on the use of certain fuel components, including butane, to reduce emissions and improve overall fuel efficiency. This ongoing regulatory evolution necessitates continuous adaptation by fuel producers and refiners to meet changing standards while maintaining optimal octane ratings in their fuel blends.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!