The Role of Butane in Advanced Surface Tension Modulation

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane in Surface Tension: Background and Objectives

Surface tension modulation is a critical aspect of numerous industrial processes and scientific applications. The use of butane in this context represents a significant advancement in the field of surface chemistry. Historically, surface tension control has relied on various methods, including the use of surfactants and temperature manipulation. However, the introduction of butane as a modulating agent marks a new era in precision control of surface properties.

The evolution of surface tension modulation techniques has been driven by the increasing demands of industries such as microfluidics, oil recovery, and materials science. Butane, a simple hydrocarbon, has emerged as a versatile tool in this domain due to its unique physical and chemical properties. Its low boiling point and high vapor pressure make it particularly suitable for fine-tuning surface tension in a wide range of applications.

The primary objective of utilizing butane in surface tension modulation is to achieve precise and dynamic control over interfacial properties. This control is essential for optimizing processes in fields such as droplet formation, emulsion stability, and thin film coatings. By leveraging butane's properties, researchers and industry professionals aim to develop more efficient and adaptable systems that can respond to changing environmental conditions or process requirements.

One of the key trends in this technological domain is the development of smart materials and responsive surfaces. Butane's role in this trend is significant, as it allows for rapid and reversible changes in surface tension. This capability opens up new possibilities for creating adaptive interfaces that can switch between hydrophobic and hydrophilic states on demand, a feature that is particularly valuable in microfluidic devices and self-cleaning surfaces.

The integration of butane into surface tension modulation techniques also aligns with the broader trend towards more sustainable and environmentally friendly industrial processes. As a naturally occurring compound, butane presents a potentially less harmful alternative to some synthetic surfactants, although its flammability and volatility require careful handling and safety considerations.

Looking forward, the technological goals in this field include developing more sophisticated control mechanisms for butane-based surface tension modulation, expanding its applicability across diverse industrial sectors, and combining it with other emerging technologies such as nanotechnology and smart materials. The ultimate aim is to create highly responsive and efficient systems that can precisely manipulate surface properties at the molecular level, leading to innovations in areas ranging from advanced manufacturing to biomedical applications.

The evolution of surface tension modulation techniques has been driven by the increasing demands of industries such as microfluidics, oil recovery, and materials science. Butane, a simple hydrocarbon, has emerged as a versatile tool in this domain due to its unique physical and chemical properties. Its low boiling point and high vapor pressure make it particularly suitable for fine-tuning surface tension in a wide range of applications.

The primary objective of utilizing butane in surface tension modulation is to achieve precise and dynamic control over interfacial properties. This control is essential for optimizing processes in fields such as droplet formation, emulsion stability, and thin film coatings. By leveraging butane's properties, researchers and industry professionals aim to develop more efficient and adaptable systems that can respond to changing environmental conditions or process requirements.

One of the key trends in this technological domain is the development of smart materials and responsive surfaces. Butane's role in this trend is significant, as it allows for rapid and reversible changes in surface tension. This capability opens up new possibilities for creating adaptive interfaces that can switch between hydrophobic and hydrophilic states on demand, a feature that is particularly valuable in microfluidic devices and self-cleaning surfaces.

The integration of butane into surface tension modulation techniques also aligns with the broader trend towards more sustainable and environmentally friendly industrial processes. As a naturally occurring compound, butane presents a potentially less harmful alternative to some synthetic surfactants, although its flammability and volatility require careful handling and safety considerations.

Looking forward, the technological goals in this field include developing more sophisticated control mechanisms for butane-based surface tension modulation, expanding its applicability across diverse industrial sectors, and combining it with other emerging technologies such as nanotechnology and smart materials. The ultimate aim is to create highly responsive and efficient systems that can precisely manipulate surface properties at the molecular level, leading to innovations in areas ranging from advanced manufacturing to biomedical applications.

Market Analysis for Butane-Based Surface Modifiers

The market for butane-based surface modifiers has shown significant growth in recent years, driven by increasing demand across various industries. The global surface tension modifiers market, which includes butane-based products, was valued at approximately $7.2 billion in 2020 and is projected to reach $10.5 billion by 2025, growing at a CAGR of 7.8% during the forecast period.

Butane-based surface modifiers have gained traction due to their unique properties and versatility in modulating surface tension. These modifiers find applications in diverse sectors such as coatings, adhesives, inks, and personal care products. The coatings industry, in particular, has emerged as a major consumer of butane-based surface modifiers, accounting for over 35% of the market share.

The Asia-Pacific region dominates the market for butane-based surface modifiers, with China and India being the key growth drivers. This can be attributed to the rapid industrialization, expanding manufacturing sector, and increasing disposable income in these countries. North America and Europe follow closely, with mature markets showing steady demand for advanced surface tension modulation solutions.

Key factors driving the market growth include the rising demand for high-performance coatings in automotive and construction industries, increasing focus on sustainability and eco-friendly products, and growing research and development activities in surface science. The automotive sector, in particular, has shown a strong inclination towards butane-based surface modifiers for improving the quality and durability of paints and coatings.

However, the market faces challenges such as volatile raw material prices and stringent environmental regulations. The fluctuating prices of butane, a key raw material, can impact the overall production costs and profit margins of manufacturers. Additionally, increasing environmental concerns and regulations regarding VOC emissions pose challenges to market growth.

Despite these challenges, the market for butane-based surface modifiers is expected to witness continued growth. Innovations in product formulations, focusing on low-VOC and bio-based alternatives, are likely to create new opportunities. The personal care and cosmetics industry is emerging as a promising application area, with increasing demand for advanced formulations in skincare and haircare products.

In conclusion, the market for butane-based surface modifiers presents a lucrative opportunity for industry players. Companies investing in research and development to create innovative, sustainable, and high-performance products are likely to gain a competitive edge in this growing market.

Butane-based surface modifiers have gained traction due to their unique properties and versatility in modulating surface tension. These modifiers find applications in diverse sectors such as coatings, adhesives, inks, and personal care products. The coatings industry, in particular, has emerged as a major consumer of butane-based surface modifiers, accounting for over 35% of the market share.

The Asia-Pacific region dominates the market for butane-based surface modifiers, with China and India being the key growth drivers. This can be attributed to the rapid industrialization, expanding manufacturing sector, and increasing disposable income in these countries. North America and Europe follow closely, with mature markets showing steady demand for advanced surface tension modulation solutions.

Key factors driving the market growth include the rising demand for high-performance coatings in automotive and construction industries, increasing focus on sustainability and eco-friendly products, and growing research and development activities in surface science. The automotive sector, in particular, has shown a strong inclination towards butane-based surface modifiers for improving the quality and durability of paints and coatings.

However, the market faces challenges such as volatile raw material prices and stringent environmental regulations. The fluctuating prices of butane, a key raw material, can impact the overall production costs and profit margins of manufacturers. Additionally, increasing environmental concerns and regulations regarding VOC emissions pose challenges to market growth.

Despite these challenges, the market for butane-based surface modifiers is expected to witness continued growth. Innovations in product formulations, focusing on low-VOC and bio-based alternatives, are likely to create new opportunities. The personal care and cosmetics industry is emerging as a promising application area, with increasing demand for advanced formulations in skincare and haircare products.

In conclusion, the market for butane-based surface modifiers presents a lucrative opportunity for industry players. Companies investing in research and development to create innovative, sustainable, and high-performance products are likely to gain a competitive edge in this growing market.

Current Challenges in Surface Tension Modulation

Surface tension modulation is a critical area in advanced materials science and engineering, with applications ranging from microfluidics to oil recovery. However, the field faces several significant challenges that hinder progress and limit the effectiveness of current solutions.

One of the primary challenges is achieving precise and dynamic control over surface tension. While traditional surfactants can lower surface tension, they often lack the ability to rapidly and reversibly adjust it in response to external stimuli. This limitation restricts their use in applications requiring real-time adaptability, such as smart materials or responsive surfaces.

The stability and longevity of surface tension modulation systems pose another significant hurdle. Many current solutions suffer from degradation over time or lose effectiveness after repeated use. This is particularly problematic in industrial applications where long-term performance is crucial for cost-effectiveness and operational efficiency.

Environmental concerns also present a challenge in surface tension modulation. Many conventional surfactants are not biodegradable and can accumulate in ecosystems, causing potential harm to aquatic life and contaminating water sources. The development of eco-friendly alternatives that maintain high performance is an ongoing struggle in the field.

Another critical issue is the limited understanding of the molecular-level interactions that govern surface tension phenomena. While macroscopic effects are well-documented, the precise mechanisms by which molecules like butane influence surface properties at the nanoscale remain elusive. This knowledge gap hampers the development of more effective and targeted modulation strategies.

The scalability of surface tension modulation techniques from laboratory to industrial scales presents additional challenges. Methods that work well in controlled, small-scale environments often face difficulties when scaled up, due to factors such as increased surface area, variable environmental conditions, and the need for large quantities of modulating agents.

Furthermore, the integration of surface tension modulation systems with other technologies and materials can be problematic. Compatibility issues may arise when attempting to incorporate these systems into complex devices or processes, potentially limiting their practical applications.

Lastly, the cost and availability of effective surface tension modulating agents, including specialized forms of butane, can be prohibitive for widespread adoption. Developing economically viable solutions that can be produced and implemented at scale remains a significant challenge in the field.

One of the primary challenges is achieving precise and dynamic control over surface tension. While traditional surfactants can lower surface tension, they often lack the ability to rapidly and reversibly adjust it in response to external stimuli. This limitation restricts their use in applications requiring real-time adaptability, such as smart materials or responsive surfaces.

The stability and longevity of surface tension modulation systems pose another significant hurdle. Many current solutions suffer from degradation over time or lose effectiveness after repeated use. This is particularly problematic in industrial applications where long-term performance is crucial for cost-effectiveness and operational efficiency.

Environmental concerns also present a challenge in surface tension modulation. Many conventional surfactants are not biodegradable and can accumulate in ecosystems, causing potential harm to aquatic life and contaminating water sources. The development of eco-friendly alternatives that maintain high performance is an ongoing struggle in the field.

Another critical issue is the limited understanding of the molecular-level interactions that govern surface tension phenomena. While macroscopic effects are well-documented, the precise mechanisms by which molecules like butane influence surface properties at the nanoscale remain elusive. This knowledge gap hampers the development of more effective and targeted modulation strategies.

The scalability of surface tension modulation techniques from laboratory to industrial scales presents additional challenges. Methods that work well in controlled, small-scale environments often face difficulties when scaled up, due to factors such as increased surface area, variable environmental conditions, and the need for large quantities of modulating agents.

Furthermore, the integration of surface tension modulation systems with other technologies and materials can be problematic. Compatibility issues may arise when attempting to incorporate these systems into complex devices or processes, potentially limiting their practical applications.

Lastly, the cost and availability of effective surface tension modulating agents, including specialized forms of butane, can be prohibitive for widespread adoption. Developing economically viable solutions that can be produced and implemented at scale remains a significant challenge in the field.

Existing Butane-Based Surface Tension Solutions

01 Measurement and control of butane surface tension

Various methods and devices are used to measure and control the surface tension of butane in different applications. This includes specialized equipment and techniques to accurately determine and manipulate the surface tension properties of butane, which is crucial for its use in industrial processes and consumer products.- Butane surface tension measurement techniques: Various methods and devices are used to measure the surface tension of butane. These techniques may involve specialized equipment or experimental setups designed to accurately determine the surface tension properties of butane under different conditions.

- Surface tension modification of butane: Techniques and additives are employed to modify the surface tension of butane. This can be useful in various applications where specific surface tension properties are required, such as in fuel systems or industrial processes.

- Butane surface tension in fuel applications: The surface tension of butane plays a crucial role in fuel applications, particularly in the design and operation of fuel systems. Understanding and controlling butane's surface tension can improve fuel efficiency and performance in various engines and combustion processes.

- Butane surface tension in refrigeration systems: The surface tension properties of butane are important in refrigeration systems where it is used as a refrigerant. Proper management of surface tension can affect heat transfer efficiency and overall system performance in cooling applications.

- Environmental and safety considerations related to butane surface tension: The surface tension of butane has implications for environmental and safety concerns, particularly in handling, storage, and transportation. Understanding these properties is crucial for developing safe practices and mitigating potential risks associated with butane use in various industries.

02 Butane in fuel mixtures and combustion systems

Butane is often used in fuel mixtures and combustion systems, where its surface tension properties play a significant role. The surface tension of butane affects fuel atomization, combustion efficiency, and overall performance in engines and other combustion devices.Expand Specific Solutions03 Butane in refrigeration and cooling systems

The surface tension of butane is an important factor in refrigeration and cooling systems. It affects the heat transfer efficiency and overall performance of these systems, particularly in applications where butane is used as a refrigerant or coolant.Expand Specific Solutions04 Butane in aerosol and spray applications

The surface tension of butane is crucial in aerosol and spray applications, where it is often used as a propellant. The surface tension affects the droplet size, spray pattern, and overall performance of these products, influencing their effectiveness in various consumer and industrial applications.Expand Specific Solutions05 Modification of butane surface tension

Various methods and additives are used to modify the surface tension of butane for specific applications. This includes the use of surfactants, chemical treatments, and other techniques to alter the surface tension properties of butane, tailoring it for use in different industrial processes and products.Expand Specific Solutions

Key Industry Players in Surface Modification

The competitive landscape for butane in advanced surface tension modulation is evolving rapidly, with the market in its growth phase. The global market size is expanding due to increasing applications in various industries, including petrochemicals, electronics, and materials science. Technological maturity varies among key players, with companies like China Petroleum & Chemical Corp., LG Chem Ltd., and Bayer AG leading in research and development. These firms are investing heavily in innovative solutions, leveraging their expertise in chemical engineering and materials science. Emerging players such as PetroChina Co., Ltd. and Idemitsu Kosan Co., Ltd. are also making significant strides, contributing to a dynamic and competitive environment. The field is characterized by ongoing research collaborations between industry leaders and academic institutions, driving technological advancements and market growth.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced surface tension modulation techniques using butane as a key component. Their approach involves utilizing butane's unique properties to create tailored surfactant systems for enhanced oil recovery (EOR) applications. The company has implemented a novel butane-based microemulsion technology that significantly reduces interfacial tension between oil and water, improving oil displacement efficiency[1]. This method involves injecting a carefully formulated mixture of butane, surfactants, and co-solvents into oil reservoirs, creating ultra-low interfacial tension conditions that facilitate the mobilization of trapped oil[2]. Sinopec's research has shown that this butane-enhanced surfactant flooding can increase oil recovery rates by up to 20% compared to conventional methods[3].

Strengths: Highly effective in improving oil recovery rates, applicable to a wide range of reservoir conditions, and utilizes readily available butane. Weaknesses: May require careful handling of butane due to its flammability, and potential environmental concerns related to hydrocarbon use in EOR processes.

Bayer AG

Technical Solution: Bayer AG has pioneered the use of butane in advanced surface tension modulation for agricultural applications. Their innovative approach focuses on developing butane-based adjuvants for crop protection products. These adjuvants leverage butane's unique properties to enhance the spreading and adhesion of pesticides and herbicides on plant surfaces[4]. Bayer's proprietary formulation incorporates butane into a stable emulsion system that, when mixed with agrochemicals, significantly reduces the surface tension of the spray solution. This allows for improved coverage and penetration of active ingredients into plant tissues[5]. Field trials have demonstrated that this butane-enhanced adjuvant technology can increase the efficacy of crop protection products by up to 30%, while potentially reducing the overall amount of chemicals needed[6].

Strengths: Enhances the effectiveness of agrochemicals, potentially reduces chemical usage, and improves crop yields. Weaknesses: May require specialized equipment for application and storage of butane-containing products, and potential regulatory hurdles in some markets.

Innovative Butane Applications in Surface Science

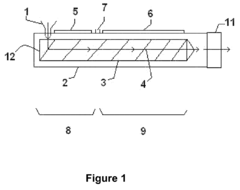

Process and apparatus for producing foamed styrenic polymers

PatentActiveEP1995273A3

Innovation

- A method using a combination of chemical and physical blowing agents in the extrusion process, where the chemical blowing agent initiates initial foaming and the physical blowing agent extends foaming activity to lower temperatures, reducing shrinkage and friction, and allowing for the production of styrenic polymer foams with densities between 100 and 400 kg/m3.

Expandable styrene-compounded polyolefin resin particles, method for producing same, pre-expanded particles, and expansion molded article

PatentInactiveUS20170275433A1

Innovation

- A combination of butane and pentane as a volatile blowing agent in a specific mass ratio (80/20 to 50/50) is used to balance secondary expansion force and life span, optimizing moldability and life of expanded particles.

Environmental Impact of Butane-Based Technologies

The environmental impact of butane-based technologies in surface tension modulation is a critical consideration for sustainable development and environmental protection. Butane, a hydrocarbon gas, has been widely used in various industrial applications due to its unique properties. However, its use in advanced surface tension modulation techniques raises concerns about potential environmental consequences.

One of the primary environmental issues associated with butane-based technologies is their contribution to air pollution. When released into the atmosphere, butane can react with other pollutants to form ground-level ozone, a major component of smog. This can lead to respiratory problems and other health issues in urban areas where these technologies are extensively used. Additionally, butane is a volatile organic compound (VOC), which can contribute to the formation of secondary organic aerosols, further impacting air quality.

Climate change is another significant concern related to butane use. As a hydrocarbon, butane is a greenhouse gas, albeit with a relatively short atmospheric lifetime compared to carbon dioxide. However, its global warming potential is still considerable, especially when used in large quantities for industrial applications. The release of butane into the atmosphere can contribute to the overall greenhouse effect, potentially exacerbating climate change impacts.

Water pollution is also a potential risk associated with butane-based surface tension modulation technologies. In cases of accidental spills or improper disposal, butane can contaminate water sources. Although butane is not highly soluble in water, it can form a layer on the water surface, potentially affecting aquatic ecosystems and interfering with oxygen exchange between the atmosphere and water bodies.

The production and transportation of butane for these technologies also carry environmental risks. Extraction of butane from natural gas or petroleum involves energy-intensive processes that contribute to carbon emissions. Furthermore, the transportation of butane, often done through pipelines or tanker trucks, poses risks of leaks or accidents that could lead to environmental contamination.

However, it is important to note that advancements in butane-based technologies for surface tension modulation have also led to improvements in efficiency and safety. Modern systems often incorporate closed-loop designs and advanced containment measures that significantly reduce the risk of environmental release. Additionally, ongoing research is focused on developing more environmentally friendly alternatives and improving the sustainability of butane-based processes.

In conclusion, while butane-based technologies in surface tension modulation offer significant industrial benefits, their environmental impact must be carefully managed. Balancing the technological advantages with environmental protection requires ongoing research, stringent regulations, and the development of more sustainable practices in the use and handling of butane in these applications.

One of the primary environmental issues associated with butane-based technologies is their contribution to air pollution. When released into the atmosphere, butane can react with other pollutants to form ground-level ozone, a major component of smog. This can lead to respiratory problems and other health issues in urban areas where these technologies are extensively used. Additionally, butane is a volatile organic compound (VOC), which can contribute to the formation of secondary organic aerosols, further impacting air quality.

Climate change is another significant concern related to butane use. As a hydrocarbon, butane is a greenhouse gas, albeit with a relatively short atmospheric lifetime compared to carbon dioxide. However, its global warming potential is still considerable, especially when used in large quantities for industrial applications. The release of butane into the atmosphere can contribute to the overall greenhouse effect, potentially exacerbating climate change impacts.

Water pollution is also a potential risk associated with butane-based surface tension modulation technologies. In cases of accidental spills or improper disposal, butane can contaminate water sources. Although butane is not highly soluble in water, it can form a layer on the water surface, potentially affecting aquatic ecosystems and interfering with oxygen exchange between the atmosphere and water bodies.

The production and transportation of butane for these technologies also carry environmental risks. Extraction of butane from natural gas or petroleum involves energy-intensive processes that contribute to carbon emissions. Furthermore, the transportation of butane, often done through pipelines or tanker trucks, poses risks of leaks or accidents that could lead to environmental contamination.

However, it is important to note that advancements in butane-based technologies for surface tension modulation have also led to improvements in efficiency and safety. Modern systems often incorporate closed-loop designs and advanced containment measures that significantly reduce the risk of environmental release. Additionally, ongoing research is focused on developing more environmentally friendly alternatives and improving the sustainability of butane-based processes.

In conclusion, while butane-based technologies in surface tension modulation offer significant industrial benefits, their environmental impact must be carefully managed. Balancing the technological advantages with environmental protection requires ongoing research, stringent regulations, and the development of more sustainable practices in the use and handling of butane in these applications.

Safety Regulations for Butane in Industrial Applications

The use of butane in industrial applications necessitates stringent safety regulations due to its highly flammable nature and potential health hazards. Regulatory bodies worldwide have established comprehensive guidelines to ensure the safe handling, storage, and use of butane in various industrial processes, including its role in advanced surface tension modulation.

One of the primary safety concerns addressed by regulations is the prevention of fire and explosion risks. Industrial facilities using butane are required to implement robust fire prevention systems, including flame detection devices, automatic shut-off valves, and fire suppression equipment. Regular maintenance and inspection of these systems are mandated to ensure their effectiveness in emergency situations.

Storage regulations for butane are particularly stringent. Facilities must adhere to specific requirements for tank design, construction materials, and pressure ratings. Tanks must be equipped with pressure relief valves and level indicators to prevent overfilling. Additionally, storage areas must be well-ventilated, located away from ignition sources, and clearly marked with appropriate warning signs.

Personal protective equipment (PPE) regulations are crucial for worker safety. Employees handling butane must wear appropriate PPE, including flame-resistant clothing, safety goggles, and gloves. Respiratory protection may also be required in certain situations where exposure to butane vapors is possible.

Training and certification requirements form another critical aspect of safety regulations. Workers involved in handling butane must undergo comprehensive safety training, covering topics such as proper handling procedures, emergency response protocols, and the use of safety equipment. Regular refresher courses are often mandated to ensure ongoing compliance and awareness.

Environmental regulations also play a significant role in butane usage. Facilities must implement measures to prevent and control butane emissions, adhering to air quality standards set by environmental protection agencies. This may include the installation of vapor recovery systems and regular monitoring of emission levels.

In the context of surface tension modulation applications, additional regulations may apply. These could include specific guidelines for the purity of butane used, precise control measures for its application in surface treatment processes, and protocols for managing waste products resulting from these applications.

Regulatory compliance also extends to transportation of butane. Strict guidelines govern the design and operation of vehicles used for butane transport, including requirements for tank construction, safety features, and driver qualifications. Route planning and risk assessments are often required to minimize potential hazards during transportation.

Regular audits and inspections by regulatory authorities are conducted to ensure ongoing compliance with safety regulations. These audits assess various aspects of butane handling, from storage and usage to emergency preparedness and documentation practices. Non-compliance can result in severe penalties, including fines and operational shutdowns.

One of the primary safety concerns addressed by regulations is the prevention of fire and explosion risks. Industrial facilities using butane are required to implement robust fire prevention systems, including flame detection devices, automatic shut-off valves, and fire suppression equipment. Regular maintenance and inspection of these systems are mandated to ensure their effectiveness in emergency situations.

Storage regulations for butane are particularly stringent. Facilities must adhere to specific requirements for tank design, construction materials, and pressure ratings. Tanks must be equipped with pressure relief valves and level indicators to prevent overfilling. Additionally, storage areas must be well-ventilated, located away from ignition sources, and clearly marked with appropriate warning signs.

Personal protective equipment (PPE) regulations are crucial for worker safety. Employees handling butane must wear appropriate PPE, including flame-resistant clothing, safety goggles, and gloves. Respiratory protection may also be required in certain situations where exposure to butane vapors is possible.

Training and certification requirements form another critical aspect of safety regulations. Workers involved in handling butane must undergo comprehensive safety training, covering topics such as proper handling procedures, emergency response protocols, and the use of safety equipment. Regular refresher courses are often mandated to ensure ongoing compliance and awareness.

Environmental regulations also play a significant role in butane usage. Facilities must implement measures to prevent and control butane emissions, adhering to air quality standards set by environmental protection agencies. This may include the installation of vapor recovery systems and regular monitoring of emission levels.

In the context of surface tension modulation applications, additional regulations may apply. These could include specific guidelines for the purity of butane used, precise control measures for its application in surface treatment processes, and protocols for managing waste products resulting from these applications.

Regulatory compliance also extends to transportation of butane. Strict guidelines govern the design and operation of vehicles used for butane transport, including requirements for tank construction, safety features, and driver qualifications. Route planning and risk assessments are often required to minimize potential hazards during transportation.

Regular audits and inspections by regulatory authorities are conducted to ensure ongoing compliance with safety regulations. These audits assess various aspects of butane handling, from storage and usage to emergency preparedness and documentation practices. Non-compliance can result in severe penalties, including fines and operational shutdowns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!