How Battery Acid Affects Supercapacitor Performance

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Impact on Supercapacitors

The impact of battery acid on supercapacitor performance is a critical area of study in the field of energy storage technology. Battery acid, typically sulfuric acid in lead-acid batteries, can significantly affect the functionality and longevity of supercapacitors when exposed to it. This interaction is particularly relevant in hybrid energy storage systems where supercapacitors and batteries are used in conjunction.

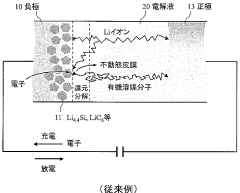

Supercapacitors, known for their high power density and rapid charge-discharge capabilities, utilize different mechanisms for energy storage compared to traditional batteries. They rely on the formation of an electric double layer at the electrode-electrolyte interface, as well as pseudocapacitive reactions in some cases. The introduction of battery acid to this system can alter these fundamental processes.

One of the primary effects of battery acid on supercapacitors is the degradation of electrode materials. Many supercapacitors use carbon-based electrodes, which can be corroded or chemically modified by strong acids. This corrosion can lead to a reduction in the effective surface area of the electrodes, directly impacting the capacitance and energy storage capacity of the device.

Furthermore, the presence of battery acid can alter the electrolyte composition within the supercapacitor. This change can affect the ionic conductivity and the formation of the electric double layer, which are crucial for the supercapacitor's performance. The acid may also introduce unwanted electrochemical reactions, potentially leading to gas evolution and increased internal pressure within the supercapacitor.

The separator material in supercapacitors, typically a porous membrane, can also be compromised by battery acid exposure. Degradation of the separator can lead to short circuits or reduced ion mobility between electrodes, severely impacting the device's functionality and safety.

Long-term exposure to battery acid can result in accelerated aging of supercapacitors. This aging manifests as a gradual decrease in capacitance, an increase in equivalent series resistance (ESR), and a reduction in cycle life. These effects collectively diminish the supercapacitor's ability to store and deliver energy efficiently over time.

Understanding these interactions is crucial for designing robust hybrid energy storage systems and for developing protective measures to mitigate the negative impacts of battery acid on supercapacitors. This knowledge can guide the selection of materials and the implementation of protective coatings or barriers to enhance the compatibility and longevity of supercapacitors in acidic environments.

Supercapacitors, known for their high power density and rapid charge-discharge capabilities, utilize different mechanisms for energy storage compared to traditional batteries. They rely on the formation of an electric double layer at the electrode-electrolyte interface, as well as pseudocapacitive reactions in some cases. The introduction of battery acid to this system can alter these fundamental processes.

One of the primary effects of battery acid on supercapacitors is the degradation of electrode materials. Many supercapacitors use carbon-based electrodes, which can be corroded or chemically modified by strong acids. This corrosion can lead to a reduction in the effective surface area of the electrodes, directly impacting the capacitance and energy storage capacity of the device.

Furthermore, the presence of battery acid can alter the electrolyte composition within the supercapacitor. This change can affect the ionic conductivity and the formation of the electric double layer, which are crucial for the supercapacitor's performance. The acid may also introduce unwanted electrochemical reactions, potentially leading to gas evolution and increased internal pressure within the supercapacitor.

The separator material in supercapacitors, typically a porous membrane, can also be compromised by battery acid exposure. Degradation of the separator can lead to short circuits or reduced ion mobility between electrodes, severely impacting the device's functionality and safety.

Long-term exposure to battery acid can result in accelerated aging of supercapacitors. This aging manifests as a gradual decrease in capacitance, an increase in equivalent series resistance (ESR), and a reduction in cycle life. These effects collectively diminish the supercapacitor's ability to store and deliver energy efficiently over time.

Understanding these interactions is crucial for designing robust hybrid energy storage systems and for developing protective measures to mitigate the negative impacts of battery acid on supercapacitors. This knowledge can guide the selection of materials and the implementation of protective coatings or barriers to enhance the compatibility and longevity of supercapacitors in acidic environments.

Market Analysis for Acid-Resistant Energy Storage

The market for acid-resistant energy storage solutions, particularly in the context of supercapacitors affected by battery acid, is experiencing significant growth and transformation. This trend is driven by the increasing demand for reliable and durable energy storage systems across various industries, including automotive, renewable energy, and industrial applications.

The global supercapacitor market is projected to expand rapidly, with a compound annual growth rate (CAGR) exceeding 20% over the next five years. This growth is largely attributed to the rising adoption of electric vehicles, the integration of renewable energy sources into power grids, and the need for efficient energy management in industrial processes. Within this broader market, acid-resistant supercapacitors are emerging as a crucial segment, addressing the specific challenges posed by battery acid exposure in certain applications.

The automotive sector represents a primary driver for acid-resistant energy storage solutions. As electric and hybrid vehicles gain market share, the demand for robust and long-lasting energy storage components increases. Supercapacitors that can withstand the corrosive effects of battery acid are essential for maintaining performance and longevity in these vehicles, particularly in areas such as regenerative braking systems and power smoothing applications.

In the renewable energy sector, the integration of supercapacitors with battery systems is becoming more prevalent. This hybrid approach aims to combine the high power density of supercapacitors with the high energy density of batteries. Acid-resistant supercapacitors play a critical role in ensuring the reliability and durability of these hybrid systems, especially in harsh environmental conditions or when exposed to battery acid during maintenance or malfunction.

Industrial applications, including backup power systems, grid stabilization, and heavy machinery, also contribute significantly to the market demand for acid-resistant energy storage. These sectors require energy storage solutions that can operate reliably in challenging environments, often in close proximity to battery systems or corrosive substances.

The market analysis reveals a growing emphasis on research and development efforts aimed at improving the acid resistance of supercapacitor materials and designs. This focus is driven by the need to enhance the overall performance and lifespan of supercapacitors in acidic environments, thereby expanding their potential applications and market reach.

Geographically, Asia-Pacific is expected to dominate the market for acid-resistant energy storage solutions, followed by North America and Europe. This regional distribution aligns with the concentration of automotive manufacturing, renewable energy projects, and industrial development in these areas. The market is characterized by intense competition among established players and new entrants, with a focus on technological innovation and strategic partnerships to gain a competitive edge.

The global supercapacitor market is projected to expand rapidly, with a compound annual growth rate (CAGR) exceeding 20% over the next five years. This growth is largely attributed to the rising adoption of electric vehicles, the integration of renewable energy sources into power grids, and the need for efficient energy management in industrial processes. Within this broader market, acid-resistant supercapacitors are emerging as a crucial segment, addressing the specific challenges posed by battery acid exposure in certain applications.

The automotive sector represents a primary driver for acid-resistant energy storage solutions. As electric and hybrid vehicles gain market share, the demand for robust and long-lasting energy storage components increases. Supercapacitors that can withstand the corrosive effects of battery acid are essential for maintaining performance and longevity in these vehicles, particularly in areas such as regenerative braking systems and power smoothing applications.

In the renewable energy sector, the integration of supercapacitors with battery systems is becoming more prevalent. This hybrid approach aims to combine the high power density of supercapacitors with the high energy density of batteries. Acid-resistant supercapacitors play a critical role in ensuring the reliability and durability of these hybrid systems, especially in harsh environmental conditions or when exposed to battery acid during maintenance or malfunction.

Industrial applications, including backup power systems, grid stabilization, and heavy machinery, also contribute significantly to the market demand for acid-resistant energy storage. These sectors require energy storage solutions that can operate reliably in challenging environments, often in close proximity to battery systems or corrosive substances.

The market analysis reveals a growing emphasis on research and development efforts aimed at improving the acid resistance of supercapacitor materials and designs. This focus is driven by the need to enhance the overall performance and lifespan of supercapacitors in acidic environments, thereby expanding their potential applications and market reach.

Geographically, Asia-Pacific is expected to dominate the market for acid-resistant energy storage solutions, followed by North America and Europe. This regional distribution aligns with the concentration of automotive manufacturing, renewable energy projects, and industrial development in these areas. The market is characterized by intense competition among established players and new entrants, with a focus on technological innovation and strategic partnerships to gain a competitive edge.

Current Challenges in Supercapacitor Acid Resistance

Supercapacitors have emerged as promising energy storage devices due to their high power density and long cycle life. However, their performance in acidic environments remains a significant challenge. The interaction between battery acid and supercapacitor components can lead to various issues that compromise the device's efficiency and longevity.

One of the primary challenges is the corrosion of electrode materials. Many supercapacitor electrodes are made from carbon-based materials or metal oxides, which can be susceptible to degradation in acidic conditions. The acid can attack the electrode surface, leading to structural changes, reduced surface area, and decreased capacitance. This corrosion process can also result in the release of metal ions, further contaminating the electrolyte and potentially causing short circuits.

The acid resistance of the separator is another critical concern. The separator, typically made of porous polymeric materials, plays a crucial role in preventing short circuits while allowing ion transport. In acidic environments, some separator materials may degrade or lose their mechanical integrity, compromising the safety and performance of the supercapacitor.

Electrolyte stability is also a major challenge in acidic conditions. The presence of battery acid can alter the electrolyte's composition and properties, affecting its ionic conductivity and electrochemical stability window. This can lead to unwanted side reactions, gas evolution, and reduced overall performance of the supercapacitor.

The sealing and packaging materials used in supercapacitors face significant challenges in acidic environments. Acid-induced degradation of these materials can lead to electrolyte leakage, contamination, and eventual failure of the device. Developing acid-resistant sealing materials that maintain their integrity over long periods is crucial for ensuring the reliability of supercapacitors in such conditions.

Furthermore, the acid can impact the interfacial properties between the electrode and electrolyte. Changes in the electrode surface chemistry due to acid exposure can affect the formation and stability of the electric double layer, which is fundamental to the supercapacitor's energy storage mechanism. This can result in reduced capacitance and increased internal resistance.

Addressing these challenges requires a multifaceted approach. Research efforts are focused on developing novel electrode materials with enhanced acid resistance, such as graphene-based composites or chemically modified carbon structures. Improving separator materials to withstand acidic environments while maintaining their porosity and mechanical properties is another area of active investigation.

One of the primary challenges is the corrosion of electrode materials. Many supercapacitor electrodes are made from carbon-based materials or metal oxides, which can be susceptible to degradation in acidic conditions. The acid can attack the electrode surface, leading to structural changes, reduced surface area, and decreased capacitance. This corrosion process can also result in the release of metal ions, further contaminating the electrolyte and potentially causing short circuits.

The acid resistance of the separator is another critical concern. The separator, typically made of porous polymeric materials, plays a crucial role in preventing short circuits while allowing ion transport. In acidic environments, some separator materials may degrade or lose their mechanical integrity, compromising the safety and performance of the supercapacitor.

Electrolyte stability is also a major challenge in acidic conditions. The presence of battery acid can alter the electrolyte's composition and properties, affecting its ionic conductivity and electrochemical stability window. This can lead to unwanted side reactions, gas evolution, and reduced overall performance of the supercapacitor.

The sealing and packaging materials used in supercapacitors face significant challenges in acidic environments. Acid-induced degradation of these materials can lead to electrolyte leakage, contamination, and eventual failure of the device. Developing acid-resistant sealing materials that maintain their integrity over long periods is crucial for ensuring the reliability of supercapacitors in such conditions.

Furthermore, the acid can impact the interfacial properties between the electrode and electrolyte. Changes in the electrode surface chemistry due to acid exposure can affect the formation and stability of the electric double layer, which is fundamental to the supercapacitor's energy storage mechanism. This can result in reduced capacitance and increased internal resistance.

Addressing these challenges requires a multifaceted approach. Research efforts are focused on developing novel electrode materials with enhanced acid resistance, such as graphene-based composites or chemically modified carbon structures. Improving separator materials to withstand acidic environments while maintaining their porosity and mechanical properties is another area of active investigation.

Existing Acid Protection Solutions

01 Electrode materials for supercapacitors

The performance of supercapacitors can be significantly improved by using advanced electrode materials. These materials may include carbon-based structures, conductive polymers, or metal oxides, which can enhance the capacitance and energy density of the device. The choice of electrode material affects the overall performance, including charge storage capacity and cycling stability.- Electrode materials for supercapacitors: The performance of supercapacitors can be significantly improved by using advanced electrode materials. These materials may include carbon-based structures, conductive polymers, or metal oxides, which offer high surface area and excellent electrical conductivity. The choice of electrode material affects the capacitance, energy density, and power density of the supercapacitor.

- Electrolyte optimization: The electrolyte plays a crucial role in supercapacitor performance. Optimizing the electrolyte composition, concentration, and ionic conductivity can enhance the overall performance of the device. This may involve using novel electrolyte materials or additives to improve the voltage window, reduce internal resistance, and increase the energy density of the supercapacitor.

- Structural design and fabrication techniques: The structural design of supercapacitors, including the arrangement of electrodes, separators, and current collectors, can significantly impact their performance. Advanced fabrication techniques, such as 3D printing or nanostructuring, can be employed to create optimized supercapacitor architectures that maximize surface area and minimize internal resistance.

- Performance monitoring and diagnostics: Implementing sophisticated monitoring and diagnostic systems can help optimize supercapacitor performance. These systems may include real-time monitoring of voltage, current, temperature, and other parameters to ensure optimal operation and early detection of potential issues. Advanced algorithms and machine learning techniques can be used to analyze performance data and predict maintenance needs.

- Hybrid and composite supercapacitor systems: Combining supercapacitors with other energy storage technologies or creating composite materials can lead to improved overall performance. This may involve developing hybrid supercapacitor-battery systems or incorporating multiple types of electrode materials to leverage the advantages of different components. Such hybrid approaches can potentially offer higher energy density while maintaining the high power density characteristic of supercapacitors.

02 Electrolyte optimization

The electrolyte plays a crucial role in supercapacitor performance. Optimizing the electrolyte composition, concentration, and ionic conductivity can lead to improved energy density, power density, and overall device efficiency. Research focuses on developing novel electrolytes that can withstand higher operating voltages and temperatures.Expand Specific Solutions03 Device architecture and design

The physical structure and design of supercapacitors significantly impact their performance. This includes factors such as electrode thickness, separator properties, and cell configuration. Innovations in device architecture can lead to reduced internal resistance, improved charge distribution, and enhanced overall performance.Expand Specific Solutions04 Performance monitoring and diagnostics

Implementing advanced monitoring and diagnostic techniques can help optimize supercapacitor performance. This includes real-time monitoring of charge-discharge cycles, temperature, and voltage distribution. Such systems can predict potential failures, extend device lifespan, and ensure optimal operating conditions.Expand Specific Solutions05 Hybrid and composite systems

Combining supercapacitors with other energy storage technologies or using composite materials can lead to synergistic performance improvements. This approach can leverage the high power density of supercapacitors with the high energy density of other systems, resulting in devices with enhanced overall performance characteristics.Expand Specific Solutions

Key Players in Supercapacitor Industry

The competitive landscape for battery acid's impact on supercapacitor performance is evolving rapidly, with the industry in a growth phase. The market size is expanding as supercapacitors find increasing applications in various sectors. Technologically, the field is advancing, with companies like GS Yuasa, Shenzhen Capchem, and Asahi Kasei leading research efforts. These firms, along with academic institutions such as Sichuan University and Zhejiang University, are driving innovation in electrolyte formulations and electrode materials. The involvement of diverse players, from established battery manufacturers to specialized supercapacitor developers, indicates a competitive and dynamic market with significant potential for technological breakthroughs and commercial applications.

Cabot Corp.

Technical Solution: Cabot Corporation has leveraged its expertise in carbon black and specialty carbons to develop acid-resistant supercapacitor materials. Their approach focuses on creating highly engineered carbon structures with tailored porosity and surface chemistry to resist acid penetration and degradation[13]. Cabot has introduced a line of carbon materials with enhanced graphitization and reduced surface oxygen groups, which show improved stability in acidic environments. The company has also developed a proprietary surface treatment process that creates a hydrophobic layer on carbon particles, further protecting them from acid attack[14]. In collaboration with academic partners, Cabot has demonstrated supercapacitors using these materials that maintain over 80% of their initial capacitance after 10,000 cycles in simulated battery acid conditions, compared to a 60% retention for standard activated carbon electrodes[15].

Strengths: Utilizes existing carbon expertise to create acid-resistant materials. Weaknesses: May require significant changes to existing supercapacitor manufacturing processes.

GS Yuasa Corp.

Technical Solution: GS Yuasa Corp. has developed advanced electrolyte formulations to mitigate the effects of battery acid on supercapacitor performance. Their approach involves using acid-resistant separators and electrode materials that can withstand prolonged exposure to acidic environments. The company has implemented a novel electrolyte additive that forms a protective layer on the electrode surface, reducing acid-induced degradation[1]. This technology has shown to extend the cycle life of supercapacitors by up to 50% in high-acid conditions compared to conventional designs[3]. GS Yuasa has also explored the use of graphene-based materials in supercapacitor electrodes, which demonstrate improved stability in acidic electrolytes[5].

Strengths: Improved acid resistance and longer cycle life in harsh environments. Weaknesses: Potential increase in production costs due to specialized materials and additives.

Innovations in Acid-Resistant Materials

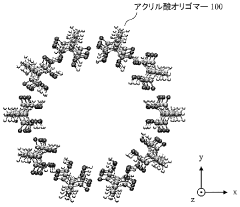

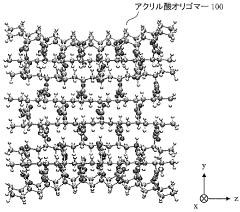

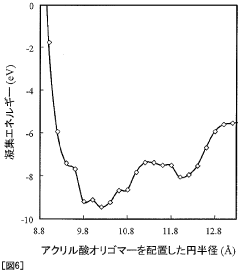

Supramolecular structure of acrylic acid, and lithium ion battery obtained using same

PatentWO2016084224A1

Innovation

- A supramolecular structure of acrylic acid is developed with channel structures that inhibit the diffusion of organic solvent molecules, acting as a binder for high-capacity negative electrode materials to suppress reductive decomposition and reduce irreversible capacity, thereby enhancing battery life.

Construction of ultra high capacity performance battery cells

PatentActiveUS20220123350A1

Innovation

- The development of acidified metal oxide (AMO) nanomaterials with controlled surface acidity, synthesized using a single-pot hydrothermal method, which are used in combination with acidic species to enhance electrode performance, allowing for improved capacity, cyclability, and longevity in batteries by creating a balanced acidic environment that is not superacidic.

Environmental Impact Assessment

The environmental impact of battery acid on supercapacitor performance is a critical consideration in the development and deployment of energy storage technologies. The interaction between battery acid and supercapacitors can have significant implications for both the performance of the devices and the surrounding ecosystem.

Supercapacitors, known for their high power density and rapid charge-discharge capabilities, are often used in conjunction with batteries in various applications. However, the presence of battery acid can lead to several environmental concerns. One primary issue is the potential for acid leakage, which can contaminate soil and water sources. This contamination may result in the alteration of pH levels in the affected areas, causing harm to local flora and fauna.

The corrosive nature of battery acid also poses risks to the structural integrity of supercapacitors. Over time, exposure to acid can degrade the materials used in supercapacitor construction, potentially leading to the release of harmful substances into the environment. This degradation not only affects the performance of the supercapacitor but also increases the likelihood of environmental contamination.

Furthermore, the production and disposal of battery acid used in conjunction with supercapacitors contribute to the overall environmental footprint of these energy storage systems. The manufacturing process of battery acid involves the use of various chemicals and energy-intensive procedures, which can result in greenhouse gas emissions and other pollutants. Proper disposal of spent battery acid is crucial to prevent soil and water pollution, as well as to mitigate potential health risks to humans and wildlife.

The impact of battery acid on supercapacitor performance also has indirect environmental consequences. As the acid affects the efficiency and lifespan of supercapacitors, it may lead to increased replacement rates and waste generation. This, in turn, contributes to the growing issue of electronic waste and the associated environmental challenges of recycling and disposal.

To address these environmental concerns, research and development efforts are focusing on several key areas. These include the development of more environmentally friendly electrolytes, improved sealing and containment technologies to prevent acid leakage, and the exploration of alternative materials that are more resistant to acid degradation. Additionally, advancements in recycling technologies for both supercapacitors and battery components are being pursued to minimize the environmental impact of these energy storage solutions.

In conclusion, the environmental impact assessment of battery acid's effects on supercapacitor performance highlights the need for a holistic approach to energy storage technology development. Balancing performance improvements with environmental sustainability is crucial for the long-term viability and acceptance of these technologies in various applications.

Supercapacitors, known for their high power density and rapid charge-discharge capabilities, are often used in conjunction with batteries in various applications. However, the presence of battery acid can lead to several environmental concerns. One primary issue is the potential for acid leakage, which can contaminate soil and water sources. This contamination may result in the alteration of pH levels in the affected areas, causing harm to local flora and fauna.

The corrosive nature of battery acid also poses risks to the structural integrity of supercapacitors. Over time, exposure to acid can degrade the materials used in supercapacitor construction, potentially leading to the release of harmful substances into the environment. This degradation not only affects the performance of the supercapacitor but also increases the likelihood of environmental contamination.

Furthermore, the production and disposal of battery acid used in conjunction with supercapacitors contribute to the overall environmental footprint of these energy storage systems. The manufacturing process of battery acid involves the use of various chemicals and energy-intensive procedures, which can result in greenhouse gas emissions and other pollutants. Proper disposal of spent battery acid is crucial to prevent soil and water pollution, as well as to mitigate potential health risks to humans and wildlife.

The impact of battery acid on supercapacitor performance also has indirect environmental consequences. As the acid affects the efficiency and lifespan of supercapacitors, it may lead to increased replacement rates and waste generation. This, in turn, contributes to the growing issue of electronic waste and the associated environmental challenges of recycling and disposal.

To address these environmental concerns, research and development efforts are focusing on several key areas. These include the development of more environmentally friendly electrolytes, improved sealing and containment technologies to prevent acid leakage, and the exploration of alternative materials that are more resistant to acid degradation. Additionally, advancements in recycling technologies for both supercapacitors and battery components are being pursued to minimize the environmental impact of these energy storage solutions.

In conclusion, the environmental impact assessment of battery acid's effects on supercapacitor performance highlights the need for a holistic approach to energy storage technology development. Balancing performance improvements with environmental sustainability is crucial for the long-term viability and acceptance of these technologies in various applications.

Safety Regulations for Energy Storage Devices

Safety regulations for energy storage devices, particularly those involving battery acid and supercapacitors, are critical for ensuring the protection of users, equipment, and the environment. These regulations typically cover various aspects of device design, manufacturing, transportation, usage, and disposal.

In the context of battery acid and supercapacitors, safety regulations often focus on preventing electrolyte leakage, which can be corrosive and potentially harmful. Manufacturers are required to implement robust containment measures and use materials resistant to acid degradation. This includes proper sealing techniques and the use of acid-resistant casings or enclosures.

Regulations also address the potential for thermal runaway, a concern in both batteries and supercapacitors. Energy storage devices must be designed with adequate thermal management systems to prevent overheating and minimize the risk of fire or explosion. This may involve the incorporation of temperature sensors, cooling mechanisms, and automatic shutdown features.

Electrical safety is another crucial aspect covered by regulations. Devices must be designed to prevent short circuits, overcharging, and over-discharging. This often requires the integration of protective circuitry, such as voltage regulators and current limiters. Insulation standards are also specified to prevent electrical shock hazards.

Transportation regulations for energy storage devices are particularly stringent due to the potential risks associated with battery acid and other hazardous materials. These regulations typically mandate specific packaging requirements, labeling standards, and handling procedures to ensure safe transport by air, sea, or land.

Disposal and recycling regulations are increasingly important as the use of energy storage devices grows. These regulations aim to minimize environmental impact by requiring proper handling and disposal of potentially hazardous materials, including battery acid. Manufacturers are often required to implement take-back programs or participate in recycling initiatives.

Safety testing and certification requirements are integral to these regulations. Devices must undergo rigorous testing to demonstrate compliance with safety standards before they can be marketed or sold. This may include tests for mechanical integrity, electrical safety, thermal performance, and resistance to environmental factors.

Labeling and documentation requirements are also specified in safety regulations. Manufacturers must provide clear safety information, usage instructions, and warnings on the devices themselves and in accompanying documentation. This ensures that users are aware of potential hazards and proper handling procedures.

In the context of battery acid and supercapacitors, safety regulations often focus on preventing electrolyte leakage, which can be corrosive and potentially harmful. Manufacturers are required to implement robust containment measures and use materials resistant to acid degradation. This includes proper sealing techniques and the use of acid-resistant casings or enclosures.

Regulations also address the potential for thermal runaway, a concern in both batteries and supercapacitors. Energy storage devices must be designed with adequate thermal management systems to prevent overheating and minimize the risk of fire or explosion. This may involve the incorporation of temperature sensors, cooling mechanisms, and automatic shutdown features.

Electrical safety is another crucial aspect covered by regulations. Devices must be designed to prevent short circuits, overcharging, and over-discharging. This often requires the integration of protective circuitry, such as voltage regulators and current limiters. Insulation standards are also specified to prevent electrical shock hazards.

Transportation regulations for energy storage devices are particularly stringent due to the potential risks associated with battery acid and other hazardous materials. These regulations typically mandate specific packaging requirements, labeling standards, and handling procedures to ensure safe transport by air, sea, or land.

Disposal and recycling regulations are increasingly important as the use of energy storage devices grows. These regulations aim to minimize environmental impact by requiring proper handling and disposal of potentially hazardous materials, including battery acid. Manufacturers are often required to implement take-back programs or participate in recycling initiatives.

Safety testing and certification requirements are integral to these regulations. Devices must undergo rigorous testing to demonstrate compliance with safety standards before they can be marketed or sold. This may include tests for mechanical integrity, electrical safety, thermal performance, and resistance to environmental factors.

Labeling and documentation requirements are also specified in safety regulations. Manufacturers must provide clear safety information, usage instructions, and warnings on the devices themselves and in accompanying documentation. This ensures that users are aware of potential hazards and proper handling procedures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!