Enhancing LDPE Transparency for Improved Aesthetics

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE Transparency Evolution and Objectives

Low-density polyethylene (LDPE) has been a cornerstone material in the packaging industry since its introduction in the 1930s. Over the decades, the quest for enhancing LDPE transparency has been driven by the growing demand for improved product visibility and aesthetic appeal in packaging applications. The evolution of LDPE transparency can be traced through several key milestones in polymer science and manufacturing technology.

In the early stages of LDPE development, the focus was primarily on improving mechanical properties and processability. However, as consumer preferences shifted towards more visually appealing packaging, the industry recognized the need for enhanced transparency. This led to the exploration of various techniques to modify the polymer structure and processing conditions to achieve better optical properties.

One significant breakthrough came with the development of advanced catalysts and polymerization techniques in the 1980s and 1990s. These innovations allowed for better control over the molecular weight distribution and branching of LDPE, which directly impacted its transparency. The introduction of metallocene catalysts, in particular, enabled the production of LDPE with more uniform molecular structures, resulting in improved clarity.

Concurrent with catalyst developments, advancements in extrusion and film-blowing technologies played a crucial role in enhancing LDPE transparency. Improved die designs and precise control of processing parameters, such as temperature and cooling rates, allowed for the production of films with more uniform thickness and reduced haze.

The objectives of enhancing LDPE transparency for improved aesthetics are multifaceted. Primarily, there is a drive to achieve higher levels of clarity and gloss, approaching the optical properties of more expensive materials like polyethylene terephthalate (PET). This would expand LDPE's applicability in premium packaging segments where visual appeal is paramount.

Another key objective is to maintain or improve transparency while simultaneously enhancing other desirable properties such as strength, barrier performance, and printability. This holistic approach aims to create a versatile material that can meet the diverse requirements of modern packaging applications without compromising on aesthetics.

Furthermore, there is a growing emphasis on developing sustainable solutions that do not sacrifice transparency. This includes research into bio-based LDPE alternatives and the incorporation of recycled content without significantly impacting optical properties. The challenge lies in balancing these environmental considerations with the demand for high-clarity packaging materials.

As we look to the future, the objectives for LDPE transparency enhancement are likely to focus on nano-scale modifications of the polymer structure, novel additive technologies, and advanced surface treatments. These approaches aim to push the boundaries of what is possible with LDPE, potentially opening up new markets and applications where transparency is a critical factor.

In the early stages of LDPE development, the focus was primarily on improving mechanical properties and processability. However, as consumer preferences shifted towards more visually appealing packaging, the industry recognized the need for enhanced transparency. This led to the exploration of various techniques to modify the polymer structure and processing conditions to achieve better optical properties.

One significant breakthrough came with the development of advanced catalysts and polymerization techniques in the 1980s and 1990s. These innovations allowed for better control over the molecular weight distribution and branching of LDPE, which directly impacted its transparency. The introduction of metallocene catalysts, in particular, enabled the production of LDPE with more uniform molecular structures, resulting in improved clarity.

Concurrent with catalyst developments, advancements in extrusion and film-blowing technologies played a crucial role in enhancing LDPE transparency. Improved die designs and precise control of processing parameters, such as temperature and cooling rates, allowed for the production of films with more uniform thickness and reduced haze.

The objectives of enhancing LDPE transparency for improved aesthetics are multifaceted. Primarily, there is a drive to achieve higher levels of clarity and gloss, approaching the optical properties of more expensive materials like polyethylene terephthalate (PET). This would expand LDPE's applicability in premium packaging segments where visual appeal is paramount.

Another key objective is to maintain or improve transparency while simultaneously enhancing other desirable properties such as strength, barrier performance, and printability. This holistic approach aims to create a versatile material that can meet the diverse requirements of modern packaging applications without compromising on aesthetics.

Furthermore, there is a growing emphasis on developing sustainable solutions that do not sacrifice transparency. This includes research into bio-based LDPE alternatives and the incorporation of recycled content without significantly impacting optical properties. The challenge lies in balancing these environmental considerations with the demand for high-clarity packaging materials.

As we look to the future, the objectives for LDPE transparency enhancement are likely to focus on nano-scale modifications of the polymer structure, novel additive technologies, and advanced surface treatments. These approaches aim to push the boundaries of what is possible with LDPE, potentially opening up new markets and applications where transparency is a critical factor.

Market Demand Analysis for High-Clarity LDPE

The market demand for high-clarity Low-Density Polyethylene (LDPE) has been steadily increasing across various industries, driven by the growing consumer preference for visually appealing and transparent packaging solutions. This trend is particularly evident in the food and beverage sector, where product visibility plays a crucial role in consumer purchasing decisions. The global LDPE market, valued at $33 billion in 2020, is projected to reach $44 billion by 2026, with a significant portion of this growth attributed to the demand for high-clarity variants.

In the packaging industry, which accounts for over 60% of LDPE consumption, there is a strong push towards enhancing product aesthetics through improved transparency. This demand is fueled by brand owners seeking to differentiate their products on store shelves and create a premium perception among consumers. The food packaging segment, in particular, has shown a robust demand for high-clarity LDPE films, as they allow for better product showcase while maintaining the necessary barrier properties.

The personal care and cosmetics industry has also emerged as a key driver for high-clarity LDPE demand. With the rise of minimalist and eco-friendly packaging designs, brands are increasingly opting for clear, recyclable LDPE containers that showcase the product's color and texture. This trend aligns with the growing consumer preference for "clean" and transparent product formulations, extending to the packaging itself.

In the medical and pharmaceutical sectors, the demand for high-clarity LDPE is driven by the need for sterile, transparent packaging that allows for easy inspection of contents. The ongoing global health concerns have further accelerated this trend, with an increased focus on visible cleanliness and integrity of medical supplies and pharmaceutical products.

The agricultural sector presents another growing market for high-clarity LDPE, particularly in greenhouse films and mulch applications. Improved transparency in these films allows for better light transmission, enhancing crop growth and yield. As sustainable agriculture practices gain traction, the demand for high-performance, transparent LDPE films is expected to rise.

Consumer electronics and household goods industries are also contributing to the market demand for high-clarity LDPE. The trend towards sleek, minimalist design in consumer products has led to increased use of transparent packaging and components, where high-clarity LDPE finds applications in protective films, display covers, and packaging inserts.

As sustainability becomes a key focus across industries, there is a growing demand for high-clarity LDPE that maintains its transparency even with increased recycled content. This presents both a challenge and an opportunity for LDPE manufacturers to innovate and meet the dual requirements of enhanced aesthetics and environmental responsibility.

In the packaging industry, which accounts for over 60% of LDPE consumption, there is a strong push towards enhancing product aesthetics through improved transparency. This demand is fueled by brand owners seeking to differentiate their products on store shelves and create a premium perception among consumers. The food packaging segment, in particular, has shown a robust demand for high-clarity LDPE films, as they allow for better product showcase while maintaining the necessary barrier properties.

The personal care and cosmetics industry has also emerged as a key driver for high-clarity LDPE demand. With the rise of minimalist and eco-friendly packaging designs, brands are increasingly opting for clear, recyclable LDPE containers that showcase the product's color and texture. This trend aligns with the growing consumer preference for "clean" and transparent product formulations, extending to the packaging itself.

In the medical and pharmaceutical sectors, the demand for high-clarity LDPE is driven by the need for sterile, transparent packaging that allows for easy inspection of contents. The ongoing global health concerns have further accelerated this trend, with an increased focus on visible cleanliness and integrity of medical supplies and pharmaceutical products.

The agricultural sector presents another growing market for high-clarity LDPE, particularly in greenhouse films and mulch applications. Improved transparency in these films allows for better light transmission, enhancing crop growth and yield. As sustainable agriculture practices gain traction, the demand for high-performance, transparent LDPE films is expected to rise.

Consumer electronics and household goods industries are also contributing to the market demand for high-clarity LDPE. The trend towards sleek, minimalist design in consumer products has led to increased use of transparent packaging and components, where high-clarity LDPE finds applications in protective films, display covers, and packaging inserts.

As sustainability becomes a key focus across industries, there is a growing demand for high-clarity LDPE that maintains its transparency even with increased recycled content. This presents both a challenge and an opportunity for LDPE manufacturers to innovate and meet the dual requirements of enhanced aesthetics and environmental responsibility.

Current Challenges in LDPE Transparency Enhancement

Despite significant advancements in polymer science, enhancing the transparency of Low-Density Polyethylene (LDPE) remains a complex challenge. The inherent semi-crystalline structure of LDPE, characterized by both amorphous and crystalline regions, contributes to its opacity. This structural composition leads to light scattering, reducing overall transparency and limiting its aesthetic appeal in various applications.

One of the primary obstacles in improving LDPE transparency is the presence of crystalline domains. These regions, formed during the polymerization process, create interfaces that scatter light, resulting in a cloudy appearance. Controlling the size, distribution, and orientation of these crystalline structures is crucial for enhancing transparency, but achieving this control without compromising other desirable properties of LDPE remains challenging.

Another significant hurdle is the trade-off between transparency and mechanical properties. Attempts to increase transparency often lead to a reduction in strength, toughness, or other essential mechanical characteristics. Balancing these competing properties requires sophisticated material engineering approaches that are not yet fully developed or widely implemented in industrial settings.

The presence of additives, while necessary for various functional properties, can also negatively impact transparency. Stabilizers, antioxidants, and other additives introduced to enhance performance or processability may contribute to light scattering or absorption, further reducing clarity. Developing additive packages that maintain or improve transparency while fulfilling their primary functions presents a significant challenge for material scientists and engineers.

Processing conditions also play a critical role in LDPE transparency. The cooling rate, shear forces, and other processing parameters significantly influence the final morphology of the polymer, affecting its optical properties. Optimizing these conditions for maximum transparency while maintaining production efficiency and other material properties is a complex task that requires precise control and advanced processing technologies.

Environmental factors pose additional challenges to LDPE transparency enhancement. Exposure to UV radiation, temperature fluctuations, and chemical agents can lead to degradation over time, affecting the material's clarity. Developing robust solutions that maintain transparency throughout the product lifecycle, especially in outdoor applications, remains an ongoing challenge for researchers and manufacturers.

Lastly, the cost-effectiveness of transparency enhancement techniques is a significant consideration. Many advanced methods for improving LDPE clarity, such as incorporating nanofillers or using sophisticated processing techniques, can substantially increase production costs. Striking a balance between improved aesthetics and economic viability is crucial for widespread adoption in commercial applications.

One of the primary obstacles in improving LDPE transparency is the presence of crystalline domains. These regions, formed during the polymerization process, create interfaces that scatter light, resulting in a cloudy appearance. Controlling the size, distribution, and orientation of these crystalline structures is crucial for enhancing transparency, but achieving this control without compromising other desirable properties of LDPE remains challenging.

Another significant hurdle is the trade-off between transparency and mechanical properties. Attempts to increase transparency often lead to a reduction in strength, toughness, or other essential mechanical characteristics. Balancing these competing properties requires sophisticated material engineering approaches that are not yet fully developed or widely implemented in industrial settings.

The presence of additives, while necessary for various functional properties, can also negatively impact transparency. Stabilizers, antioxidants, and other additives introduced to enhance performance or processability may contribute to light scattering or absorption, further reducing clarity. Developing additive packages that maintain or improve transparency while fulfilling their primary functions presents a significant challenge for material scientists and engineers.

Processing conditions also play a critical role in LDPE transparency. The cooling rate, shear forces, and other processing parameters significantly influence the final morphology of the polymer, affecting its optical properties. Optimizing these conditions for maximum transparency while maintaining production efficiency and other material properties is a complex task that requires precise control and advanced processing technologies.

Environmental factors pose additional challenges to LDPE transparency enhancement. Exposure to UV radiation, temperature fluctuations, and chemical agents can lead to degradation over time, affecting the material's clarity. Developing robust solutions that maintain transparency throughout the product lifecycle, especially in outdoor applications, remains an ongoing challenge for researchers and manufacturers.

Lastly, the cost-effectiveness of transparency enhancement techniques is a significant consideration. Many advanced methods for improving LDPE clarity, such as incorporating nanofillers or using sophisticated processing techniques, can substantially increase production costs. Striking a balance between improved aesthetics and economic viability is crucial for widespread adoption in commercial applications.

Existing LDPE Transparency Enhancement Techniques

01 Improving LDPE transparency through composition modification

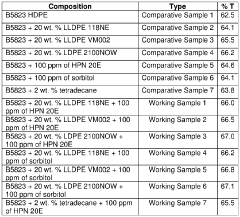

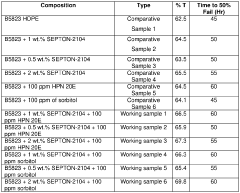

Transparency of LDPE can be enhanced by modifying its composition. This may involve blending LDPE with other polymers or additives to improve its optical properties. The modified composition can result in a more transparent film or sheet, suitable for various applications where clarity is important.- Improving LDPE transparency through additives: Various additives can be incorporated into LDPE to enhance its transparency. These may include nucleating agents, clarifying agents, or other specific compounds that modify the polymer structure to allow more light transmission. The proper selection and concentration of these additives can significantly improve the optical properties of LDPE films or products.

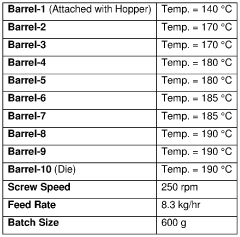

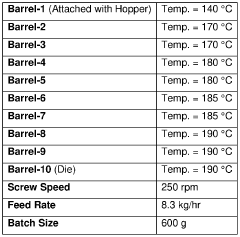

- Optimizing LDPE processing conditions: The transparency of LDPE can be improved by optimizing processing conditions during manufacturing. This includes controlling parameters such as temperature, pressure, cooling rate, and extrusion speed. Proper adjustment of these factors can lead to a more uniform polymer structure with fewer light-scattering defects, resulting in enhanced transparency.

- Blending LDPE with other polymers: Blending LDPE with other compatible polymers can enhance its transparency. Careful selection of blend components and ratios can result in a synergistic effect, improving overall optical properties while maintaining or enhancing other desirable characteristics of LDPE. This approach allows for tailoring the material properties to specific application requirements.

- Modifying LDPE molecular structure: Altering the molecular structure of LDPE through techniques such as controlled branching, crosslinking, or copolymerization can improve its transparency. These modifications can reduce crystallinity, increase amorphous regions, or create a more ordered structure that allows for better light transmission through the polymer matrix.

- Surface treatment of LDPE films: Applying surface treatments to LDPE films can enhance their transparency. Techniques such as corona discharge, plasma treatment, or application of specific coatings can modify the surface properties of LDPE, reducing light scattering and improving overall transparency. These treatments can also provide additional benefits such as improved printability or adhesion properties.

02 Processing techniques for enhancing LDPE transparency

Various processing techniques can be employed to improve the transparency of LDPE. These may include optimizing extrusion parameters, using specific cooling methods, or applying post-processing treatments. Such techniques can help reduce haze and increase light transmission through the LDPE material.Expand Specific Solutions03 Incorporation of nucleating agents for improved transparency

Adding nucleating agents to LDPE can enhance its transparency. These agents promote the formation of smaller, more uniform crystallites in the polymer structure, which reduces light scattering and improves overall transparency. The selection and concentration of nucleating agents are crucial for achieving optimal results.Expand Specific Solutions04 Use of LDPE in transparent packaging applications

LDPE with improved transparency is widely used in packaging applications. Its clarity allows for better product visibility while maintaining the material's flexibility and sealing properties. Transparent LDPE packaging can be used for food, consumer goods, and industrial products where visual appeal is important.Expand Specific Solutions05 Characterization and measurement of LDPE transparency

Various methods and techniques are used to characterize and measure the transparency of LDPE. These may include spectrophotometry, haze measurement, and light transmission tests. Accurate measurement of transparency is crucial for quality control and ensuring that the LDPE meets the required optical specifications for different applications.Expand Specific Solutions

Key Players in Transparent LDPE Development

The market for enhancing LDPE transparency is in a growth phase, driven by increasing demand for improved aesthetics in packaging and consumer goods. The global market size for transparent LDPE is estimated to be in the billions of dollars, with steady annual growth. Technologically, the field is moderately mature, with ongoing innovations focused on enhancing optical properties and processing efficiency. Key players like Dow Global Technologies, ExxonMobil Chemical, and LyondellBasell are leading research efforts, while companies such as SABIC, LG Chem, and Chevron Phillips Chemical are also making significant contributions to advancing LDPE transparency technologies.

Dow Global Technologies LLC

Technical Solution: Dow has developed a novel LDPE resin with enhanced optical properties, utilizing advanced catalyst technology and optimized polymerization conditions. The process involves controlling molecular weight distribution and reducing long-chain branching, resulting in a more uniform polymer structure. This leads to improved light transmission and reduced haze. The company has also implemented a proprietary additive package that further enhances clarity without compromising mechanical properties. Additionally, Dow has introduced a unique extrusion process that minimizes surface irregularities, contributing to better overall transparency[1][3].

Strengths: Superior optical clarity, maintained mechanical properties, scalable production process. Weaknesses: Potentially higher production costs, may require specialized equipment for optimal results.

LG Chem Ltd.

Technical Solution: LG Chem has developed a proprietary LDPE formulation with enhanced transparency through a combination of molecular engineering and advanced processing techniques. Their approach involves carefully controlling the polymer's crystallinity and morphology to reduce light scattering. The company has also implemented a unique nucleating agent system that promotes the formation of smaller, more uniform crystals, further improving optical properties. LG Chem's process includes a specialized annealing step that helps to reduce internal stress and enhance overall clarity. Furthermore, they have developed a surface treatment technology that minimizes surface defects, contributing to improved aesthetics[2][5].

Strengths: Excellent optical properties, versatile application potential, improved processing characteristics. Weaknesses: May have limitations in certain high-stress applications, potential for increased production complexity.

Innovative Approaches to LDPE Clarity Improvement

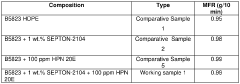

High-density polyethylene with additives for increased transparency

PatentWO2021053412A1

Innovation

- A HDPE composition is developed by incorporating a monomeric and/or polymeric additive and a clarifying/nucleating agent, which enhances transparency and reduces haze without the need for drawing or stretching, achieving transparency of 80% or more and haze of 60% or less, as determined by ASTM D1003, at a thickness of 1 mm or more.

Polyethylene with increased transparency and reduced haze

PatentWO2021033054A1

Innovation

- A high-density polyethylene composition is developed by incorporating an optics-enhancing additive with a refractive index of 1.52 or more and a nucleating agent, which increases transparency to 80% or more and reduces haze to 60% or less without the need for drawing or stretching, using a combination of unimodal, bimodal, or multimodal HDPE with specific molecular weight and density ranges.

Environmental Impact of Transparent LDPE Production

The production of transparent Low-Density Polyethylene (LDPE) has significant environmental implications that must be carefully considered. The process of enhancing LDPE transparency often involves additional chemical treatments or modifications to the polymer structure, which can increase the overall environmental footprint of the material.

One of the primary concerns is the energy consumption associated with the production of transparent LDPE. The additional processing steps required to achieve higher transparency levels typically demand more energy input, leading to increased greenhouse gas emissions. This is particularly relevant in regions where the energy grid relies heavily on fossil fuels, as the carbon footprint of transparent LDPE production can be substantially higher than that of standard LDPE.

Chemical additives used to enhance transparency may also pose environmental risks. These additives can include clarifying agents, nucleating agents, or other specialty chemicals that may have potential toxicity or persistence in the environment. The production, use, and disposal of these additives contribute to the overall environmental impact of transparent LDPE.

Water usage is another critical factor to consider. Some transparency-enhancing processes may require additional washing or cooling steps, increasing water consumption and potentially generating wastewater that requires treatment before release into the environment. This can strain local water resources and add to the complexity of waste management systems.

The end-of-life considerations for transparent LDPE also present environmental challenges. While LDPE is generally recyclable, the additives used to enhance transparency may complicate the recycling process or reduce the quality of recycled material. This could lead to a higher proportion of transparent LDPE ending up in landfills or incineration facilities, rather than being effectively recycled.

However, it's important to note that the improved aesthetics of transparent LDPE can lead to positive environmental outcomes in certain applications. For instance, in packaging, the enhanced visibility can reduce food waste by allowing consumers to better assess the condition of packaged products. Additionally, the improved appearance may increase the perceived value of products, potentially leading to longer product lifespans and reduced overall consumption.

Efforts are being made to mitigate the environmental impact of transparent LDPE production. Research into more sustainable additives, energy-efficient processing techniques, and improved recycling methods for transparent plastics are ongoing. Some manufacturers are also exploring bio-based alternatives that could offer similar transparency while reducing reliance on fossil fuel-derived materials.

In conclusion, while the production of transparent LDPE for improved aesthetics offers certain benefits, it also presents significant environmental challenges. Balancing the desire for enhanced product appearance with environmental responsibility requires ongoing innovation in materials science and manufacturing processes. As the industry evolves, it will be crucial to develop more sustainable methods for producing transparent LDPE that minimize energy consumption, reduce chemical usage, and improve end-of-life recyclability.

One of the primary concerns is the energy consumption associated with the production of transparent LDPE. The additional processing steps required to achieve higher transparency levels typically demand more energy input, leading to increased greenhouse gas emissions. This is particularly relevant in regions where the energy grid relies heavily on fossil fuels, as the carbon footprint of transparent LDPE production can be substantially higher than that of standard LDPE.

Chemical additives used to enhance transparency may also pose environmental risks. These additives can include clarifying agents, nucleating agents, or other specialty chemicals that may have potential toxicity or persistence in the environment. The production, use, and disposal of these additives contribute to the overall environmental impact of transparent LDPE.

Water usage is another critical factor to consider. Some transparency-enhancing processes may require additional washing or cooling steps, increasing water consumption and potentially generating wastewater that requires treatment before release into the environment. This can strain local water resources and add to the complexity of waste management systems.

The end-of-life considerations for transparent LDPE also present environmental challenges. While LDPE is generally recyclable, the additives used to enhance transparency may complicate the recycling process or reduce the quality of recycled material. This could lead to a higher proportion of transparent LDPE ending up in landfills or incineration facilities, rather than being effectively recycled.

However, it's important to note that the improved aesthetics of transparent LDPE can lead to positive environmental outcomes in certain applications. For instance, in packaging, the enhanced visibility can reduce food waste by allowing consumers to better assess the condition of packaged products. Additionally, the improved appearance may increase the perceived value of products, potentially leading to longer product lifespans and reduced overall consumption.

Efforts are being made to mitigate the environmental impact of transparent LDPE production. Research into more sustainable additives, energy-efficient processing techniques, and improved recycling methods for transparent plastics are ongoing. Some manufacturers are also exploring bio-based alternatives that could offer similar transparency while reducing reliance on fossil fuel-derived materials.

In conclusion, while the production of transparent LDPE for improved aesthetics offers certain benefits, it also presents significant environmental challenges. Balancing the desire for enhanced product appearance with environmental responsibility requires ongoing innovation in materials science and manufacturing processes. As the industry evolves, it will be crucial to develop more sustainable methods for producing transparent LDPE that minimize energy consumption, reduce chemical usage, and improve end-of-life recyclability.

Regulatory Framework for LDPE in Packaging Industry

The regulatory framework for LDPE in the packaging industry is a complex and evolving landscape that significantly impacts the development and implementation of enhanced LDPE transparency solutions. At the global level, organizations such as the World Health Organization (WHO) and the Food and Agriculture Organization (FAO) provide guidelines on food contact materials, which include LDPE packaging. These guidelines form the basis for many national and regional regulations.

In the United States, the Food and Drug Administration (FDA) regulates LDPE used in food packaging under the Federal Food, Drug, and Cosmetic Act. The FDA maintains a list of approved substances for use in food contact materials, including additives that may be used to enhance LDPE transparency. Manufacturers must ensure that any new formulations or modifications to LDPE for improved aesthetics comply with these regulations.

The European Union has established comprehensive regulations for food contact materials through the Framework Regulation (EC) No 1935/2004. This regulation sets out general principles of safety and inertness for all food contact materials. Additionally, the Plastic Regulation (EU) No 10/2011 specifically addresses plastic materials and articles intended to come into contact with food, including LDPE packaging.

Environmental regulations also play a crucial role in shaping the development of LDPE packaging. Many countries have implemented or are considering regulations to reduce plastic waste and promote recycling. For instance, the EU's Circular Economy Action Plan aims to make all plastic packaging recyclable or reusable by 2030. This initiative has led to increased focus on the recyclability of transparent LDPE packaging.

In Asia, countries like China and Japan have their own regulatory frameworks for food contact materials. China's GB 9685-2016 standard lists approved additives for use in food contact materials, including those that may enhance LDPE transparency. Japan's regulatory system is based on the Food Sanitation Act, which includes a positive list system for food contact materials.

As the demand for more sustainable packaging grows, regulations are evolving to address concerns about microplastics and environmental impact. This has led to increased scrutiny of additives used in LDPE, including those that enhance transparency. Manufacturers must navigate these changing regulations while developing innovative solutions for improved LDPE aesthetics.

In the United States, the Food and Drug Administration (FDA) regulates LDPE used in food packaging under the Federal Food, Drug, and Cosmetic Act. The FDA maintains a list of approved substances for use in food contact materials, including additives that may be used to enhance LDPE transparency. Manufacturers must ensure that any new formulations or modifications to LDPE for improved aesthetics comply with these regulations.

The European Union has established comprehensive regulations for food contact materials through the Framework Regulation (EC) No 1935/2004. This regulation sets out general principles of safety and inertness for all food contact materials. Additionally, the Plastic Regulation (EU) No 10/2011 specifically addresses plastic materials and articles intended to come into contact with food, including LDPE packaging.

Environmental regulations also play a crucial role in shaping the development of LDPE packaging. Many countries have implemented or are considering regulations to reduce plastic waste and promote recycling. For instance, the EU's Circular Economy Action Plan aims to make all plastic packaging recyclable or reusable by 2030. This initiative has led to increased focus on the recyclability of transparent LDPE packaging.

In Asia, countries like China and Japan have their own regulatory frameworks for food contact materials. China's GB 9685-2016 standard lists approved additives for use in food contact materials, including those that may enhance LDPE transparency. Japan's regulatory system is based on the Food Sanitation Act, which includes a positive list system for food contact materials.

As the demand for more sustainable packaging grows, regulations are evolving to address concerns about microplastics and environmental impact. This has led to increased scrutiny of additives used in LDPE, including those that enhance transparency. Manufacturers must navigate these changing regulations while developing innovative solutions for improved LDPE aesthetics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!