Evaluating Impact of LDPE on Sustainability Initiatives

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LDPE Sustainability Context

Low-density polyethylene (LDPE) has been a cornerstone of the plastics industry since its introduction in the 1930s. Its versatility, durability, and low cost have made it ubiquitous in packaging, consumer goods, and industrial applications. However, the increasing global focus on sustainability has brought LDPE under scrutiny, particularly due to its environmental impact and reliance on fossil fuels for production.

In recent years, sustainability initiatives have gained significant momentum across industries, driven by growing environmental awareness, regulatory pressures, and consumer demand for eco-friendly products. These initiatives aim to reduce carbon footprints, minimize waste, and promote circular economy principles. Within this context, LDPE presents both challenges and opportunities for sustainability efforts.

The production of LDPE is energy-intensive and primarily relies on non-renewable petrochemical feedstocks, contributing to greenhouse gas emissions and resource depletion. Additionally, the persistence of LDPE in the environment, particularly in marine ecosystems, has raised concerns about plastic pollution and its long-term ecological effects. These factors have led to increased pressure on manufacturers and consumers to find more sustainable alternatives or improve LDPE's environmental profile.

Despite these challenges, LDPE continues to play a crucial role in various applications due to its unique properties and cost-effectiveness. The material's lightweight nature can contribute to fuel efficiency in transportation, potentially offsetting some of its carbon footprint. Furthermore, LDPE's recyclability, when properly managed, aligns with circular economy principles and waste reduction goals.

Efforts to enhance LDPE's sustainability profile are ongoing, focusing on several key areas. These include improving production efficiency to reduce energy consumption, incorporating recycled content into LDPE products, and developing bio-based alternatives. Additionally, advancements in recycling technologies and infrastructure are crucial for maximizing LDPE's potential within a circular economy framework.

The evaluation of LDPE's impact on sustainability initiatives requires a comprehensive analysis of its lifecycle, from production to end-of-life management. This assessment must consider not only the material's environmental footprint but also its economic and social implications. Balancing these factors is essential for developing effective strategies that address sustainability goals while meeting the practical needs of industries and consumers.

As sustainability becomes increasingly central to corporate strategies and public policies, the future of LDPE will likely be shaped by innovations in material science, recycling technologies, and circular economy models. The challenge lies in finding ways to leverage LDPE's benefits while mitigating its environmental impact, ultimately contributing to broader sustainability objectives.

In recent years, sustainability initiatives have gained significant momentum across industries, driven by growing environmental awareness, regulatory pressures, and consumer demand for eco-friendly products. These initiatives aim to reduce carbon footprints, minimize waste, and promote circular economy principles. Within this context, LDPE presents both challenges and opportunities for sustainability efforts.

The production of LDPE is energy-intensive and primarily relies on non-renewable petrochemical feedstocks, contributing to greenhouse gas emissions and resource depletion. Additionally, the persistence of LDPE in the environment, particularly in marine ecosystems, has raised concerns about plastic pollution and its long-term ecological effects. These factors have led to increased pressure on manufacturers and consumers to find more sustainable alternatives or improve LDPE's environmental profile.

Despite these challenges, LDPE continues to play a crucial role in various applications due to its unique properties and cost-effectiveness. The material's lightweight nature can contribute to fuel efficiency in transportation, potentially offsetting some of its carbon footprint. Furthermore, LDPE's recyclability, when properly managed, aligns with circular economy principles and waste reduction goals.

Efforts to enhance LDPE's sustainability profile are ongoing, focusing on several key areas. These include improving production efficiency to reduce energy consumption, incorporating recycled content into LDPE products, and developing bio-based alternatives. Additionally, advancements in recycling technologies and infrastructure are crucial for maximizing LDPE's potential within a circular economy framework.

The evaluation of LDPE's impact on sustainability initiatives requires a comprehensive analysis of its lifecycle, from production to end-of-life management. This assessment must consider not only the material's environmental footprint but also its economic and social implications. Balancing these factors is essential for developing effective strategies that address sustainability goals while meeting the practical needs of industries and consumers.

As sustainability becomes increasingly central to corporate strategies and public policies, the future of LDPE will likely be shaped by innovations in material science, recycling technologies, and circular economy models. The challenge lies in finding ways to leverage LDPE's benefits while mitigating its environmental impact, ultimately contributing to broader sustainability objectives.

Market Demand Analysis

The market demand for Low-Density Polyethylene (LDPE) has been significantly influenced by the growing focus on sustainability initiatives across various industries. As consumers become more environmentally conscious, there has been a shift in demand towards more sustainable packaging solutions. This has created both challenges and opportunities for the LDPE market.

Despite the push for sustainability, LDPE continues to maintain a strong presence in the packaging industry due to its versatility, cost-effectiveness, and performance characteristics. The global LDPE market size was valued at over $33 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of 3.5% from 2021 to 2028. This growth is primarily driven by the increasing demand for flexible packaging in food and beverage, personal care, and pharmaceutical industries.

However, the market dynamics are evolving rapidly. There is a growing demand for recycled LDPE as companies strive to meet their sustainability goals and comply with increasingly stringent regulations. The recycled LDPE market is expected to witness substantial growth, with some estimates suggesting a CAGR of over 6% in the coming years. This trend is particularly pronounced in regions with advanced recycling infrastructure and strong environmental policies, such as Europe and North America.

The automotive industry represents another significant market for LDPE, particularly in the production of lightweight components to improve fuel efficiency. As the automotive sector transitions towards electric vehicles, the demand for lightweight materials, including LDPE, is expected to increase. This presents an opportunity for LDPE manufacturers to innovate and develop products that align with sustainability goals while meeting the performance requirements of the automotive industry.

In the agriculture sector, LDPE films are widely used for greenhouse coverings and mulching. The growing adoption of precision agriculture and the need for increased crop yields are driving demand in this segment. However, there is also increasing pressure to develop biodegradable alternatives, which could potentially impact LDPE's market share in this sector.

The packaging industry, which accounts for the largest share of LDPE consumption, is witnessing a shift towards more sustainable options. While this poses a threat to traditional LDPE products, it also creates opportunities for innovation in recyclable and bio-based LDPE formulations. Companies that can successfully develop and market these sustainable alternatives are likely to gain a competitive edge in the evolving market landscape.

In conclusion, the market demand for LDPE is at a critical juncture. While traditional applications continue to drive growth, the increasing focus on sustainability is reshaping market dynamics. The industry's ability to innovate and adapt to these changing demands will be crucial in determining the future trajectory of LDPE in the context of global sustainability initiatives.

Despite the push for sustainability, LDPE continues to maintain a strong presence in the packaging industry due to its versatility, cost-effectiveness, and performance characteristics. The global LDPE market size was valued at over $33 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of 3.5% from 2021 to 2028. This growth is primarily driven by the increasing demand for flexible packaging in food and beverage, personal care, and pharmaceutical industries.

However, the market dynamics are evolving rapidly. There is a growing demand for recycled LDPE as companies strive to meet their sustainability goals and comply with increasingly stringent regulations. The recycled LDPE market is expected to witness substantial growth, with some estimates suggesting a CAGR of over 6% in the coming years. This trend is particularly pronounced in regions with advanced recycling infrastructure and strong environmental policies, such as Europe and North America.

The automotive industry represents another significant market for LDPE, particularly in the production of lightweight components to improve fuel efficiency. As the automotive sector transitions towards electric vehicles, the demand for lightweight materials, including LDPE, is expected to increase. This presents an opportunity for LDPE manufacturers to innovate and develop products that align with sustainability goals while meeting the performance requirements of the automotive industry.

In the agriculture sector, LDPE films are widely used for greenhouse coverings and mulching. The growing adoption of precision agriculture and the need for increased crop yields are driving demand in this segment. However, there is also increasing pressure to develop biodegradable alternatives, which could potentially impact LDPE's market share in this sector.

The packaging industry, which accounts for the largest share of LDPE consumption, is witnessing a shift towards more sustainable options. While this poses a threat to traditional LDPE products, it also creates opportunities for innovation in recyclable and bio-based LDPE formulations. Companies that can successfully develop and market these sustainable alternatives are likely to gain a competitive edge in the evolving market landscape.

In conclusion, the market demand for LDPE is at a critical juncture. While traditional applications continue to drive growth, the increasing focus on sustainability is reshaping market dynamics. The industry's ability to innovate and adapt to these changing demands will be crucial in determining the future trajectory of LDPE in the context of global sustainability initiatives.

LDPE Technical Challenges

Low-density polyethylene (LDPE) faces several technical challenges in the context of sustainability initiatives. One of the primary issues is its limited recyclability. While LDPE is theoretically recyclable, the process is often complicated by contamination and the presence of additives, which can compromise the quality of the recycled material. This leads to a significant portion of LDPE waste ending up in landfills or incineration facilities, contributing to environmental pollution.

Another major challenge is the energy-intensive production process of LDPE. The traditional manufacturing methods require high temperatures and pressures, resulting in substantial carbon emissions. This energy consumption contradicts sustainability goals and efforts to reduce greenhouse gas emissions in industrial processes. The industry is under pressure to develop more energy-efficient production techniques that maintain the desirable properties of LDPE while minimizing environmental impact.

The durability of LDPE, while beneficial for many applications, poses a significant environmental challenge. Its resistance to degradation means that LDPE products persist in the environment for hundreds of years, contributing to long-term pollution, particularly in marine ecosystems. This persistence has led to increasing concerns about microplastic pollution, as LDPE breaks down into smaller particles over time without fully decomposing.

Furthermore, the petrochemical origin of LDPE raises sustainability concerns. As a product derived from non-renewable fossil fuels, LDPE production is inherently linked to the depletion of finite resources and the environmental impacts associated with oil extraction and refining. This dependency on fossil fuels conflicts with global efforts to transition towards renewable and sustainable material sources.

The additives used in LDPE production to enhance its properties also present technical challenges in terms of sustainability. Many of these additives, such as plasticizers and stabilizers, can be harmful to the environment and human health. Developing safer, bio-based alternatives that maintain the desired material properties while reducing environmental and health risks is a significant technical hurdle.

Lastly, the widespread use of LDPE in single-use packaging applications exacerbates its environmental impact. The convenience and low cost of LDPE packaging have led to its overuse, contributing significantly to plastic waste accumulation. Developing viable, eco-friendly alternatives that match the performance and cost-effectiveness of LDPE for packaging applications remains a substantial technical challenge in the pursuit of sustainability.

Another major challenge is the energy-intensive production process of LDPE. The traditional manufacturing methods require high temperatures and pressures, resulting in substantial carbon emissions. This energy consumption contradicts sustainability goals and efforts to reduce greenhouse gas emissions in industrial processes. The industry is under pressure to develop more energy-efficient production techniques that maintain the desirable properties of LDPE while minimizing environmental impact.

The durability of LDPE, while beneficial for many applications, poses a significant environmental challenge. Its resistance to degradation means that LDPE products persist in the environment for hundreds of years, contributing to long-term pollution, particularly in marine ecosystems. This persistence has led to increasing concerns about microplastic pollution, as LDPE breaks down into smaller particles over time without fully decomposing.

Furthermore, the petrochemical origin of LDPE raises sustainability concerns. As a product derived from non-renewable fossil fuels, LDPE production is inherently linked to the depletion of finite resources and the environmental impacts associated with oil extraction and refining. This dependency on fossil fuels conflicts with global efforts to transition towards renewable and sustainable material sources.

The additives used in LDPE production to enhance its properties also present technical challenges in terms of sustainability. Many of these additives, such as plasticizers and stabilizers, can be harmful to the environment and human health. Developing safer, bio-based alternatives that maintain the desired material properties while reducing environmental and health risks is a significant technical hurdle.

Lastly, the widespread use of LDPE in single-use packaging applications exacerbates its environmental impact. The convenience and low cost of LDPE packaging have led to its overuse, contributing significantly to plastic waste accumulation. Developing viable, eco-friendly alternatives that match the performance and cost-effectiveness of LDPE for packaging applications remains a substantial technical challenge in the pursuit of sustainability.

Current LDPE Solutions

01 Impact resistance of LDPE blends

Low-density polyethylene (LDPE) can be blended with other materials to improve its impact resistance. These blends often incorporate elastomers or other polymers to enhance the overall toughness and durability of the resulting material. The specific composition and processing methods of these blends can be tailored to achieve desired impact properties for various applications.- Impact resistance of LDPE blends: Low-density polyethylene (LDPE) can be blended with other materials to improve its impact resistance. These blends often incorporate elastomers or other polymers to enhance the toughness and durability of the resulting material. The specific composition and processing methods of these blends can be tailored to achieve desired impact properties for various applications.

- Environmental impact of LDPE: The environmental impact of LDPE is a significant concern due to its widespread use and persistence in the environment. Research focuses on developing biodegradable alternatives, improving recycling processes, and reducing the carbon footprint associated with LDPE production. Efforts are also being made to create more sustainable packaging solutions using LDPE or its alternatives.

- LDPE foam applications: LDPE foams are utilized in various applications due to their low density, flexibility, and impact absorption properties. These foams are particularly useful in packaging, insulation, and cushioning materials. Research in this area focuses on improving the foam structure, enhancing thermal and acoustic insulation properties, and developing new manufacturing techniques for LDPE foams.

- LDPE film properties and applications: LDPE films are widely used in packaging and agricultural applications due to their flexibility, transparency, and moisture resistance. Research in this area focuses on improving the mechanical properties, barrier characteristics, and processability of LDPE films. This includes the development of multi-layer films, incorporation of additives, and modification of film surface properties for specific applications.

- LDPE modification techniques: Various modification techniques are employed to enhance the properties of LDPE for specific applications. These include chemical modification, crosslinking, and the incorporation of nanofillers or other additives. Such modifications can improve the mechanical strength, thermal stability, and chemical resistance of LDPE, expanding its range of applications in industries such as automotive, construction, and electronics.

02 Environmental impact of LDPE

The environmental impact of LDPE is a significant concern due to its widespread use and persistence in the environment. Research focuses on developing biodegradable alternatives, improving recycling processes, and reducing the carbon footprint associated with LDPE production. Efforts are also being made to create more sustainable packaging solutions using LDPE or its alternatives.Expand Specific Solutions03 LDPE foam applications

LDPE foams are utilized in various applications due to their lightweight nature and impact absorption properties. These foams are particularly useful in packaging, insulation, and cushioning materials. Research in this area focuses on improving the foam structure, enhancing impact resistance, and developing new manufacturing techniques to expand the range of applications.Expand Specific Solutions04 LDPE film impact properties

LDPE films are widely used in packaging and agricultural applications. Improving the impact strength of these films is crucial for enhancing their durability and performance. Research in this area includes modifying the molecular structure of LDPE, incorporating additives, and developing new processing techniques to produce films with superior impact resistance.Expand Specific Solutions05 Recycling and upcycling of LDPE

The recycling and upcycling of LDPE waste is an important area of research aimed at reducing environmental impact. This includes developing more efficient recycling processes, finding new applications for recycled LDPE, and creating value-added products from waste materials. Efforts are also being made to improve the properties of recycled LDPE to make it suitable for a wider range of applications.Expand Specific Solutions

Key Industry Players

The market for Low-Density Polyethylene (LDPE) in sustainability initiatives is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The global LDPE market size is projected to reach significant volumes, with major players like Dow Global Technologies, ExxonMobil Chemical, and LyondellBasell Industries leading the way. Technologically, LDPE is mature but evolving, with companies like Braskem and Borealis AG focusing on bio-based and recycled LDPE innovations. Chinese firms such as Kingfa Sci. & Tech. and Sinopec are also making strides in sustainable LDPE solutions, indicating a competitive and globally diverse landscape.

Dow Global Technologies LLC

Technical Solution: Dow has developed ELITE™ Enhanced Polyethylene (EPE) resins, which offer improved sustainability performance compared to traditional LDPE. These resins are designed to reduce material usage while maintaining or enhancing product performance. Dow's INNATE™ Precision Packaging Resins, derived from their proprietary INSITE™ technology, provide up to 30% thinner packaging films[1], contributing to reduced plastic waste. Additionally, Dow has introduced AGILITY™ CE, a circular economy-based resin containing up to 70% post-consumer recycled (PCR) content[2], addressing the growing demand for recycled plastics in packaging applications.

Strengths: Advanced polymer science capabilities, wide range of sustainable solutions, strong market presence. Weaknesses: Dependence on fossil-based feedstocks, potential regulatory challenges in some markets.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed Exceed™ XP performance polymers, which enable the production of thinner, stronger films that use less material while maintaining performance. Their Vistamaxx™ performance polymers allow for the incorporation of recycled content in various applications, improving overall sustainability. ExxonMobil's advanced catalyst and process technology has led to the creation of Exceed™ S performance polyethylene, which offers up to 35% thinner packaging solutions[3]. The company has also invested in advanced recycling technologies, aiming to recycle 500,000 metric tons of plastic waste annually by 2026[4], demonstrating a commitment to circular economy principles.

Strengths: Extensive R&D capabilities, global scale, integrated operations. Weaknesses: Historical focus on traditional petrochemicals, potential public perception challenges regarding environmental impact.

LDPE Innovation Analysis

Composition for use in rotational moulding processes and use of the composition

PatentWO2019126845A1

Innovation

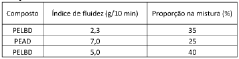

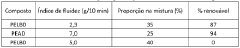

- A composition comprising a mixture of linear low-density polyethylene (LLDPE), high-density polyethylene (HDPE), and low-density polyethylene (LDPE) with specific fluidity and density ranges, sourced from renewable materials like starch, cellulose, and glycerol, allowing for customizable physical and mechanical properties.

High-strength and high-stability wood-plastic composite board and manufacturing method thereof

PatentActiveCN110126052A

Innovation

- By optimizing the proportion of material components and hot-pressing molding process parameters, a combination of pine wood powder, fir wood powder, poplar wood powder, linear low-density polyethylene, titanium dioxide, zinc stearate and melamine formaldehyde resin was used, and during the hot-pressing process Control the temperature and pressure curve, including the initial heating, constant temperature and cooling stages, as well as the initial pressure increase, pressure regulation and pressure reduction stages, combined with the mold opening and deflation operation to ensure uniform fusion and stress relief of materials.

Environmental Regulations

Environmental regulations play a crucial role in shaping the sustainability initiatives surrounding Low-Density Polyethylene (LDPE) usage. These regulations are designed to mitigate the environmental impact of plastic production, consumption, and disposal. In recent years, governments worldwide have implemented increasingly stringent measures to address the growing concerns about plastic pollution and its effects on ecosystems.

One of the primary focuses of environmental regulations concerning LDPE is the reduction of single-use plastic products. Many countries have introduced bans or restrictions on items such as plastic bags, straws, and packaging materials made from LDPE. These regulations aim to encourage the use of more sustainable alternatives and promote a circular economy approach to plastic management.

Extended Producer Responsibility (EPR) schemes have also been adopted in various jurisdictions. These regulations require manufacturers and retailers to take responsibility for the entire lifecycle of their LDPE products, including collection, recycling, and disposal. EPR schemes incentivize companies to design products with improved recyclability and to invest in recycling infrastructure.

Recycling targets and standards have been established to increase the recovery and reuse of LDPE materials. These regulations often set minimum recycled content requirements for certain products and packaging, driving demand for recycled LDPE and supporting the development of more efficient recycling technologies.

Waste management regulations have been updated to address the specific challenges posed by LDPE and other plastic materials. These include requirements for improved sorting and collection systems, as well as restrictions on landfilling and incineration of recyclable plastics. Some countries have implemented deposit-return schemes for plastic containers to encourage higher recycling rates.

Carbon pricing mechanisms and emissions trading systems are increasingly being applied to the plastics industry, including LDPE production. These regulations aim to internalize the environmental costs associated with greenhouse gas emissions and incentivize the adoption of cleaner production processes and more sustainable materials.

International agreements and conventions, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, have been amended to include plastic waste. These global regulations aim to reduce the export of plastic waste to countries with less stringent environmental standards and promote domestic recycling and waste management solutions.

As environmental regulations continue to evolve, they are likely to have a significant impact on the LDPE industry and related sustainability initiatives. Companies will need to adapt their production processes, product designs, and business models to comply with these regulations and meet the growing demand for more environmentally friendly alternatives to traditional LDPE products.

One of the primary focuses of environmental regulations concerning LDPE is the reduction of single-use plastic products. Many countries have introduced bans or restrictions on items such as plastic bags, straws, and packaging materials made from LDPE. These regulations aim to encourage the use of more sustainable alternatives and promote a circular economy approach to plastic management.

Extended Producer Responsibility (EPR) schemes have also been adopted in various jurisdictions. These regulations require manufacturers and retailers to take responsibility for the entire lifecycle of their LDPE products, including collection, recycling, and disposal. EPR schemes incentivize companies to design products with improved recyclability and to invest in recycling infrastructure.

Recycling targets and standards have been established to increase the recovery and reuse of LDPE materials. These regulations often set minimum recycled content requirements for certain products and packaging, driving demand for recycled LDPE and supporting the development of more efficient recycling technologies.

Waste management regulations have been updated to address the specific challenges posed by LDPE and other plastic materials. These include requirements for improved sorting and collection systems, as well as restrictions on landfilling and incineration of recyclable plastics. Some countries have implemented deposit-return schemes for plastic containers to encourage higher recycling rates.

Carbon pricing mechanisms and emissions trading systems are increasingly being applied to the plastics industry, including LDPE production. These regulations aim to internalize the environmental costs associated with greenhouse gas emissions and incentivize the adoption of cleaner production processes and more sustainable materials.

International agreements and conventions, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, have been amended to include plastic waste. These global regulations aim to reduce the export of plastic waste to countries with less stringent environmental standards and promote domestic recycling and waste management solutions.

As environmental regulations continue to evolve, they are likely to have a significant impact on the LDPE industry and related sustainability initiatives. Companies will need to adapt their production processes, product designs, and business models to comply with these regulations and meet the growing demand for more environmentally friendly alternatives to traditional LDPE products.

Circular Economy Impact

The impact of Low-Density Polyethylene (LDPE) on circular economy initiatives is significant and multifaceted. LDPE, a widely used plastic material, presents both challenges and opportunities in the context of sustainability and circular economy principles.

LDPE's durability and versatility have made it a popular choice in various industries, particularly in packaging. However, this durability becomes problematic when considering end-of-life scenarios. The material's resistance to degradation contributes to long-lasting environmental pollution, especially in marine ecosystems. This persistence challenges the core principles of circular economy, which aim to eliminate waste and maximize resource efficiency.

Despite these challenges, LDPE has potential within circular economy models. Recycling technologies for LDPE have advanced significantly, allowing for the material to be reprocessed multiple times without substantial loss of quality. This aligns with the circular economy's emphasis on keeping materials in use for as long as possible. Innovative recycling methods, such as chemical recycling, offer promising avenues for transforming LDPE waste into valuable raw materials for new products.

The circular economy impact of LDPE extends beyond recycling. Design for recyclability has become a key focus, with manufacturers developing LDPE products that are easier to collect, sort, and recycle. This shift in product design philosophy supports the transition towards a more circular plastics economy.

LDPE's lightweight nature contributes to reduced transportation emissions, aligning with circular economy goals of minimizing environmental impact across the product lifecycle. However, this benefit must be balanced against the material's end-of-life challenges.

The circular economy also emphasizes the importance of reducing material use. In this context, LDPE's efficiency in providing protective packaging with minimal material input is noteworthy. Innovations in LDPE film technology have led to thinner, yet equally effective packaging solutions, supporting resource efficiency principles.

Efforts to incorporate recycled LDPE into new products are gaining traction, creating closed-loop systems that exemplify circular economy ideals. This not only reduces the demand for virgin LDPE but also creates market incentives for plastic waste collection and recycling.

However, the successful integration of LDPE into circular economy models requires systemic changes. Improved waste collection infrastructure, consumer education on proper disposal, and policy support for recycling initiatives are crucial. Extended Producer Responsibility (EPR) schemes are emerging as a potential solution, encouraging manufacturers to take responsibility for the entire lifecycle of their LDPE products.

LDPE's durability and versatility have made it a popular choice in various industries, particularly in packaging. However, this durability becomes problematic when considering end-of-life scenarios. The material's resistance to degradation contributes to long-lasting environmental pollution, especially in marine ecosystems. This persistence challenges the core principles of circular economy, which aim to eliminate waste and maximize resource efficiency.

Despite these challenges, LDPE has potential within circular economy models. Recycling technologies for LDPE have advanced significantly, allowing for the material to be reprocessed multiple times without substantial loss of quality. This aligns with the circular economy's emphasis on keeping materials in use for as long as possible. Innovative recycling methods, such as chemical recycling, offer promising avenues for transforming LDPE waste into valuable raw materials for new products.

The circular economy impact of LDPE extends beyond recycling. Design for recyclability has become a key focus, with manufacturers developing LDPE products that are easier to collect, sort, and recycle. This shift in product design philosophy supports the transition towards a more circular plastics economy.

LDPE's lightweight nature contributes to reduced transportation emissions, aligning with circular economy goals of minimizing environmental impact across the product lifecycle. However, this benefit must be balanced against the material's end-of-life challenges.

The circular economy also emphasizes the importance of reducing material use. In this context, LDPE's efficiency in providing protective packaging with minimal material input is noteworthy. Innovations in LDPE film technology have led to thinner, yet equally effective packaging solutions, supporting resource efficiency principles.

Efforts to incorporate recycled LDPE into new products are gaining traction, creating closed-loop systems that exemplify circular economy ideals. This not only reduces the demand for virgin LDPE but also creates market incentives for plastic waste collection and recycling.

However, the successful integration of LDPE into circular economy models requires systemic changes. Improved waste collection infrastructure, consumer education on proper disposal, and policy support for recycling initiatives are crucial. Extended Producer Responsibility (EPR) schemes are emerging as a potential solution, encouraging manufacturers to take responsibility for the entire lifecycle of their LDPE products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!