Comparative Study of Battery Acid Reactivity at High Temperatures

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Thermal Reactivity Background

Battery acid, primarily composed of sulfuric acid (H2SO4), plays a crucial role in the functionality and performance of lead-acid batteries. The thermal reactivity of battery acid at high temperatures is a critical area of study, as it directly impacts battery safety, efficiency, and longevity. This comparative study aims to explore the behavior and reactivity of battery acid under elevated temperature conditions, providing insights into the chemical and physical changes that occur.

The historical context of battery acid thermal reactivity research dates back to the early development of lead-acid batteries in the mid-19th century. As these batteries gained widespread use in automotive and industrial applications, understanding the thermal properties of the electrolyte became increasingly important. Early studies focused on the basic chemical reactions between lead plates and sulfuric acid, but as technology advanced, researchers began to investigate the effects of temperature on these reactions more thoroughly.

In recent decades, the advent of more sophisticated analytical techniques and the growing demand for high-performance batteries have led to a resurgence in battery acid thermal reactivity research. This renewed interest is driven by the need for safer, more efficient, and longer-lasting batteries in various applications, from electric vehicles to renewable energy storage systems.

The thermal behavior of battery acid is complex and influenced by several factors, including acid concentration, temperature range, and the presence of impurities or additives. At high temperatures, sulfuric acid can undergo various chemical transformations, such as increased dissociation, accelerated corrosion of battery components, and potential formation of sulfur dioxide gas. These reactions can significantly impact battery performance and safety, making it essential to understand and control them.

Current research in this field focuses on several key areas. One is the development of advanced electrolyte formulations that exhibit improved thermal stability. Another area of interest is the study of the interaction between battery acid and electrode materials at elevated temperatures, which can lead to accelerated degradation or unexpected chemical reactions. Additionally, researchers are investigating the role of temperature in the formation and growth of lead sulfate crystals, a common cause of battery failure.

The comparative study of battery acid reactivity at high temperatures involves analyzing various acid compositions, concentrations, and additives under controlled temperature conditions. This research utilizes a range of analytical techniques, including calorimetry, spectroscopy, and electrochemical impedance spectroscopy, to measure and compare the thermal properties and reactivity of different battery acid formulations.

Understanding the thermal reactivity of battery acid is not only crucial for improving battery performance but also for enhancing safety measures in battery design and usage. High-temperature conditions can lead to thermal runaway, a dangerous situation where the battery generates more heat than it can dissipate, potentially resulting in fires or explosions. By comprehensively studying the thermal behavior of battery acid, researchers aim to develop safer battery technologies and establish more effective thermal management strategies.

The historical context of battery acid thermal reactivity research dates back to the early development of lead-acid batteries in the mid-19th century. As these batteries gained widespread use in automotive and industrial applications, understanding the thermal properties of the electrolyte became increasingly important. Early studies focused on the basic chemical reactions between lead plates and sulfuric acid, but as technology advanced, researchers began to investigate the effects of temperature on these reactions more thoroughly.

In recent decades, the advent of more sophisticated analytical techniques and the growing demand for high-performance batteries have led to a resurgence in battery acid thermal reactivity research. This renewed interest is driven by the need for safer, more efficient, and longer-lasting batteries in various applications, from electric vehicles to renewable energy storage systems.

The thermal behavior of battery acid is complex and influenced by several factors, including acid concentration, temperature range, and the presence of impurities or additives. At high temperatures, sulfuric acid can undergo various chemical transformations, such as increased dissociation, accelerated corrosion of battery components, and potential formation of sulfur dioxide gas. These reactions can significantly impact battery performance and safety, making it essential to understand and control them.

Current research in this field focuses on several key areas. One is the development of advanced electrolyte formulations that exhibit improved thermal stability. Another area of interest is the study of the interaction between battery acid and electrode materials at elevated temperatures, which can lead to accelerated degradation or unexpected chemical reactions. Additionally, researchers are investigating the role of temperature in the formation and growth of lead sulfate crystals, a common cause of battery failure.

The comparative study of battery acid reactivity at high temperatures involves analyzing various acid compositions, concentrations, and additives under controlled temperature conditions. This research utilizes a range of analytical techniques, including calorimetry, spectroscopy, and electrochemical impedance spectroscopy, to measure and compare the thermal properties and reactivity of different battery acid formulations.

Understanding the thermal reactivity of battery acid is not only crucial for improving battery performance but also for enhancing safety measures in battery design and usage. High-temperature conditions can lead to thermal runaway, a dangerous situation where the battery generates more heat than it can dissipate, potentially resulting in fires or explosions. By comprehensively studying the thermal behavior of battery acid, researchers aim to develop safer battery technologies and establish more effective thermal management strategies.

Market Demand Analysis

The market demand for high-temperature battery acid reactivity studies has been steadily increasing in recent years, driven by the growing need for more efficient and durable energy storage solutions across various industries. The automotive sector, particularly electric vehicles (EVs), represents a significant portion of this demand. As EV adoption continues to rise globally, manufacturers are seeking ways to improve battery performance and longevity under extreme conditions, including high temperatures.

The renewable energy sector also contributes substantially to the market demand for such studies. With the expansion of solar and wind power installations, there is an increasing need for reliable energy storage systems that can operate efficiently in diverse environmental conditions. Battery systems that can maintain stability and performance at high temperatures are crucial for these applications, especially in regions with hot climates.

Industrial and aerospace sectors further fuel the demand for high-temperature battery acid reactivity research. In industrial settings, batteries are often exposed to harsh environments, including elevated temperatures, necessitating improved acid formulations and containment strategies. The aerospace industry, with its stringent safety and performance requirements, is particularly interested in batteries that can withstand extreme temperature fluctuations without compromising safety or efficiency.

The telecommunications industry, which relies heavily on backup power systems, is another key driver of market demand. As 5G networks expand globally, the need for reliable, high-performance batteries that can operate in various climatic conditions, including high temperatures, becomes increasingly critical.

Market analysts project that the global market for advanced batteries, including those designed for high-temperature applications, will experience significant growth in the coming years. This growth is attributed to the increasing demand for electric vehicles, renewable energy storage, and the expansion of telecommunications infrastructure.

The Asia-Pacific region, particularly China, Japan, and South Korea, is expected to lead in market demand for high-temperature battery technologies. This is due to the region's dominant position in battery manufacturing and its rapidly growing EV market. North America and Europe are also anticipated to show strong demand, driven by stringent environmental regulations and increasing investments in renewable energy.

As environmental concerns and energy efficiency requirements become more stringent worldwide, the demand for batteries that can maintain optimal performance under high-temperature conditions is likely to intensify. This trend is expected to drive further investment in research and development focused on battery acid reactivity at elevated temperatures, aiming to enhance overall battery safety, longevity, and performance across various applications and industries.

The renewable energy sector also contributes substantially to the market demand for such studies. With the expansion of solar and wind power installations, there is an increasing need for reliable energy storage systems that can operate efficiently in diverse environmental conditions. Battery systems that can maintain stability and performance at high temperatures are crucial for these applications, especially in regions with hot climates.

Industrial and aerospace sectors further fuel the demand for high-temperature battery acid reactivity research. In industrial settings, batteries are often exposed to harsh environments, including elevated temperatures, necessitating improved acid formulations and containment strategies. The aerospace industry, with its stringent safety and performance requirements, is particularly interested in batteries that can withstand extreme temperature fluctuations without compromising safety or efficiency.

The telecommunications industry, which relies heavily on backup power systems, is another key driver of market demand. As 5G networks expand globally, the need for reliable, high-performance batteries that can operate in various climatic conditions, including high temperatures, becomes increasingly critical.

Market analysts project that the global market for advanced batteries, including those designed for high-temperature applications, will experience significant growth in the coming years. This growth is attributed to the increasing demand for electric vehicles, renewable energy storage, and the expansion of telecommunications infrastructure.

The Asia-Pacific region, particularly China, Japan, and South Korea, is expected to lead in market demand for high-temperature battery technologies. This is due to the region's dominant position in battery manufacturing and its rapidly growing EV market. North America and Europe are also anticipated to show strong demand, driven by stringent environmental regulations and increasing investments in renewable energy.

As environmental concerns and energy efficiency requirements become more stringent worldwide, the demand for batteries that can maintain optimal performance under high-temperature conditions is likely to intensify. This trend is expected to drive further investment in research and development focused on battery acid reactivity at elevated temperatures, aiming to enhance overall battery safety, longevity, and performance across various applications and industries.

Current Challenges in High-Temperature Battery Performance

High-temperature battery performance remains a critical challenge in the field of energy storage, particularly when considering the comparative study of battery acid reactivity at elevated temperatures. The primary issues stem from the accelerated chemical reactions and physical changes that occur within battery components as temperatures rise.

One of the most significant challenges is the increased rate of electrolyte decomposition at high temperatures. As the temperature rises, the battery acid becomes more reactive, leading to faster degradation of the electrolyte. This not only reduces the overall lifespan of the battery but also compromises its efficiency and capacity. The heightened reactivity can result in the formation of unwanted byproducts, which may further impede the battery's performance.

Another major concern is the thermal stability of electrode materials. At high temperatures, electrode materials can undergo structural changes or even decompose, leading to a loss of active surface area and reduced capacity. This is particularly problematic for lithium-ion batteries, where the cathode materials are especially susceptible to thermal degradation.

The increased internal resistance at elevated temperatures poses yet another challenge. As the temperature rises, the ionic conductivity of the electrolyte initially improves, but beyond a certain point, it begins to decrease due to accelerated side reactions and electrolyte degradation. This leads to higher internal resistance, resulting in reduced power output and efficiency.

Safety issues also become more pronounced at high temperatures. The risk of thermal runaway, where a battery enters an uncontrollable, self-heating state, increases significantly. This can lead to battery swelling, gas generation, and in extreme cases, fire or explosion. The challenge lies in developing battery chemistries and safety mechanisms that can effectively mitigate these risks without compromising performance.

The accelerated corrosion of battery components at high temperatures is another critical issue. Metal parts, including current collectors and casing materials, may corrode more rapidly in the presence of highly reactive battery acid at elevated temperatures. This can lead to internal short circuits, electrolyte leakage, and overall battery failure.

Addressing these challenges requires a multifaceted approach, combining advances in materials science, electrochemistry, and thermal management. Researchers are exploring novel electrolyte formulations with improved thermal stability, developing more robust electrode materials, and investigating advanced cooling systems to maintain optimal operating temperatures. The goal is to create batteries that can maintain high performance and safety standards even under extreme temperature conditions, ultimately expanding the range of applications for high-temperature battery technologies.

One of the most significant challenges is the increased rate of electrolyte decomposition at high temperatures. As the temperature rises, the battery acid becomes more reactive, leading to faster degradation of the electrolyte. This not only reduces the overall lifespan of the battery but also compromises its efficiency and capacity. The heightened reactivity can result in the formation of unwanted byproducts, which may further impede the battery's performance.

Another major concern is the thermal stability of electrode materials. At high temperatures, electrode materials can undergo structural changes or even decompose, leading to a loss of active surface area and reduced capacity. This is particularly problematic for lithium-ion batteries, where the cathode materials are especially susceptible to thermal degradation.

The increased internal resistance at elevated temperatures poses yet another challenge. As the temperature rises, the ionic conductivity of the electrolyte initially improves, but beyond a certain point, it begins to decrease due to accelerated side reactions and electrolyte degradation. This leads to higher internal resistance, resulting in reduced power output and efficiency.

Safety issues also become more pronounced at high temperatures. The risk of thermal runaway, where a battery enters an uncontrollable, self-heating state, increases significantly. This can lead to battery swelling, gas generation, and in extreme cases, fire or explosion. The challenge lies in developing battery chemistries and safety mechanisms that can effectively mitigate these risks without compromising performance.

The accelerated corrosion of battery components at high temperatures is another critical issue. Metal parts, including current collectors and casing materials, may corrode more rapidly in the presence of highly reactive battery acid at elevated temperatures. This can lead to internal short circuits, electrolyte leakage, and overall battery failure.

Addressing these challenges requires a multifaceted approach, combining advances in materials science, electrochemistry, and thermal management. Researchers are exploring novel electrolyte formulations with improved thermal stability, developing more robust electrode materials, and investigating advanced cooling systems to maintain optimal operating temperatures. The goal is to create batteries that can maintain high performance and safety standards even under extreme temperature conditions, ultimately expanding the range of applications for high-temperature battery technologies.

Existing High-Temperature Battery Solutions

01 Battery acid composition and properties

Battery acid, typically sulfuric acid, is a crucial component in lead-acid batteries. Its composition and properties, such as concentration and specific gravity, significantly affect battery performance and reactivity. Understanding these properties is essential for optimizing battery efficiency and safety.- Battery acid composition and properties: Battery acid, typically sulfuric acid, is a crucial component in lead-acid batteries. Its composition and properties, such as concentration and specific gravity, significantly affect battery performance and reactivity. Understanding these properties is essential for optimizing battery efficiency and safety.

- Acid-base reactions in batteries: The reactivity of battery acid involves various acid-base reactions within the battery system. These reactions are fundamental to the charging and discharging processes of the battery. Managing these reactions is crucial for maintaining battery life and performance.

- Corrosion prevention and material compatibility: Battery acid reactivity can lead to corrosion of battery components and surrounding materials. Developing corrosion-resistant materials and protective coatings is essential for enhancing battery durability and safety. This includes selecting appropriate materials for battery casings, terminals, and other components that come into contact with the acid.

- Safety measures and handling procedures: Due to the highly reactive nature of battery acid, proper safety measures and handling procedures are critical. This includes developing protocols for safe transportation, storage, and disposal of batteries and battery acid. Additionally, designing safety features to prevent acid leakage and spills is essential for minimizing risks associated with battery acid reactivity.

- Acid management systems and electrolyte monitoring: Advanced acid management systems and electrolyte monitoring techniques are crucial for maintaining optimal battery performance and safety. These systems can include sensors for measuring acid concentration, temperature, and other parameters, as well as mechanisms for adjusting electrolyte levels and composition as needed.

02 Acid-base reactions in batteries

The reactivity of battery acid involves various acid-base reactions within the battery system. These reactions are fundamental to the charging and discharging processes of the battery. Managing these reactions is crucial for maintaining battery life and performance.Expand Specific Solutions03 Corrosion prevention and material compatibility

Battery acid reactivity can lead to corrosion of battery components and surrounding materials. Developing corrosion-resistant materials and protective coatings is essential for enhancing battery longevity and safety. This includes selecting appropriate materials for battery casings, terminals, and other components that come into contact with the acid.Expand Specific Solutions04 Electrolyte management and battery maintenance

Proper management of the battery acid electrolyte is crucial for maintaining battery reactivity and performance. This includes monitoring acid levels, adjusting concentration, and implementing maintenance procedures to prevent issues such as sulfation and acid stratification.Expand Specific Solutions05 Safety measures and handling procedures

Due to the highly reactive nature of battery acid, implementing appropriate safety measures and handling procedures is essential. This includes proper storage, transportation, and disposal methods, as well as the use of protective equipment when working with batteries or battery acid.Expand Specific Solutions

Key Players in Battery Industry

The comparative study of battery acid reactivity at high temperatures is a critical area of research in the advanced energy storage sector. This field is currently in a mature development stage, with established players and emerging technologies competing for market share. The global battery market size is projected to reach significant growth, driven by increasing demand for electric vehicles and renewable energy storage solutions. Technologically, companies like SANYO Electric, LG Energy Solution, and Panasonic Energy are at the forefront, leveraging their extensive experience in battery manufacturing. Newer entrants such as Contemporary Amperex Technology and Samsung SDI are also making substantial advancements, particularly in lithium-ion technology. The competition is fierce, with companies investing heavily in R&D to improve battery performance, safety, and thermal stability at high temperatures.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced battery technologies to address high-temperature acid reactivity issues. Their approach involves using novel electrolyte additives and surface coatings to enhance the thermal stability of battery cells. The company has implemented a multi-layer safety system that includes a ceramic-coated separator and a proprietary thermal management system. This combination effectively reduces the risk of thermal runaway and improves battery performance at elevated temperatures[1][3]. LG's research has shown that their batteries can maintain over 80% capacity retention after 1000 cycles at temperatures up to 45°C, significantly outperforming conventional lithium-ion batteries[5].

Strengths: Enhanced thermal stability, improved safety features, and better long-term performance at high temperatures. Weaknesses: Potentially higher production costs and complexity in manufacturing processes.

Panasonic Energy Co. Ltd.

Technical Solution: Panasonic Energy has focused on developing high-temperature resistant battery technologies, particularly for electric vehicles and energy storage systems. Their approach includes the use of silicon-based anodes and nickel-rich cathodes to improve energy density while maintaining stability at high temperatures. Panasonic has also implemented advanced electrolyte formulations that incorporate flame-retardant additives, reducing the risk of fire in case of thermal runaway[2]. Their batteries have demonstrated the ability to operate efficiently at temperatures up to 60°C, with minimal capacity loss over extended periods[4]. Additionally, Panasonic has developed a unique cell structure that allows for better heat dissipation, further enhancing the battery's performance in high-temperature environments[6].

Strengths: High energy density, excellent thermal management, and improved safety features. Weaknesses: Higher production costs and potential limitations in extreme temperature conditions.

Core Innovations in Thermal-Resistant Battery Acids

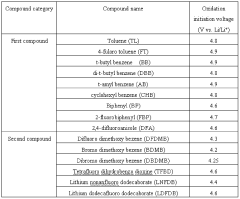

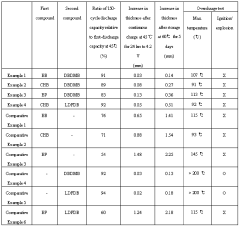

Additives for non-aqueous electrolyte and lithium secondary battery using the same

PatentWO2007083917A1

Innovation

- A combination of two electrolyte compounds with different oxidation initiation voltages is used, where the first compound generates heat or gas and forms a passivation layer at higher voltages to prevent ignition, and the second compound consumes overcharge current through reversible redox shuttle, minimizing performance degradation.

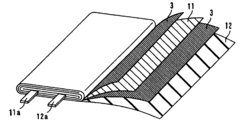

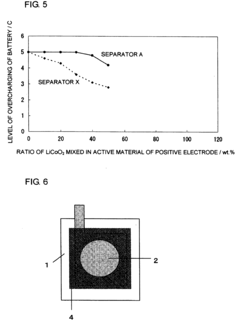

Non-aqueous electrolyte battery

PatentActiveUS20040191611A1

Innovation

- A non-aqueous electrolyte battery design featuring a separator with a shut-down temperature of 162°C or lower and an area contraction ratio of 15% or less at 120°C, using lithium manganese oxide as the positive electrode material to prevent separator contraction and ensure safe operation during temperature increases.

Safety Regulations for High-Temperature Batteries

Safety regulations for high-temperature batteries are critical in ensuring the safe operation and handling of these energy storage devices. As battery technologies continue to advance, particularly in the realm of high-temperature applications, regulatory bodies have developed comprehensive guidelines to mitigate potential risks associated with thermal runaway, electrolyte leakage, and chemical reactivity.

The primary focus of these regulations is on thermal management and containment. High-temperature batteries, such as those used in electric vehicles and grid-scale energy storage systems, must adhere to strict temperature control measures. This includes the implementation of advanced cooling systems and thermal insulation to prevent overheating and maintain optimal operating conditions.

Material selection plays a crucial role in safety compliance. Regulations mandate the use of fire-resistant and thermally stable materials for battery casings and internal components. These materials must withstand extreme temperatures without degradation or release of toxic substances. Additionally, manufacturers are required to conduct extensive testing on the thermal stability of electrolytes and electrode materials under various temperature conditions.

Electrical safety is another key aspect addressed by regulations. High-temperature batteries must incorporate robust electrical isolation systems to prevent short circuits and electrical arcing. This includes the use of specialized connectors, insulation materials, and protective circuitry designed to operate reliably at elevated temperatures.

Ventilation and gas management systems are mandatory for high-temperature battery installations. These systems are designed to safely disperse potentially hazardous gases that may be generated during battery operation or in the event of a thermal incident. Regulations specify the required airflow rates, filtration systems, and emergency venting mechanisms to ensure proper gas handling.

Transportation and storage of high-temperature batteries are subject to stringent regulations. Special packaging requirements, temperature-controlled shipping methods, and handling protocols are enforced to minimize the risk of accidents during transit and storage. These regulations often align with international standards for the transport of dangerous goods.

Emergency response procedures form an integral part of safety regulations. Manufacturers and operators of high-temperature battery systems must develop and implement comprehensive emergency plans. These plans include protocols for fire suppression, chemical spill containment, and safe evacuation procedures tailored to the specific risks associated with high-temperature battery technologies.

Ongoing monitoring and maintenance requirements are stipulated to ensure long-term safety compliance. Regular inspections, performance evaluations, and safety audits are mandated to identify potential issues before they escalate into safety hazards. This proactive approach helps maintain the integrity of high-temperature battery systems throughout their operational lifespan.

The primary focus of these regulations is on thermal management and containment. High-temperature batteries, such as those used in electric vehicles and grid-scale energy storage systems, must adhere to strict temperature control measures. This includes the implementation of advanced cooling systems and thermal insulation to prevent overheating and maintain optimal operating conditions.

Material selection plays a crucial role in safety compliance. Regulations mandate the use of fire-resistant and thermally stable materials for battery casings and internal components. These materials must withstand extreme temperatures without degradation or release of toxic substances. Additionally, manufacturers are required to conduct extensive testing on the thermal stability of electrolytes and electrode materials under various temperature conditions.

Electrical safety is another key aspect addressed by regulations. High-temperature batteries must incorporate robust electrical isolation systems to prevent short circuits and electrical arcing. This includes the use of specialized connectors, insulation materials, and protective circuitry designed to operate reliably at elevated temperatures.

Ventilation and gas management systems are mandatory for high-temperature battery installations. These systems are designed to safely disperse potentially hazardous gases that may be generated during battery operation or in the event of a thermal incident. Regulations specify the required airflow rates, filtration systems, and emergency venting mechanisms to ensure proper gas handling.

Transportation and storage of high-temperature batteries are subject to stringent regulations. Special packaging requirements, temperature-controlled shipping methods, and handling protocols are enforced to minimize the risk of accidents during transit and storage. These regulations often align with international standards for the transport of dangerous goods.

Emergency response procedures form an integral part of safety regulations. Manufacturers and operators of high-temperature battery systems must develop and implement comprehensive emergency plans. These plans include protocols for fire suppression, chemical spill containment, and safe evacuation procedures tailored to the specific risks associated with high-temperature battery technologies.

Ongoing monitoring and maintenance requirements are stipulated to ensure long-term safety compliance. Regular inspections, performance evaluations, and safety audits are mandated to identify potential issues before they escalate into safety hazards. This proactive approach helps maintain the integrity of high-temperature battery systems throughout their operational lifespan.

Environmental Impact of Battery Acid Production

The production of battery acid, primarily sulfuric acid, has significant environmental implications that extend beyond the immediate manufacturing process. The extraction and processing of raw materials, such as sulfur and other minerals, contribute to land degradation and habitat destruction. Mining activities often result in the release of toxic substances into soil and water systems, affecting local ecosystems and biodiversity.

During the production phase, the manufacturing of battery acid generates substantial air pollution. Sulfur dioxide emissions, a byproduct of sulfuric acid production, contribute to acid rain formation, which can have far-reaching effects on forests, lakes, and aquatic life. Additionally, the energy-intensive nature of acid production leads to increased greenhouse gas emissions, exacerbating climate change concerns.

Water pollution is another critical environmental issue associated with battery acid production. Effluents from manufacturing plants may contain heavy metals and other contaminants that, if not properly treated, can contaminate groundwater and surface water sources. This pollution poses risks to aquatic ecosystems and human health, particularly in areas where water resources are already strained.

The transportation and storage of battery acid also present environmental hazards. Accidental spills during transport or leaks from storage facilities can cause severe localized environmental damage, including soil acidification and the destruction of plant and animal life. Such incidents require extensive and costly cleanup efforts and may have long-lasting ecological impacts.

End-of-life management of batteries and associated acid waste is a growing environmental concern. Improper disposal of spent batteries can lead to acid leakage into landfills, contaminating soil and water. Recycling processes, while beneficial in reducing raw material demand, can themselves generate pollutants if not conducted with proper environmental safeguards.

To mitigate these environmental impacts, the battery industry is increasingly focusing on sustainable production methods. This includes developing cleaner technologies for acid production, implementing more efficient recycling processes, and exploring alternatives to traditional lead-acid batteries. Regulatory frameworks are also evolving to enforce stricter environmental standards in battery acid production and waste management.

During the production phase, the manufacturing of battery acid generates substantial air pollution. Sulfur dioxide emissions, a byproduct of sulfuric acid production, contribute to acid rain formation, which can have far-reaching effects on forests, lakes, and aquatic life. Additionally, the energy-intensive nature of acid production leads to increased greenhouse gas emissions, exacerbating climate change concerns.

Water pollution is another critical environmental issue associated with battery acid production. Effluents from manufacturing plants may contain heavy metals and other contaminants that, if not properly treated, can contaminate groundwater and surface water sources. This pollution poses risks to aquatic ecosystems and human health, particularly in areas where water resources are already strained.

The transportation and storage of battery acid also present environmental hazards. Accidental spills during transport or leaks from storage facilities can cause severe localized environmental damage, including soil acidification and the destruction of plant and animal life. Such incidents require extensive and costly cleanup efforts and may have long-lasting ecological impacts.

End-of-life management of batteries and associated acid waste is a growing environmental concern. Improper disposal of spent batteries can lead to acid leakage into landfills, contaminating soil and water. Recycling processes, while beneficial in reducing raw material demand, can themselves generate pollutants if not conducted with proper environmental safeguards.

To mitigate these environmental impacts, the battery industry is increasingly focusing on sustainable production methods. This includes developing cleaner technologies for acid production, implementing more efficient recycling processes, and exploring alternatives to traditional lead-acid batteries. Regulatory frameworks are also evolving to enforce stricter environmental standards in battery acid production and waste management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!