Battery Acid's Role in Hybrid Vehicle Energy Systems

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Evolution

Battery acid, primarily composed of sulfuric acid and water, has played a crucial role in the evolution of hybrid vehicle energy systems. The development of battery acid technology has been closely intertwined with the advancement of lead-acid batteries, which have been the foundation of automotive electrical systems for over a century.

In the early stages of hybrid vehicle development, traditional lead-acid batteries were used alongside internal combustion engines to provide electrical power. These batteries relied on the chemical reaction between lead plates and sulfuric acid to store and release energy. However, the limitations of conventional lead-acid batteries, such as their weight and limited energy density, prompted researchers to explore alternative battery chemistries and electrolyte compositions.

As hybrid vehicle technology progressed, the focus shifted towards improving the performance and efficiency of battery systems. This led to the development of advanced lead-acid battery designs, such as valve-regulated lead-acid (VRLA) batteries and absorbed glass mat (AGM) batteries. These innovations aimed to enhance the power density, cycle life, and charge acceptance of lead-acid batteries while minimizing maintenance requirements.

The evolution of battery acid formulations played a significant role in these advancements. Researchers experimented with different acid concentrations, additives, and electrolyte compositions to optimize battery performance. For instance, the introduction of carbon additives to the negative electrode improved charge acceptance and cycle life, while the use of silica-based gelling agents in VRLA batteries reduced acid stratification and improved overall battery longevity.

As hybrid vehicle technology continued to mature, the limitations of lead-acid batteries became more apparent. This led to the exploration of alternative battery chemistries, such as nickel-metal hydride (NiMH) and lithium-ion batteries. These newer technologies offered higher energy density, improved power-to-weight ratios, and longer cycle life compared to traditional lead-acid batteries.

Despite the shift towards more advanced battery technologies, the principles and lessons learned from battery acid evolution in lead-acid batteries have continued to influence the development of electrolytes and electrode materials in modern hybrid vehicle energy systems. The understanding of acid-base reactions, ion transport mechanisms, and electrode-electrolyte interfaces gained from years of research on lead-acid batteries has provided valuable insights for the design of next-generation energy storage solutions.

In recent years, there has been renewed interest in advanced lead-acid battery technologies for hybrid vehicles, particularly in mild hybrid applications. Innovations such as carbon-enhanced electrodes, bipolar designs, and advanced electrolyte formulations have breathed new life into lead-acid battery technology, demonstrating its continued relevance in the evolving landscape of hybrid vehicle energy systems.

In the early stages of hybrid vehicle development, traditional lead-acid batteries were used alongside internal combustion engines to provide electrical power. These batteries relied on the chemical reaction between lead plates and sulfuric acid to store and release energy. However, the limitations of conventional lead-acid batteries, such as their weight and limited energy density, prompted researchers to explore alternative battery chemistries and electrolyte compositions.

As hybrid vehicle technology progressed, the focus shifted towards improving the performance and efficiency of battery systems. This led to the development of advanced lead-acid battery designs, such as valve-regulated lead-acid (VRLA) batteries and absorbed glass mat (AGM) batteries. These innovations aimed to enhance the power density, cycle life, and charge acceptance of lead-acid batteries while minimizing maintenance requirements.

The evolution of battery acid formulations played a significant role in these advancements. Researchers experimented with different acid concentrations, additives, and electrolyte compositions to optimize battery performance. For instance, the introduction of carbon additives to the negative electrode improved charge acceptance and cycle life, while the use of silica-based gelling agents in VRLA batteries reduced acid stratification and improved overall battery longevity.

As hybrid vehicle technology continued to mature, the limitations of lead-acid batteries became more apparent. This led to the exploration of alternative battery chemistries, such as nickel-metal hydride (NiMH) and lithium-ion batteries. These newer technologies offered higher energy density, improved power-to-weight ratios, and longer cycle life compared to traditional lead-acid batteries.

Despite the shift towards more advanced battery technologies, the principles and lessons learned from battery acid evolution in lead-acid batteries have continued to influence the development of electrolytes and electrode materials in modern hybrid vehicle energy systems. The understanding of acid-base reactions, ion transport mechanisms, and electrode-electrolyte interfaces gained from years of research on lead-acid batteries has provided valuable insights for the design of next-generation energy storage solutions.

In recent years, there has been renewed interest in advanced lead-acid battery technologies for hybrid vehicles, particularly in mild hybrid applications. Innovations such as carbon-enhanced electrodes, bipolar designs, and advanced electrolyte formulations have breathed new life into lead-acid battery technology, demonstrating its continued relevance in the evolving landscape of hybrid vehicle energy systems.

Hybrid Vehicle Market

The hybrid vehicle market has experienced significant growth and transformation over the past decade, driven by increasing environmental concerns, stricter emissions regulations, and advancements in battery technology. As consumers become more environmentally conscious and governments worldwide implement stringent fuel efficiency standards, the demand for hybrid vehicles has surged across various segments, including passenger cars, SUVs, and commercial vehicles.

The global hybrid vehicle market size was valued at approximately $26 billion in 2020 and is projected to reach $92 billion by 2027, growing at a compound annual growth rate (CAGR) of around 19% during the forecast period. This robust growth is attributed to several factors, including improved fuel efficiency, reduced emissions, and government incentives promoting the adoption of eco-friendly vehicles.

In terms of regional distribution, Asia-Pacific dominates the hybrid vehicle market, with Japan and China leading in both production and consumption. The North American and European markets have also shown substantial growth, driven by stringent emission norms and increasing consumer awareness. Emerging economies in Latin America and Africa are expected to present significant growth opportunities in the coming years as infrastructure improves and environmental regulations tighten.

The passenger car segment currently holds the largest market share in the hybrid vehicle industry, followed by SUVs and light commercial vehicles. However, the commercial vehicle segment is anticipated to witness the highest growth rate in the coming years, as fleet operators seek to reduce operational costs and comply with emissions regulations.

Key players in the hybrid vehicle market include Toyota, Honda, Ford, Hyundai, and Volkswagen, among others. These companies are investing heavily in research and development to improve battery technology, enhance fuel efficiency, and reduce production costs. The market is also witnessing the entry of new players, particularly from emerging economies, intensifying competition and driving innovation.

Consumer preferences are shifting towards hybrid vehicles due to their lower running costs, reduced environmental impact, and improved performance compared to conventional internal combustion engine vehicles. Additionally, the availability of a wider range of hybrid models across different price points has made these vehicles more accessible to a broader consumer base.

Government initiatives and policies play a crucial role in shaping the hybrid vehicle market. Many countries offer tax incentives, subsidies, and other benefits to promote the adoption of hybrid vehicles. For instance, China's New Energy Vehicle (NEV) policy and the European Union's emissions targets have significantly boosted hybrid vehicle sales in their respective regions.

The global hybrid vehicle market size was valued at approximately $26 billion in 2020 and is projected to reach $92 billion by 2027, growing at a compound annual growth rate (CAGR) of around 19% during the forecast period. This robust growth is attributed to several factors, including improved fuel efficiency, reduced emissions, and government incentives promoting the adoption of eco-friendly vehicles.

In terms of regional distribution, Asia-Pacific dominates the hybrid vehicle market, with Japan and China leading in both production and consumption. The North American and European markets have also shown substantial growth, driven by stringent emission norms and increasing consumer awareness. Emerging economies in Latin America and Africa are expected to present significant growth opportunities in the coming years as infrastructure improves and environmental regulations tighten.

The passenger car segment currently holds the largest market share in the hybrid vehicle industry, followed by SUVs and light commercial vehicles. However, the commercial vehicle segment is anticipated to witness the highest growth rate in the coming years, as fleet operators seek to reduce operational costs and comply with emissions regulations.

Key players in the hybrid vehicle market include Toyota, Honda, Ford, Hyundai, and Volkswagen, among others. These companies are investing heavily in research and development to improve battery technology, enhance fuel efficiency, and reduce production costs. The market is also witnessing the entry of new players, particularly from emerging economies, intensifying competition and driving innovation.

Consumer preferences are shifting towards hybrid vehicles due to their lower running costs, reduced environmental impact, and improved performance compared to conventional internal combustion engine vehicles. Additionally, the availability of a wider range of hybrid models across different price points has made these vehicles more accessible to a broader consumer base.

Government initiatives and policies play a crucial role in shaping the hybrid vehicle market. Many countries offer tax incentives, subsidies, and other benefits to promote the adoption of hybrid vehicles. For instance, China's New Energy Vehicle (NEV) policy and the European Union's emissions targets have significantly boosted hybrid vehicle sales in their respective regions.

Acid Tech Challenges

The development of hybrid vehicle energy systems has brought significant advancements in automotive technology, but it also presents several challenges related to battery acid management. One of the primary concerns is the corrosive nature of battery acid, which can lead to degradation of various components within the energy system. This corrosion not only affects the battery itself but can also impact surrounding materials and electrical connections, potentially compromising the overall system integrity and performance.

Another critical challenge is maintaining the proper acid concentration within the battery. Hybrid vehicles often experience frequent charge-discharge cycles, which can lead to electrolyte imbalances. These imbalances may result in reduced battery efficiency and shortened lifespan. Additionally, temperature fluctuations during vehicle operation can cause changes in acid density, further complicating the maintenance of optimal battery conditions.

Safety concerns also pose significant challenges in acid-based hybrid vehicle energy systems. The potential for acid leaks or spills during maintenance or in the event of an accident presents risks to both human health and the environment. Developing robust containment systems and implementing stringent safety protocols are essential to mitigate these risks, but they add complexity and cost to vehicle design and manufacturing processes.

The weight of traditional lead-acid batteries used in hybrid systems is another obstacle. While these batteries are reliable and cost-effective, their high weight-to-energy ratio can negatively impact vehicle performance and fuel efficiency. This challenge has driven research into alternative battery technologies and lightweight materials that can withstand the corrosive effects of battery acid while maintaining structural integrity.

Recycling and disposal of acid-based batteries at the end of their lifecycle present environmental challenges. The toxic nature of battery acid requires specialized handling and processing facilities, which may not be readily available in all regions. Developing efficient and environmentally friendly recycling methods for these batteries is crucial for the sustainable growth of hybrid vehicle technology.

Lastly, the integration of acid-based batteries with other components of hybrid energy systems poses engineering challenges. Ensuring compatibility between the battery and power electronics, managing heat generation, and optimizing the overall system architecture to accommodate the unique characteristics of acid-based batteries require innovative design solutions and extensive testing.

Another critical challenge is maintaining the proper acid concentration within the battery. Hybrid vehicles often experience frequent charge-discharge cycles, which can lead to electrolyte imbalances. These imbalances may result in reduced battery efficiency and shortened lifespan. Additionally, temperature fluctuations during vehicle operation can cause changes in acid density, further complicating the maintenance of optimal battery conditions.

Safety concerns also pose significant challenges in acid-based hybrid vehicle energy systems. The potential for acid leaks or spills during maintenance or in the event of an accident presents risks to both human health and the environment. Developing robust containment systems and implementing stringent safety protocols are essential to mitigate these risks, but they add complexity and cost to vehicle design and manufacturing processes.

The weight of traditional lead-acid batteries used in hybrid systems is another obstacle. While these batteries are reliable and cost-effective, their high weight-to-energy ratio can negatively impact vehicle performance and fuel efficiency. This challenge has driven research into alternative battery technologies and lightweight materials that can withstand the corrosive effects of battery acid while maintaining structural integrity.

Recycling and disposal of acid-based batteries at the end of their lifecycle present environmental challenges. The toxic nature of battery acid requires specialized handling and processing facilities, which may not be readily available in all regions. Developing efficient and environmentally friendly recycling methods for these batteries is crucial for the sustainable growth of hybrid vehicle technology.

Lastly, the integration of acid-based batteries with other components of hybrid energy systems poses engineering challenges. Ensuring compatibility between the battery and power electronics, managing heat generation, and optimizing the overall system architecture to accommodate the unique characteristics of acid-based batteries require innovative design solutions and extensive testing.

Current Acid Solutions

01 Battery acid composition and management

This category focuses on the composition and management of battery acid, including its formulation, concentration control, and handling techniques. It covers aspects such as acid density regulation, electrolyte management, and safety measures for handling battery acid in various applications.- Battery acid composition and management: Battery acid, typically sulfuric acid, is a crucial component in lead-acid batteries. Its composition, concentration, and management are essential for optimal battery performance and longevity. Innovations in this area focus on improving acid formulations, controlling acid levels, and developing methods for acid circulation and maintenance.

- Battery charging and monitoring systems: Advanced charging and monitoring systems are developed to optimize battery performance and prevent acid-related issues. These systems may include intelligent charging algorithms, acid level sensors, and temperature monitoring to ensure proper acid distribution and prevent overcharging or undercharging, which can affect acid concentration and battery life.

- Acid circulation and electrolyte management: Innovations in acid circulation and electrolyte management aim to improve battery efficiency and lifespan. These may include pumping systems, electrolyte mixing techniques, and methods for maintaining proper acid stratification within the battery cells. Such systems can help prevent acid stratification and ensure uniform acid distribution.

- Battery acid safety and containment: Safety measures and containment systems are crucial in handling battery acid. Innovations in this area include improved acid-resistant materials, spill containment designs, and safety mechanisms to prevent acid leakage or exposure. These developments aim to enhance the overall safety of battery systems in various applications.

- Acid recovery and recycling systems: Environmental concerns have led to the development of acid recovery and recycling systems for batteries. These innovations focus on methods to extract, purify, and reuse battery acid, reducing waste and environmental impact. Such systems may include acid filtration, neutralization processes, and techniques for separating acid from other battery components.

02 Battery charging and monitoring systems

This point addresses systems and methods for charging batteries and monitoring their acid levels. It includes innovations in charging algorithms, state-of-charge estimation, and automated acid level detection to optimize battery performance and lifespan.Expand Specific Solutions03 Battery acid recycling and disposal

This category covers techniques for recycling and safely disposing of battery acid. It includes methods for neutralizing spent acid, recovering valuable materials, and implementing environmentally friendly disposal processes to minimize the environmental impact of battery waste.Expand Specific Solutions04 Battery acid-resistant materials and coatings

This point focuses on the development of materials and coatings that are resistant to battery acid corrosion. It includes innovations in protective layers, acid-resistant alloys, and surface treatments to enhance the durability of battery components and related equipment.Expand Specific Solutions05 Battery acid leak detection and prevention

This category addresses methods and systems for detecting and preventing battery acid leaks. It covers sensor technologies, containment strategies, and early warning systems designed to minimize the risk of acid spills and associated hazards in various battery applications.Expand Specific Solutions

Key Industry Players

The battery acid technology in hybrid vehicle energy systems is in a mature stage of development, with a competitive landscape shaped by established automotive manufacturers and specialized battery companies. The market size is substantial, driven by the growing demand for hybrid vehicles worldwide. Companies like Hyundai Motor Co., Toyota Motor Corp., and Ford Global Technologies LLC are leading players, leveraging their extensive automotive expertise. Specialized firms such as Energy Power Systems LLC and Furukawa Battery Co., Ltd. contribute significant innovations in battery technology. The industry is characterized by ongoing research and development efforts to improve battery performance, efficiency, and sustainability, with collaborations between automakers and battery manufacturers becoming increasingly common.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a cutting-edge hybrid vehicle energy system that maximizes the efficiency of battery acid usage. Their parallel hybrid system combines a gasoline engine with an electric motor, allowing for both independent and combined operation[10]. Hyundai's Transmission-Mounted Electrical Device (TMED) integrates the electric motor directly into the transmission, reducing energy loss and improving overall system efficiency[11]. The company has also implemented an advanced lithium-polymer battery technology, which offers higher energy density and improved thermal management compared to traditional lithium-ion batteries[12]. Hyundai's hybrid system includes a sophisticated power control unit that optimizes the power distribution between the engine and electric motor based on driving conditions and battery state of charge.

Strengths: Compact and lightweight hybrid system design, advanced battery technology. Weaknesses: Limited all-electric range compared to some competitors.

GM Global Technology Operations LLC

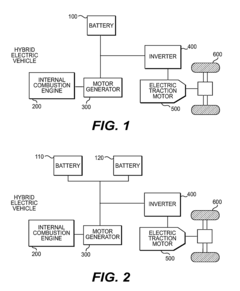

Technical Solution: GM has developed a sophisticated hybrid vehicle energy system that leverages advanced battery acid technology. Their system utilizes a split-power transmission, which combines two electric motors with a planetary gear set[4]. This allows for multiple power flow paths, optimizing efficiency across various driving conditions. GM's eAssist technology incorporates a lithium-ion battery pack and a belt-driven motor-generator, providing electric power assist and regenerative braking capabilities[5]. The company has also implemented an intelligent energy management system that continuously monitors and adjusts the power distribution between the electric motors and the internal combustion engine, maximizing fuel economy and performance[6].

Strengths: Versatile hybrid system adaptable to various vehicle sizes, strong regenerative braking capabilities. Weaknesses: Complexity of the system may lead to higher maintenance costs.

Acid Tech Innovations

Hybrid battery

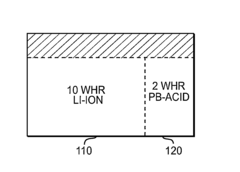

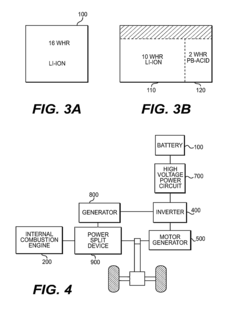

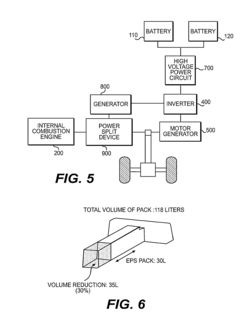

PatentWO2006116774A2

Innovation

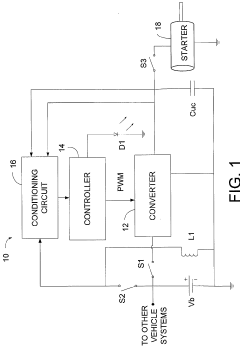

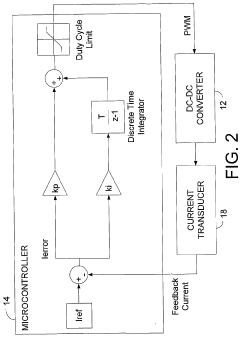

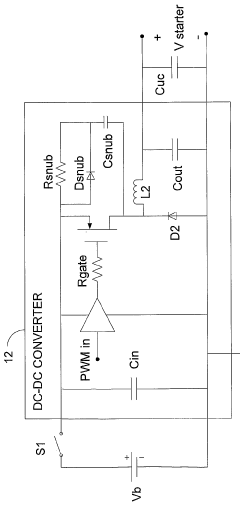

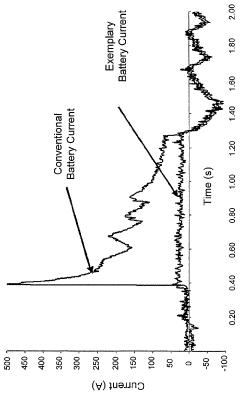

- A hybrid battery system combining electro-chemical batteries with ultracapacitors and digitally controlled power electronics, where ultracapacitors provide high power output and batteries offer high-energy storage, with a controller regulating energy transfer to extend battery life and improve performance.

Hybrid battery system for electric and hybrid electric vehicles

PatentInactiveUS20130244061A1

Innovation

- A hybrid-battery system combining lead-acid batteries for high power and another electrochemistry, such as Li-ion or Ni-MH, to optimize energy and power requirements, reducing overall size, weight, and cost, while maintaining reliability and safety.

Environmental Impact

The environmental impact of battery acid in hybrid vehicle energy systems is a critical consideration in the ongoing development and adoption of these technologies. As hybrid vehicles become increasingly prevalent on roads worldwide, the potential ecological consequences of their battery components, particularly the acid used in lead-acid batteries, warrant careful examination.

Battery acid, typically sulfuric acid in lead-acid batteries, poses several environmental risks throughout the lifecycle of hybrid vehicles. During production, the manufacturing process of these batteries can result in the release of harmful chemicals and heavy metals into the environment if not properly managed. Stringent regulations and advanced manufacturing techniques have been implemented to mitigate these risks, but the potential for environmental contamination remains a concern.

In the operational phase of hybrid vehicles, the risk of battery acid leakage due to accidents or improper maintenance can lead to soil and water pollution. While modern hybrid vehicles are designed with robust safety features to prevent such incidents, the cumulative impact of even small-scale leaks across a large fleet of vehicles could be significant. This underscores the importance of proper vehicle maintenance and the need for effective emergency response protocols in the event of accidents involving hybrid vehicles.

The end-of-life disposal and recycling of hybrid vehicle batteries present another set of environmental challenges. Improper disposal of batteries containing sulfuric acid can lead to severe environmental degradation, affecting soil quality, water resources, and local ecosystems. To address this, many countries have implemented strict regulations and recycling programs for automotive batteries. These initiatives aim to recover valuable materials and safely neutralize hazardous components, including battery acid.

However, the recycling process itself is not without environmental implications. The treatment of battery acid and the extraction of materials from used batteries require energy-intensive processes that can contribute to carbon emissions. Balancing the environmental benefits of recycling against the potential negative impacts of the recycling process remains an ongoing challenge for the industry.

On a positive note, the use of hybrid vehicle energy systems, including their battery components, contributes to overall reductions in greenhouse gas emissions and fossil fuel consumption compared to conventional vehicles. This broader environmental benefit must be weighed against the localized risks associated with battery acid and other battery components.

As the automotive industry continues to evolve, there is a growing trend towards the development of more environmentally friendly battery technologies. Advanced lithium-ion batteries and emerging solid-state batteries promise to reduce or eliminate the use of liquid acids, potentially mitigating many of the environmental concerns associated with traditional lead-acid batteries. However, these new technologies bring their own set of environmental considerations that require ongoing research and assessment.

Battery acid, typically sulfuric acid in lead-acid batteries, poses several environmental risks throughout the lifecycle of hybrid vehicles. During production, the manufacturing process of these batteries can result in the release of harmful chemicals and heavy metals into the environment if not properly managed. Stringent regulations and advanced manufacturing techniques have been implemented to mitigate these risks, but the potential for environmental contamination remains a concern.

In the operational phase of hybrid vehicles, the risk of battery acid leakage due to accidents or improper maintenance can lead to soil and water pollution. While modern hybrid vehicles are designed with robust safety features to prevent such incidents, the cumulative impact of even small-scale leaks across a large fleet of vehicles could be significant. This underscores the importance of proper vehicle maintenance and the need for effective emergency response protocols in the event of accidents involving hybrid vehicles.

The end-of-life disposal and recycling of hybrid vehicle batteries present another set of environmental challenges. Improper disposal of batteries containing sulfuric acid can lead to severe environmental degradation, affecting soil quality, water resources, and local ecosystems. To address this, many countries have implemented strict regulations and recycling programs for automotive batteries. These initiatives aim to recover valuable materials and safely neutralize hazardous components, including battery acid.

However, the recycling process itself is not without environmental implications. The treatment of battery acid and the extraction of materials from used batteries require energy-intensive processes that can contribute to carbon emissions. Balancing the environmental benefits of recycling against the potential negative impacts of the recycling process remains an ongoing challenge for the industry.

On a positive note, the use of hybrid vehicle energy systems, including their battery components, contributes to overall reductions in greenhouse gas emissions and fossil fuel consumption compared to conventional vehicles. This broader environmental benefit must be weighed against the localized risks associated with battery acid and other battery components.

As the automotive industry continues to evolve, there is a growing trend towards the development of more environmentally friendly battery technologies. Advanced lithium-ion batteries and emerging solid-state batteries promise to reduce or eliminate the use of liquid acids, potentially mitigating many of the environmental concerns associated with traditional lead-acid batteries. However, these new technologies bring their own set of environmental considerations that require ongoing research and assessment.

Safety Regulations

Safety regulations play a crucial role in the development and implementation of battery acid systems in hybrid vehicle energy systems. These regulations are designed to protect consumers, workers, and the environment from potential hazards associated with the use of battery acid.

One of the primary safety concerns addressed by regulations is the prevention of acid leaks and spills. Manufacturers are required to design and construct battery containers that can withstand the corrosive nature of the acid and prevent leakage under normal operating conditions. This includes using materials that are resistant to acid degradation and implementing robust sealing mechanisms.

Regulations also mandate the inclusion of safety features such as pressure relief valves to prevent the buildup of dangerous gases within the battery. These valves are designed to release excess pressure while maintaining the integrity of the battery system. Additionally, regulations often require the installation of temperature sensors to monitor and control battery temperature, preventing overheating and potential thermal runaway incidents.

Proper labeling and warning systems are another critical aspect of safety regulations. Batteries containing acid must be clearly marked with appropriate hazard symbols and handling instructions. This ensures that users and maintenance personnel are aware of the potential risks and can take necessary precautions when working with or around the battery systems.

Transportation of battery acid and batteries containing acid is subject to strict regulations. These guidelines cover packaging requirements, documentation, and handling procedures to minimize the risk of accidents during transit. Special containers designed to withstand impact and prevent leakage are often mandated for the transportation of battery acid.

Disposal and recycling of battery acid and related components are also regulated to protect the environment. Manufacturers and end-users are required to follow specific procedures for the safe disposal of spent batteries and acid. Many regulations promote recycling programs to recover valuable materials and reduce environmental impact.

Worker safety is a key focus of regulations surrounding battery acid in hybrid vehicle energy systems. Employers are required to provide appropriate personal protective equipment (PPE) and training for workers who handle battery acid. This includes protective clothing, eyewear, and respiratory protection when necessary. Workplace safety protocols must be established and followed to minimize the risk of accidents and exposure.

Emergency response procedures are another critical component of safety regulations. Manufacturers and operators of hybrid vehicles must have plans in place to address potential acid spills or leaks. This includes providing appropriate neutralizing agents and spill containment materials, as well as training personnel in proper emergency response techniques.

One of the primary safety concerns addressed by regulations is the prevention of acid leaks and spills. Manufacturers are required to design and construct battery containers that can withstand the corrosive nature of the acid and prevent leakage under normal operating conditions. This includes using materials that are resistant to acid degradation and implementing robust sealing mechanisms.

Regulations also mandate the inclusion of safety features such as pressure relief valves to prevent the buildup of dangerous gases within the battery. These valves are designed to release excess pressure while maintaining the integrity of the battery system. Additionally, regulations often require the installation of temperature sensors to monitor and control battery temperature, preventing overheating and potential thermal runaway incidents.

Proper labeling and warning systems are another critical aspect of safety regulations. Batteries containing acid must be clearly marked with appropriate hazard symbols and handling instructions. This ensures that users and maintenance personnel are aware of the potential risks and can take necessary precautions when working with or around the battery systems.

Transportation of battery acid and batteries containing acid is subject to strict regulations. These guidelines cover packaging requirements, documentation, and handling procedures to minimize the risk of accidents during transit. Special containers designed to withstand impact and prevent leakage are often mandated for the transportation of battery acid.

Disposal and recycling of battery acid and related components are also regulated to protect the environment. Manufacturers and end-users are required to follow specific procedures for the safe disposal of spent batteries and acid. Many regulations promote recycling programs to recover valuable materials and reduce environmental impact.

Worker safety is a key focus of regulations surrounding battery acid in hybrid vehicle energy systems. Employers are required to provide appropriate personal protective equipment (PPE) and training for workers who handle battery acid. This includes protective clothing, eyewear, and respiratory protection when necessary. Workplace safety protocols must be established and followed to minimize the risk of accidents and exposure.

Emergency response procedures are another critical component of safety regulations. Manufacturers and operators of hybrid vehicles must have plans in place to address potential acid spills or leaks. This includes providing appropriate neutralizing agents and spill containment materials, as well as training personnel in proper emergency response techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!