Battery Acid's Role in Conductive Additive Performance

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Evolution

The evolution of battery acid has played a crucial role in the development and performance of conductive additives in battery technology. Initially, lead-acid batteries utilized sulfuric acid as the electrolyte, which served as both the ionic conductor and the source of sulfate ions for the electrochemical reactions. This traditional approach, while effective, had limitations in terms of energy density and cycle life.

As battery technology progressed, researchers began exploring alternative acid compositions to enhance battery performance. The introduction of gel electrolytes in the 1970s marked a significant milestone. These gel-based acids offered improved safety and reduced maintenance requirements compared to liquid sulfuric acid. This innovation paved the way for valve-regulated lead-acid (VRLA) batteries, which became widely adopted in various applications.

The advent of lithium-ion batteries in the 1990s brought about a paradigm shift in battery acid evolution. Instead of aqueous acids, these batteries employed non-aqueous electrolytes, typically consisting of lithium salts dissolved in organic solvents. This change allowed for higher operating voltages and significantly improved energy density. The role of the electrolyte in these systems expanded beyond just ionic conduction to include the formation of a crucial solid electrolyte interphase (SEI) layer on the electrode surfaces.

Further advancements in electrolyte technology led to the development of ionic liquids and solid-state electrolytes. Ionic liquids, with their unique properties such as low volatility and high thermal stability, offered potential improvements in safety and performance. Solid-state electrolytes, on the other hand, promised even greater safety benefits and the possibility of higher energy densities through the use of lithium metal anodes.

The evolution of battery acids has had a profound impact on the performance of conductive additives. As electrolyte compositions changed, so did the requirements for conductive additives. In traditional lead-acid batteries, the conductive additives primarily served to enhance the conductivity of the active material. However, in modern lithium-ion batteries, conductive additives play a more complex role, influencing not only conductivity but also the formation and stability of the SEI layer.

Recent research has focused on tailoring conductive additives to specific electrolyte compositions. For instance, carbon-based additives have been modified to improve their compatibility with different electrolyte systems, enhancing their effectiveness in promoting electron transport and maintaining electrode integrity. The interplay between advanced electrolytes and engineered conductive additives has become a key area of study in the pursuit of next-generation battery technologies.

As battery technology progressed, researchers began exploring alternative acid compositions to enhance battery performance. The introduction of gel electrolytes in the 1970s marked a significant milestone. These gel-based acids offered improved safety and reduced maintenance requirements compared to liquid sulfuric acid. This innovation paved the way for valve-regulated lead-acid (VRLA) batteries, which became widely adopted in various applications.

The advent of lithium-ion batteries in the 1990s brought about a paradigm shift in battery acid evolution. Instead of aqueous acids, these batteries employed non-aqueous electrolytes, typically consisting of lithium salts dissolved in organic solvents. This change allowed for higher operating voltages and significantly improved energy density. The role of the electrolyte in these systems expanded beyond just ionic conduction to include the formation of a crucial solid electrolyte interphase (SEI) layer on the electrode surfaces.

Further advancements in electrolyte technology led to the development of ionic liquids and solid-state electrolytes. Ionic liquids, with their unique properties such as low volatility and high thermal stability, offered potential improvements in safety and performance. Solid-state electrolytes, on the other hand, promised even greater safety benefits and the possibility of higher energy densities through the use of lithium metal anodes.

The evolution of battery acids has had a profound impact on the performance of conductive additives. As electrolyte compositions changed, so did the requirements for conductive additives. In traditional lead-acid batteries, the conductive additives primarily served to enhance the conductivity of the active material. However, in modern lithium-ion batteries, conductive additives play a more complex role, influencing not only conductivity but also the formation and stability of the SEI layer.

Recent research has focused on tailoring conductive additives to specific electrolyte compositions. For instance, carbon-based additives have been modified to improve their compatibility with different electrolyte systems, enhancing their effectiveness in promoting electron transport and maintaining electrode integrity. The interplay between advanced electrolytes and engineered conductive additives has become a key area of study in the pursuit of next-generation battery technologies.

Market Demand Analysis

The market demand for conductive additives in battery technology has been experiencing significant growth, driven by the rapid expansion of the electric vehicle (EV) industry and the increasing adoption of renewable energy storage systems. As battery manufacturers strive to improve the performance, longevity, and safety of their products, the role of conductive additives has become increasingly crucial.

The global battery market is projected to reach substantial volumes in the coming years, with lithium-ion batteries leading the charge. This growth is primarily fueled by the automotive sector's shift towards electrification, with major car manufacturers committing to electric vehicle production. Consequently, the demand for high-performance batteries with enhanced conductivity and stability has surged, directly impacting the market for conductive additives.

In the context of battery acid's role in conductive additive performance, there is a growing interest in developing additives that can withstand and even leverage the acidic environment within batteries. This demand stems from the need to improve the overall efficiency and lifespan of batteries, particularly in applications where high power output and long-term stability are critical.

The renewable energy sector is another key driver for the market demand of conductive additives. As countries worldwide invest in solar and wind power infrastructure, the need for efficient energy storage solutions has intensified. Grid-scale battery storage systems require advanced conductive additives to maintain performance under various operational conditions, including exposure to acidic electrolytes.

Furthermore, the consumer electronics industry continues to push for smaller, more powerful devices with longer battery life. This trend has created a demand for conductive additives that can enhance the performance of compact battery designs without compromising safety or durability in acidic environments.

The aerospace and defense sectors also contribute to the market demand, requiring high-performance batteries capable of operating in extreme conditions. These applications often involve exposure to corrosive substances, making the development of acid-resistant conductive additives a priority for manufacturers serving these industries.

As environmental concerns grow, there is an increasing focus on sustainable and eco-friendly battery technologies. This shift has led to a rising demand for conductive additives that not only perform well in acidic conditions but also align with green manufacturing practices and end-of-life recyclability requirements.

The market for conductive additives is also influenced by regulatory pressures, with governments worldwide implementing stricter safety standards for batteries. This has created a need for additives that can improve the stability and safety of batteries, particularly in managing thermal runaway risks associated with acidic reactions.

The global battery market is projected to reach substantial volumes in the coming years, with lithium-ion batteries leading the charge. This growth is primarily fueled by the automotive sector's shift towards electrification, with major car manufacturers committing to electric vehicle production. Consequently, the demand for high-performance batteries with enhanced conductivity and stability has surged, directly impacting the market for conductive additives.

In the context of battery acid's role in conductive additive performance, there is a growing interest in developing additives that can withstand and even leverage the acidic environment within batteries. This demand stems from the need to improve the overall efficiency and lifespan of batteries, particularly in applications where high power output and long-term stability are critical.

The renewable energy sector is another key driver for the market demand of conductive additives. As countries worldwide invest in solar and wind power infrastructure, the need for efficient energy storage solutions has intensified. Grid-scale battery storage systems require advanced conductive additives to maintain performance under various operational conditions, including exposure to acidic electrolytes.

Furthermore, the consumer electronics industry continues to push for smaller, more powerful devices with longer battery life. This trend has created a demand for conductive additives that can enhance the performance of compact battery designs without compromising safety or durability in acidic environments.

The aerospace and defense sectors also contribute to the market demand, requiring high-performance batteries capable of operating in extreme conditions. These applications often involve exposure to corrosive substances, making the development of acid-resistant conductive additives a priority for manufacturers serving these industries.

As environmental concerns grow, there is an increasing focus on sustainable and eco-friendly battery technologies. This shift has led to a rising demand for conductive additives that not only perform well in acidic conditions but also align with green manufacturing practices and end-of-life recyclability requirements.

The market for conductive additives is also influenced by regulatory pressures, with governments worldwide implementing stricter safety standards for batteries. This has created a need for additives that can improve the stability and safety of batteries, particularly in managing thermal runaway risks associated with acidic reactions.

Current Challenges

The current challenges in understanding and optimizing the role of battery acid in conductive additive performance are multifaceted and complex. One of the primary obstacles is the limited understanding of the intricate interactions between battery acid and various conductive additives at the molecular level. This knowledge gap hinders the development of more efficient and durable battery systems.

Another significant challenge lies in the corrosive nature of battery acid, which can degrade conductive additives over time. This degradation process affects the long-term performance and reliability of batteries, particularly in high-demand applications. Researchers are grappling with finding ways to mitigate this corrosive effect without compromising the acid's essential role in the electrochemical reactions.

The variability in battery acid composition across different battery types and manufacturers presents another hurdle. This diversity makes it difficult to develop universal solutions for enhancing conductive additive performance. Each acid formulation may interact differently with additives, necessitating tailored approaches for optimization.

Furthermore, the environmental impact of battery acid and conductive additives is a growing concern. As the demand for batteries increases, particularly in the electric vehicle and renewable energy sectors, there is mounting pressure to develop more environmentally friendly alternatives. This challenge extends to finding eco-friendly conductive additives that can withstand the harsh acidic environment while maintaining optimal performance.

The scalability of new conductive additive technologies is also a significant challenge. While promising solutions may be developed in laboratory settings, translating these innovations to large-scale manufacturing processes presents numerous technical and economic hurdles. This scaling issue is particularly critical as the battery industry continues to expand rapidly.

Additionally, there is a lack of standardized testing protocols for evaluating the performance of conductive additives in battery acid environments. This absence of uniform testing methods makes it difficult to compare different additives and technologies accurately, slowing down the pace of innovation and adoption of new materials.

Lastly, the interdisciplinary nature of this field poses a challenge in itself. Addressing the role of battery acid in conductive additive performance requires expertise from various domains, including electrochemistry, materials science, and chemical engineering. Bridging these different areas of knowledge and fostering effective collaboration among experts remains a significant hurdle in advancing the field.

Another significant challenge lies in the corrosive nature of battery acid, which can degrade conductive additives over time. This degradation process affects the long-term performance and reliability of batteries, particularly in high-demand applications. Researchers are grappling with finding ways to mitigate this corrosive effect without compromising the acid's essential role in the electrochemical reactions.

The variability in battery acid composition across different battery types and manufacturers presents another hurdle. This diversity makes it difficult to develop universal solutions for enhancing conductive additive performance. Each acid formulation may interact differently with additives, necessitating tailored approaches for optimization.

Furthermore, the environmental impact of battery acid and conductive additives is a growing concern. As the demand for batteries increases, particularly in the electric vehicle and renewable energy sectors, there is mounting pressure to develop more environmentally friendly alternatives. This challenge extends to finding eco-friendly conductive additives that can withstand the harsh acidic environment while maintaining optimal performance.

The scalability of new conductive additive technologies is also a significant challenge. While promising solutions may be developed in laboratory settings, translating these innovations to large-scale manufacturing processes presents numerous technical and economic hurdles. This scaling issue is particularly critical as the battery industry continues to expand rapidly.

Additionally, there is a lack of standardized testing protocols for evaluating the performance of conductive additives in battery acid environments. This absence of uniform testing methods makes it difficult to compare different additives and technologies accurately, slowing down the pace of innovation and adoption of new materials.

Lastly, the interdisciplinary nature of this field poses a challenge in itself. Addressing the role of battery acid in conductive additive performance requires expertise from various domains, including electrochemistry, materials science, and chemical engineering. Bridging these different areas of knowledge and fostering effective collaboration among experts remains a significant hurdle in advancing the field.

Existing Acid Solutions

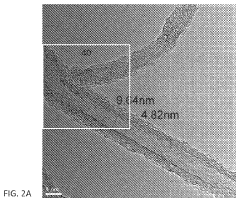

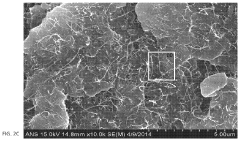

01 Carbon-based conductive additives

Carbon-based materials such as graphene, carbon nanotubes, and carbon black are commonly used as conductive additives in battery acid formulations. These materials enhance the electrical conductivity of the electrolyte, improving overall battery performance and efficiency. The high surface area and excellent conductivity of carbon-based additives contribute to better charge transfer and reduced internal resistance in the battery.- Carbon-based conductive additives: Carbon-based materials such as graphene, carbon nanotubes, and carbon black are commonly used as conductive additives in battery acid formulations. These materials enhance the electrical conductivity of the electrolyte, improving overall battery performance and efficiency.

- Metal-based conductive additives: Metal particles or metal oxides, such as silver, copper, or tin oxide, can be incorporated into battery acid as conductive additives. These materials help to increase the ionic conductivity of the electrolyte, leading to improved battery capacity and charge-discharge rates.

- Polymer-based conductive additives: Conductive polymers, such as polyaniline or polypyrrole, can be used as additives in battery acid to enhance its conductivity. These materials offer the advantage of being lightweight and flexible, potentially improving the overall energy density of the battery.

- Nanostructured conductive additives: Nanostructured materials, including nanoparticles, nanowires, and nanofibers, can be utilized as conductive additives in battery acid. These materials offer high surface area and unique electronic properties, potentially leading to improved charge transfer and overall battery performance.

- Composite conductive additives: Composite materials combining different types of conductive additives, such as carbon-metal hybrids or polymer-carbon composites, can be used to enhance the performance of battery acid. These composites often synergistically improve conductivity and other electrochemical properties of the electrolyte.

02 Metal-based conductive additives

Metal particles or metal oxides are utilized as conductive additives in battery acid to improve conductivity and electrochemical performance. Materials such as silver, copper, nickel, or their oxides can be incorporated into the electrolyte to enhance electron transfer and reduce internal resistance. These additives can also contribute to improved cycling stability and capacity retention of the battery.Expand Specific Solutions03 Polymer-based conductive additives

Conductive polymers or polymer composites are employed as additives in battery acid to improve conductivity while maintaining the desired viscosity and stability of the electrolyte. These additives can include materials such as polyaniline, polypyrrole, or polymer-carbon composites. The use of polymer-based additives can enhance the mechanical properties of the electrolyte and contribute to better electrode-electrolyte interface interactions.Expand Specific Solutions04 Nanostructured conductive additives

Nanostructured materials, such as nanoparticles, nanowires, or nanofibers, are utilized as conductive additives in battery acid to enhance performance. These materials offer high surface area and unique properties that can improve charge transfer, electrolyte wetting, and overall battery efficiency. Nanostructured additives can also contribute to better dispersion and stability of the conductive network within the electrolyte.Expand Specific Solutions05 Hybrid conductive additive systems

Combinations of different types of conductive additives are used to create synergistic effects and optimize battery acid performance. These hybrid systems may include mixtures of carbon-based materials with metal particles, or polymer-based additives with nanostructured materials. The combination of different additives can lead to improved conductivity, better dispersion, and enhanced overall battery performance compared to single-component additive systems.Expand Specific Solutions

Key Industry Players

The battery acid's role in conductive additive performance is a critical area of research in the evolving energy storage industry. The market is in a growth phase, with increasing demand for high-performance batteries across various sectors. The global battery market size is projected to reach significant figures in the coming years, driven by electric vehicle adoption and renewable energy integration. Technologically, the field is advancing rapidly, with companies like LG Energy Solution, GS Yuasa, and BYD leading innovation. These firms are investing heavily in R&D to enhance battery performance, focusing on aspects such as electrolyte composition and conductive additives. The involvement of research institutions like CSIRO and universities indicates a collaborative approach to solving complex technical challenges in this domain.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has made significant strides in improving lead-acid battery performance through innovative conductive additive technologies. Their approach involves the use of advanced carbon-based additives, including graphene and carbon nanotubes, to enhance the conductivity and stability of the battery's electrode materials[4]. LG's research has shown that these nano-structured carbon additives can significantly improve the charge acceptance and cycle life of lead-acid batteries, particularly in partial state of charge (PSoC) applications[5]. The company has also developed proprietary surface modification techniques for these additives to optimize their interaction with the battery acid, resulting in improved dispersion and reduced agglomeration[6]. Additionally, LG has explored the use of conductive polymers as additives, which can form a protective layer on the electrode surface, reducing acid-induced corrosion and extending battery life[7].

Strengths: Enhanced conductivity, improved PSoC performance, and increased battery lifespan. Weaknesses: Higher production costs and potential scalability issues for mass production.

Cabot Corp.

Technical Solution: Cabot Corporation has developed advanced carbon additives specifically designed to enhance the performance of lead-acid batteries. Their proprietary conductive carbon additives, such as EMPEROX™, are engineered to improve charge acceptance and cycle life in lead-acid batteries. These additives work by creating a more efficient conductive network within the battery's active material, facilitating better electron transfer and reducing sulfation[1]. Cabot's technology involves precise control of particle size, surface area, and pore structure of the carbon additives, which allows for optimized interaction with the battery acid and active material[2]. The company has also focused on developing carbon additives that are resistant to acid corrosion, ensuring long-term stability and performance in the harsh battery environment[3].

Strengths: Improved charge acceptance, extended cycle life, and reduced sulfation. Weaknesses: Potential increase in manufacturing costs and complexity of battery production process.

Core Acid Innovations

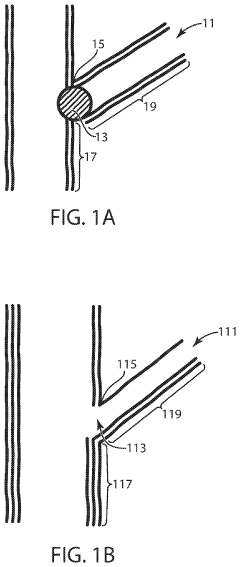

Anode electrode compositions for battery applications

PatentActiveUS20220181625A1

Innovation

- The use of carbon nanostructures (CNSs), including crosslinked and branched multiwall carbon nanotubes, as conductive additives at low loading levels to enhance anode performance by reducing lithium plating, improving cycling life, and maintaining electrical conductivity, even when used in small amounts compared to conventional carbon additives like carbon black.

Additive for lead-acid battery, lead-acid battery, and method of recycling lead-acid battery

PatentInactiveJP2020173926A

Innovation

- An additive containing polyvinyl alcohol with specific viscosity and saponification degree is used in the electrolyte, inhibiting sulfation and maintaining electrode conductivity.

Environmental Impact

The environmental impact of battery acid's role in conductive additive performance is a critical consideration in the development and implementation of battery technologies. The use of conductive additives in battery systems, particularly those involving acid-based electrolytes, has significant implications for both the environment and human health.

One of the primary environmental concerns is the potential for acid leakage or spillage during battery manufacturing, use, or disposal. Battery acid, typically sulfuric acid in lead-acid batteries, can cause severe soil and water contamination if not properly contained. This contamination can lead to the degradation of ecosystems, affecting plant and animal life in the surrounding areas. Moreover, the acidification of soil and water bodies can have long-lasting effects on local biodiversity and agricultural productivity.

The production of conductive additives and their integration with battery acid also contributes to the overall carbon footprint of battery manufacturing. Many conductive additives are derived from carbon-based materials, such as graphite or carbon black, which require energy-intensive processes for extraction and refinement. The combination of these additives with battery acid often involves additional chemical processes, further increasing the environmental impact through energy consumption and potential emissions.

Recycling and disposal of batteries containing acid and conductive additives present another set of environmental challenges. Improper disposal can lead to the release of toxic substances into the environment, including heavy metals and acidic compounds. While recycling technologies for lead-acid batteries are well-established, the presence of conductive additives may complicate the recycling process, potentially reducing the efficiency of material recovery and increasing the energy required for recycling.

Water consumption is another significant environmental factor to consider. The production of battery acid and the manufacturing processes involving conductive additives often require substantial amounts of water. In water-stressed regions, this can exacerbate existing water scarcity issues and compete with other essential water needs, such as agriculture and domestic use.

The environmental impact extends to air quality as well. The production and processing of battery acid and conductive additives can release various air pollutants, including sulfur dioxide, particulate matter, and volatile organic compounds. These emissions contribute to air pollution and can have adverse effects on human health and the environment, particularly in areas surrounding manufacturing facilities.

To mitigate these environmental impacts, ongoing research and development efforts are focused on developing more environmentally friendly alternatives to traditional battery acid and conductive additive combinations. This includes exploring bio-based electrolytes, water-based systems, and advanced recycling technologies that can more effectively recover and reuse materials from spent batteries. Additionally, there is a growing emphasis on life cycle assessments to comprehensively evaluate the environmental footprint of different battery technologies and guide the development of more sustainable solutions.

One of the primary environmental concerns is the potential for acid leakage or spillage during battery manufacturing, use, or disposal. Battery acid, typically sulfuric acid in lead-acid batteries, can cause severe soil and water contamination if not properly contained. This contamination can lead to the degradation of ecosystems, affecting plant and animal life in the surrounding areas. Moreover, the acidification of soil and water bodies can have long-lasting effects on local biodiversity and agricultural productivity.

The production of conductive additives and their integration with battery acid also contributes to the overall carbon footprint of battery manufacturing. Many conductive additives are derived from carbon-based materials, such as graphite or carbon black, which require energy-intensive processes for extraction and refinement. The combination of these additives with battery acid often involves additional chemical processes, further increasing the environmental impact through energy consumption and potential emissions.

Recycling and disposal of batteries containing acid and conductive additives present another set of environmental challenges. Improper disposal can lead to the release of toxic substances into the environment, including heavy metals and acidic compounds. While recycling technologies for lead-acid batteries are well-established, the presence of conductive additives may complicate the recycling process, potentially reducing the efficiency of material recovery and increasing the energy required for recycling.

Water consumption is another significant environmental factor to consider. The production of battery acid and the manufacturing processes involving conductive additives often require substantial amounts of water. In water-stressed regions, this can exacerbate existing water scarcity issues and compete with other essential water needs, such as agriculture and domestic use.

The environmental impact extends to air quality as well. The production and processing of battery acid and conductive additives can release various air pollutants, including sulfur dioxide, particulate matter, and volatile organic compounds. These emissions contribute to air pollution and can have adverse effects on human health and the environment, particularly in areas surrounding manufacturing facilities.

To mitigate these environmental impacts, ongoing research and development efforts are focused on developing more environmentally friendly alternatives to traditional battery acid and conductive additive combinations. This includes exploring bio-based electrolytes, water-based systems, and advanced recycling technologies that can more effectively recover and reuse materials from spent batteries. Additionally, there is a growing emphasis on life cycle assessments to comprehensively evaluate the environmental footprint of different battery technologies and guide the development of more sustainable solutions.

Safety Regulations

Safety regulations play a crucial role in the development and implementation of battery technologies, particularly concerning the use of battery acid and conductive additives. These regulations are designed to protect workers, consumers, and the environment from potential hazards associated with battery production and usage.

In the context of battery acid's role in conductive additive performance, safety regulations primarily focus on handling, storage, and disposal procedures. Manufacturers must adhere to strict guidelines for the proper containment and management of battery acid to prevent leaks, spills, or accidental exposure. This includes requirements for appropriate personal protective equipment (PPE) for workers, such as acid-resistant gloves, goggles, and protective clothing.

Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) in the United States, have established specific standards for battery manufacturing facilities. These standards outline permissible exposure limits for airborne contaminants, including acid mists and vapors, and mandate the implementation of engineering controls and work practices to minimize employee exposure.

The transportation of battery acid and conductive additives is also subject to stringent regulations. The United Nations' Recommendations on the Transport of Dangerous Goods classify battery acid as a corrosive substance, requiring specific packaging, labeling, and documentation for shipment. Similarly, many conductive additives are classified as hazardous materials, necessitating compliance with transportation safety regulations.

Environmental regulations play a significant role in shaping the development of battery technologies. The disposal of spent batteries and associated materials is governed by laws such as the Battery Directive in the European Union and the Mercury-Containing and Rechargeable Battery Management Act in the United States. These regulations aim to minimize environmental impact and promote recycling of battery components, including the recovery of conductive additives.

As research into new conductive additives progresses, safety regulations continue to evolve. Manufacturers must demonstrate compliance with emerging standards related to the toxicity, flammability, and environmental persistence of novel materials. This often involves extensive testing and documentation to obtain regulatory approval before commercialization.

The increasing focus on sustainability has led to the development of regulations promoting the use of safer, more environmentally friendly conductive additives. This includes incentives for research into bio-based or recyclable materials that can enhance battery performance while reducing environmental impact.

In conclusion, safety regulations significantly influence the development and application of battery acid and conductive additives in battery technology. Compliance with these regulations is essential for ensuring worker safety, consumer protection, and environmental stewardship throughout the battery lifecycle.

In the context of battery acid's role in conductive additive performance, safety regulations primarily focus on handling, storage, and disposal procedures. Manufacturers must adhere to strict guidelines for the proper containment and management of battery acid to prevent leaks, spills, or accidental exposure. This includes requirements for appropriate personal protective equipment (PPE) for workers, such as acid-resistant gloves, goggles, and protective clothing.

Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) in the United States, have established specific standards for battery manufacturing facilities. These standards outline permissible exposure limits for airborne contaminants, including acid mists and vapors, and mandate the implementation of engineering controls and work practices to minimize employee exposure.

The transportation of battery acid and conductive additives is also subject to stringent regulations. The United Nations' Recommendations on the Transport of Dangerous Goods classify battery acid as a corrosive substance, requiring specific packaging, labeling, and documentation for shipment. Similarly, many conductive additives are classified as hazardous materials, necessitating compliance with transportation safety regulations.

Environmental regulations play a significant role in shaping the development of battery technologies. The disposal of spent batteries and associated materials is governed by laws such as the Battery Directive in the European Union and the Mercury-Containing and Rechargeable Battery Management Act in the United States. These regulations aim to minimize environmental impact and promote recycling of battery components, including the recovery of conductive additives.

As research into new conductive additives progresses, safety regulations continue to evolve. Manufacturers must demonstrate compliance with emerging standards related to the toxicity, flammability, and environmental persistence of novel materials. This often involves extensive testing and documentation to obtain regulatory approval before commercialization.

The increasing focus on sustainability has led to the development of regulations promoting the use of safer, more environmentally friendly conductive additives. This includes incentives for research into bio-based or recyclable materials that can enhance battery performance while reducing environmental impact.

In conclusion, safety regulations significantly influence the development and application of battery acid and conductive additives in battery technology. Compliance with these regulations is essential for ensuring worker safety, consumer protection, and environmental stewardship throughout the battery lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!