Tablet cassette of automatic tablet packing apparatus

a tablet cassette and automatic technology, applied in the direction of tobacco, instruments, de-stacking articles, etc., can solve the problems of tablets breaking, affecting the smooth separation and discharging of tablets, and mixing different kinds of medicines, so as to prevent tablets from breaking and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

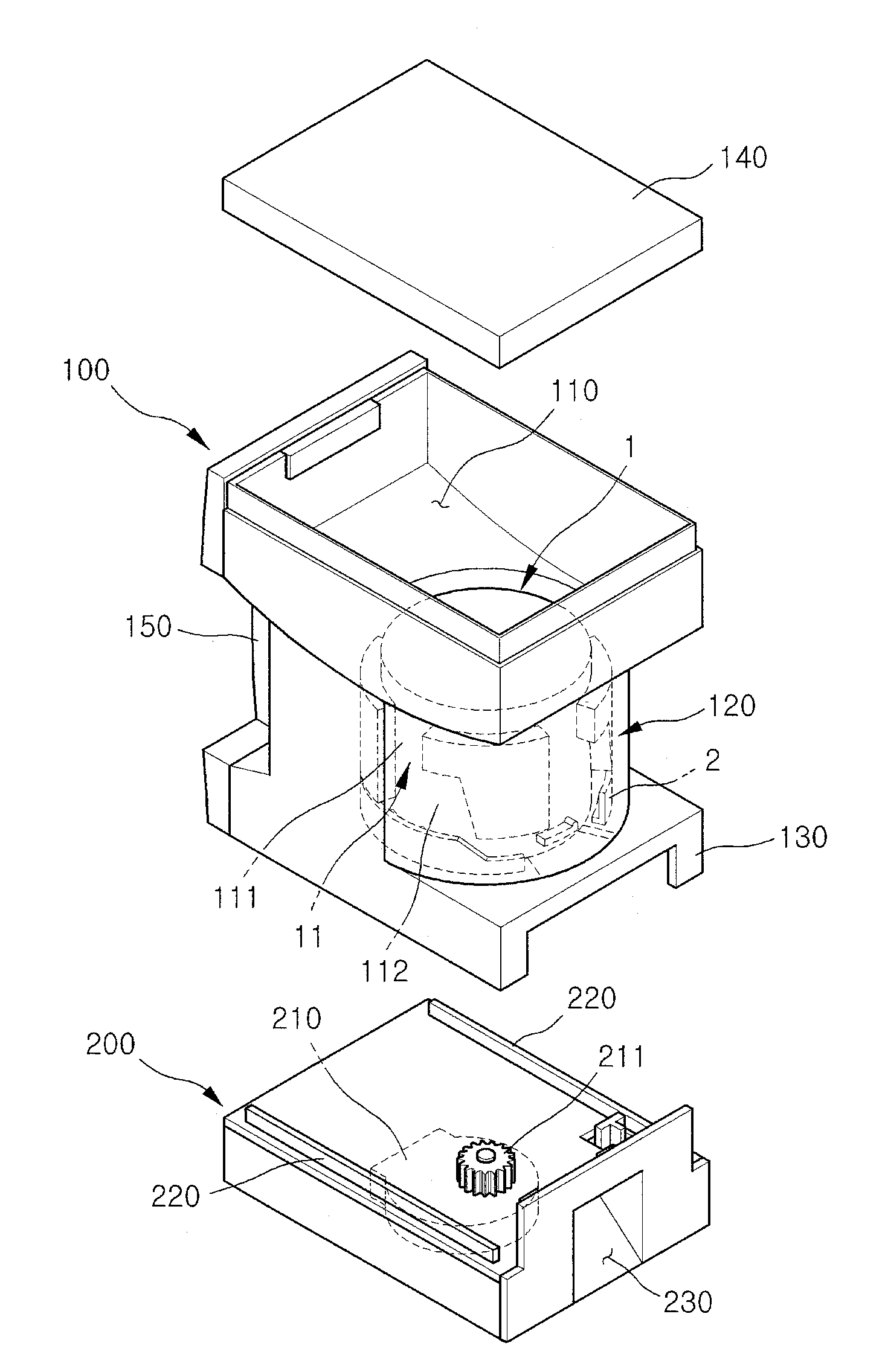

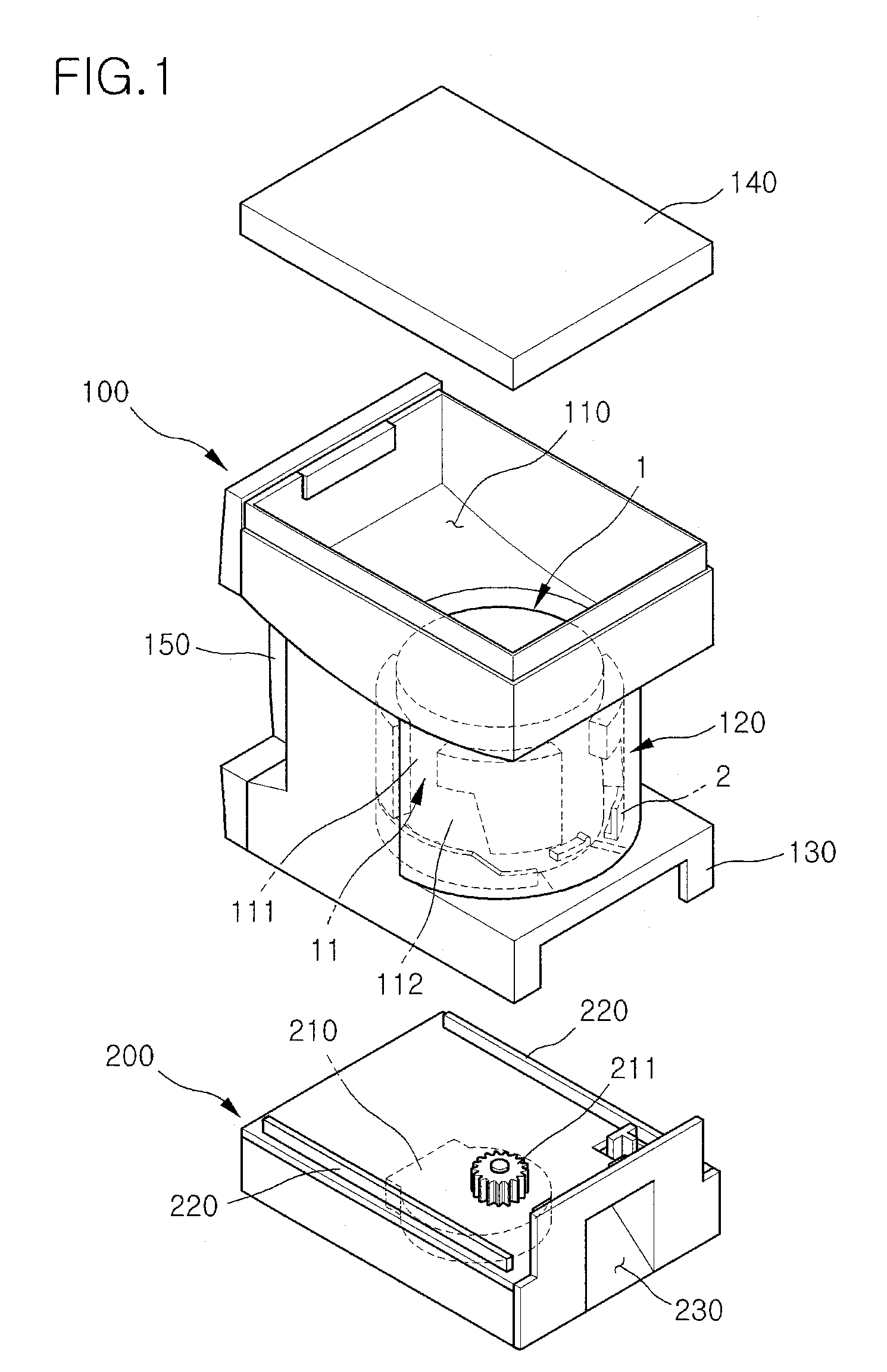

[0077]FIG. 12 is a partial perspective view illustrating the coupling relationship between the division block and the bottom ring provided in the tablet cassette of the automatic tablet packing apparatus according to the present invention, and FIG. 13 is a partial sectional view of FIG. 12.

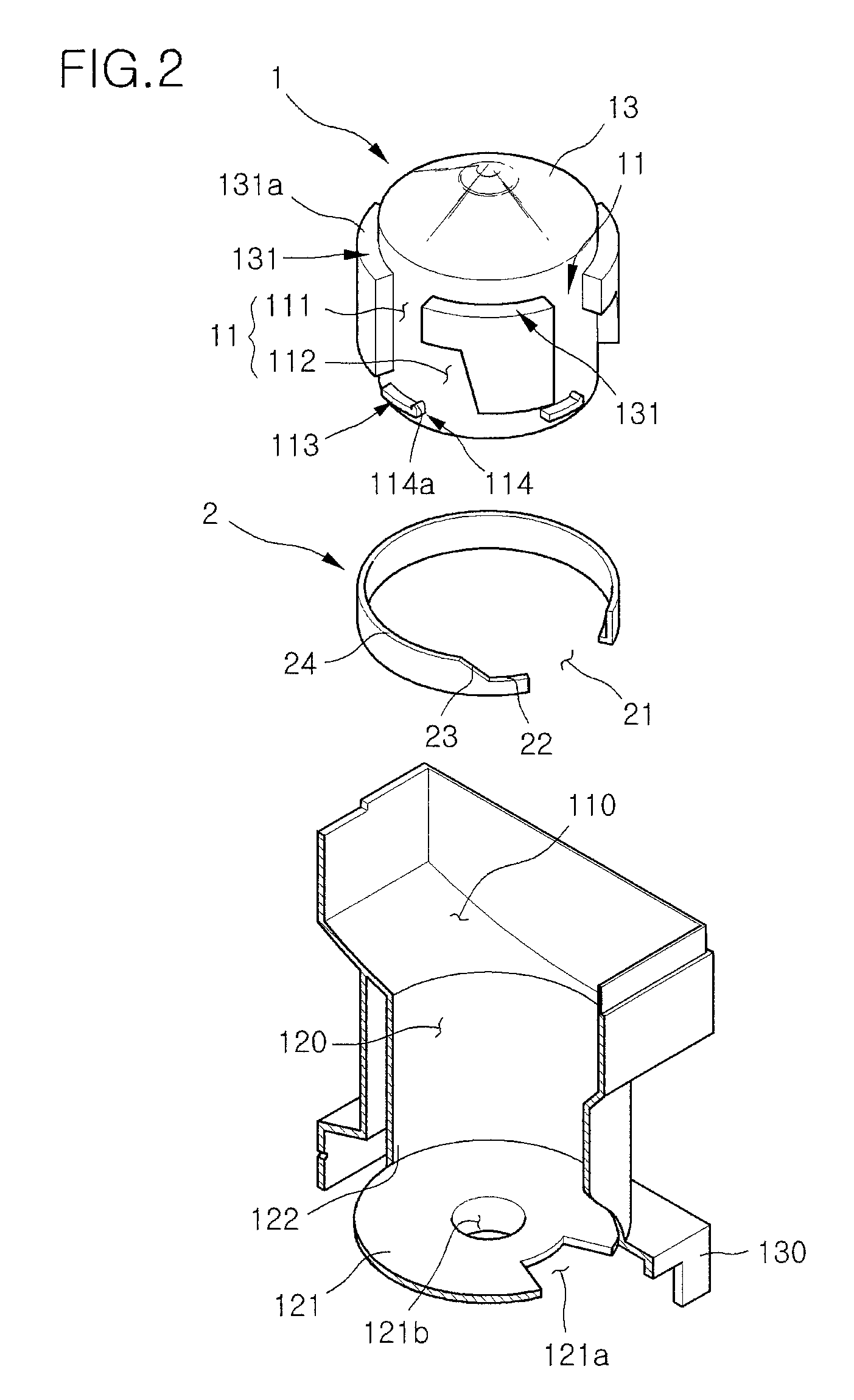

[0078]The division block 1, provided in the tablet cassette 100 of the automatic tablet packing apparatus according to the second embodiment of the present invention is configured in such a manner that the transfer passage 11 has a depth equal to half of the thickness of the tablet T. In addition, when the tablet T is aligned in an upright posture on the upper surface 131a of the outwardly raised portion 131 of the division block 1, approximately half of the bottom of the tablet T (i.e. half of the bottom close to the division block 1) is supported on the upper surface 131a of the outwardly raised portion 131.

[0079]The separation recess 111, the supply recess 112, and the prop 113, which constitut...

first embodiment

[0080]In the present embodiment, an outer diameter of the bottom ring 2 is larger than an outer diameter of the division block 1. With this configuration, the supporting edge surface 24 and a part of the inclined edge surface 23 of the bottom ring 2 may be located higher than the lower end of the transfer passage 11. In this case, in the same manner as that of the previously described first embodiment, the bottom ring 2 comes into contact with an outer surface (i.e. a surface close to an imaginary inner surface of an interior space defined between the bottom ring 2 and the division block 1) of the tablet T received in the transfer passage 11, thereby functioning to transfer the tablet from the separation recess 111 into the supply recess 112.

[0081]More specifically, the inclined edge surface 23 of the bottom ring 2 obliquely extends from a position lower than the prop 113 to a position higher than the prop 113, to cause the tablet located in the separation recess 111 to be moved upw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com