Forced-air helmet air coupling and system

a technology of air coupling and helmet, which is applied in the field of vehicle helmet accessories, can solve the problems of pilots not being able to see the connection, no way to ensure the connection of the air supply duct, and more difficult to do, so as to improve the connection, improve the connection, and facilitate the connection. and the effect of attaching and releasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

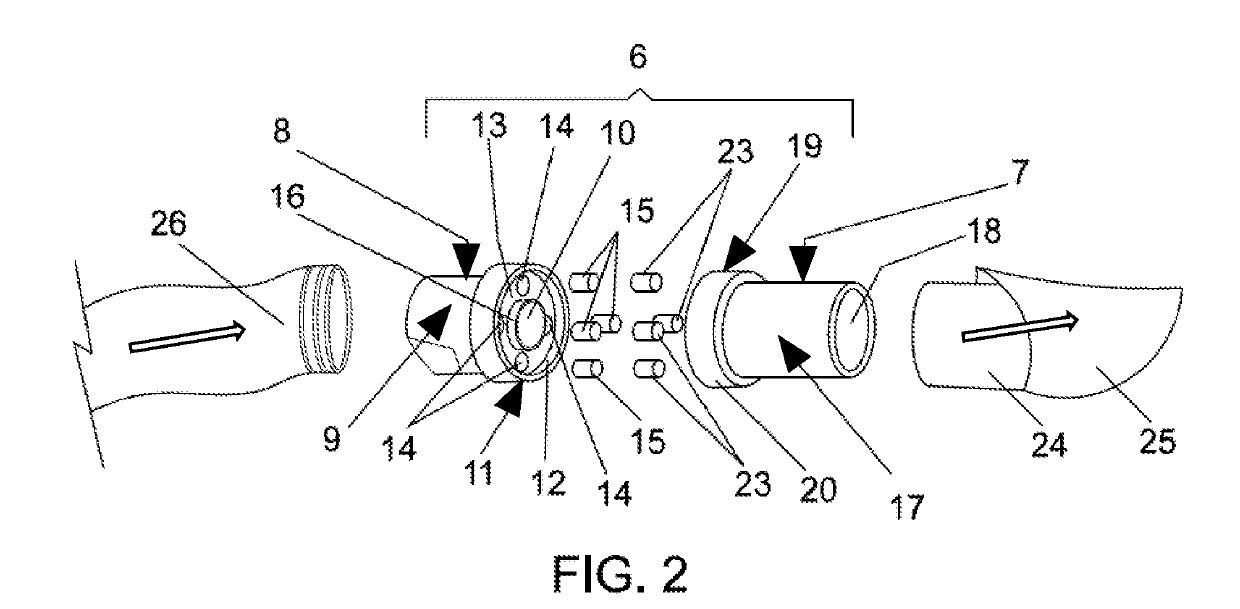

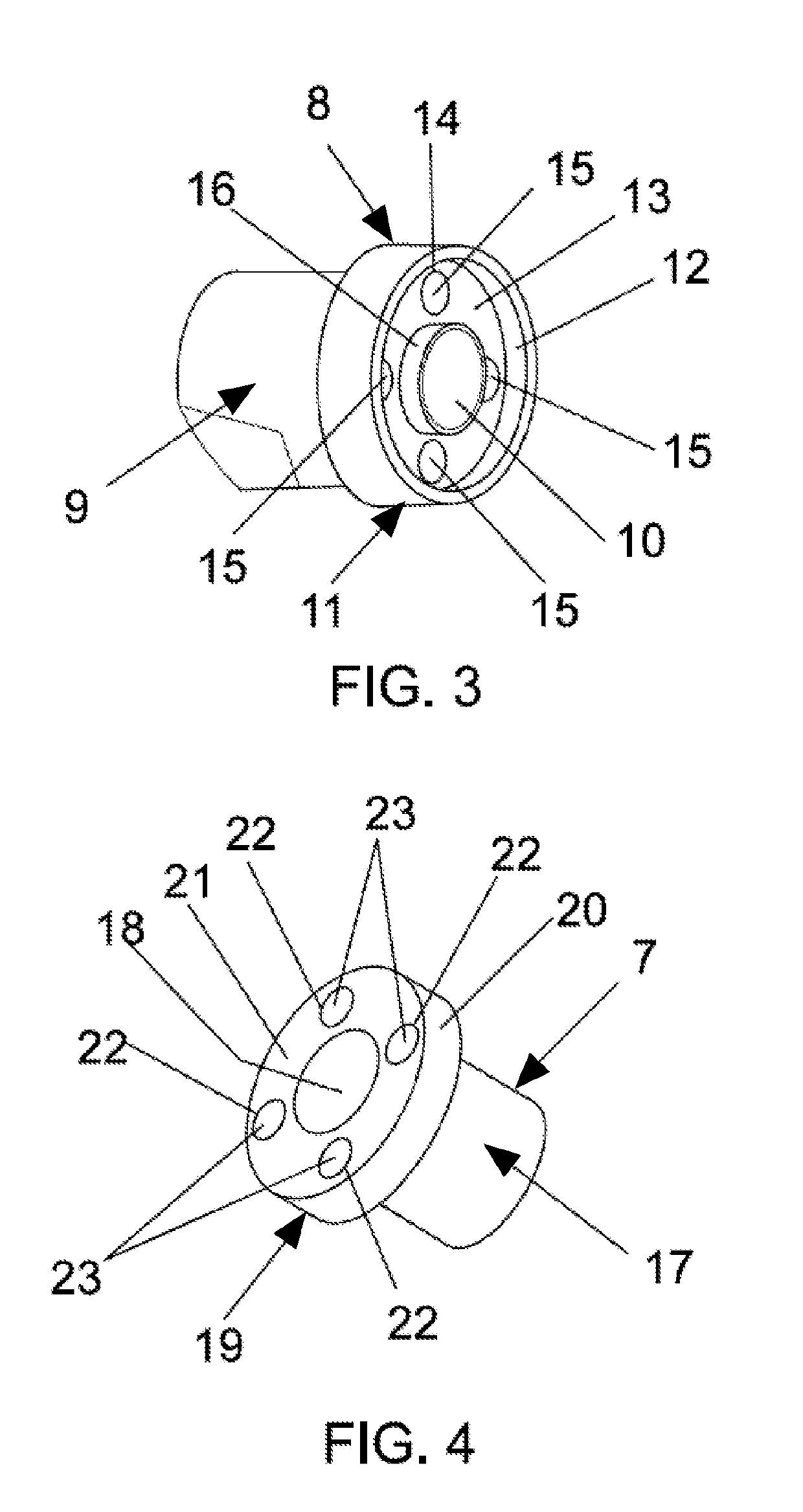

[0020]For a better understanding of the present disclosure, the follow detailed description of some of the embodiments thereof will be given, and shown in the appended drawings, which are for illustrative purposes, but are not limited to the following description. Accordingly, characteristic details of the forced-air helmet air coupling, system and method are clearly shown in the following description and in the illustrative drawings which are attached, the same reference signs serving to indicate the same or similar parts.

[0021]Aspects of the present disclosure generally pertain to an air coupling for a forced-air helmet to an air supply duct that may be easy and quick to attach and release. One purpose of the present disclosure is to make available an improved connection for forced-air helmet, and allows an easy connection and disconnection of the air supply ducts in the vehicle pilot's helmet without the need to apply force and without the need of tools. Another objective of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com