Turbine engine component with deflector

a turbine engine and deflector technology, applied in the direction of machines/engines, stators, mechanical equipment, etc., can solve the problems of reducing service life, requiring additional maintenance, and collecting excessive dust or particulates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

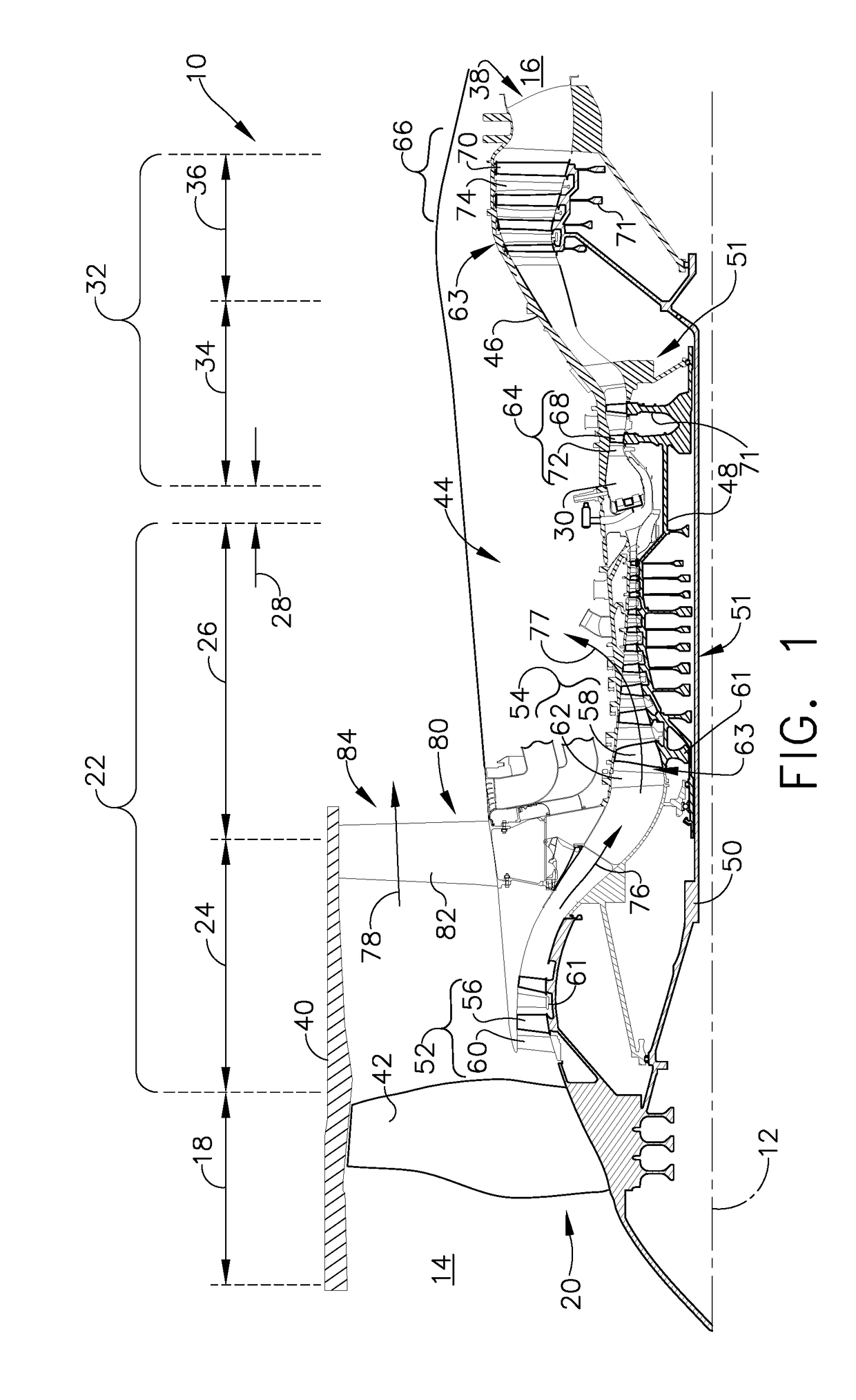

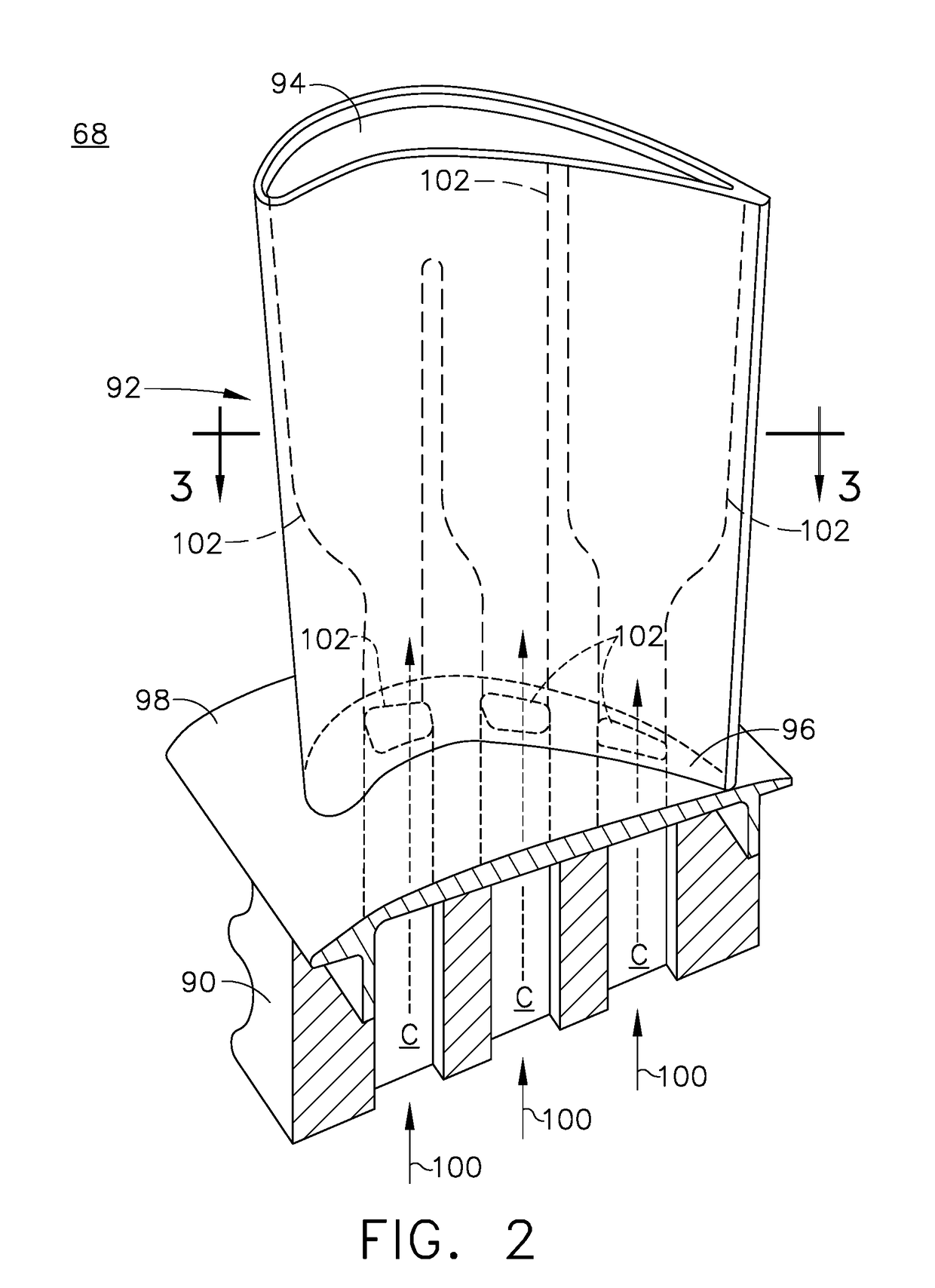

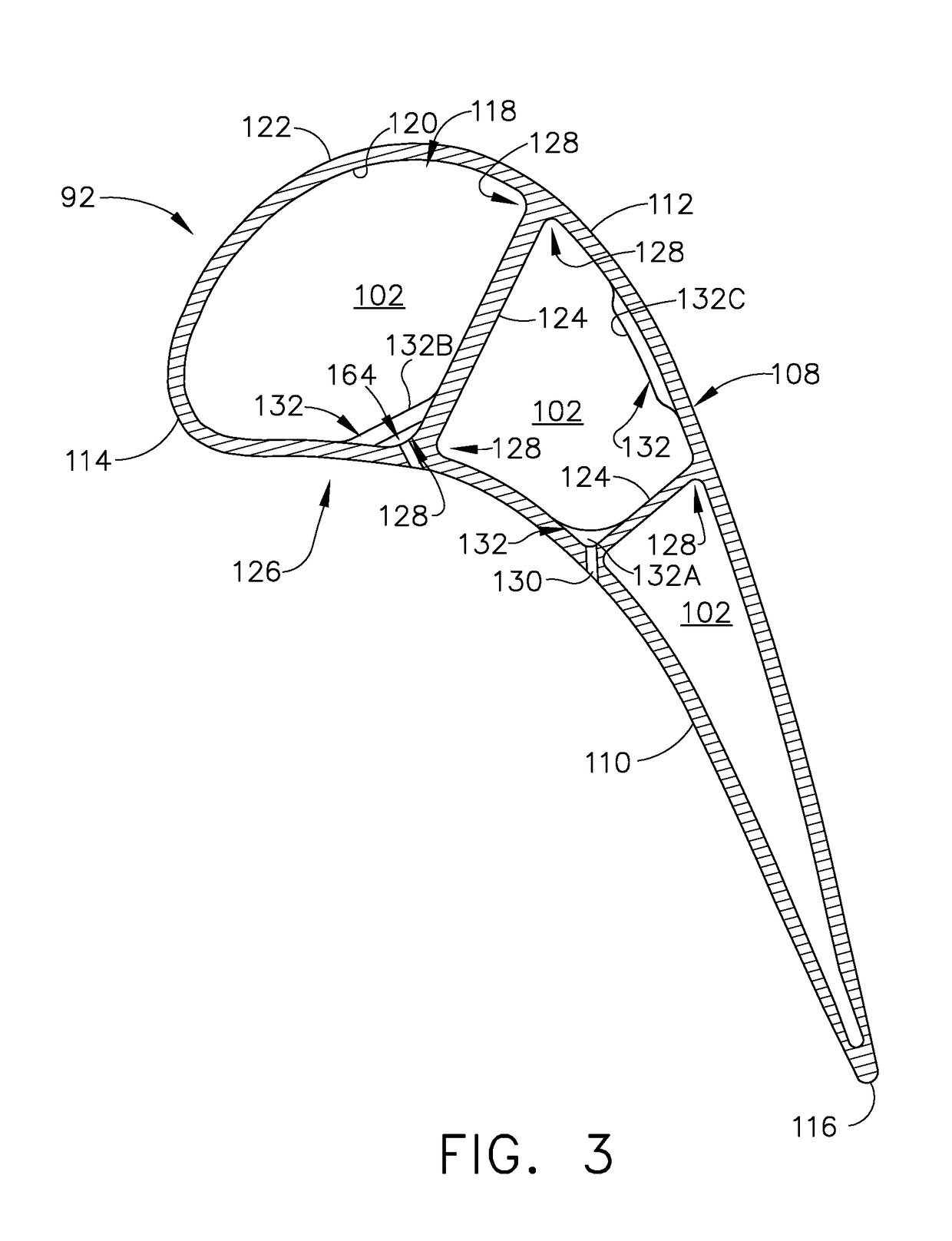

[0022]Aspects of the disclosure described herein are directed to airflow deflectors provided within an airfoil blade. For purposes of illustration, the present disclosure will be described with respect to the turbine for an aircraft gas turbine engine. It will be understood, however, that aspects of the disclosure described herein are not so limited and may have general applicability within an engine, including compressors, as well as in non-aircraft applications, such as other mobile applications and non-mobile industrial, commercial, and residential applications. Similarly, the aspects as described herein will have equal applicability to other engine components having film cooling and are not limited to airfoils or blades alone.

[0023]As used herein, the term “forward” or “upstream” refers to moving in a direction nearer to an origin of a flow of fluid relative to the direction of the local flow of fluid, such as air, or toward the engine inlet, or a component being relatively clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com