Oil skimmer assembly and system

a technology of oil skimmer and assembly, which is applied in the direction of water cleaning, separation process, filtration separation, etc., can solve the problems of oil spilling into the waterways, the general impracticality of shallow water devices, and the time-consuming and costly use of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

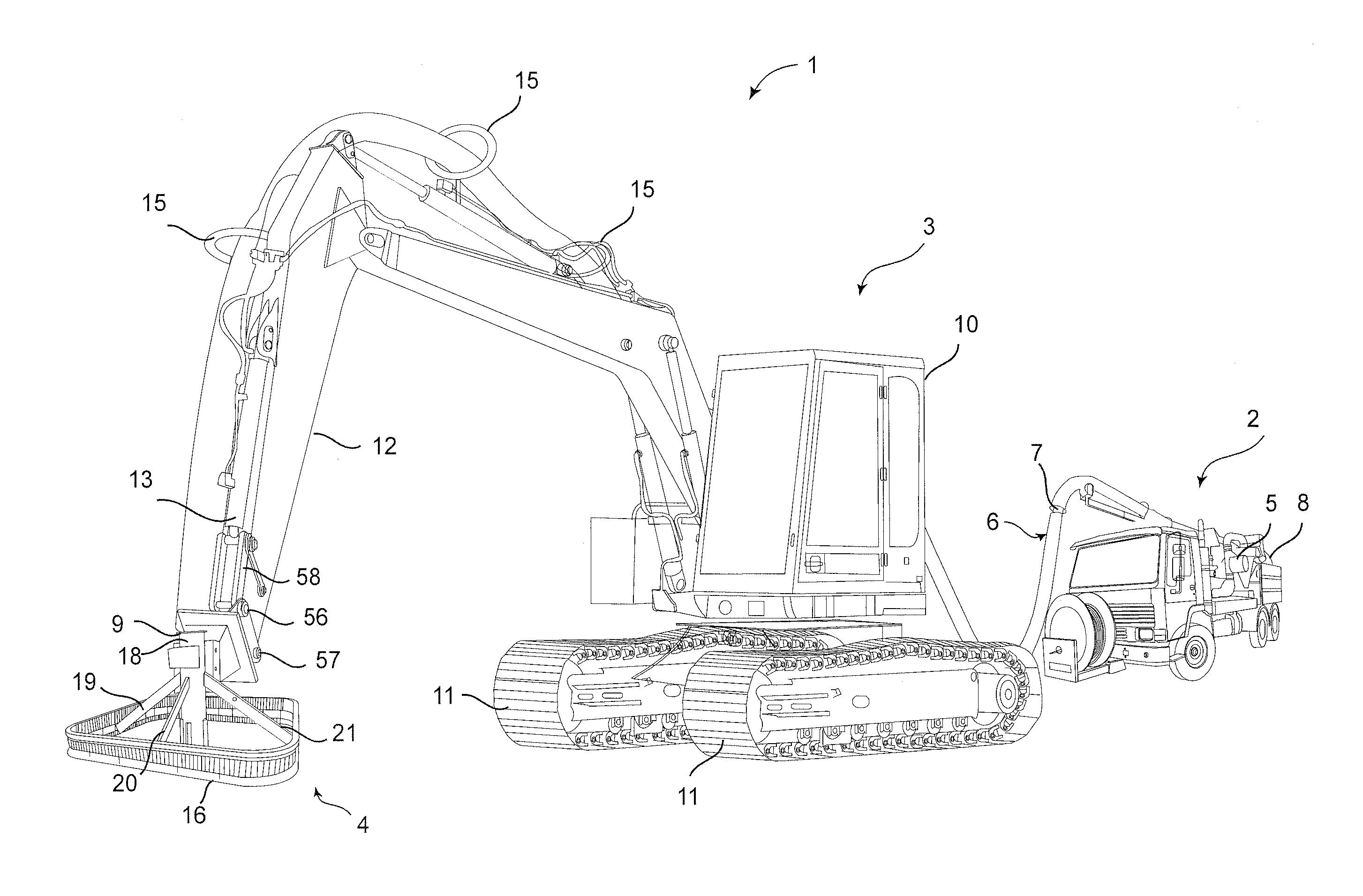

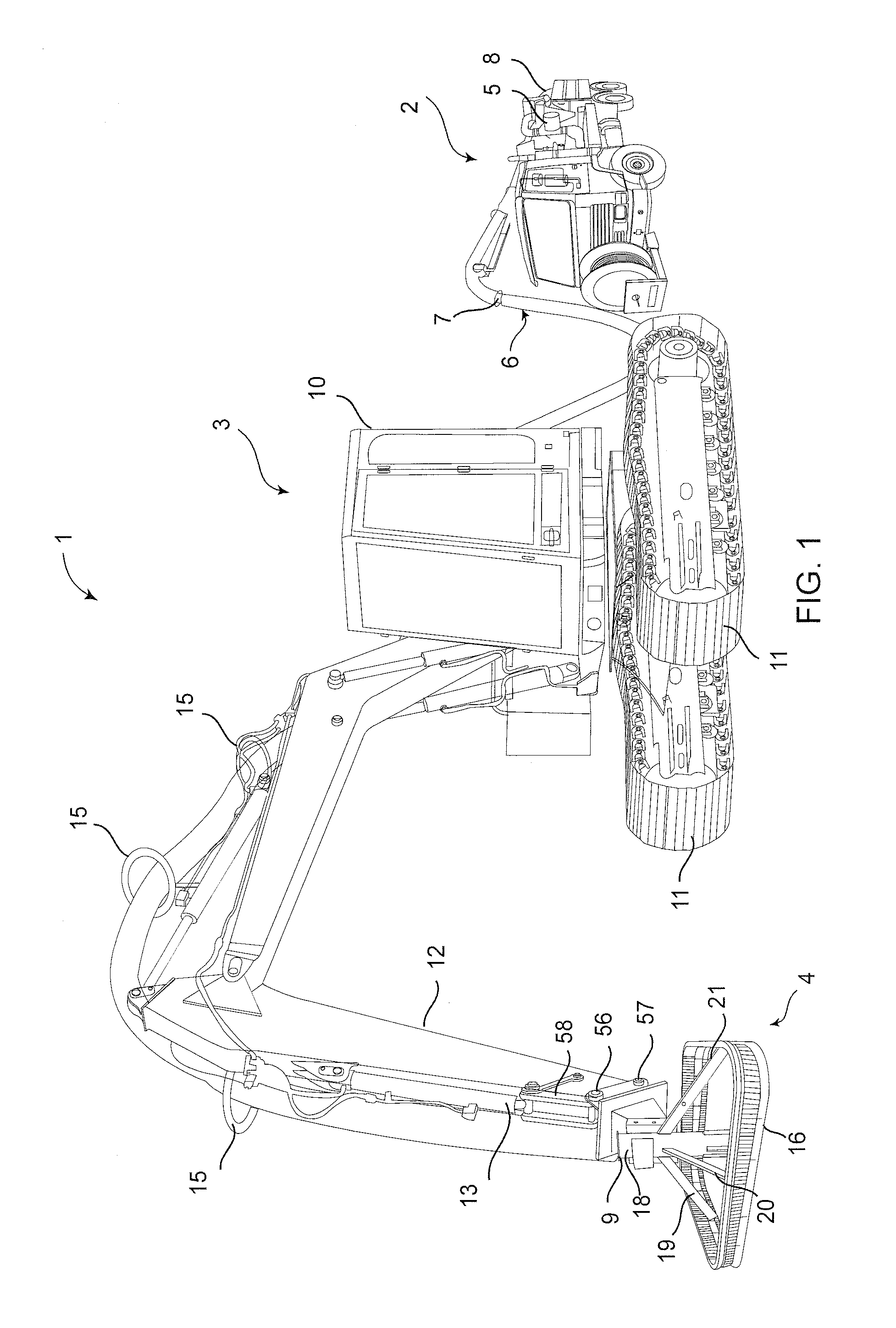

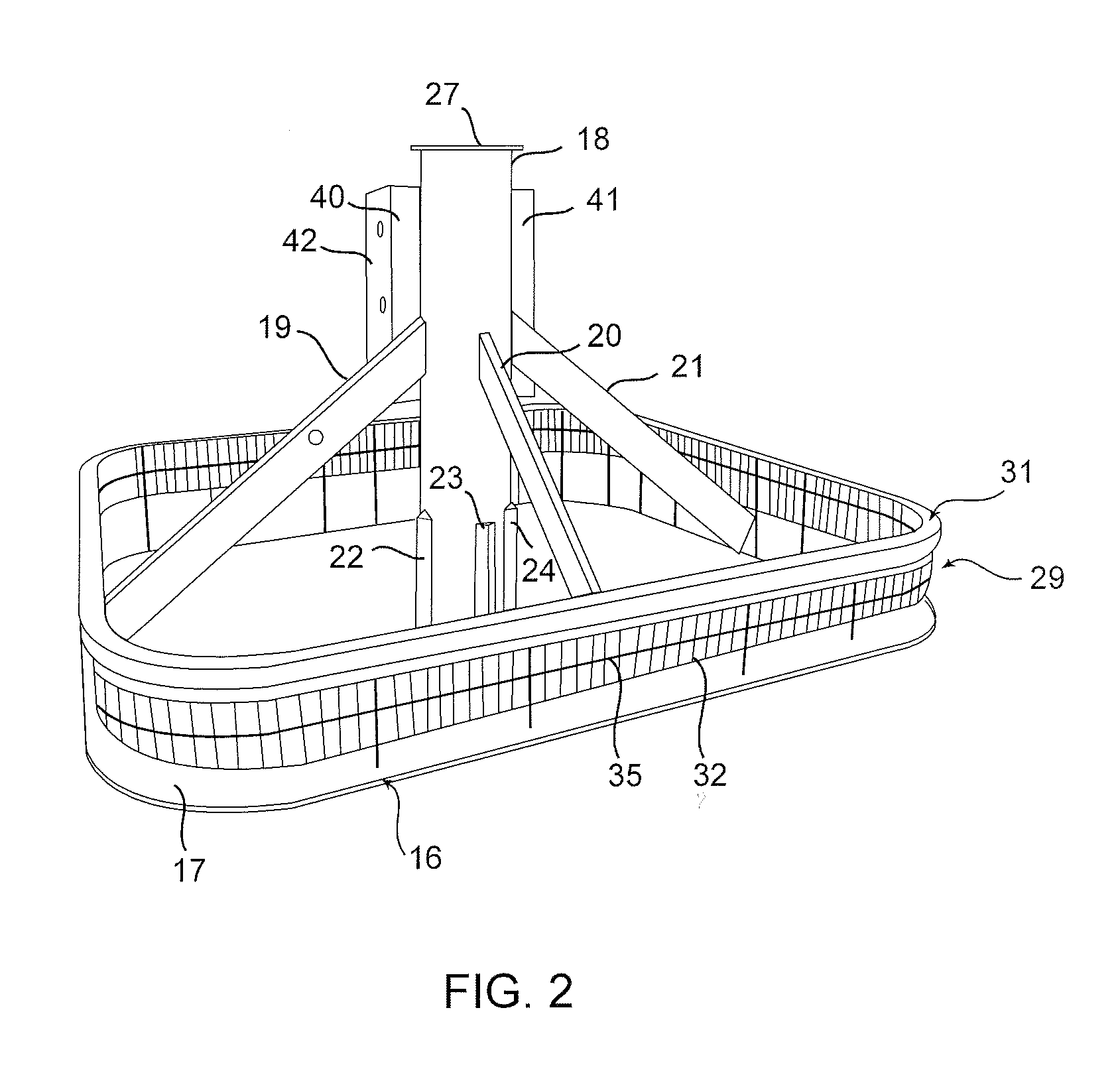

[0021]The oil skimmer assembly and system of this invention can be used to skim a wide variety of matter from a fluid surface. This can include skimming particulates or other material from the surface of a sludge pond or waste pit. However, without any intent to limit the scope of this invention, the preferred embodiments of the invention are described making reference to the skimming of oil from a water surface.

[0022]The system includes three basic elements: a pump with an intake hose attached to the intake port of the pump and a discharge hose attached to the discharge port of the pump, an articulating and extendable extension member mounted on vessel or land vehicle, and the oil skimmer assembly affixed to the extension member and operatively attached to the intake hose. If the oil cleanup is to be conducted from the shore line, in order to obtain maximum operational flexibility and mobility it would be preferred that the pump on a conventional vacuum truck be used and the hydrau...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com