Omnidirectional wheel and method for the assembly thereof

a technology of omnidirectional wheels and wheels, which is applied in the directions of multi-purpose tools, manufacturing tools, transportation and packaging, etc., can solve the problems of complicated installation of such wheels and problems with the bearing of all rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

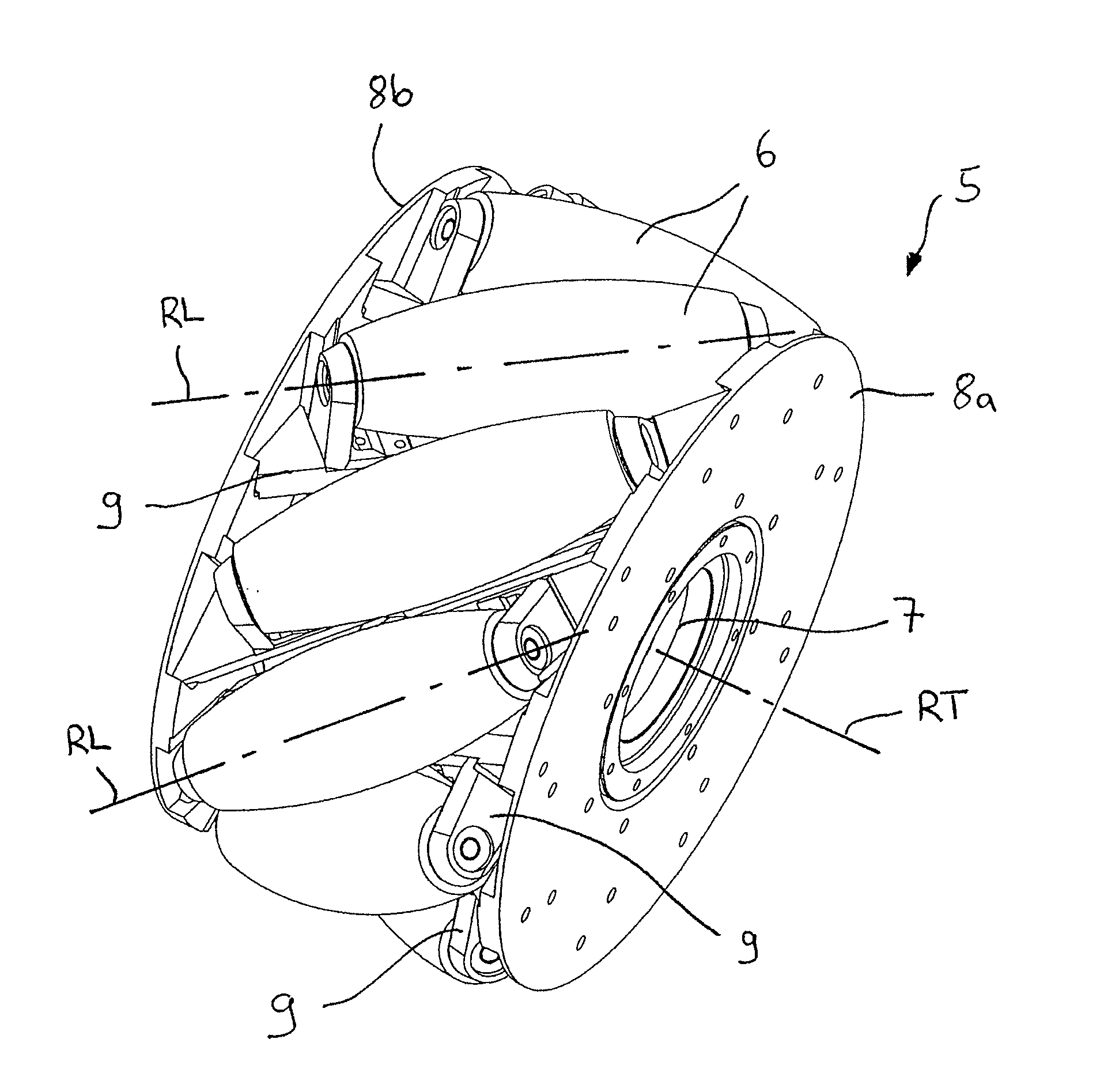

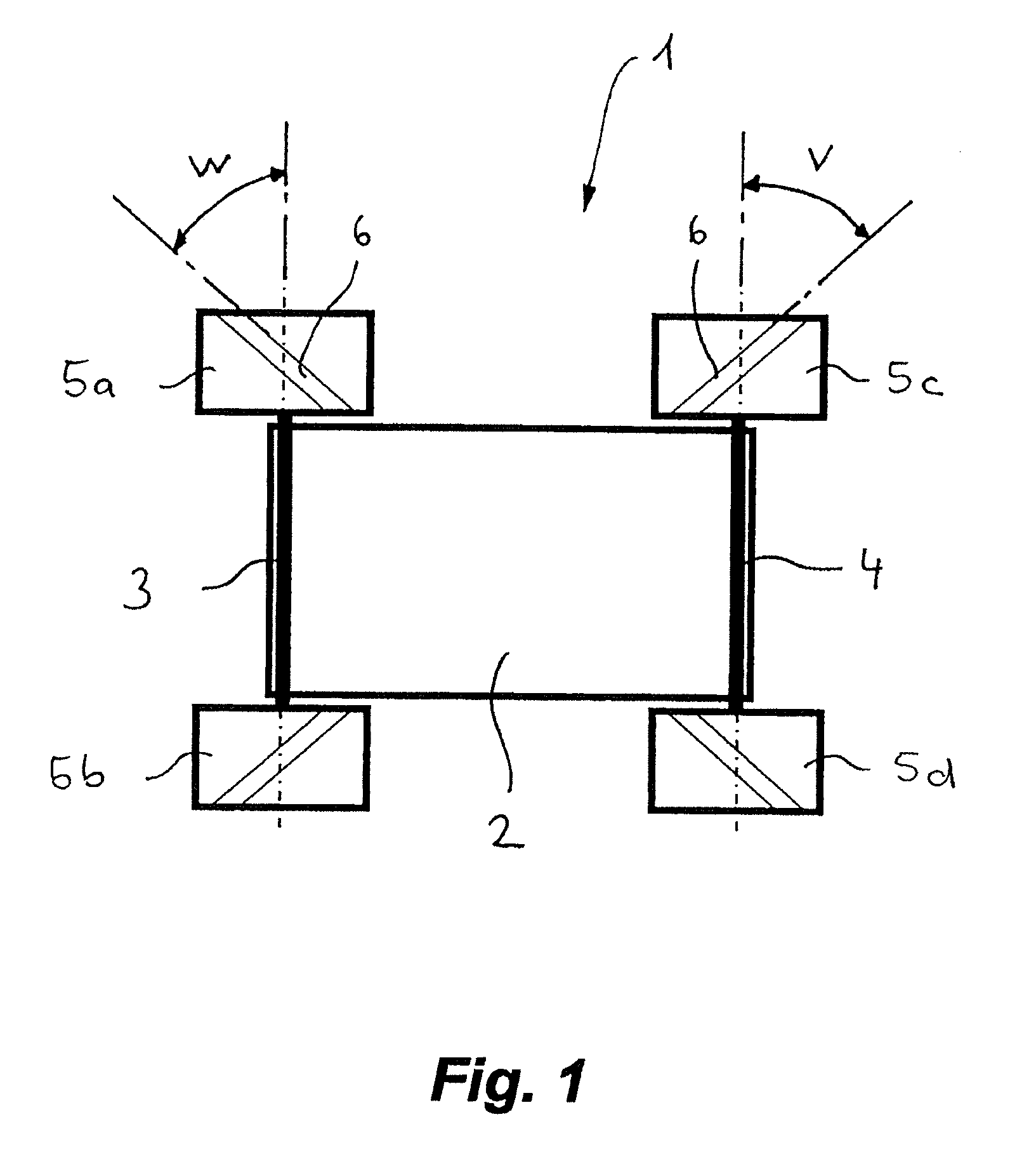

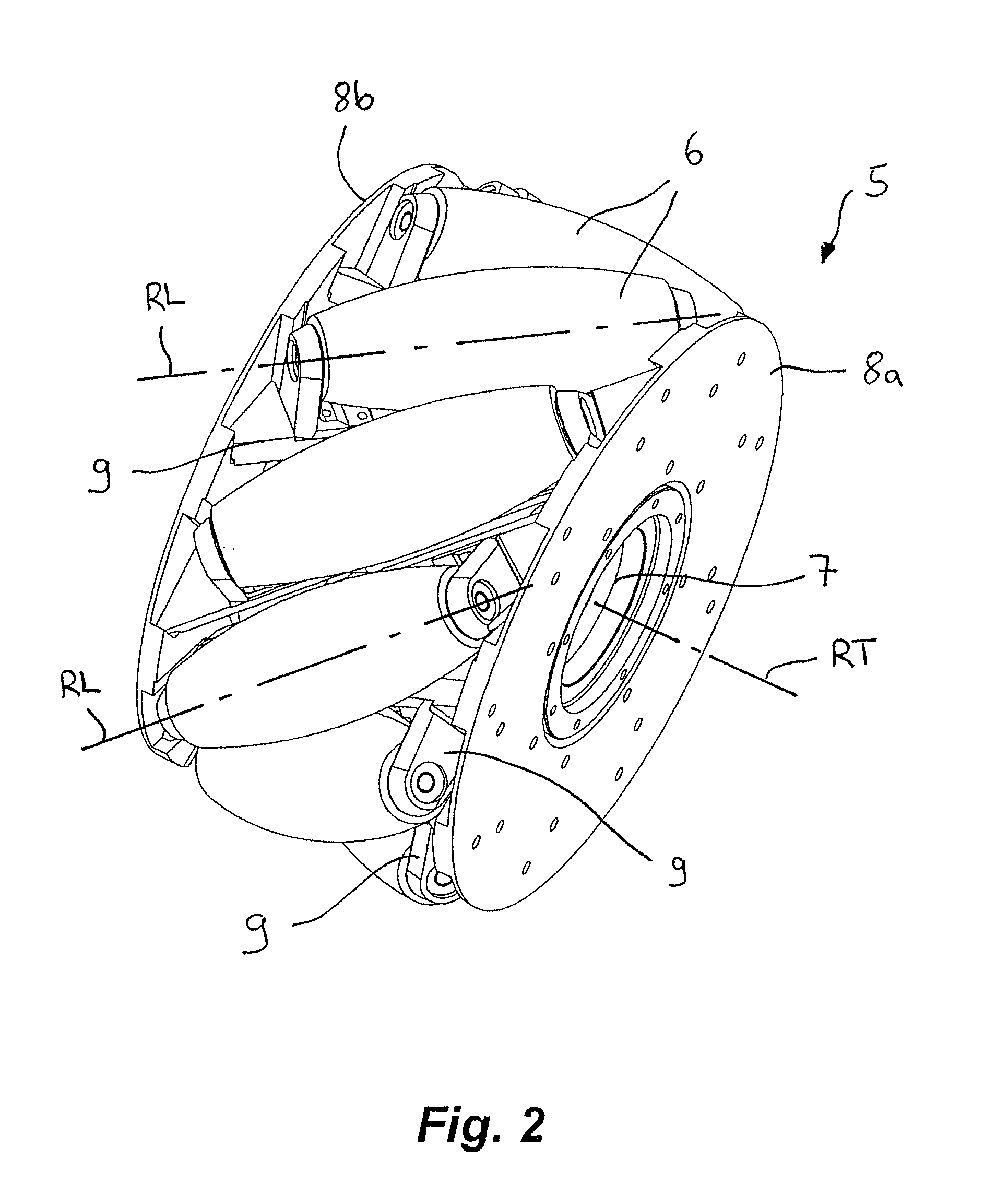

[0052]FIG. 1 shows an omnidirectionally movable carriage 1 with a chassis 2 as well as a first geometric wheel axis 3 and a second geometric wheel axis 4. Aligned along the first wheel axis 3, the chassis 2 bears a right front omnidirectional wheel 5a and a left front omnidirectional wheel 5b. Aligned along the second wheel axis 4, the chassis 2 bears a right rear omnidirectional wheel 5c and a left rear omnidirectional wheel 5d. Each omnidirectional wheel 5a, 5b, 5c, 5d is connected with its own drive. Every drive can be controlled independent of the other drives, both with regard to rotation speed and with regard to rotation direction. Each diagonal wheel pair 5a, 5c and 5b, 5d has roller bodies 6 that are aligned running in the same direction at an angle W inclined relative to the wheel axis 3 or wheel axis 4. The respective other diagonal wheel pair 5a, 5c and 5b, 5d has roller bodies 6 that are aligned running in the same direction at an angle V opposite the angle W, inclined r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com