Structure of a modular shelf rack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

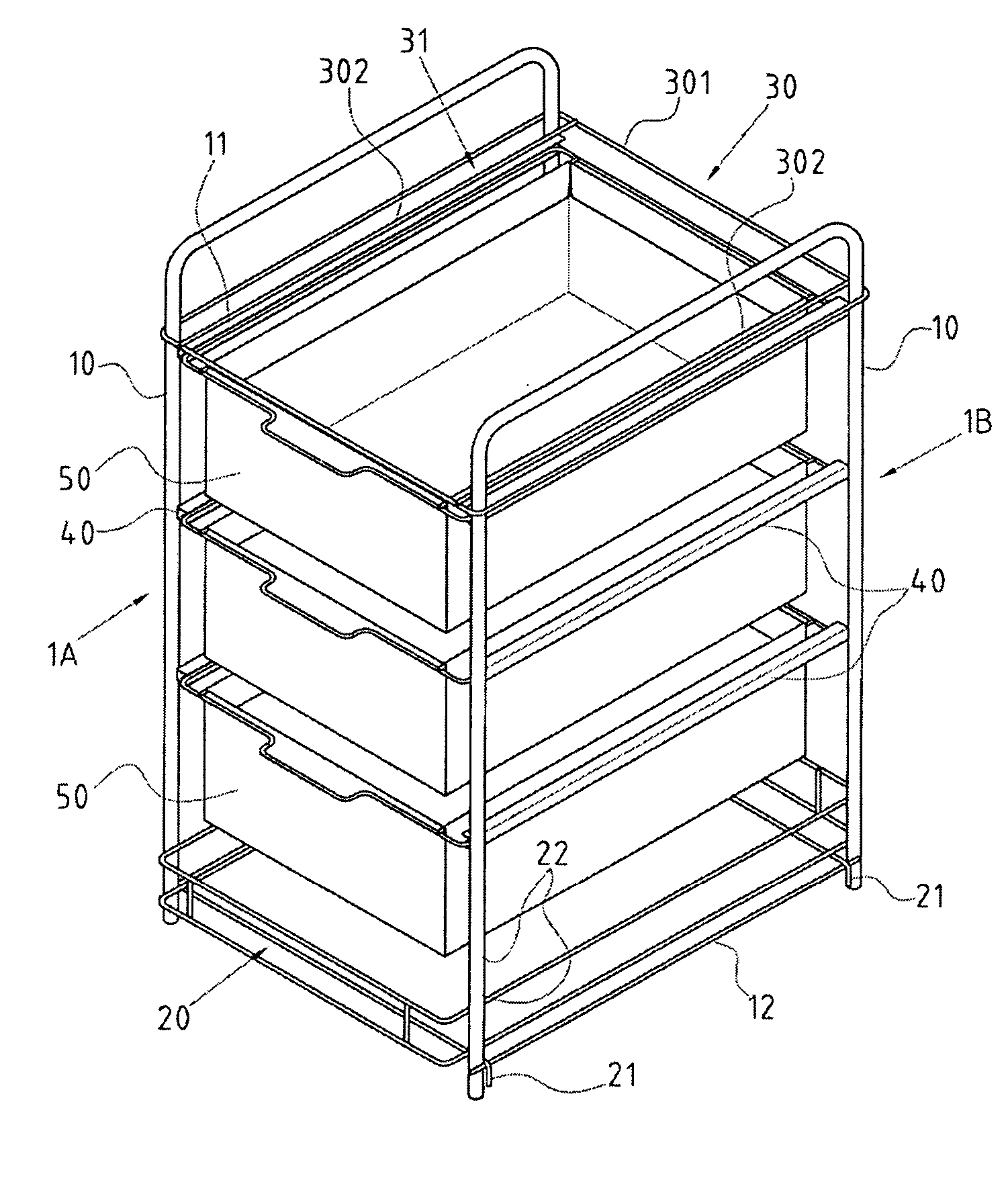

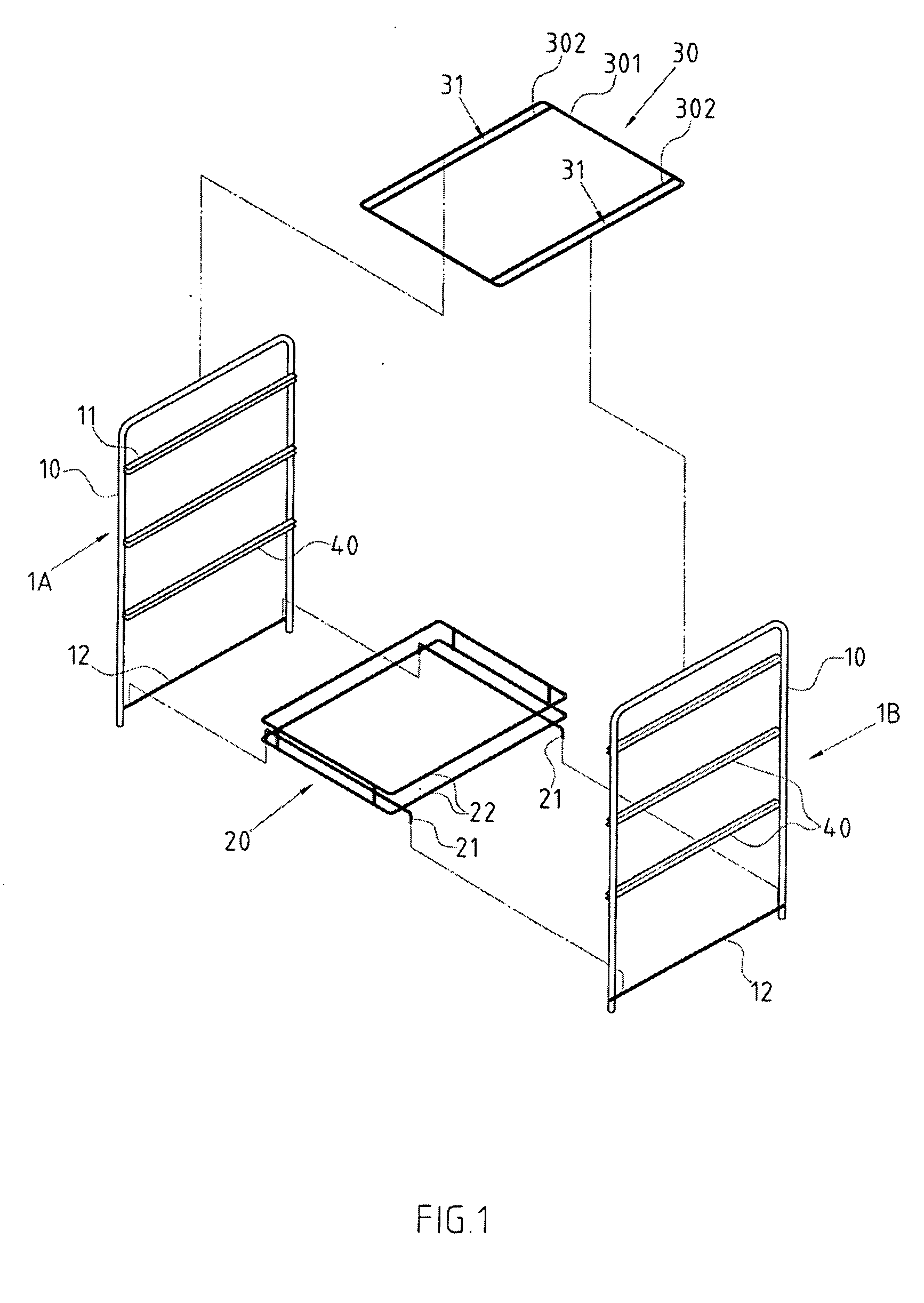

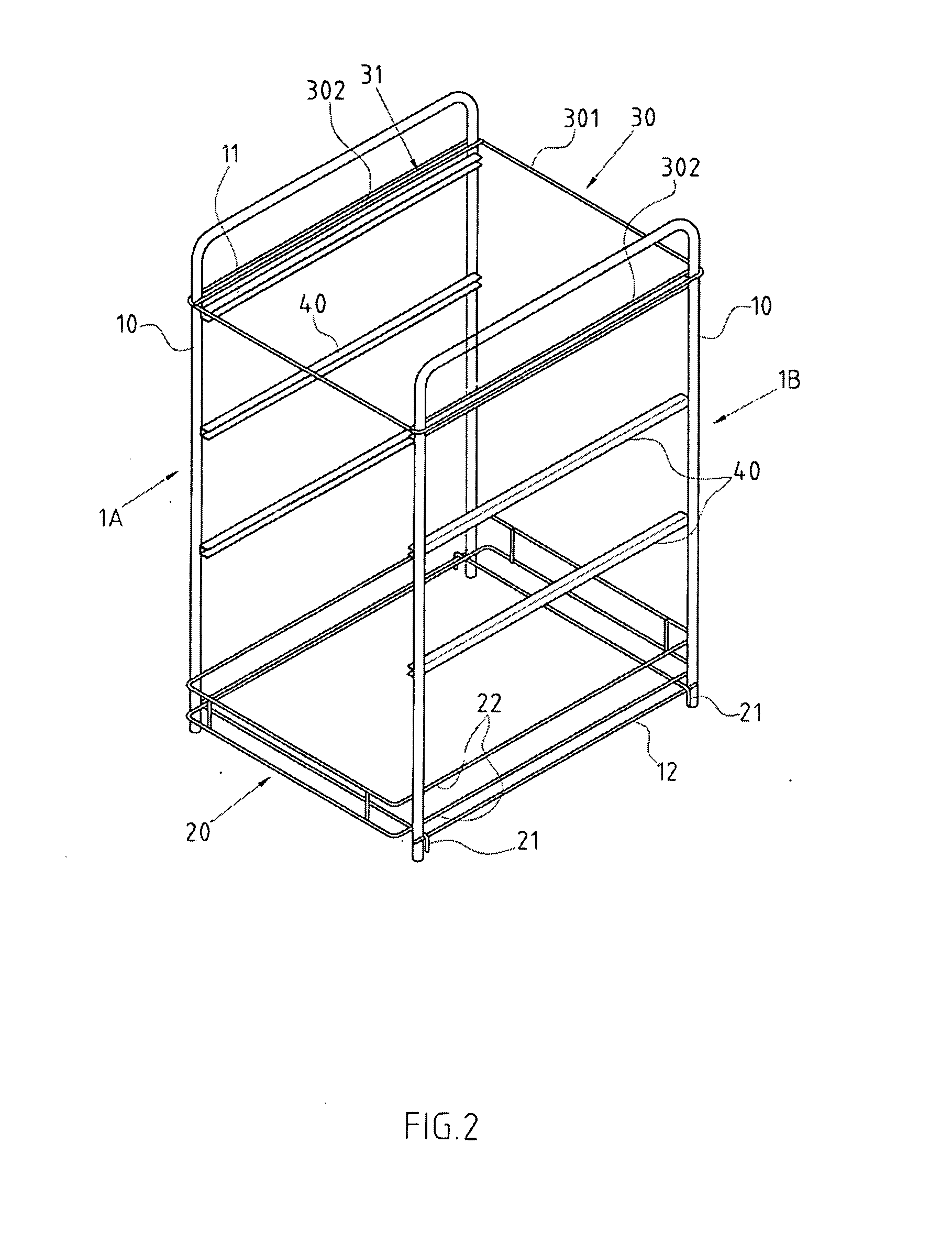

[0022] The features and the advantages of the present invention will be more readily understood upon a thoughtful deliberation of the following detailed description of a preferred embodiment of the present invention with reference to the accompanying drawings.

[0023] As shown in FIGS. 1-4, there is a structure of modular shelf rack, this embodiment being for description only, and not being limited to this structure when applying for the patent. The structure of the modular shelf rack comprises the following.

[0024] A bar-type side rack 1A 1B is standing vertically, and the bar-type side rack is made by a single bar frame 10. Among them, the top and bottom of the two side racks 1A 1B have an upper positioning part 11 and lower positioning part 12 with pre-determined height, the lower positioning part 12 being a horizontal rod.

[0025] A lower stationary rack 20 is placed horizontally between the bottom of the two side bars 1A 1B, and a hook 21 and a vertical blocker 22 are placed two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com