Method and apparatus for the scheduled production of plant extracts

a plant extract and schedule technology, applied in the field of harvesting plant material, can solve the problems of not being suitable for human or animal consumption or exposure, harming the general environment,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Effectively the present invention provides a method by which ‘just-in-time’ production of harvested plant material can be implemented using controlled growing conditions in a genetically-isolated underground growth chamber. Just-in-time production of the plant material, in an environment in which the possibility of exposure to genetic material or contaminants from outside the growth chamber is minimized, is accomplished by the method of the present invention, which is described in further detail below. The following sections are intended to provide in further detail an outline of the illustrated embodiments of the present invention, and the contemplated scope of the invention intended to be covered herein.

Production of Harvested Plant Material:

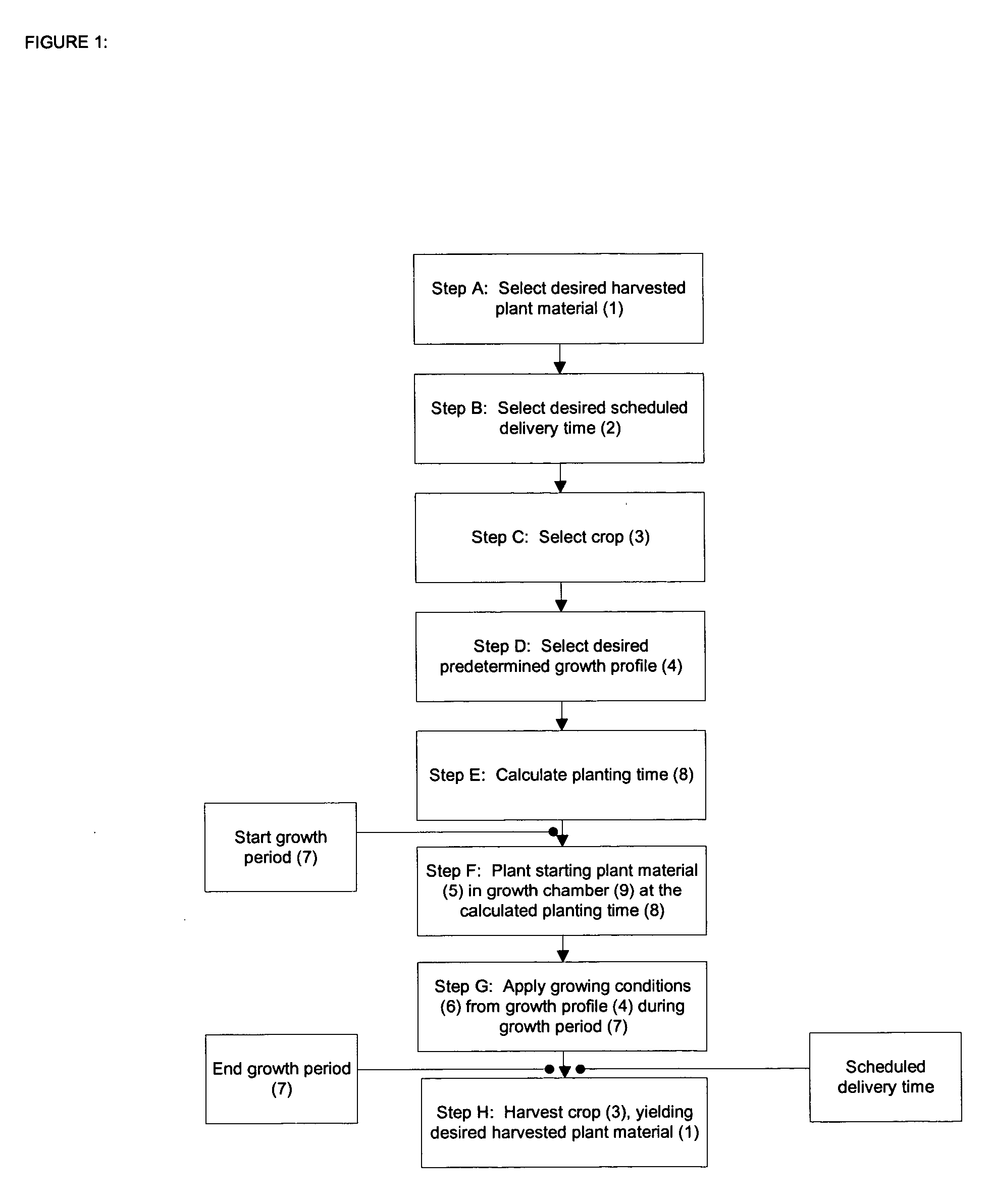

[0042] Referring to FIG. 1, the general method of the present invention will now be discussed. FIG. 1 shows a flow diagram of one embodiment of the method of the present invention, in which harvested plant material of a single plant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com