Ventilation mattress

a technology of ventilation mattress and mattress, applied in the field of mattresses, can solve the problems of user's body, seat or bed mattress becoming hot within a short time, and its cooling effect is gradually reduced, so as to improve the flexibility and ventilation of the ventilation mattress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

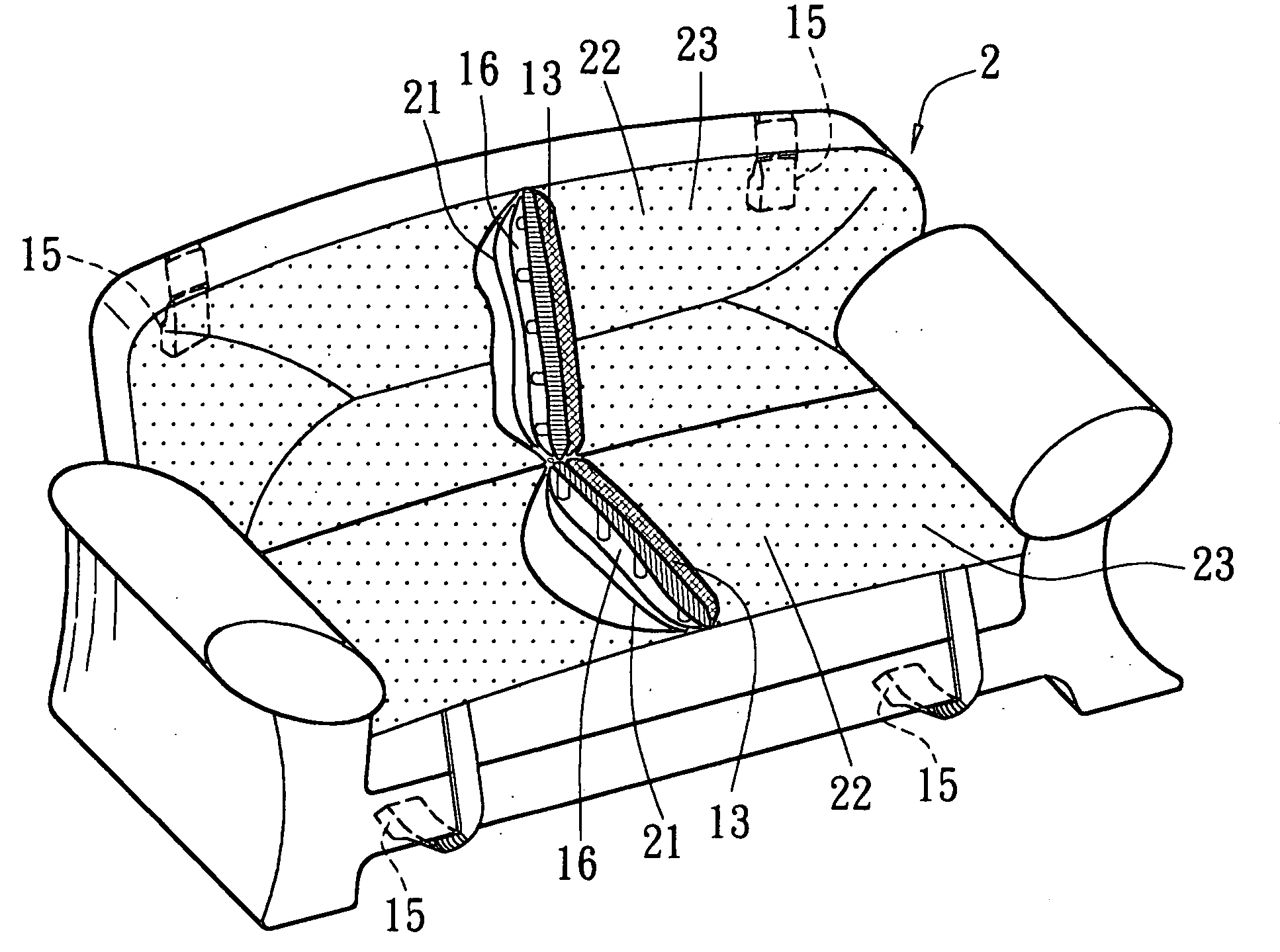

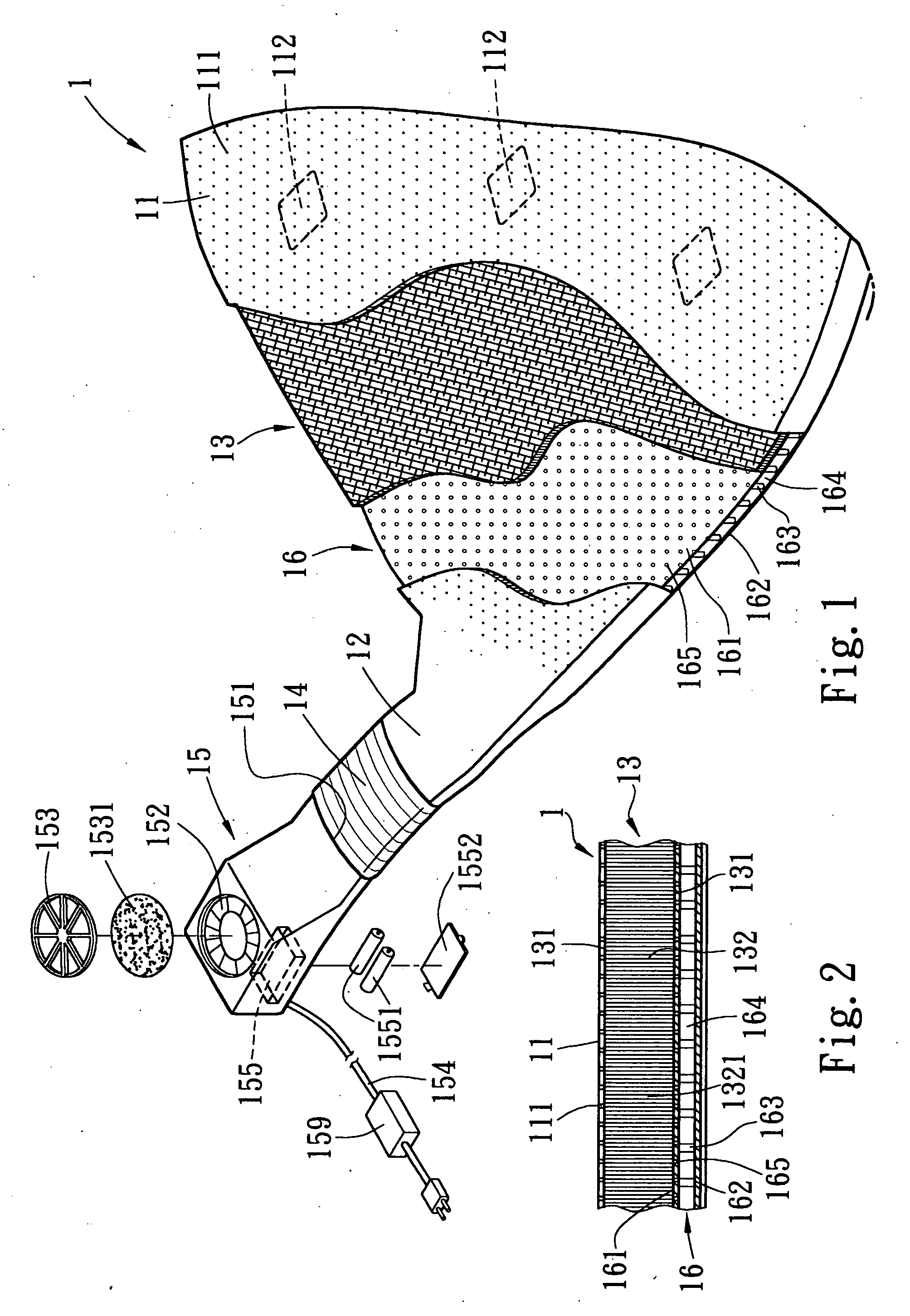

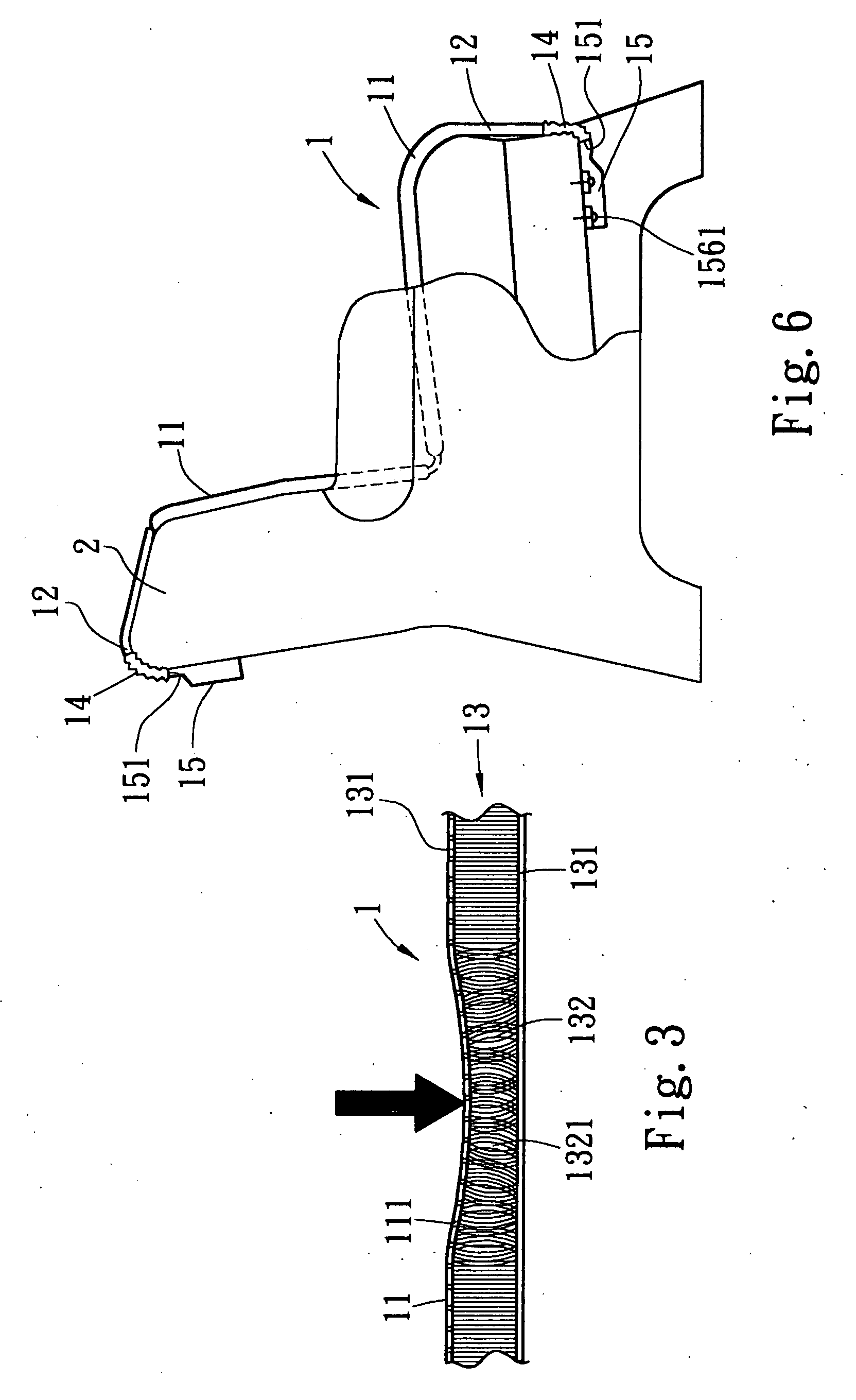

[0031] Referring to FIGS. 1˜4, a ventilation mattress 1 is shown comprising an outer bag 11, a fabric stuffing member 13 put in the outer bag 11, a flexible pad 16 provided at the bottom side of the fabric stuffing member 13 inside the outer bag 11, an air inlet 12 formed in one side of the outer bag 11, a flexible tube 14 extended from the air inlet 12, and a high-performance fan 15 provided at one end of the flexible tube 14 remote from the air inlet 12. The fabric stuffing member 13 is three-dimensional device formed of interwoven spandex fibers 132, having open spaces 1321 in it for ventilation. The outer bag 11 is formed of top and bottom fabric sheet layers 131, having small air vents 111 in the top side (top fabric sheet layer). The flexible pad 16 comprises a top cover layer 161, a bottom cover layer 162, a plurality of springy support members 163 connected between the top cover layer 161 and the bottom cover layer 162, an air passage 164 defined in between the top cover lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com