Method for manufacturing liquid crystal display device

A technology for a liquid crystal display and a manufacturing method, which is applied to static indicators and other directions, can solve the problems of display quality degradation and polymer residues, and achieve the effect of improving display quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following diagrams and preferred embodiments are used to describe the present invention in more detail.

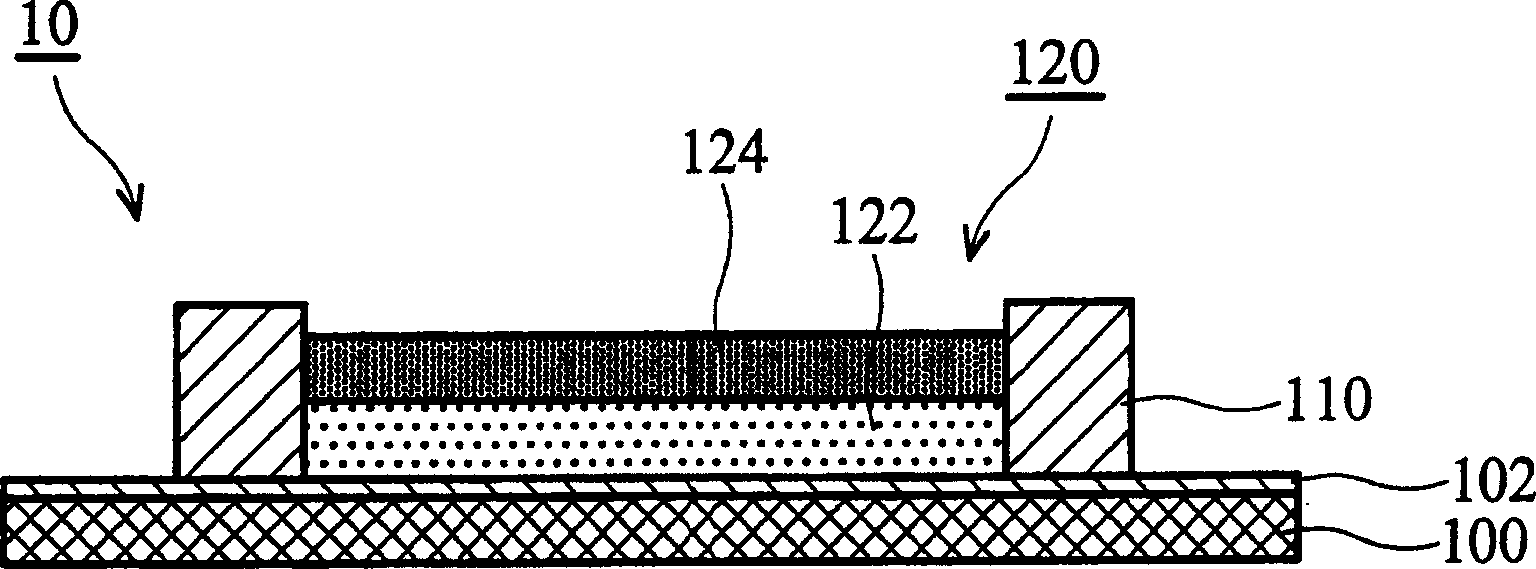

[0036] figure 2 It is a liquid crystal display that shows a single-substrate structure formed by combining inkjet method and liquid crystal / polymer phase separation technology according to an embodiment of the present invention. see figure 2 , a liquid crystal display 10 with a single-substrate structure includes a substrate 100 with a first electrode layer thereon. An alignment layer 102 is disposed on the substrate 100 with the first electrode layer. A patterned protrusion structure 110 is disposed on the substrate 100 to be divided into a plurality of pixel regions 120 . A liquid crystal layer 122 is filled in each pixel region 120 . A polymer material layer 124 is disposed in each pixel area 120 and located on the liquid crystal layer 122 .

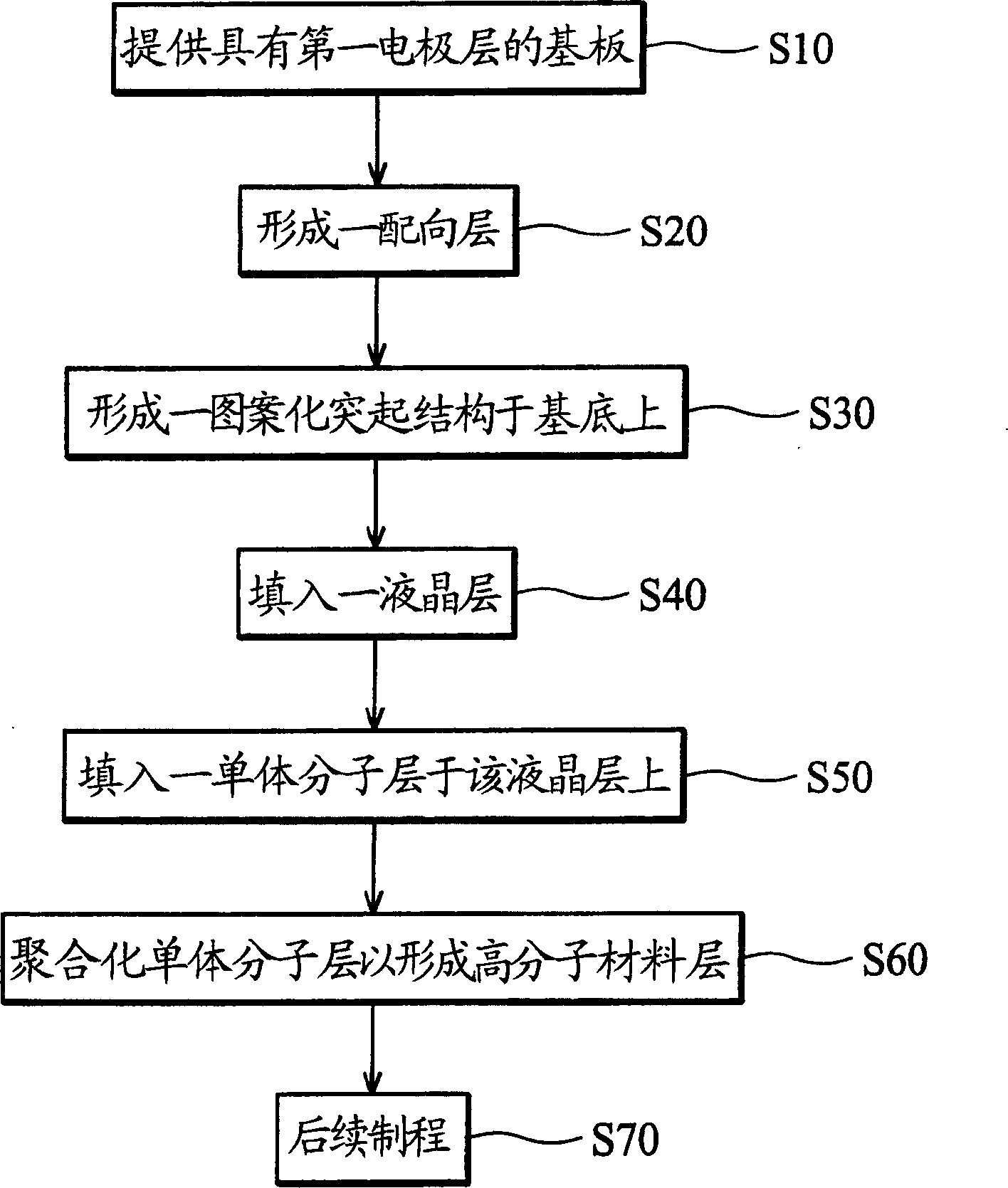

[0037] image 3 It is a flowchart showing a method of manufacturing the liquid crystal display 10 . First, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com