Grain discharging device

A technology for discharging devices and grains, which is applied in threshing equipment, applications, agricultural machinery and implements, etc., can solve problems such as the decline of operation performance, and achieve the effect of easy operation and improved operation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

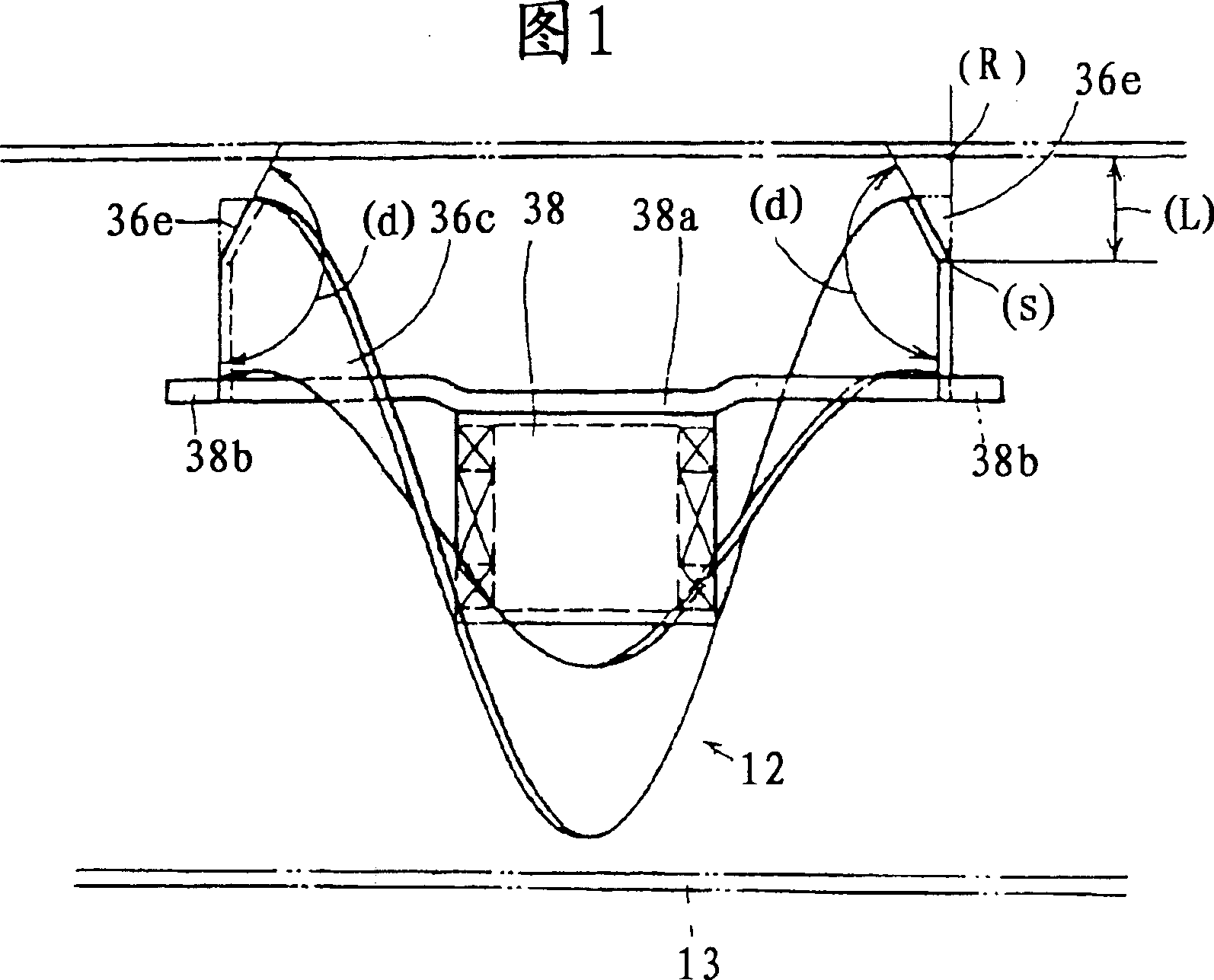

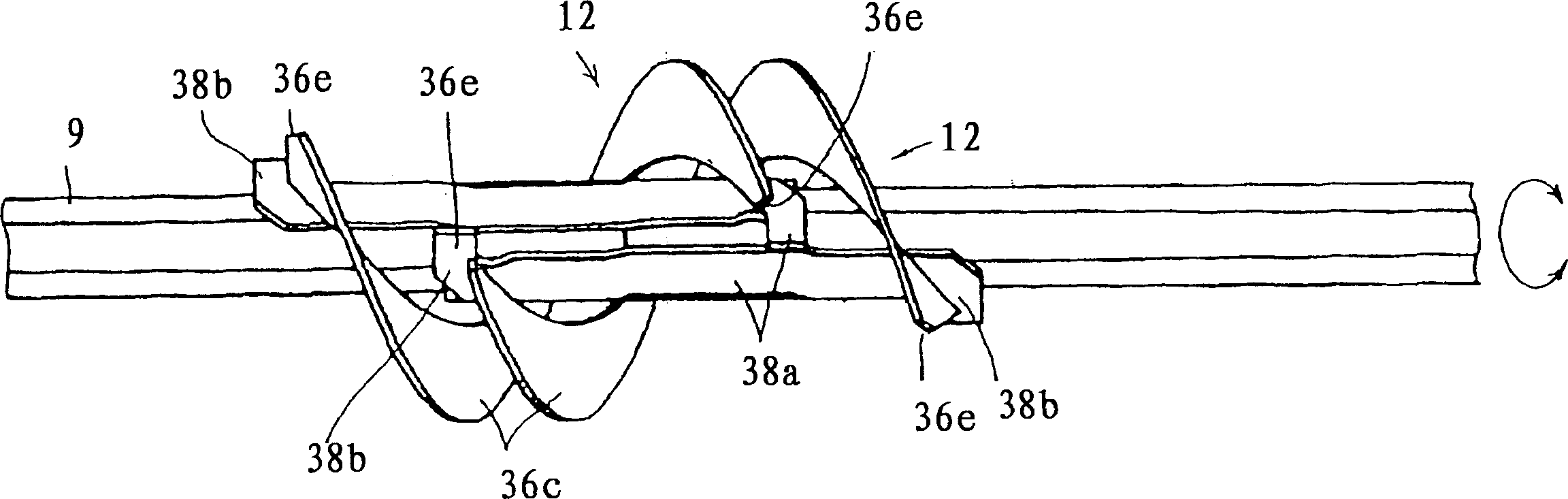

[0058] Hereinafter, embodiments of the present invention will be described with reference to the drawings. exist Figure 17 In the figure, the combine harvester which is the agricultural machine which embodied this invention is shown.

[0059] Under the traveling chassis 2 of the combine harvester 1 , a traveling device 15 is arranged. The left and right pairs of traveling crawlers 15 a traveling on the soil surface are arranged, and the threshing machine 3 is placed on the upper side of the traveling chassis 2 . The harvester 16 on the front side of the driving chassis 2 reaps the planted grain stalks, transports the harvested grain stalks to the rear, and is clamped and transported by the feed chain 3a and the clamping rod 3b of the threshing machine 3 for threshing. After threshing, the sorted grains are recovered into the grain storage container 4 installed on the right side of the threshing machine 3 .

[0060] On the front side of the aforementioned threshing machine 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com