Structure for addressing electrodes in plasma panel display

A flat-panel display, addressing electrode technology, applied in circuits, discharge tubes, electrical components, etc., can solve the problems of high probability of disconnection, low current, slow writing speed, etc., to improve current resistance and increase writing speed. , to avoid the effect of overloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

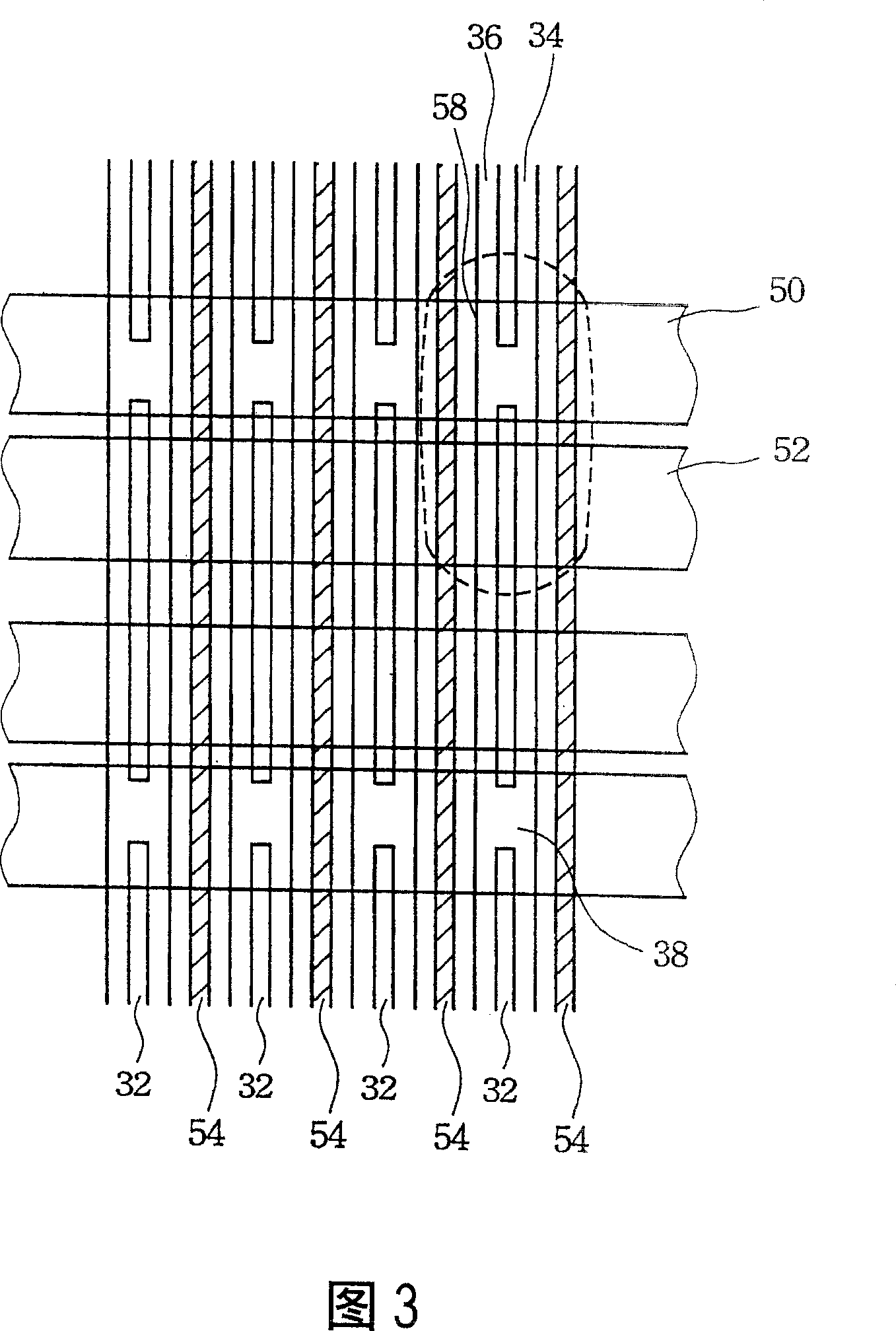

[0029] Without limiting the spirit and scope of application of the present invention, the implementation of the present invention is described below with an embodiment; those of ordinary skill in the art, after understanding the spirit of the present invention, can apply the addressing electrode of the present invention structure in various plasma displays. Each addressing electrode structure is composed of two wires, which are connected at the adjoining positions of the X electrode and the Y electrode close to the light-emitting unit, thereby increasing the writing speed. The application of the present invention should not be limited to the preferred embodiments described below.

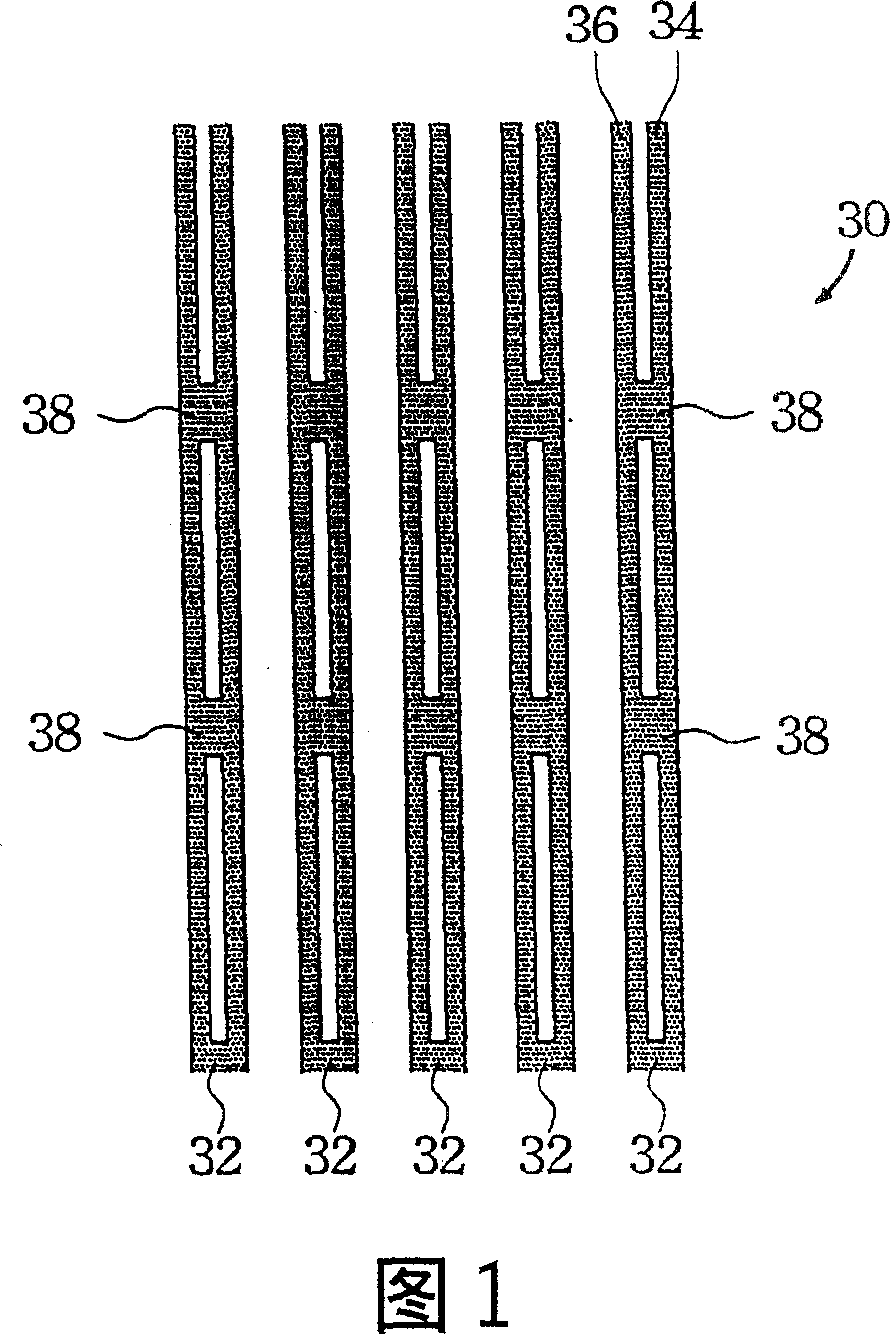

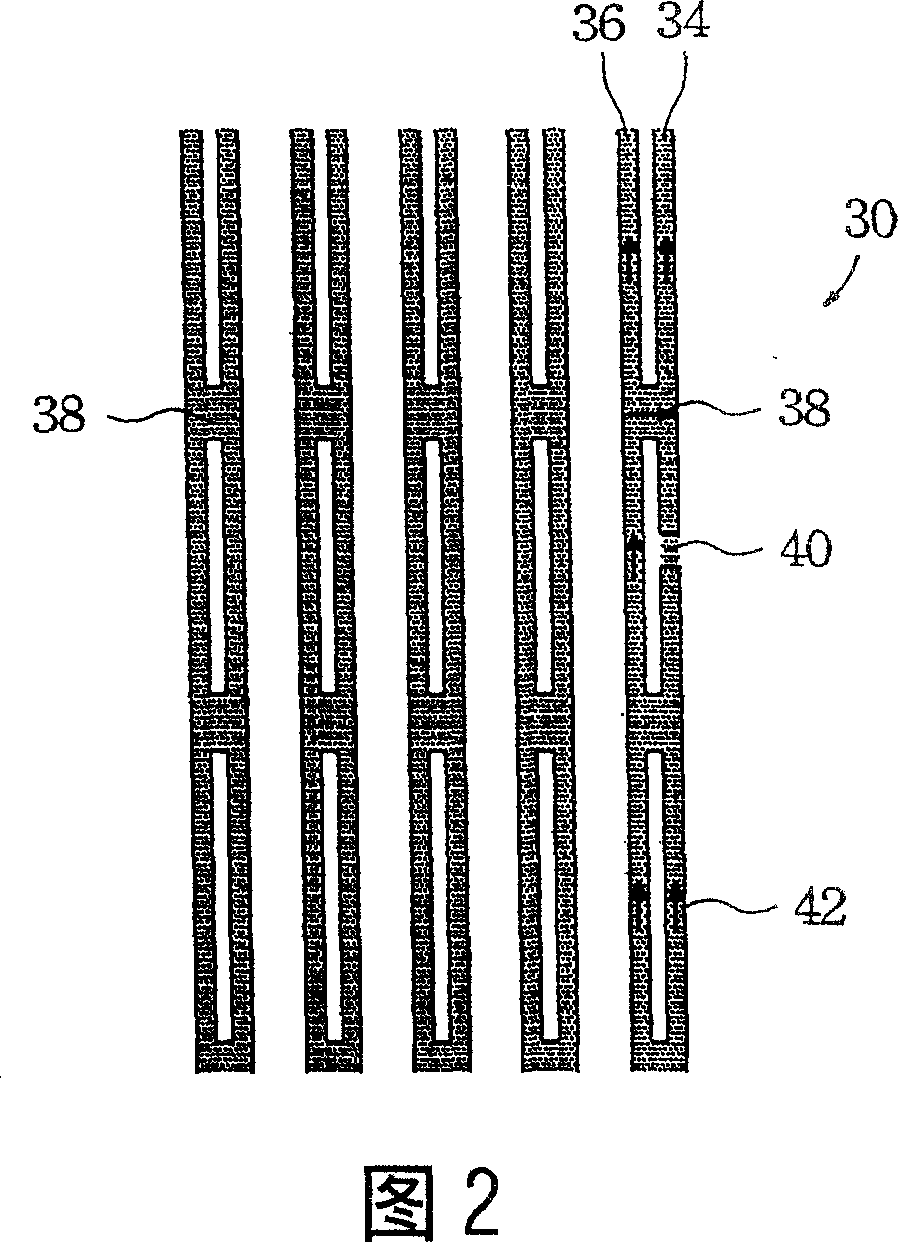

[0030] As shown in FIG. 1 , it is a schematic top view of an address electrode structure of a plasma flat panel display according to a preferred embodiment of the present invention. The addressing electrode structure 30 of the present invention adopts the design of two wires, that is, each addressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com