Precipitation pneumatically supported serial composite solid-liquid separator

A technology of solid-liquid separation and series combination, which is applied in the direction of sedimentation separation, solid separation, separation methods, etc., can solve the problem of large floor area, easy breakage of flocs, and the inability of a single solid-liquid separation device to adapt to changes in source water quality, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

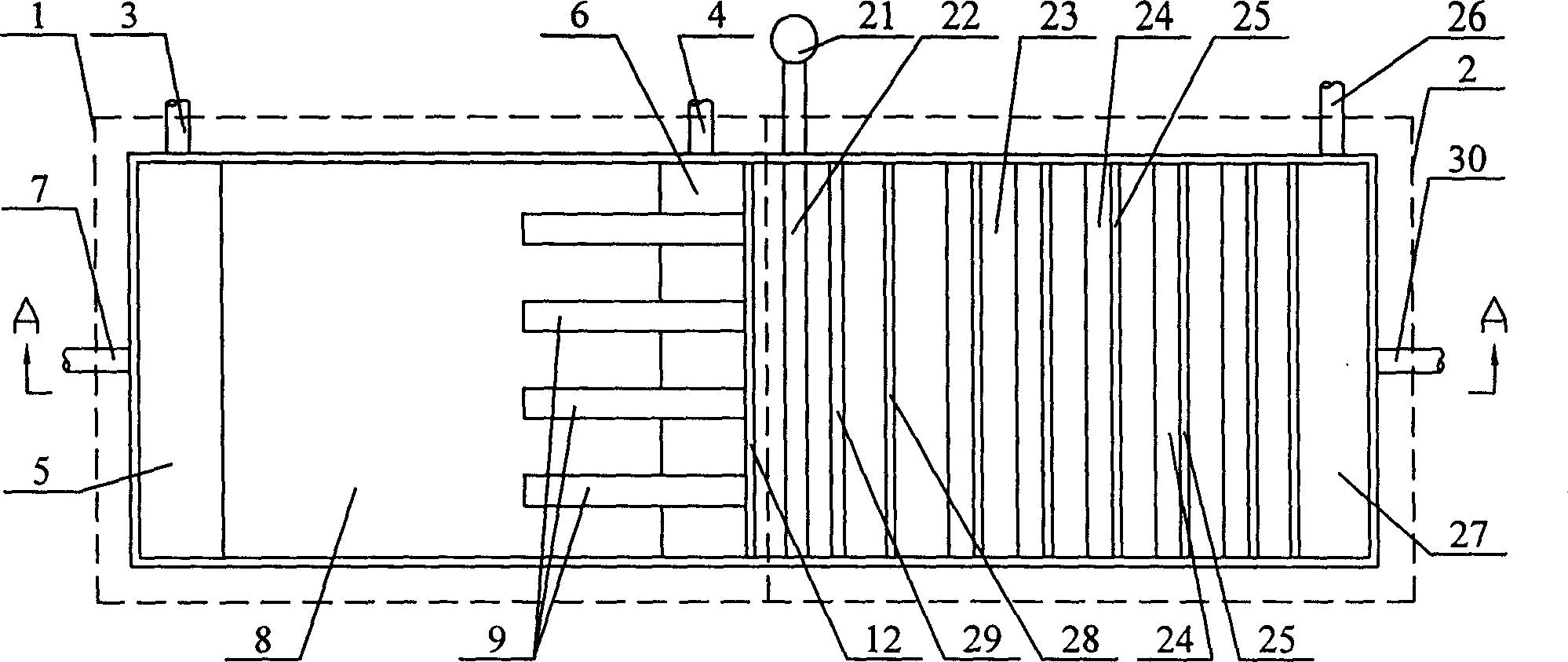

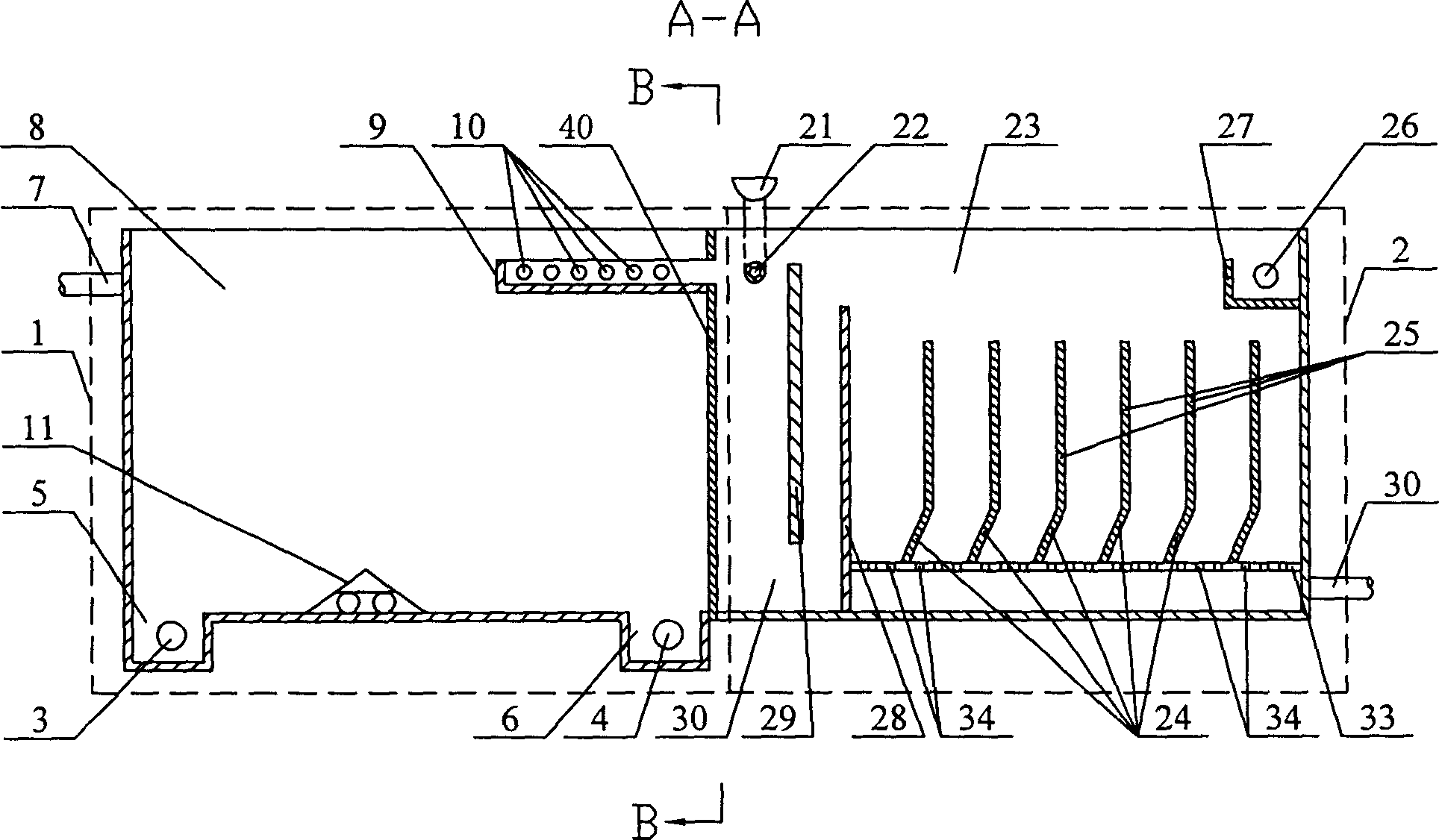

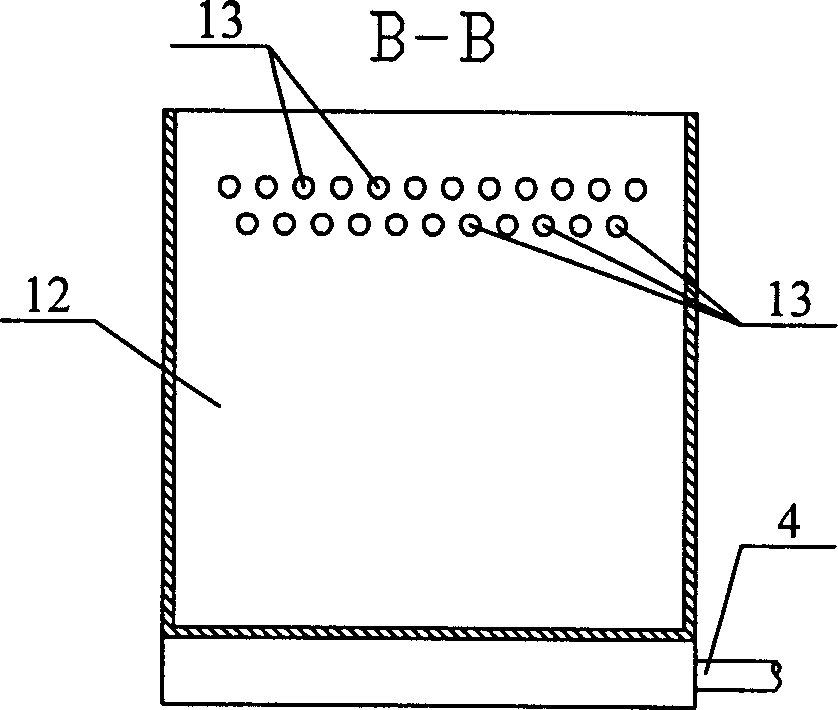

[0005] Specific implementation mode one: (see Figure 1 ~ Figure 3 ) This embodiment is made up of precipitation solid-liquid separation device 1 and air flotation solid-liquid separation device 2, and precipitation solid-liquid separation device 1 is connected in series with air flotation solid-liquid separation device 2, and precipitation solid-liquid separation device 1 is composed of sedimentation tank 8, water inlet Channel 7, perforated flower wall 12, No. 1 sludge tank 5, No. 1 slag outlet 3, No. 2 sludge tank 6, and No. 2 slag outlet 4; the water inlet channel 7 is set on the water inlet side of the sedimentation tank 8 , the perforated flower wall 12 is located on the water outlet side of the sedimentation tank 8, the perforated flower wall 12 has a water outlet hole 13, the No. 1 sludge tank 5 is located at the bottom of the water inlet side of the sedimentation tank 8, and the No. 1 slag outlet 3 is located at On the outer wall of the sedimentation tank 8 at the No....

specific Embodiment approach 2

[0006] Specific implementation mode two: (see figure 1 , figure 2 ) The difference between this embodiment and the specific embodiment one is that the first mixing plate 29, the second mixing plate 28, the perforated pipe 22 and the high-level medicine box or the dosing pump 21 are added in the air flotation tank 23, and the first mixing plate 29 is fixed on the water inlet side in the air flotation pool 23, the lower end of the first mixing plate 29 and the bottom surface of the air flotation pool 23 leave a water space 30, and the second mixing plate 28 is fixed in the air flotation pool 23 close to the first mixing plate 29 on the water outlet side, the lower end of the second mixing plate 28 is sealed and connected with the bottom surface of the air flotation pool 23, the height of the upper end of the second mixing plate 28 is lower than the height of the upper end of the first mixing plate 29, and the first mixing plate 29 and the perforated flower wall The upper part ...

specific Embodiment approach 3

[0007] Specific implementation mode three: (see figure 2 ) The difference between this embodiment and the specific embodiment one is that the perforated flower wall 12 and the water outlet hole 13 are replaced by the water collecting tank 9 and the retaining wall 40, the retaining wall 40 is fixed on the water outlet side of the sedimentation tank 8, and the water collecting tank 9 is fixed on the sedimentation tank. On the top of the retaining wall 40 on one side of the pool 8, the water collecting tank 9 has a through hole 10, the water collecting tank 9 is vertically arranged with the retaining wall 40, and one end of the water collecting tank 9 is fixed on the retaining wall 40, and communicates with the air flotation pool 23 . Other compositions and connections are the same as in the first embodiment. The effect of this embodiment is to make the water outlet of the sedimentation tank 8 uniform, which is conducive to improving the treatment effect of the air flotation ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com