Traction sleeve continuous type garbage bag roll

A technology of garbage bag rolls and traction sleeves, which is applied in the direction of garbage cans, garbage collection, bags, etc., can solve the problem of inconvenient replacement, and achieve the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

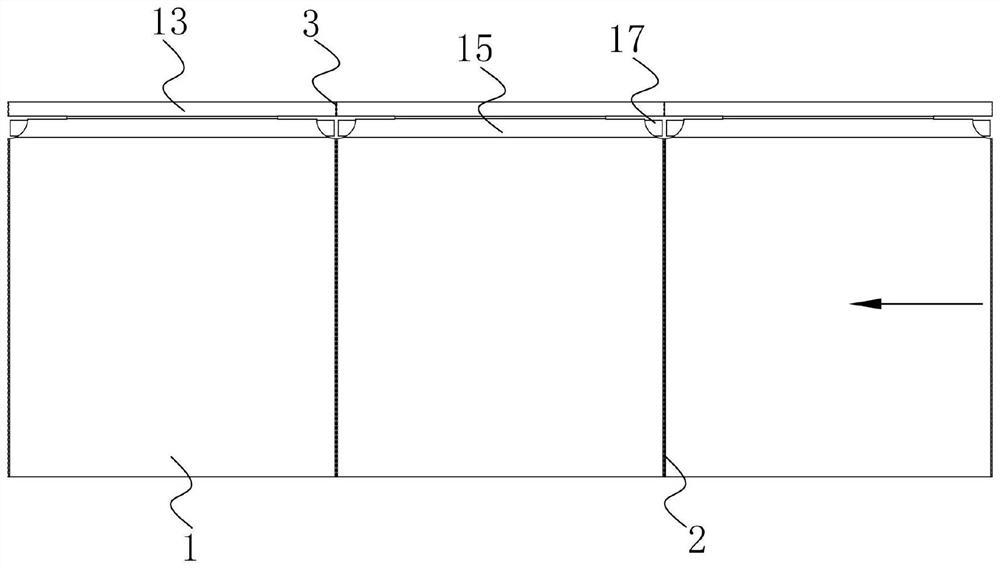

[0040] see Figure 1 to Figure 7 , this embodiment provides a traction sleeve continuous garbage bag roll, which includes a plurality of garbage bags 1 connected in series, and is rolled from the side end of the garbage bag 1 to ensure that the injection port 12 faces the outside, wherein figure 1 The arrow on the right is the direction of winding.

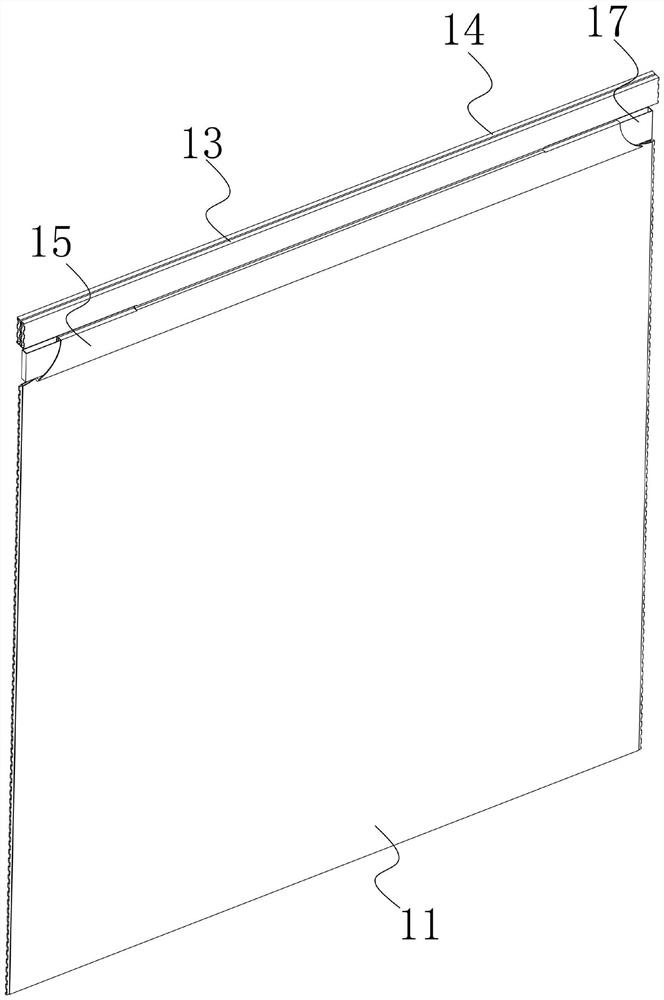

[0041] see figure 1 , figure 2 and Figure 5 , the garbage bag 1 includes an expandable bag body 11, the bag body 11 is used to hold garbage, and one end of the bag body 11 has a delivery opening 12; The body 11 is torn from the garbage bag roll.

[0042] see Figure 2 to Figure 4 , the bag body 11 is provided with a first traction cover 13 on one side of the injection port 12, and a second traction cover 14 corresponding to the first traction cover 13 on the other side. The first traction cover 13 and the second traction cover The sleeve 14 can be correspondingly worn on the two expansion arms 53 of the outer barrel 5 . T...

Embodiment 2

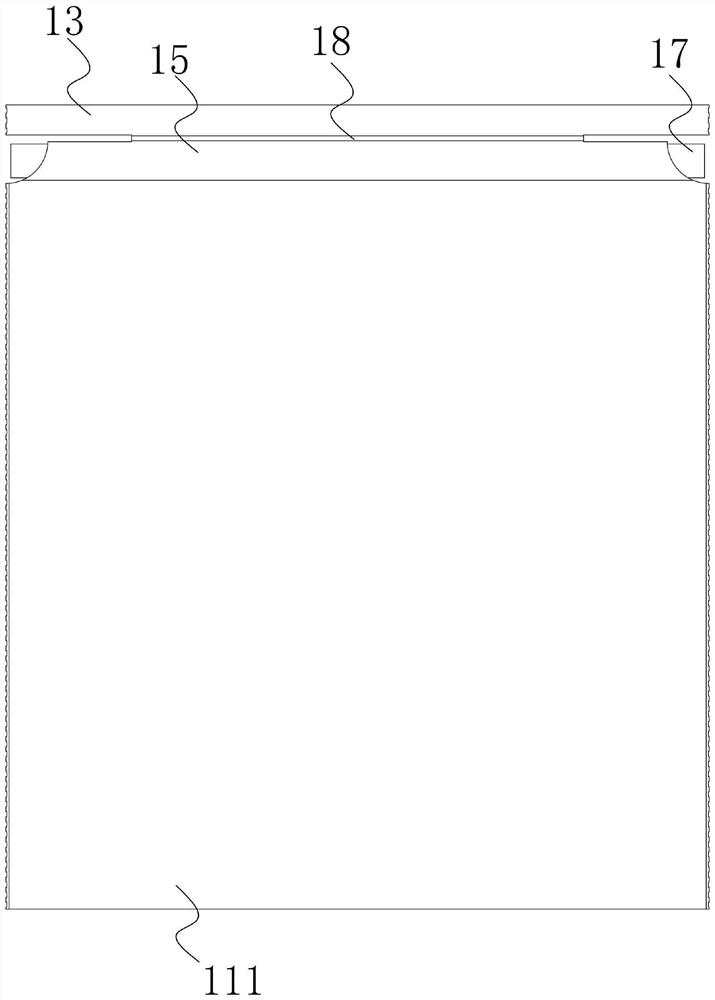

[0051] see Figures 9 to 15 , the difference between the traction sleeve continuous garbage bag roll provided in this embodiment and the embodiment 1 is that in this embodiment, the first traction sleeve 13 and the second traction sleeve 14 are both fixed on the outer wall surface of the pulling rope sleeve 15 . In order to ensure that the bag body 11 can be fully unfolded, both sides of the first traction cover 13 and both sides of the second traction cover 14 are not fixed with the drawstring cover 15. In this way, the structure of the garbage bag 1 is simpler and the manufacturing cost is lower. , which is more convenient to use.

[0052] The invention provides a continuous garbage bag roll with a traction sleeve, which adopts a continuous first traction sleeve and a second traction sleeve. When the pulling rope is pulled to close the mouth, the latter garbage bag can be driven to automatically feed; The pulling sleeve and the second pulling sleeve are matched with the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com