Feeding equipment for industrial breeding of poultry and chicken and use method of feeding equipment

A chicken and industrial technology, applied in the poultry industry, application, animal husbandry and other directions, can solve the problems of inconvenient feeding, low efficiency, inconvenient feeding, etc., to improve feeding efficiency, improve feeding effect, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

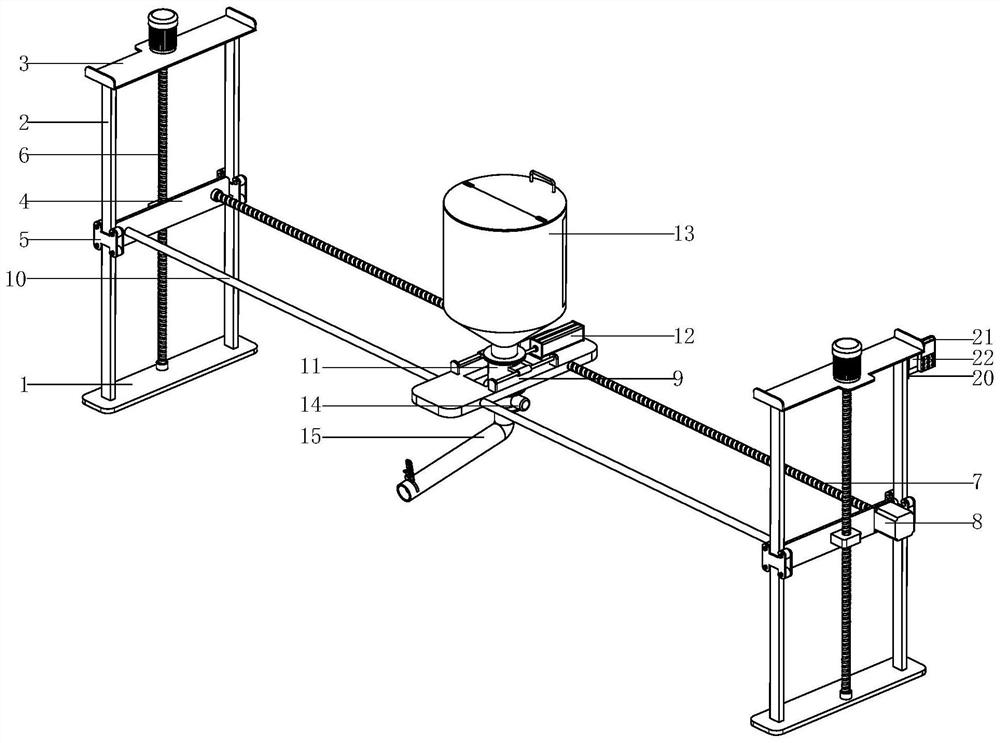

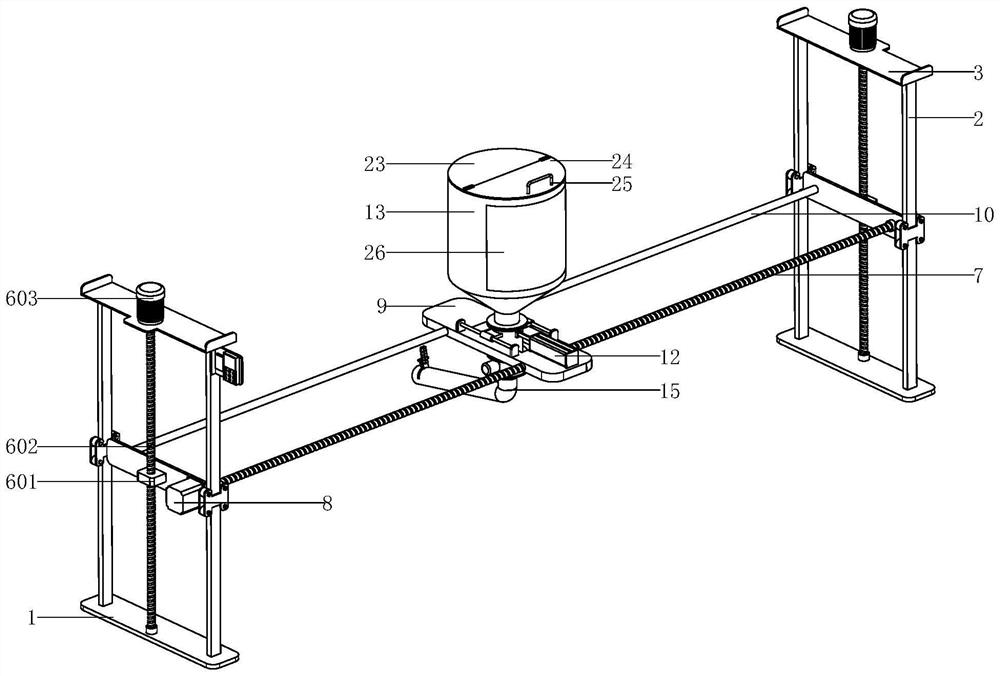

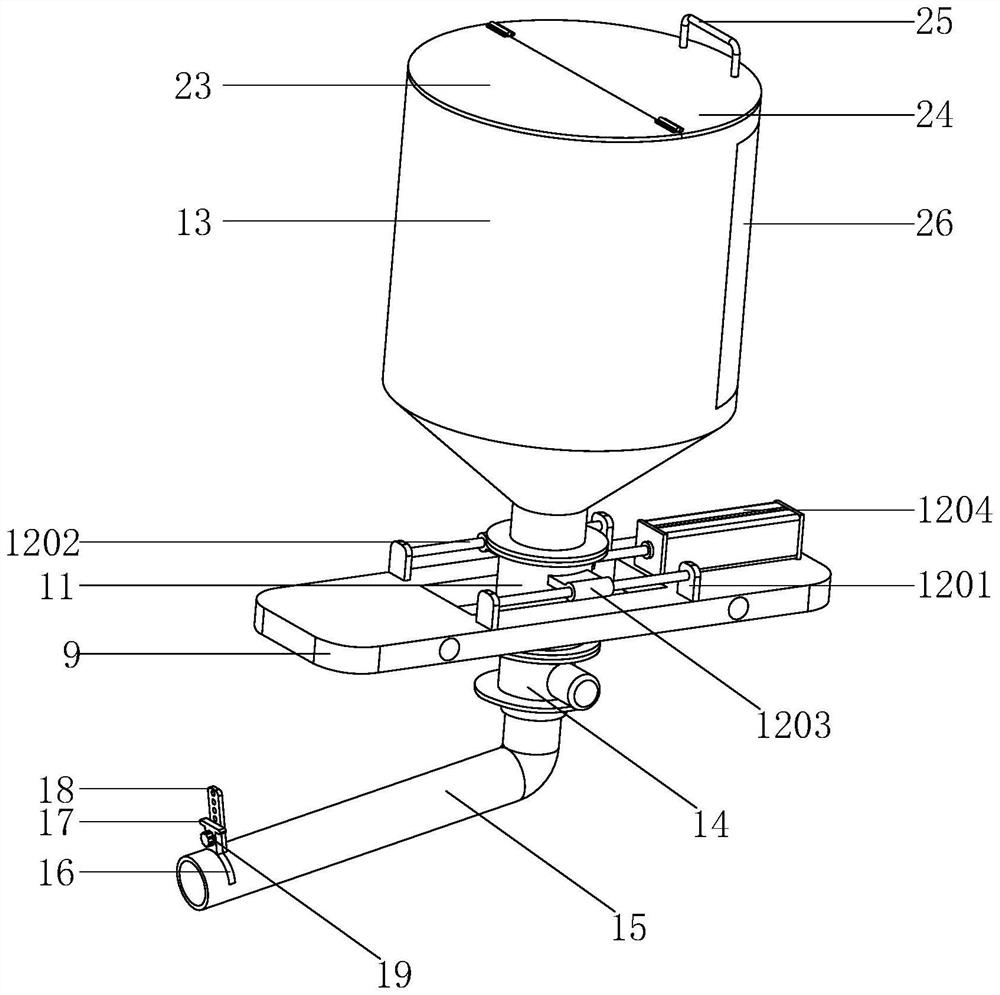

[0032] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, an embodiment of the present invention proposes a feeding equipment for poultry and chicken industrial breeding, comprising two bottom plates 1 arranged in parallel, and two upright columns 2 are fixedly connected to the upper end surfaces of the two bottom plates 1. The tops are fixedly connected with a top plate 3, a moving plate 4 is arranged between the uprights 2, and both ends of the moving plate 4 are provided with a sliding mechanism 5. The top plate 3 is provided with a driving mechanism 6 that drives the moving plate 4 to move. A threaded rod 7 is rotatably connected between 4, and a servo motor 8 is fixedly connected to the side wall of one of the moving plates 4. The driving end of the servo motor 8 penetrates the moving plate 4 and is fixedly connected with the threaded rod 7, and the threaded rod 7 is threadedly connected. A mounting plate 9 is connected, a sliding rod 10 is slida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com