Multi-station efficient manipulator glass unloading table

A manipulator and multi-station technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems that the vertical loading and unloading table cannot be rotated, the adaptability of large and small glasses is poor, and the speed of manual glass loading and unloading is slow, so as to improve the whole machine. The effect of automatic processing ability, improvement of bulk order production capacity, and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

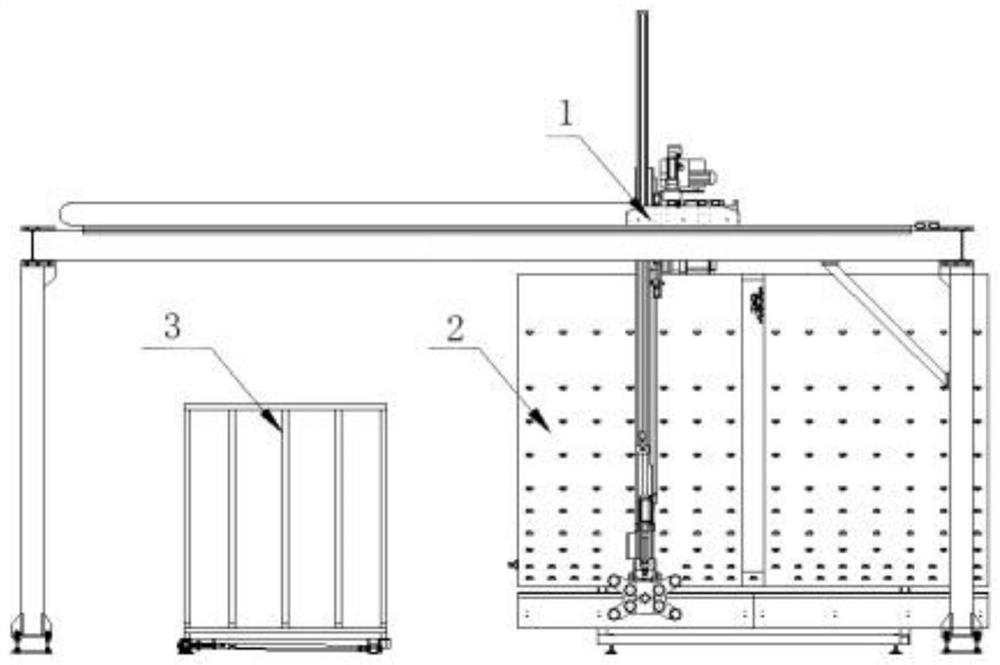

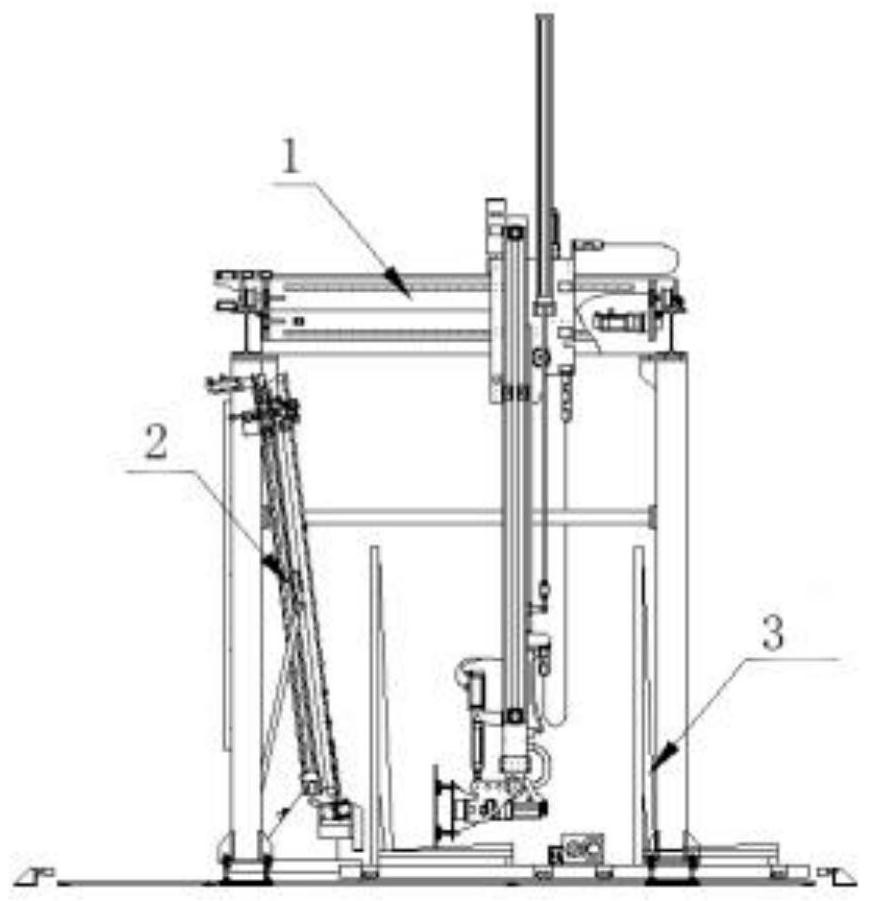

[0033] The invention discloses a multi-station high-efficiency manipulator glass unloading table. Figure 1-Figure 8 As shown, it includes a manipulator assembly 1 , a detection table assembly 2 and a moving glass shelf assembly 3 .

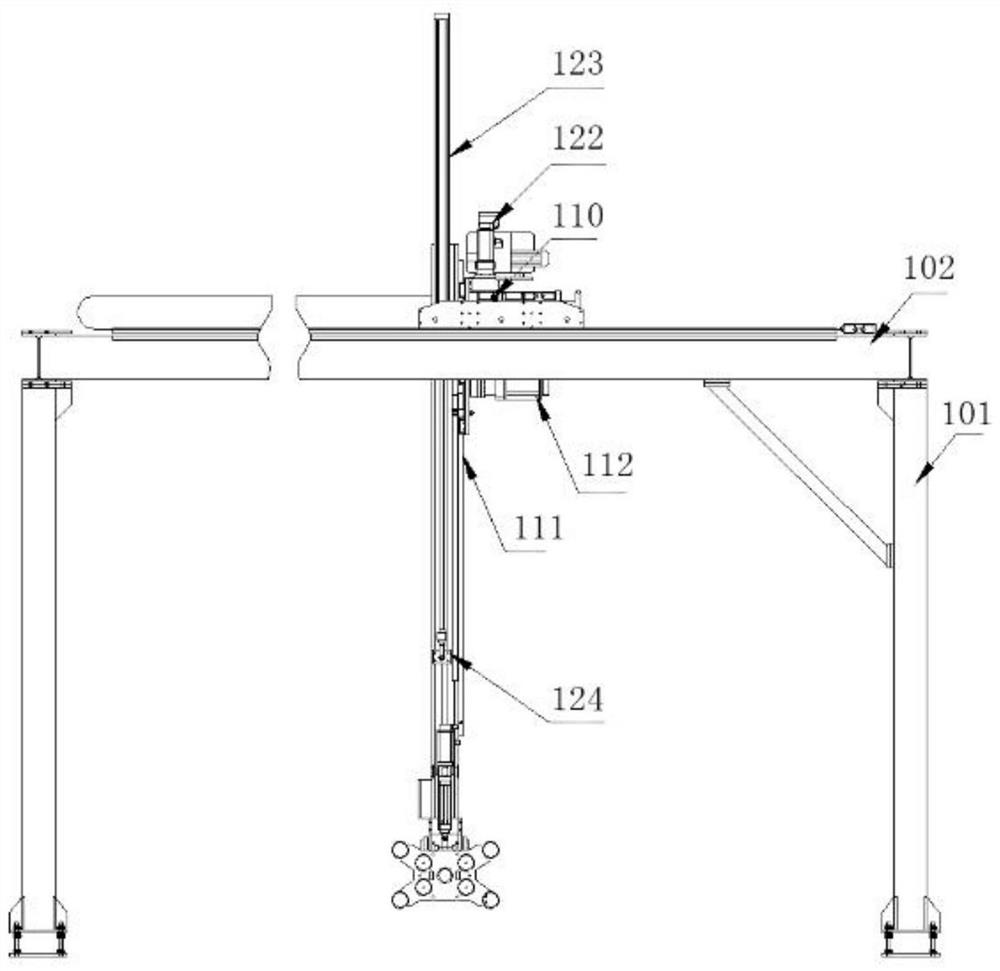

[0034] Wherein, the manipulator assembly 1 includes an X-axis moving part, a Y-axis moving part, a Z-axis moving part, an angle adjusting part, a rotating part and a lifting auxiliary part.

[0035] In addition, the X-axis moving parts include frame columns 101, beams 102, sliding beams 103, rolling wheels 107, guide rails 108 and X-axis motor reducer assembly 109. It is fixed on the beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com