Brushless motor with built-in drive

A technology of motors and sliding plates, which is applied in the direction of electromechanical devices, electric components, casings/covers/supports, etc., and can solve problems such as motors are prone to vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

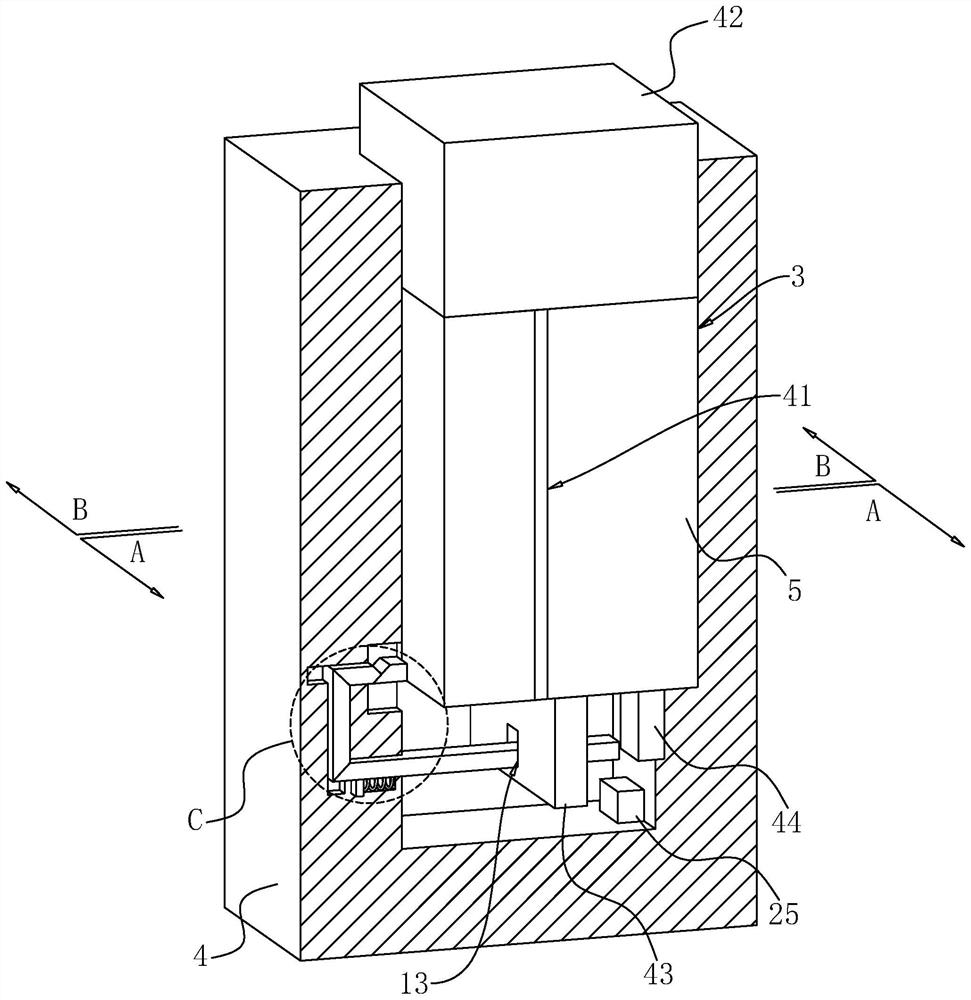

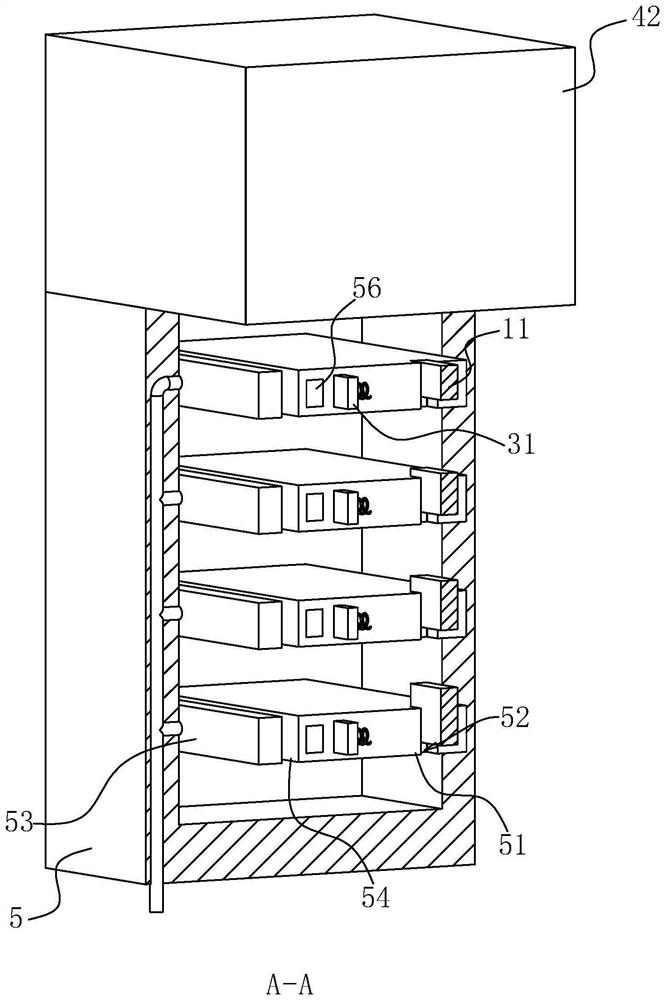

[0037] The following is attached Figure 1-7 The application is described in further detail.

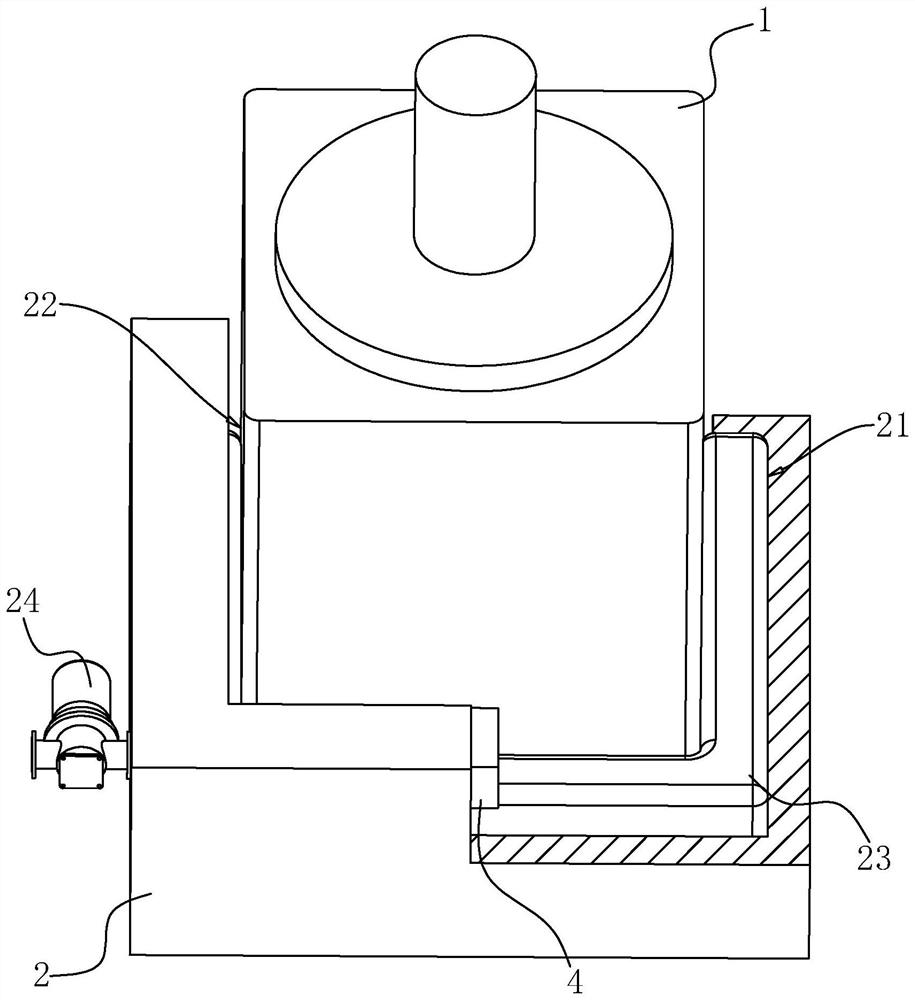

[0038] The embodiment of the present application discloses a built-in drive brushless motor. refer tofigure 1 A brushless motor with built-in drive includes a motor 1 and a base 2 arranged at the bottom of the motor 1 for fixing the motor 1 . The cross section of the base 2 is U-shaped; the base 2 is provided with a cavity 21 , and the inner peripheral surface of the base 2 is provided with a communication hole 22 communicating with the cavity 21 along its own circumference. The base 2 is fixed with an air cushion 23 through the cavity 21 . An air pump 24 is fixed on the outer peripheral surface of the base 2 , and the outlet end of the air pump 24 communicates with the inflatable cushion 23 . The base 2 provides reinforcement for the motor 1 , and when the vibration frequency of the motor 1 exceeds a preset frequency, the air pump 24 starts and inflates the air cushion 23 , so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com