Storage method of enzymolysis beef tallow

A storage method and technology of butter, which is applied in the direction of essential oil/spices, edible oil/fat, fat production, etc., can solve the problems of loss of flavor substances of butter, discount of actual effect of butter, etc., so as to improve storage cycle and preservation period , to avoid the effect of oxidation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

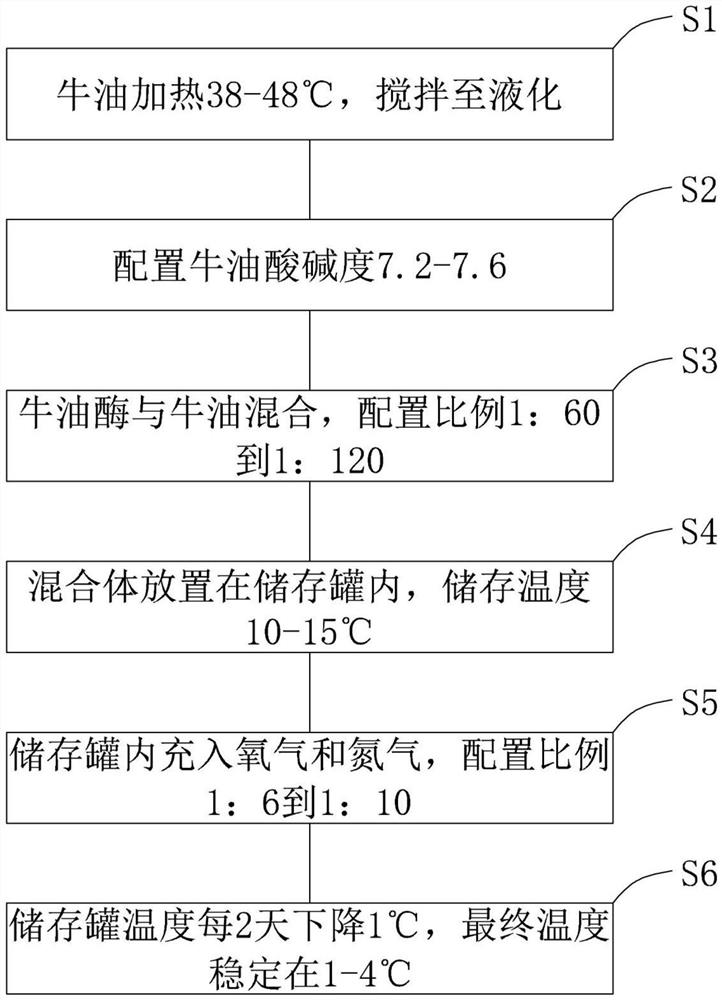

[0023] Such as figure 1 Shown, a kind of storage method of enzymolysis tallow of the present invention comprises the following steps:

[0024] S1: Weigh a certain weight of butter, and heat the butter to 38-48°C. During the heating process, keep stirring the butter until the butter is completely liquefied;

[0025] S2: Use water, NaOH and HCl, and configure the pH of tallow to be 7.2-7.6;

[0026] S3: Weigh a certain amount of tallow enzyme and tallow and stir and mix, the ratio of tallow enzyme and tallow is 1:60 to 1:120;

[0027] S4: placing the mixture of tallow enzyme and tallow in a storage tank, setting the temperature of the storage tank at 10 to 15° C. to refrigerate the mixture;

[0028] S5: Fill nitrogen into the storage tank, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com