Double-aluminum Mylar electronic film

A technology of electronic film and mylar, which is applied in the field of electronic film, can solve the problems of insufficient shading performance, backlight module panel protection, anti-static, and insufficient electromagnetic shielding performance, and achieve strong electromagnetic shielding performance and good light absorption And full shading, anti-leakage performance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

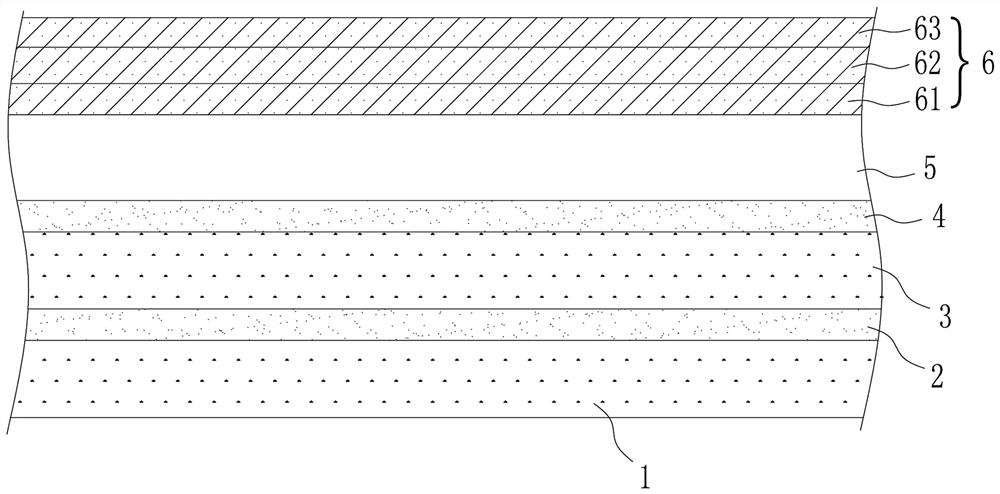

[0015] Such as figure 1 As shown, the present invention is a double-aluminum Mylar electronic film, which is the first aluminum foil layer 1, the first composite adhesive layer 2, the second aluminum foil layer 3, the second composite adhesive layer 4, and the transparent PET layer 5 from bottom to top. and black matte coating 6; the first aluminum foil layer 1 and the second aluminum foil layer 3 are bonded together through the first composite adhesive layer 2, and the second aluminum foil layer 3 and the transparent PET layer 5 are bonded together through the second composite adhesive The layers 4 are bonded together and the black matte coating 6 is applied over the transparent PET layer 5 . The upper layer of the double-aluminum Mylar electronic film is a black matte coating 6. When the double-aluminum Mylar electronic film is attached to the back of the backlight module panel, the black matte coating faces inward, and the light leaked from the backlight module panel can be...

Embodiment 2

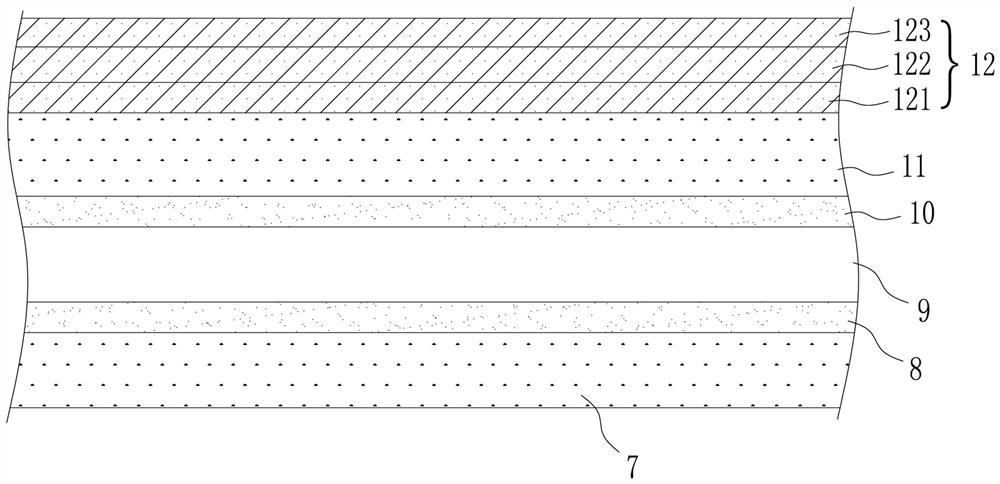

[0020] Such as figure 2 As shown, the present invention is a double-aluminum Mylar electronic film, which is the first aluminum foil layer 7, the first composite adhesive layer 8, the transparent PET layer 9, the second composite adhesive layer 10, and the second aluminum foil layer 11 from bottom to top. and a black matte coating 12; the first aluminum foil layer 7 and the transparent PET layer 9 are bonded together through the first composite adhesive layer 8, and the transparent PET layer 9 and the second aluminum foil layer 11 are bonded together through the second composite adhesive layer 10 bonded together, the black matte coating 12 is coated on the second aluminum foil layer 11. The upper layer of the double-aluminum Mylar electronic film is a black matte coating 12. When the double-aluminum Mylar electronic film is attached to the back of the backlight module panel, the black matte coating faces inward, and the light leaked from the backlight module panel can be abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com