Synthetic fiber concrete and preparation method thereof

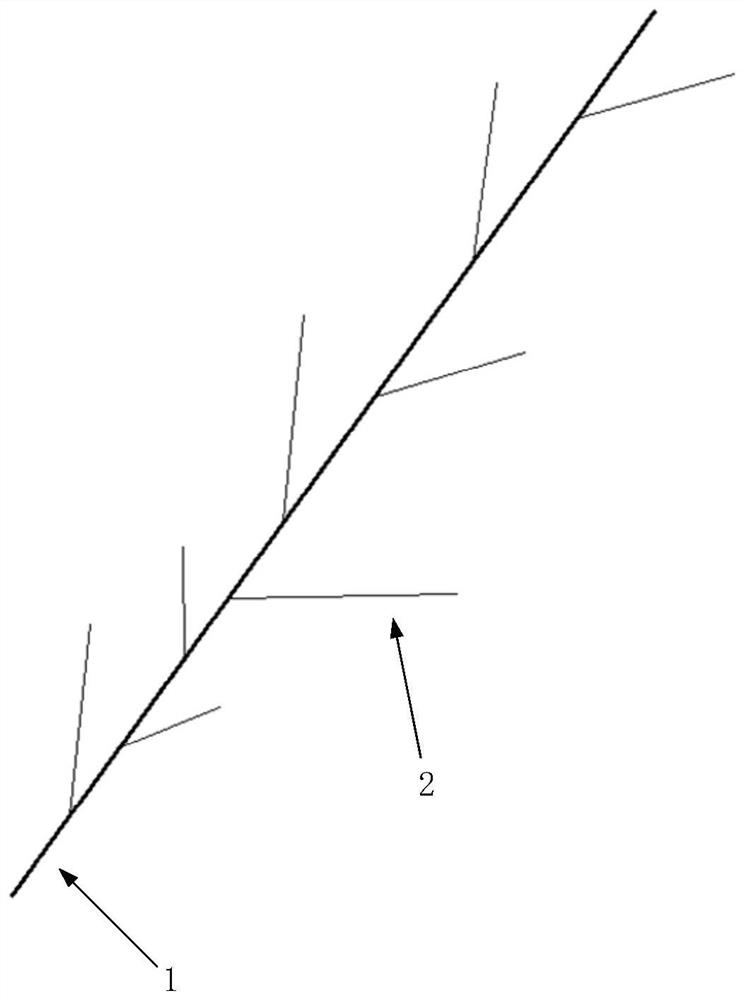

A synthetic fiber and concrete technology, applied in the field of building materials, can solve the problem of not improving the bending toughness and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

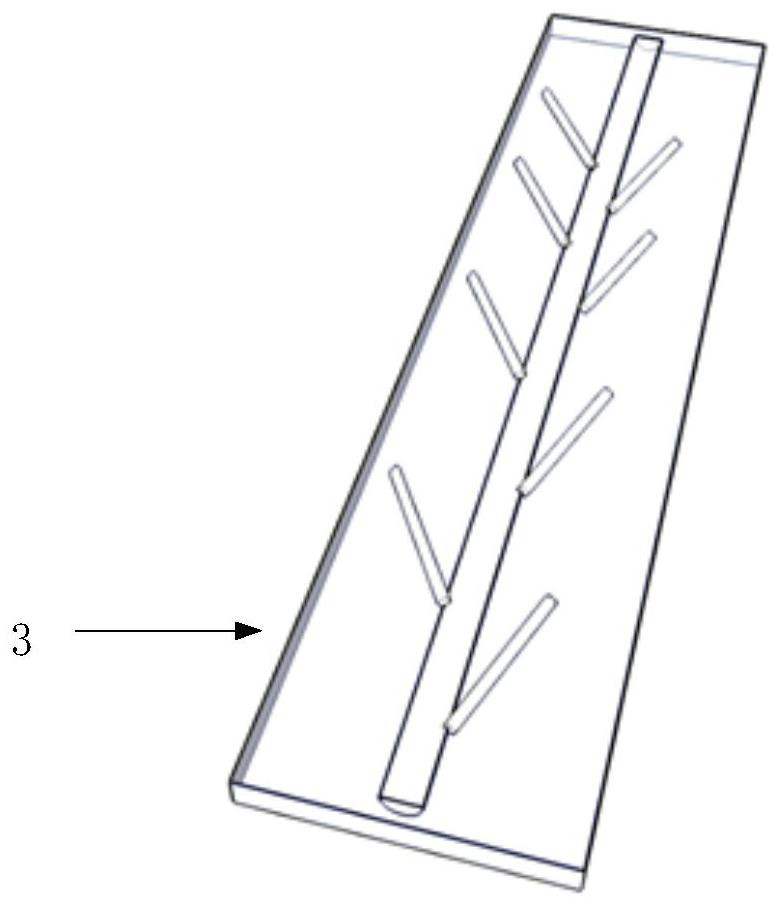

Method used

Image

Examples

preparation example Construction

[0042] The embodiment of the present application also provides a preparation method of synthetic fiber concrete, comprising the following steps:

[0043] Step 1. Pour the concrete base material and the synthetic fiber into a mixing device, and dry mix at a preset speed for a first preset time to obtain a premix.

[0044] In step 1, the raw materials except water are dry-mixed in advance, so that the synthetic fibers are broken up by dry mixing, and then distributed in the premix as evenly as possible, and at the same time, the concrete base material and synthetic fibers are mixed. Friction makes the surface of the synthetic fiber rough and improves the bonding performance between the synthetic fiber and the cementitious material in the concrete base.

[0045]This application does not limit the first preset duration of dry mixing. In one implementation, dry mixing can be performed at a preset speed of 47r / min for 30-60s. If the duration of dry mixing exceeds 60s, it will damage...

Embodiment 1

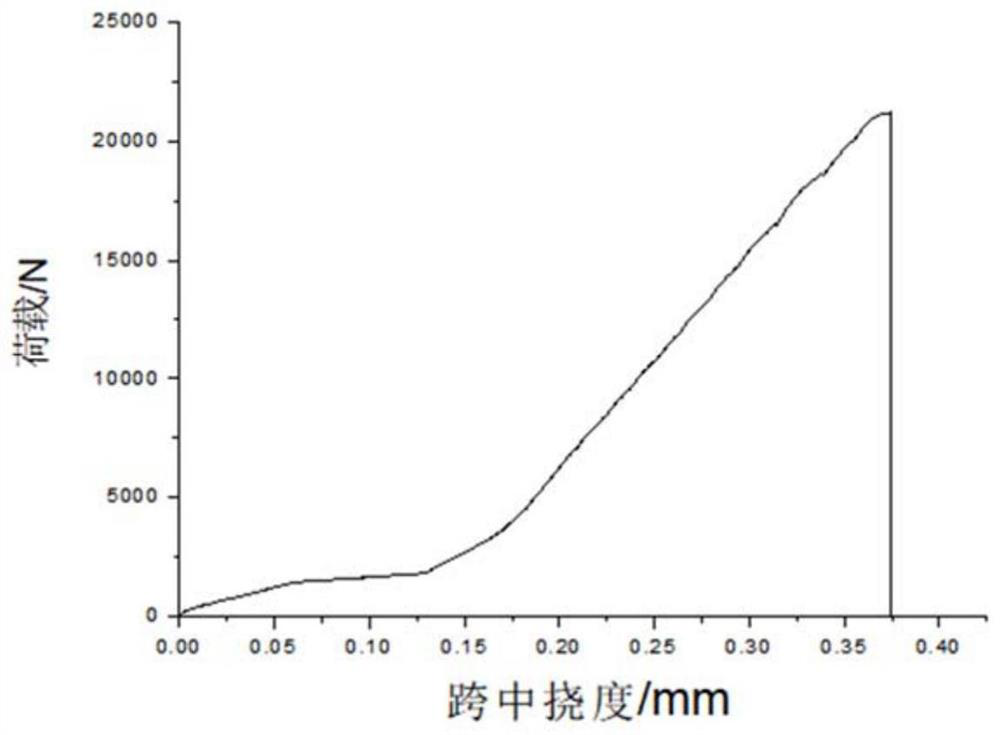

[0065] In embodiment one, mix 0.9kg / m in concrete 3 Synthetic fiber, from the test results, the equivalent bending strength is 1.7MPa, and the toughness index is 3.1.

[0066] From the analysis of Comparative Example 1 and Example 1, it can be seen that under the condition of the same fiber content, the toughness index of the prepared concrete reaches 3.1, which meets the toughness index requirement by using the synthetic fiber provided by the application instead of the monofilament fiber. Combined with Comparative Example 4, it can be seen that only 0.9kg / m 3 The synthetic fiber provided by this application can prepare concrete with a toughness index that meets the requirements without adding a dispersant, which is a technical effect that cannot be realized at present.

Embodiment 2

[0067] In embodiment two, the mixing amount of synthetic fiber in concrete is promoted to 1.8kg / m 3 , From the test results, the equivalent bending strength is increased to 2.9MPa, and the toughness index is increased to 6.1.

[0068] Analysis embodiment one and embodiment two can know, 1.8kg / m 3 The dispersibility of the added amount of synthetic fibers in the concrete is still very good, so that the toughness index of the prepared concrete reaches 6.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com