Variable steering wheel structure

A steering wheel and variable technology, which is applied to the steering control and handwheels installed on the car, can solve the problems of easy steering of the steering wheel, different operating requirements, and affecting the speed of operating steering, so as to achieve the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

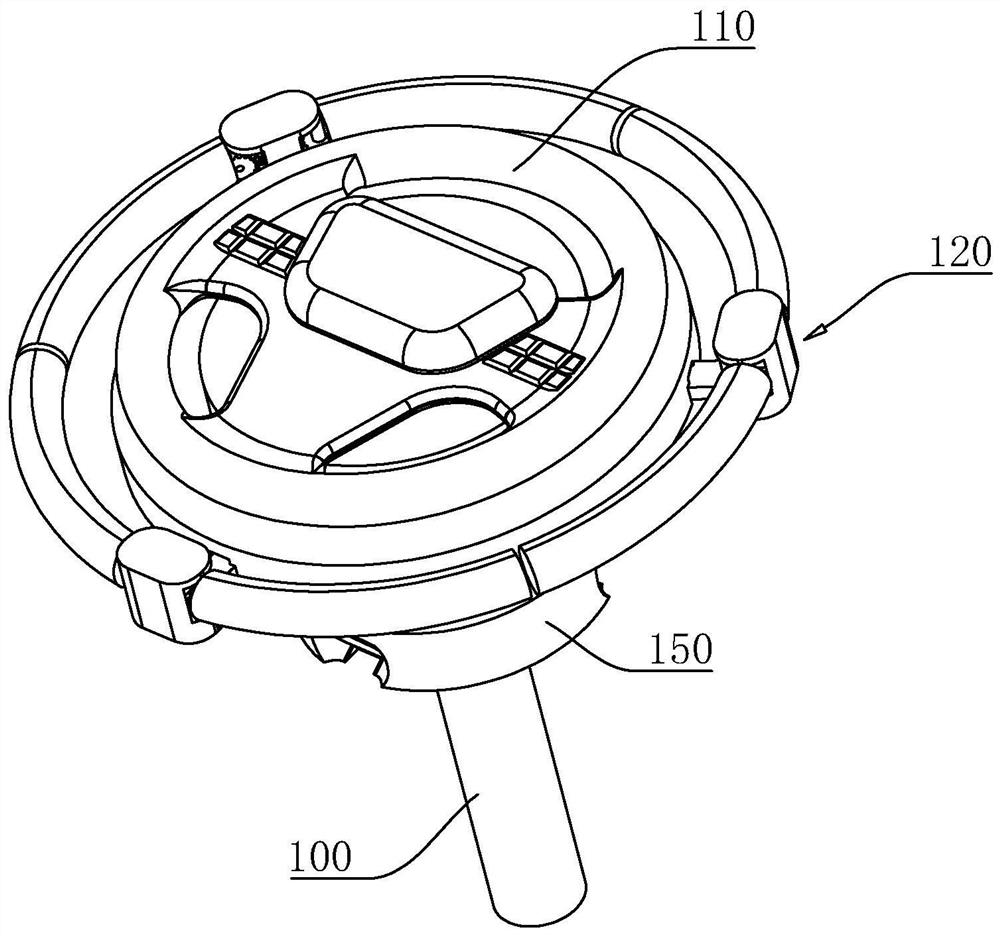

[0043] A variable steering wheel structure, refer to figure 1 , including the linkage frame 100, the end of the linkage frame 100 is equipped with an auxiliary steering wheel 110, the auxiliary steering wheel 110 is provided with the steering wheel body 120, and the steering wheel body 120 is evenly distributed along the circumferential direction. 1, located at 4 o'clock, 8 o'clock, and 12 o'clock respectively. The steering wheel body 120 can be folded and arranged on the sub-steering wheel 110 for changing the overall diameter for easy operation.

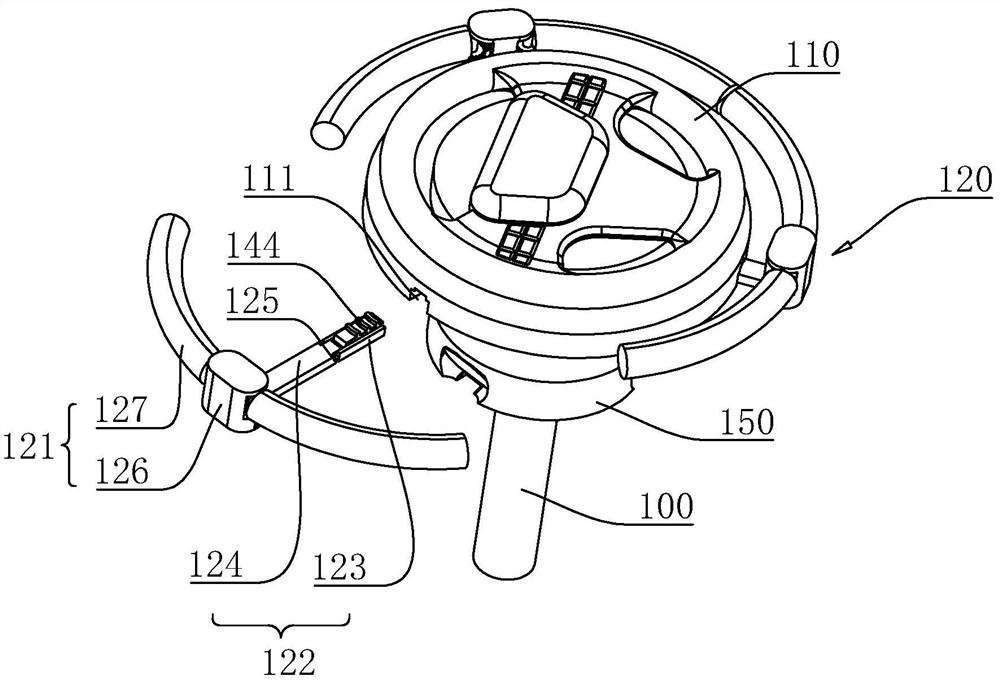

[0044] refer to figure 2, the steering wheel body 120 includes a grip ring 121 and a connecting folding rod 122, the grip ring 121 is connected to the end of the connecting folding rod 122, and the three grip rings 121 will form a complete circle, connecting the folding rod 122 is slidably connected to the underside of the auxiliary steering wheel 110 in the radial direction, and the auxiliary steering wheel 110 is radially prov...

Embodiment 2

[0053] The difference from Example 1 is that, referring to Figure 9 , what is rotationally connected in the auxiliary steering wheel 110 is the linkage ring 160, the side of the linkage ring 160 close to the sliding part 123 has a threaded line 143, and the sliding part 123 has a spiral groove 144 matching with the threaded line 143, the linkage ring 160 There is a rebound block 161 on the outer side, and there is a corresponding sliding groove (not shown in the figure) on the auxiliary steering wheel 110. There is a rebound elastic member in the sliding groove. In this embodiment, the rebound elastic member is a rebound The spring 162 is located in the sliding groove, and one end of the rebound spring 162 is fixedly connected to the rebound block 161 .

[0054] The implementation principle of Embodiment 2 of the present application is: the three connecting folding rods 122 can be stretched out by hand pulling, and the rebound spring 162 will be compressed at this time. The ...

Embodiment 3

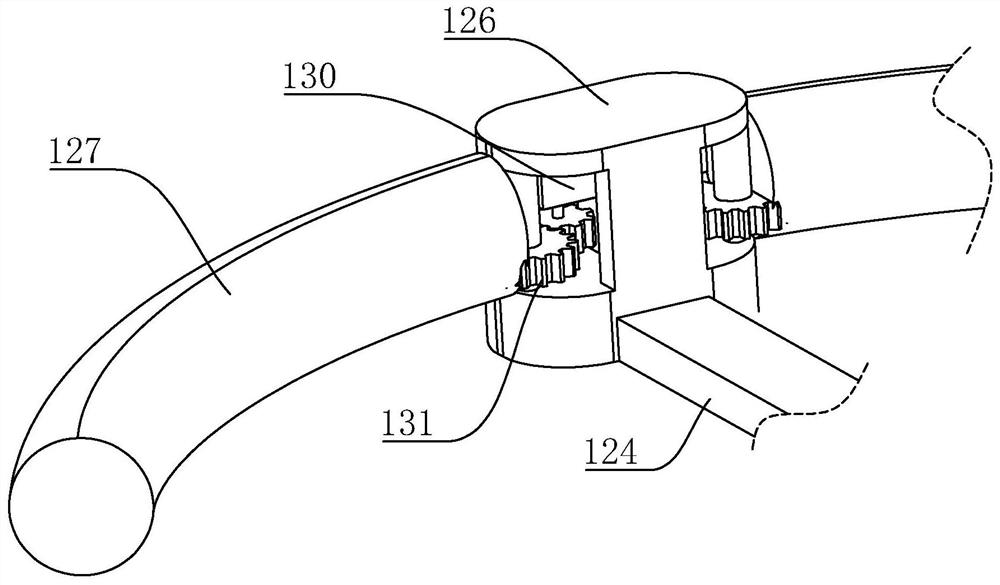

[0056] The difference from Example 1 is that, referring to Figure 10 The end of the slideway 111 is rotatably connected with an adjusting gear 170 , and a rotating motor 171 is installed on the slide, and the output shaft of the rotating motor 171 is coaxially connected with the adjusting gear 170 . The rotating part 124 is connected to the fixed part 126 through the hinge shaft 125 , and the hinge shaft 125 has a linkage gear 172 for meshing with the adjusting gear 170 . At the same time, an accommodating groove 173 for the adjustment gear 170 to pass through is defined on the rotating portion 124 along the length direction. That is, when the connecting folding rod 122 moves, the adjusting gear 170 will relatively slide in the receiving groove 173, and when the sliding part 123 moves to the end of the slideway 111, the adjusting gear 170 will mesh with the linkage gear 172 to form meshing, so when the adjusting gear 170 rotates, it will drive the rotating part 124 to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com