Land supporting structure for green building

A green building and support structure technology, applied in the field of land support structures, can solve problems such as unfavorable plant growth, water source deterioration, and plant rot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

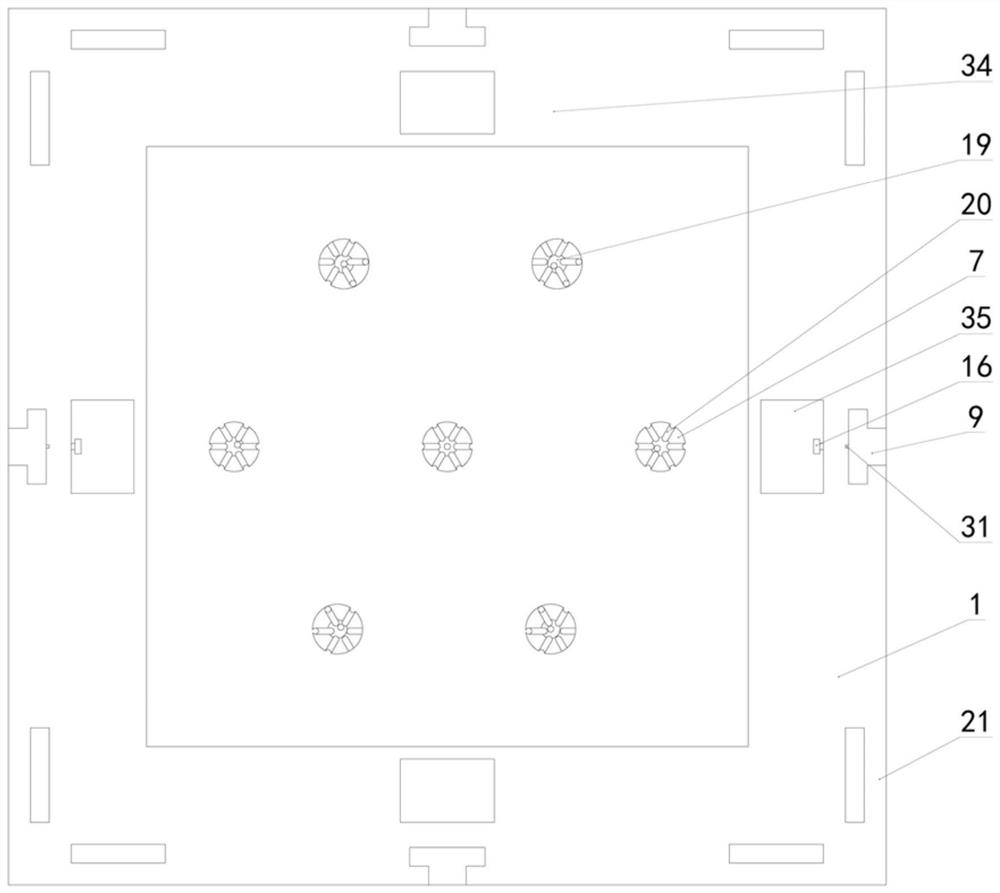

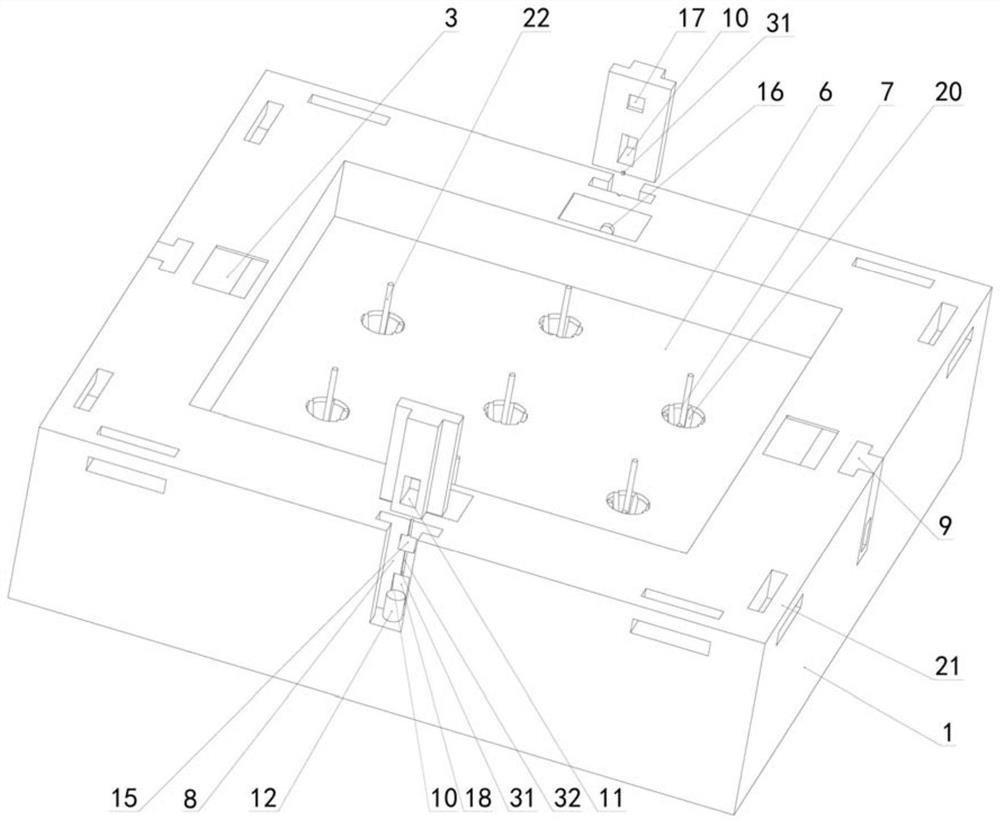

[0028] Embodiment 1, a ground support structure for green buildings, including a plurality of basins 1, the basins 1 are in the shape of a cube, the basins 1 are horizontally provided with water retaining boards 2, and the water retaining boards 2 separate the inside of the basins 1 The overflow tank 3 and the water storage chamber 4 are divided into upper and lower parts. The overflow tank 3 is placed above the water storage chamber 4. A plurality of overflow ports 5 are provided on the water retaining plate 2. The overflow tank 3 and the water storage chamber 4 are overflowed. The outlet 5 is connected, and the top of the basin body 1 is provided with a baffle plate 34 matched with the overflow tank 3, the baffle plate 34 is used to cover the overflow tank 3, and reduces external pollution to the water source in the basin body 1, and the baffle plate 34 is provided with a A plurality of connecting grooves 8 correspond to a plurality of through holes 35 one by one. The existen...

Embodiment 2

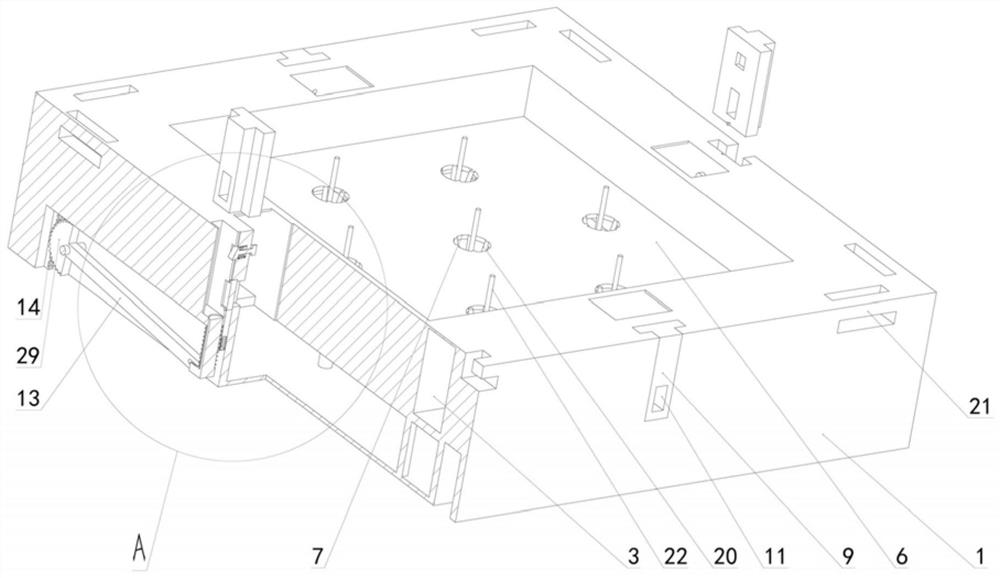

[0029] Embodiment 2. On the basis of Embodiment 1, the support mechanism includes a push rod 12, a gear connecting rod 13 and a rack 14. The push rod 12 vertically penetrates the bottom wall of the connecting groove 8, and the distance between the push rod 12 and the bottom wall of the connecting groove 8 is The space is vertically sealed and slidably connected. The first spring 27 placed between the lower end of the push rod 12 and the basin body 1 is coaxially sleeved on the top rod 12. One end 27 of the first spring is connected to the basin body 1. The other end of the first spring is connected to the basin body 1. One end is connected with the lower end of the push rod, the first spring 27 gives the push rod 12 a vertical upward pulling force, the basin body 1 is vertically slidably connected with racks 14 opposite to the two sides of the push rod 12, and the basin body 1 is rotatably connected with The sector gear 29 meshed with the rack 14, the gear connecting rod 13 is ...

Embodiment 3

[0030]Embodiment 3, on the basis of Embodiment 1, the limit mechanism includes a wedge block 15 and a connecting rod 16. The connecting rod 16 is arranged horizontally and runs through the basin body 1. One end of the connecting rod 16 is placed in the connecting groove 8 and connected to the wedge block. 15 is connected at one end, and the other end of the connecting rod 16 slides through the basin body 1 and is placed in the overflow tank 3. The connecting rod 16 is coaxially sleeved with a second spring 28 between the inner wall of the wedge-shaped block 15 and the basin body 1. One end of the second spring 28 is connected with the basin body 1, and the other end of the second spring 28 is connected with the wedge block 15, and the second spring 28 gives the wedge block 15 a thrust away from the basin body 1. Matching slot 17, when the connecting block 9 is inserted into the connecting slot 8, the connecting block 9 will squeeze the wedge block 15 and drive the connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com