Shear fork arm performance test system

A test system and scissor technology, applied in the field of scissor arm performance test system, to achieve the effect of reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

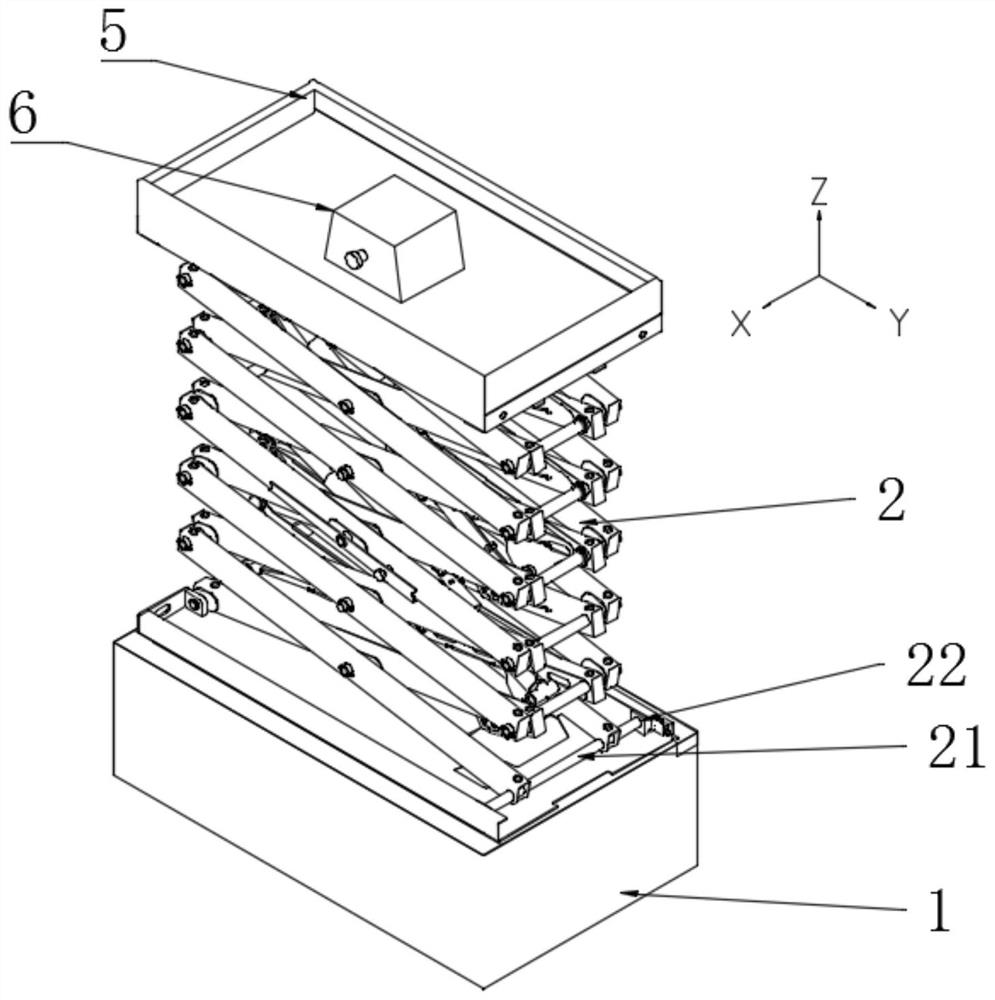

[0025] In addition, the upper, lower, left, right, front, and rear mentioned in the embodiments of the invention refer to when the scissor arm performance testing system of the present invention is vertically placed on the ground (attached figure 2 Placement position in ) the corresponding position of the entire test system; among them, X positive represents "front", X reverse represents "rear", Y positive represents "left", Y reverse represents "right", Z positive Represents "up", and the reverse Z represents "down".

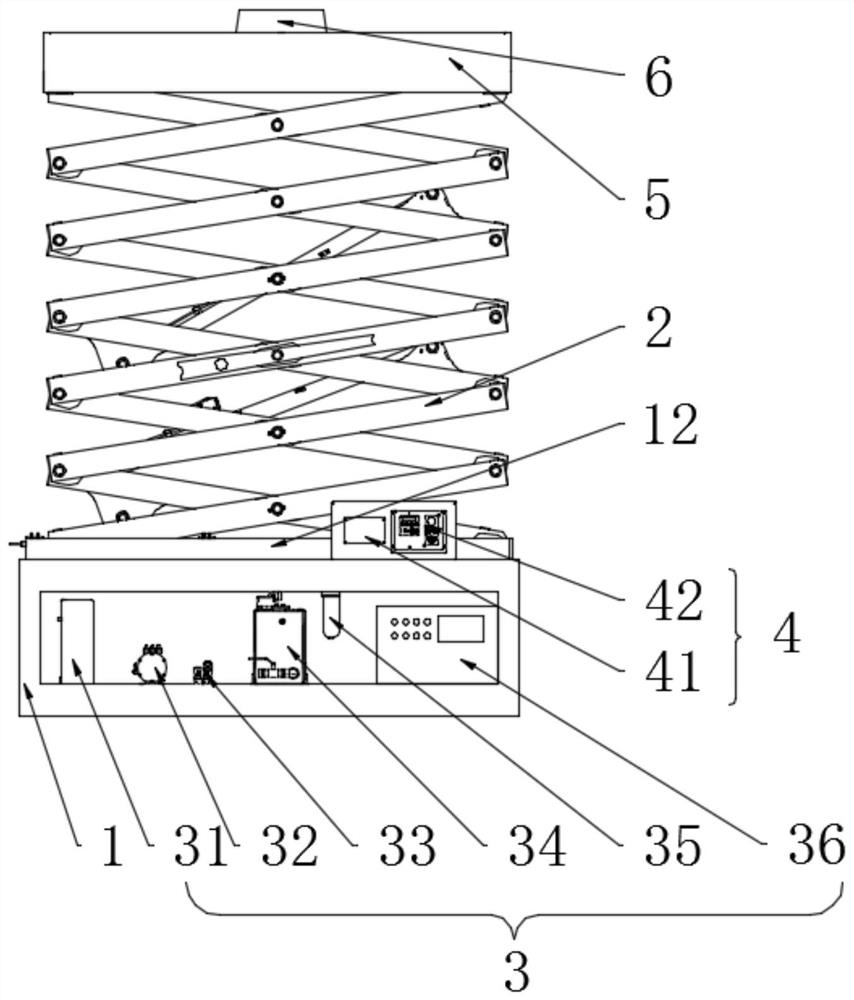

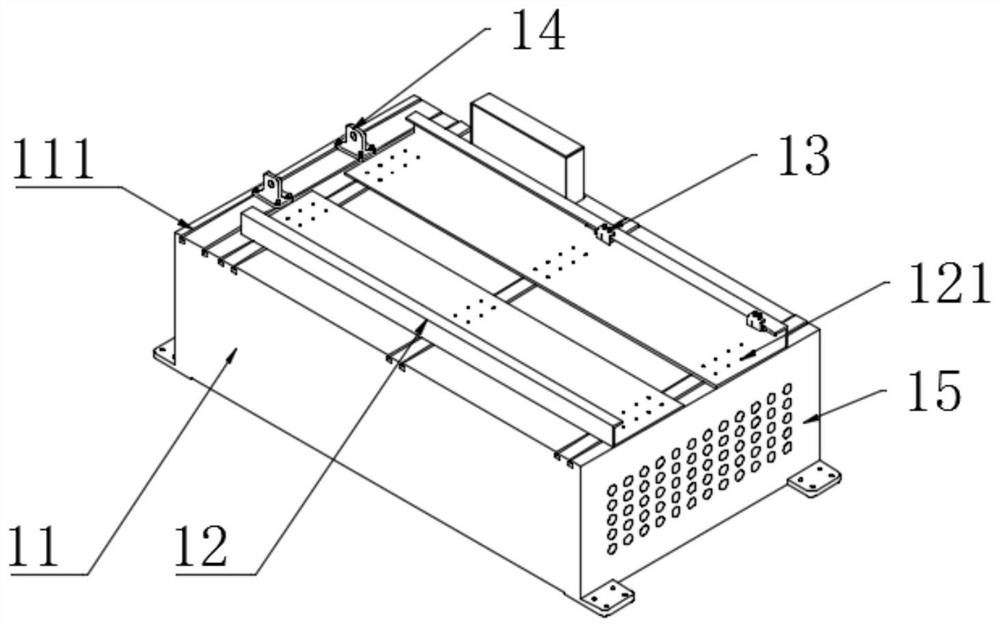

[0026] see Figure 1-3 As shown, the embodiment of the present invention provides a scissor arm performance test system (hereinafter referred to as the test system), including a test bench 1 and a power system 3, the test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com