A flat vulcanizing machine

A flat vulcanizing machine and frame technology, applied in the field of vulcanizing machines, can solve problems such as waste and low production efficiency, and achieve the effects of reducing equipment costs, improving production efficiency, and reducing power units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

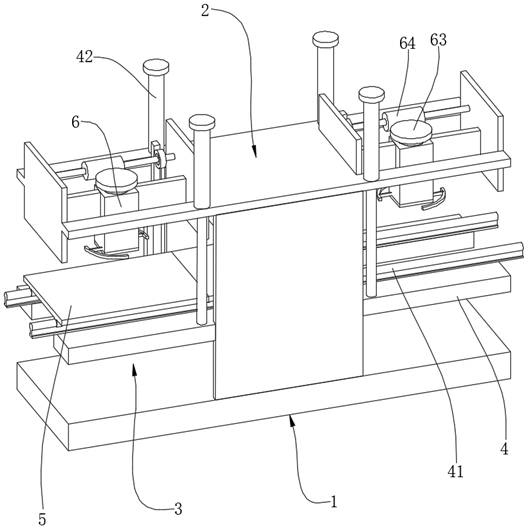

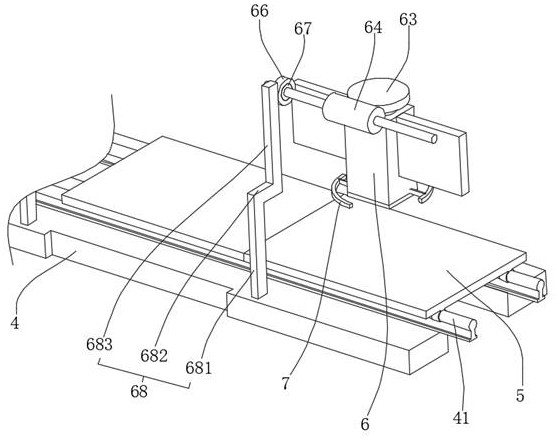

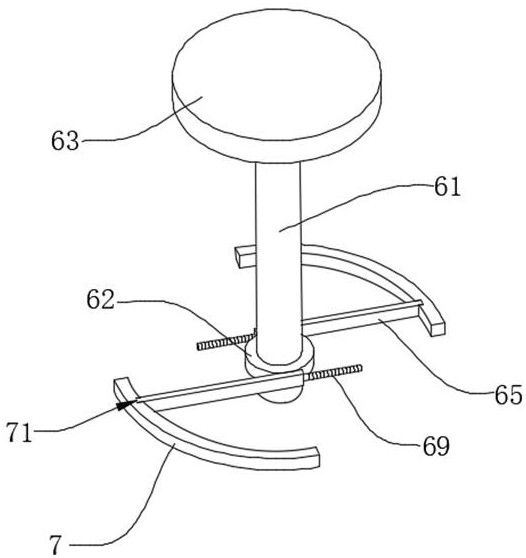

[0025] The present invention will be further described in detail below with reference to the accompanying drawings.

[0026] like figure 1 As shown, a flat vulcanizing machine includes a frame 1, a fixed upper die 2 and a movable lower die 3 are mounted on the frame 1, and a processing area is formed on the frame 1 and below the upper die 2, The symmetrical two sides of the processing area in the horizontal direction form the loading and unloading areas, wherein the lower die 3 includes a pair of relatively fixed support plates 5, the support plates 5 are used for placing raw materials, and the support plates 5 can move between the processing area and the loading and unloading areas. And each time, only one support plate 5 is located in the processing area, and the other support plate 5 is located in the loading and unloading area. At the same time, the lower mold 3 can also be lifted vertically until the support plate 5 and the upper mold 2 are closed and aligned. The raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com