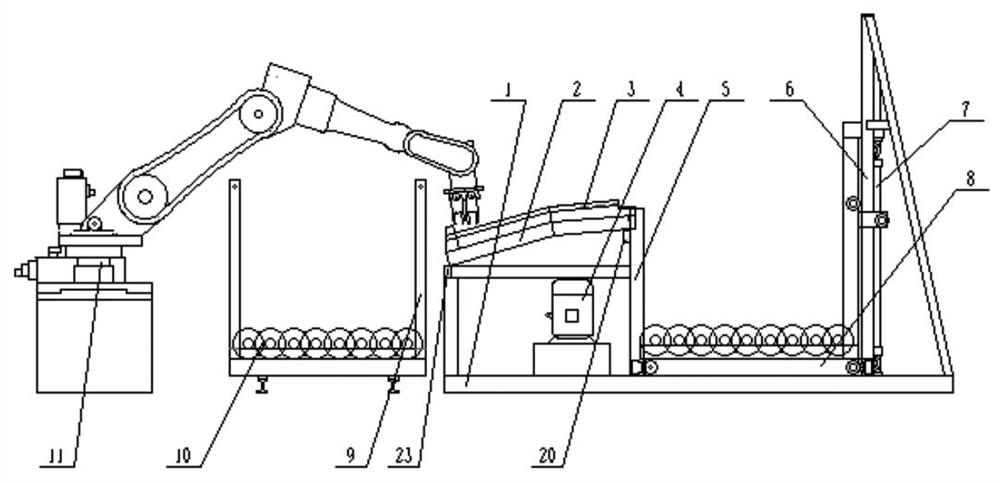

Ring lock scaffold vertical rod box filling machine

A pole packing machine and scaffolding technology, which is applied in the field of buckle scaffolding pole packing machine, can solve the problems of low packing efficiency, inaccurate pole positioning, and affecting the robot's grasping of poles, etc., and achieve high packing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

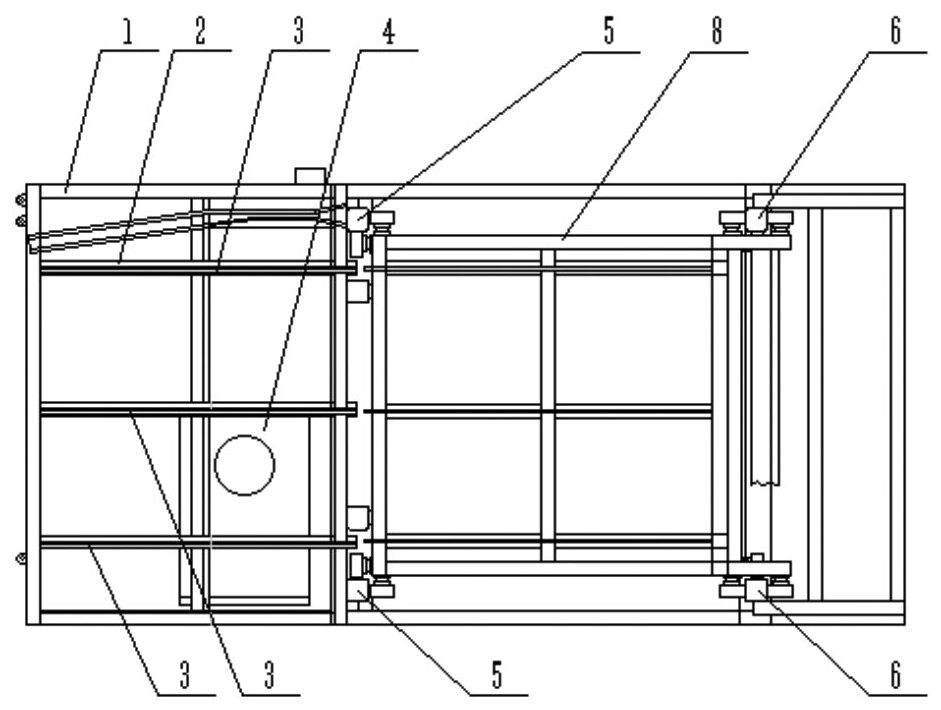

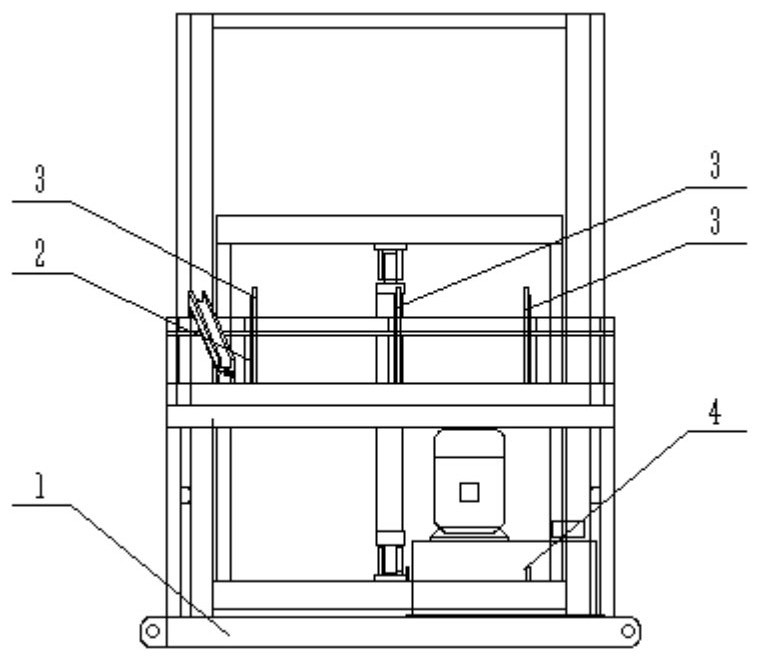

[0035] Below the slide rail 3, there is a dial shaft supported on the bearing on the frame to drive the output shaft of the speed reducer, and the input shaft of the speed reducer is connected to the power shaft of the motor. There are at least two dial wheels 17 in parallel on the dial shaft. In the space between the two slide rails 3, there is at least one in-phase notch on the periphery of the dial to match the outer diameter of the vertical rod.

[0036] The angle between the left section of the guide slide rail 17 and the deflection slide rail 3 projected on the vertical plane containing the first cross bar 20 is 30 degrees, and the left section and the right section of the guide slide rail are projected on the vertical plane containing the slide rail The included angle is 150 degrees.

[0037] Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com