Hair-pin motor shaping mechanism

A card-issuing, wire-structured technology, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of different degrees of bending, affecting the quality of the card-issuing motor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

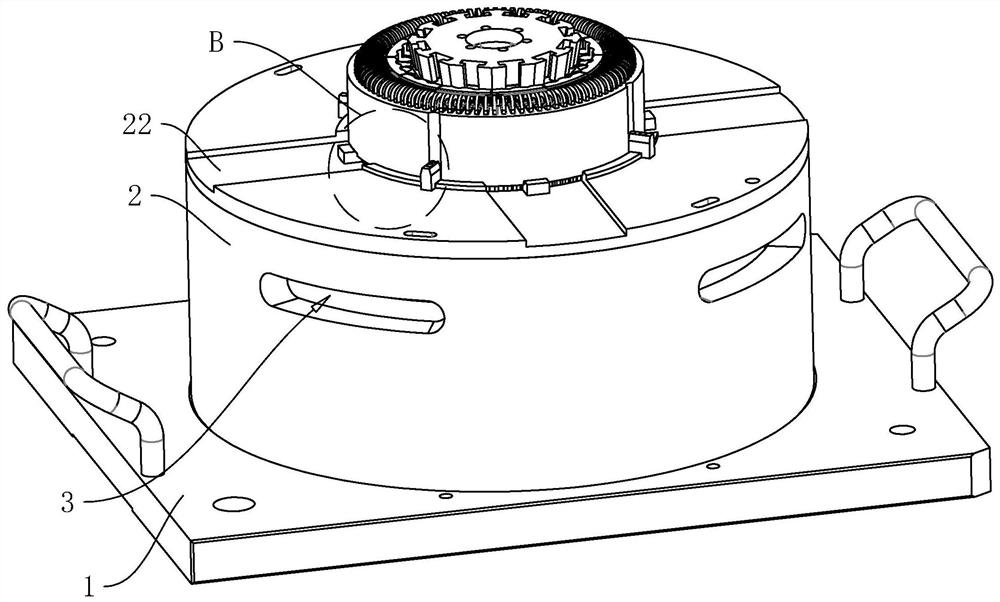

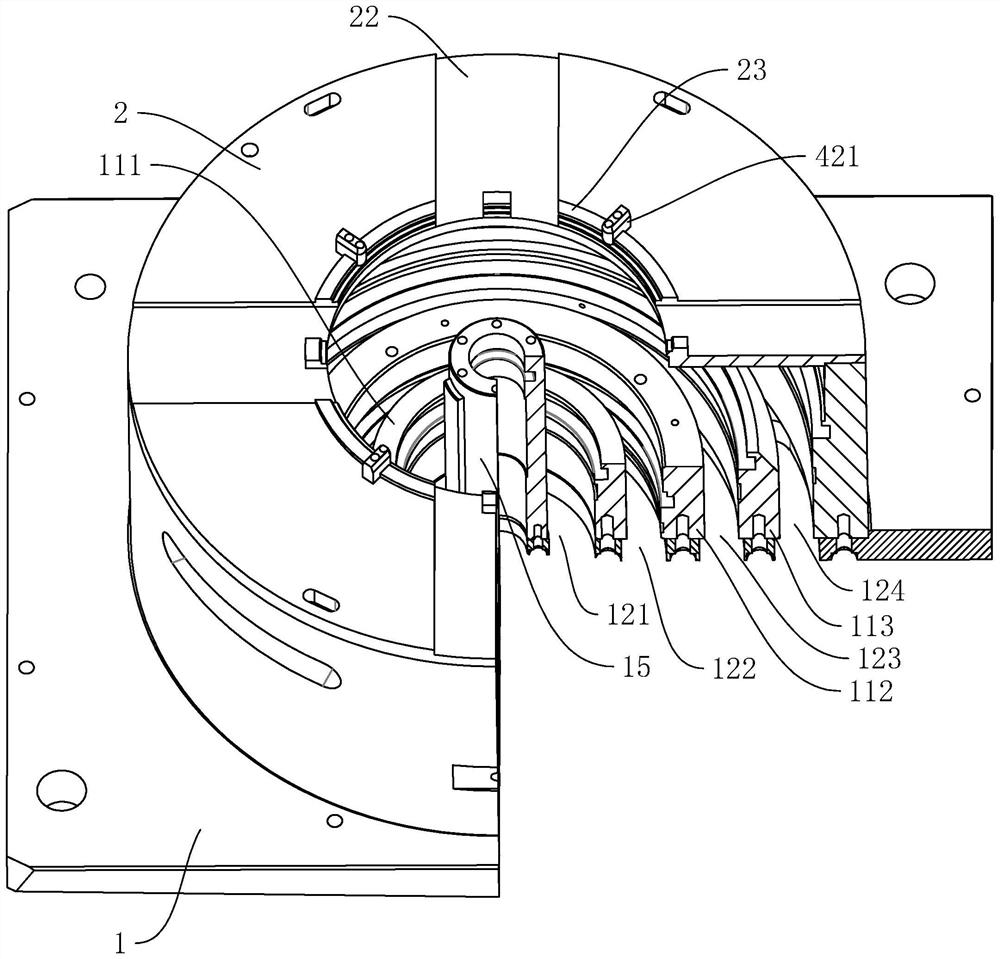

[0041] The following is attached Figure 1-10 The application is described in further detail.

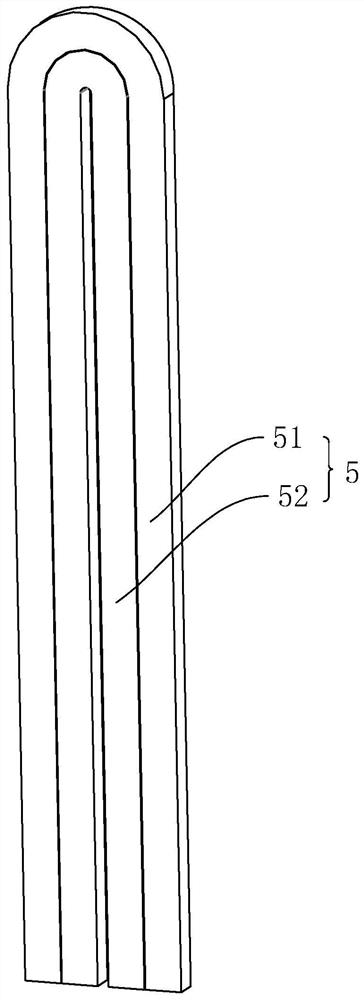

[0042] The embodiment of the present application discloses a shaping mechanism for a hairpin motor, which can simultaneously shape multiple sets of flat wire groups 5 and have the same shaping effect.

[0043] refer to figure 2 , including a bottom plate 1, a stator seat 2 and a broken line structure 3, the stator seat 2 is fixed on the upper surface of the bottom plate 1 by bolts, the broken line structure 3 is located in the stator seat 2, and the stator seat 2 is arranged with an upper opening.

[0044] refer to image 3 The upper end of the bottom plate 1 is fixed with a first separation ring 111, a second separation ring 112 and a third separation ring 113 by bolts, the first separation ring 111, the second separation ring 112 and the third separation ring 113 are located in the cavity of the stator base 2 and The axis coincides with the axis of the stator base 2 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com