Pulse detonation tube performance calculation method and device

A technology of pulse detonation and calculation method, applied in jet propulsion devices, rocket engine devices, ramjet engines, etc., can solve problems such as cumbersome process, high detonation frequency, heavy workload, etc., and achieve accuracy and convenience uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

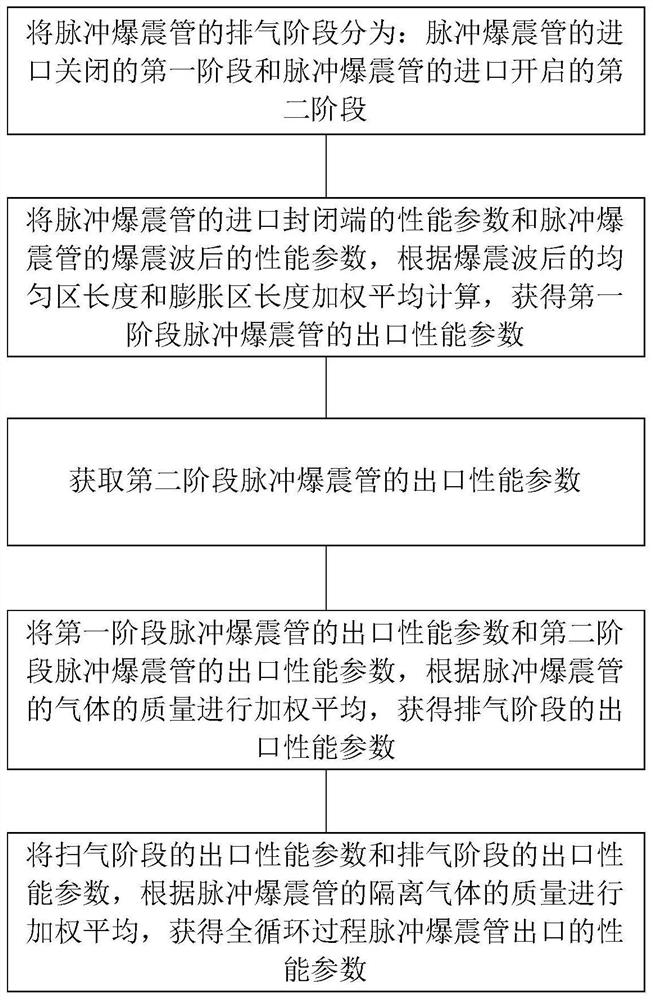

[0073] refer to figure 1 , an embodiment of the present invention provides a method for calculating the performance of a pulse detonation tube, including:

[0074] The exhaust stage of the pulse detonation tube is divided into: the first stage when the inlet of the pulse detonation tube is closed and the second stage when the inlet of the pulse detonation tube is opened;

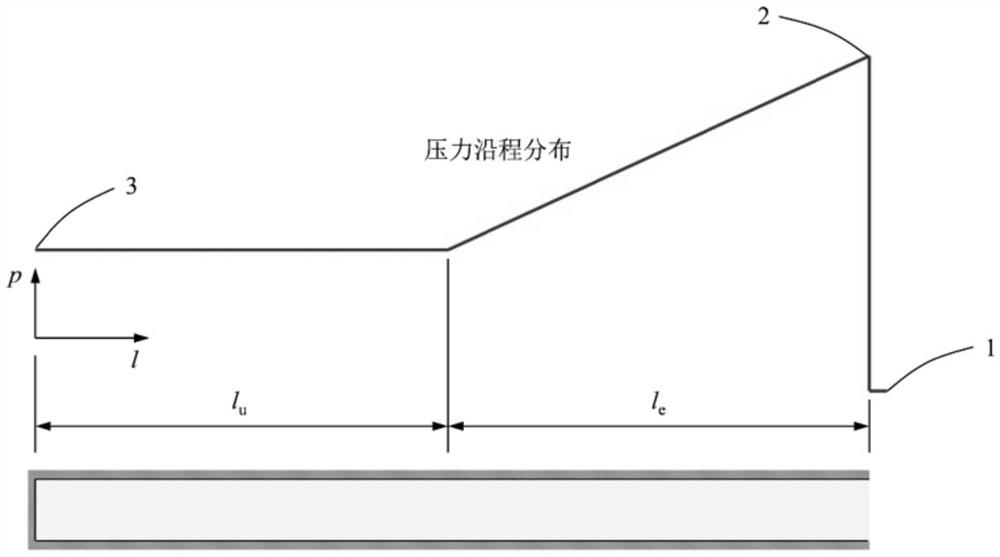

[0075] The performance parameters of the closed end of the inlet of the pulse detonation tube and the performance parameters of the pulse detonation tube after the detonation wave are calculated according to the weighted average of the length of the uniform zone and the length of the expansion zone after the detonation wave to obtain the outlet of the first stage pulse detonation tube performance parameters;

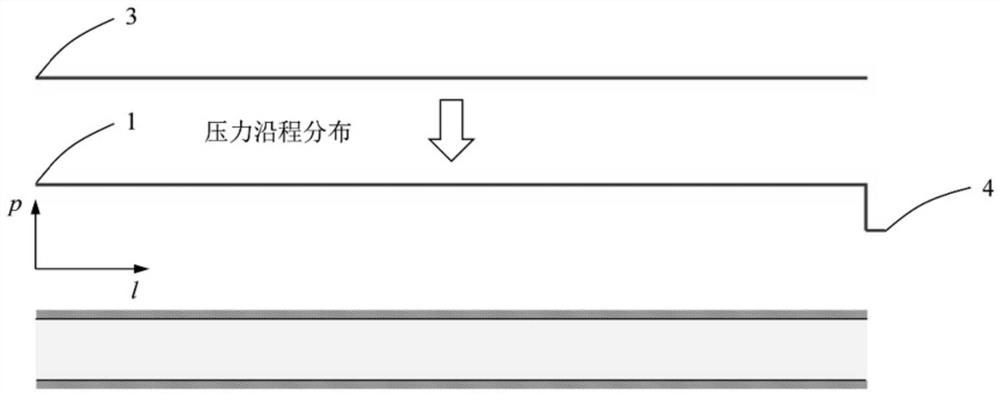

[0076] Based on the performance parameters of the inlet closed end and the performance parameters of the detonation wave front of the pulse detonation tube, the outlet performance parameters of the se...

Embodiment 2

[0152] refer to Figure 5 , an embodiment of the present invention provides a pulse detonation tube performance calculation device, including:

[0153] The exhaust stage is divided into stages, which is used to divide the exhaust stage of the pulse detonation tube into: the first stage in which the inlet of the pulse detonation tube is closed and the second stage in which the inlet of the pulse detonation tube is opened;

[0154] The first-stage pulse detonation tube outlet performance parameter acquisition module is used to obtain the performance parameters of the closed inlet end of the pulse detonation tube and the performance parameters after the detonation wave of the pulse detonation tube, according to the uniform zone length and expansion after the detonation wave Calculate the weighted average of the zone length to obtain the outlet performance parameters of the first-stage pulse detonation tube;

[0155] The second-stage pulse detonation tube outlet performance param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com