A prefabricated building wall panel installation machine

A panel installation machine and building wall technology, applied in construction, building structure, processing of building materials, etc., can solve the problems of low installation efficiency, easy fatigue, high labor intensity, etc., to improve installation efficiency and reduce labor intensity. , the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

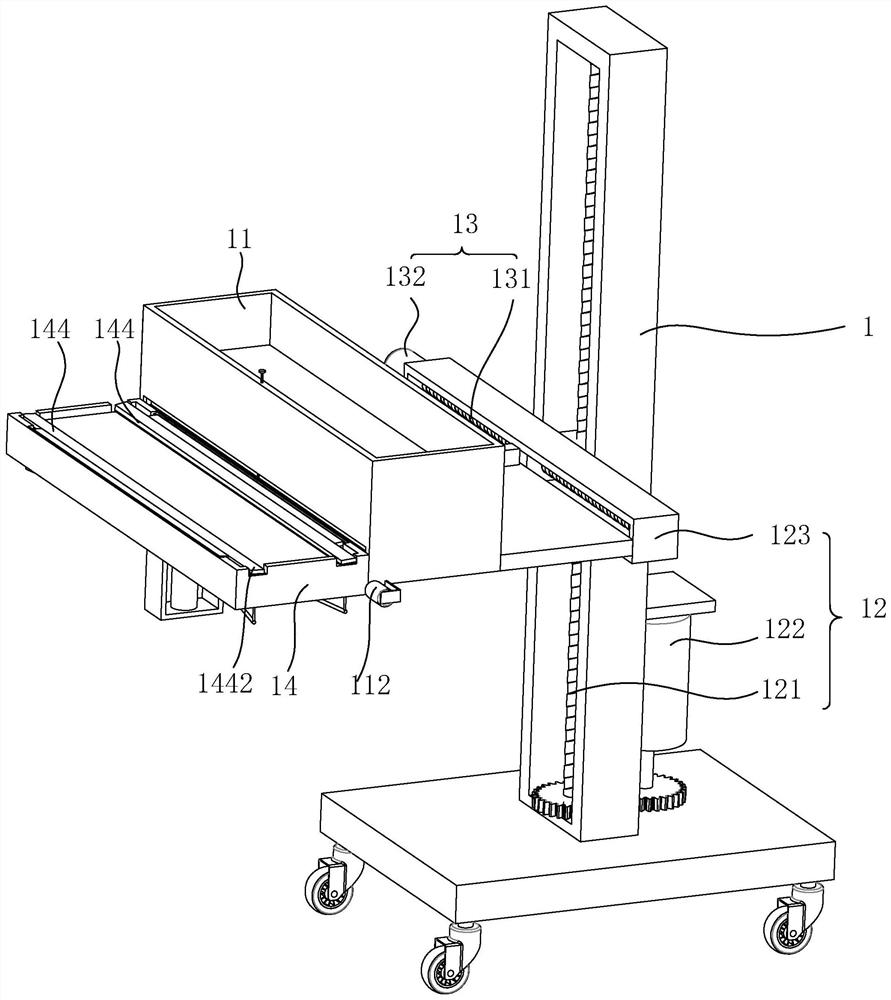

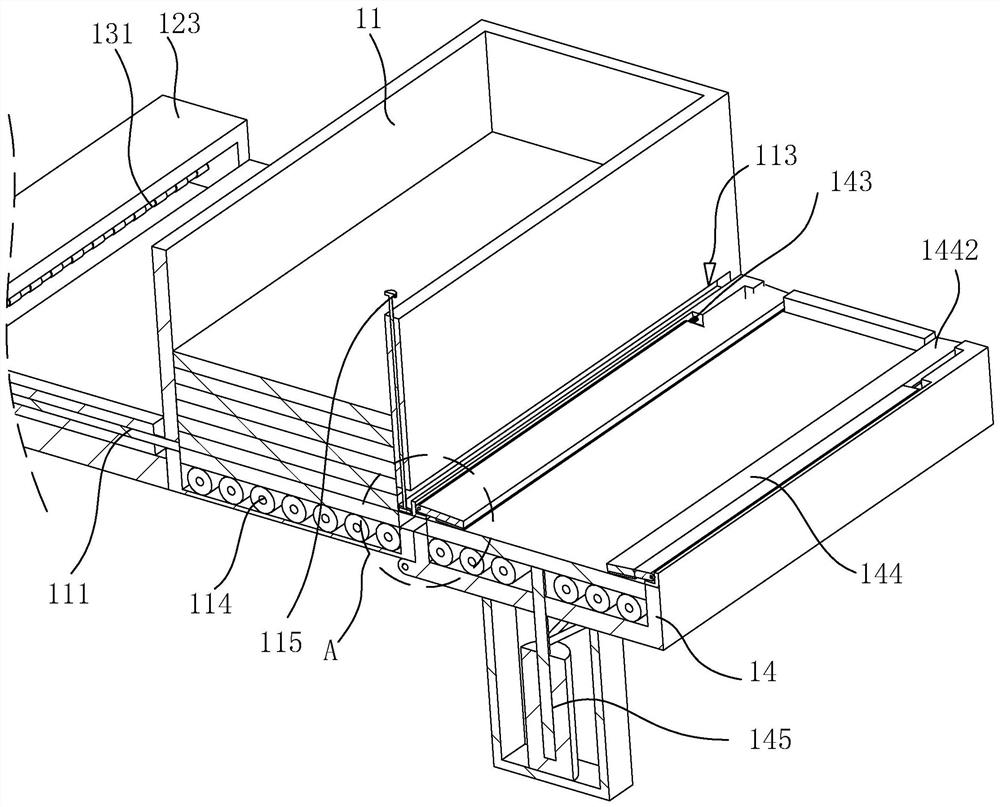

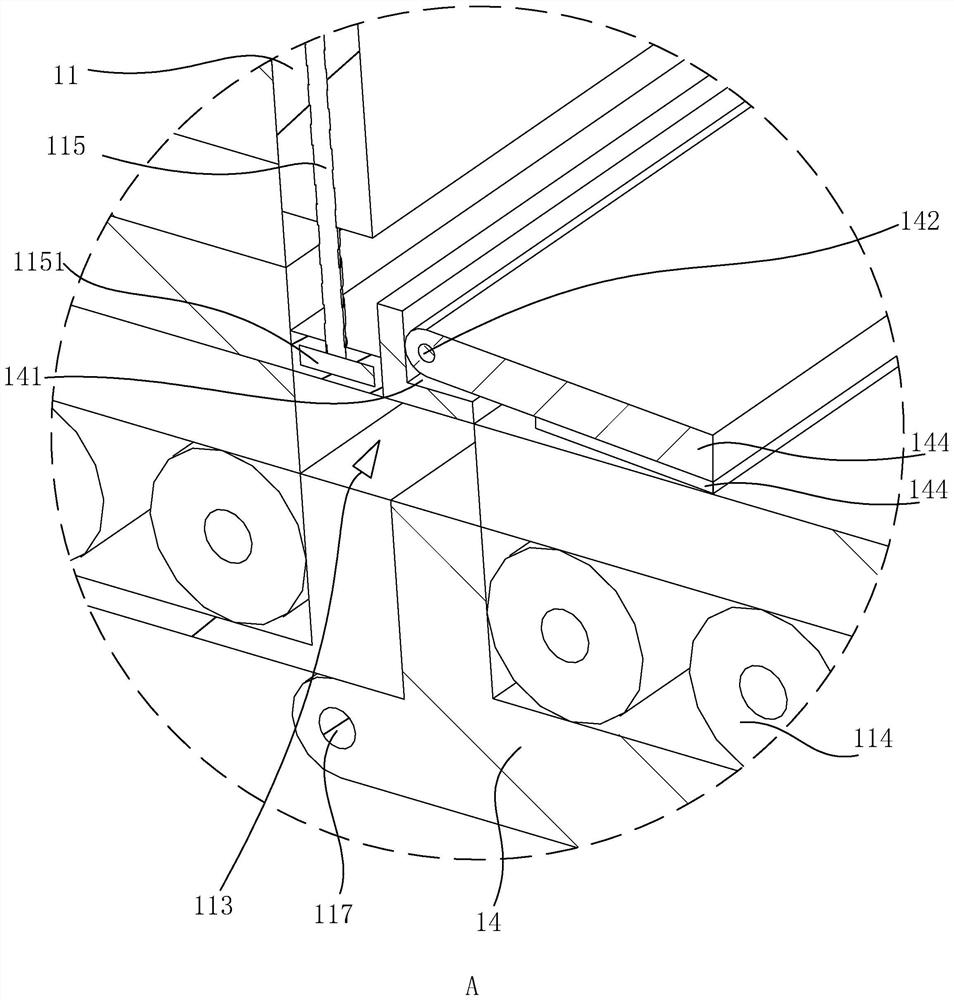

[0035] The following is attached Figure 1-5 The application is described in further detail.

[0036] The embodiment of the application discloses a prefabricated building wall panel installation machine. refer to figure 1 with figure 2 , the prefabricated building wall panel installation machine includes a frame 1, and the frame 1 is provided with a storage box 11, a vertical conveying assembly 12 for driving the storage box 11 to move in the vertical direction, and a vertical conveying assembly 12 for driving the storage box 11 to move along the horizontal direction. The lateral conveying assembly 13 that moves in the direction, the top of the storage box 11 is open and the inside of the storage box 11 is stacked with several wallboards.

[0037] refer to figure 1 with figure 2The vertical conveying assembly 12 includes a vertical screw 121 rotatably connected to the side wall of the frame 1, a vertical motor 122 fixedly mounted on the frame 1 by bolts, and a support t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com