A pipe threading trolley and pipe threading method for the construction of box girder prestressed tunnels

A prestressed, trolley technology, applied in bridges, bridge construction, bridge materials, etc., can solve the problems of easy pulling of rubber hoses, high work intensity, and potential safety hazards, so as to facilitate construction and transportation, reduce construction time, and save energy. human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings.

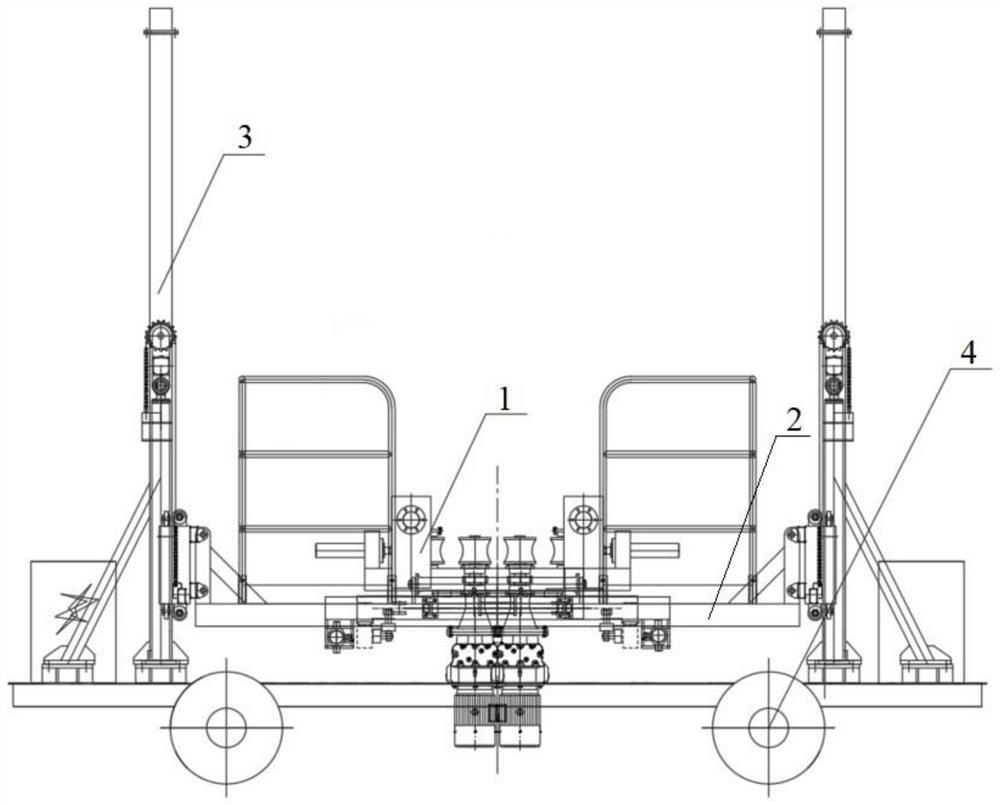

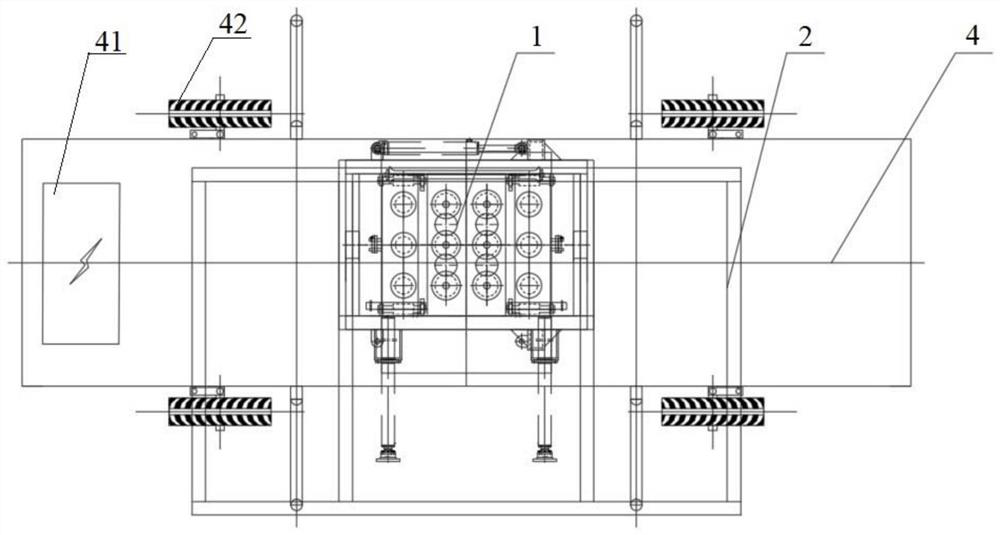

[0034] The structure of the pipe pulling trolley provided in the present invention for the construction of the box girder prestressed tunnel is as follows: figure 1 and figure 2 As shown, it includes at least a chassis 4, the side of the chassis is provided with wheels 42 and supports, a drive motor, a steering oil cylinder and a battery 41 are installed on the chassis, and the chassis is provided with a pipe-piercing and pulling mechanism 1, a working platform 2, Lifting mechanism 3 and reel mechanism 5.

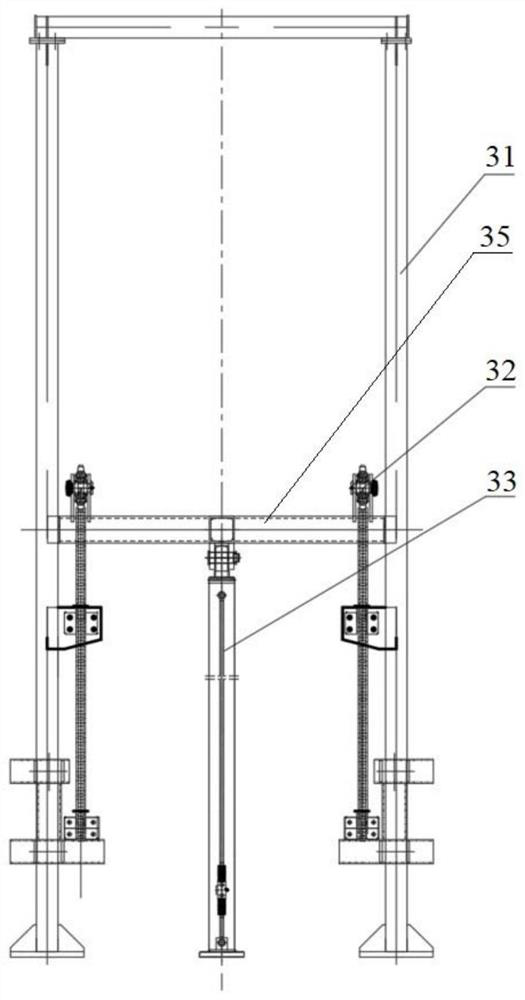

[0035] The side view of the lifting mechanism in this embodiment is as follows image 3 As shown, two groups of door-shaped frames 31 are provided in the lifting mechanism, and the door-shaped frames are respectively vertically fixed at the front and rear ends of the chassis, and the vertical bars of the door-shaped frame are provided with support rods 36, The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com