Welding head of self-adaptive reinforcement cage and welding device of self-adaptive reinforcement cage

A welding head and welding device technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of troublesome parts replacement and adjustment, poor practicability and adaptability, and unfavorable actual production, and achieve good practicability and adaptability. The effect of reducing welding torch clogging and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

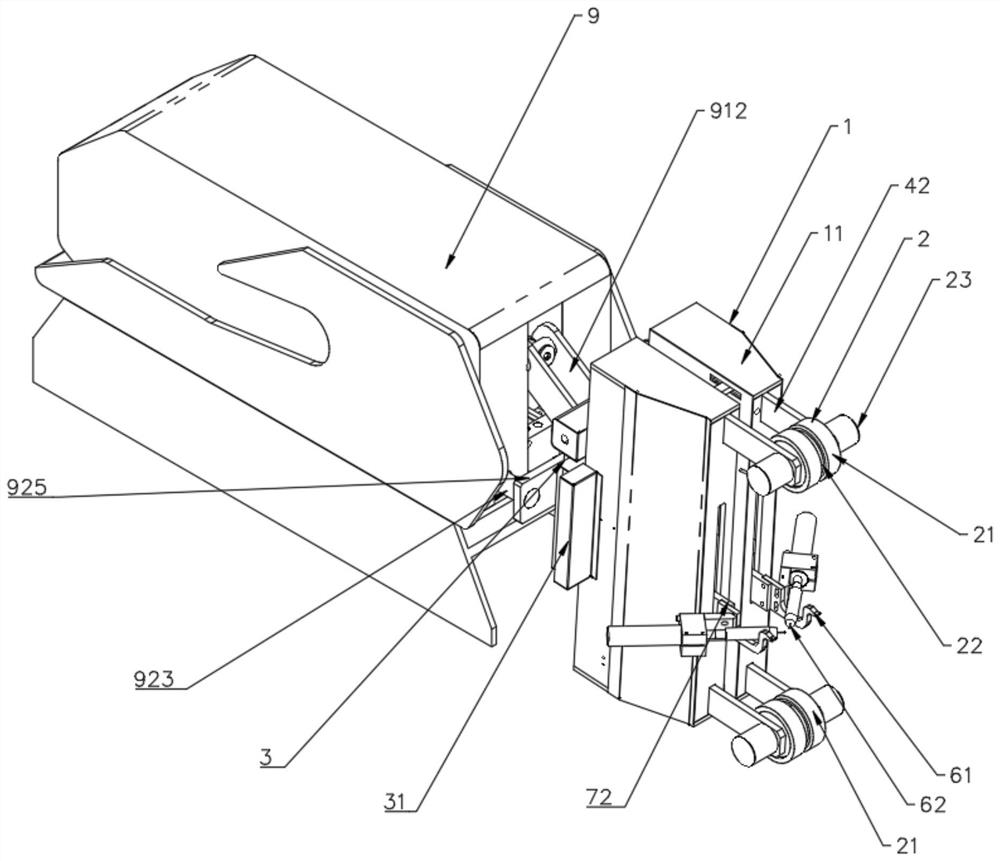

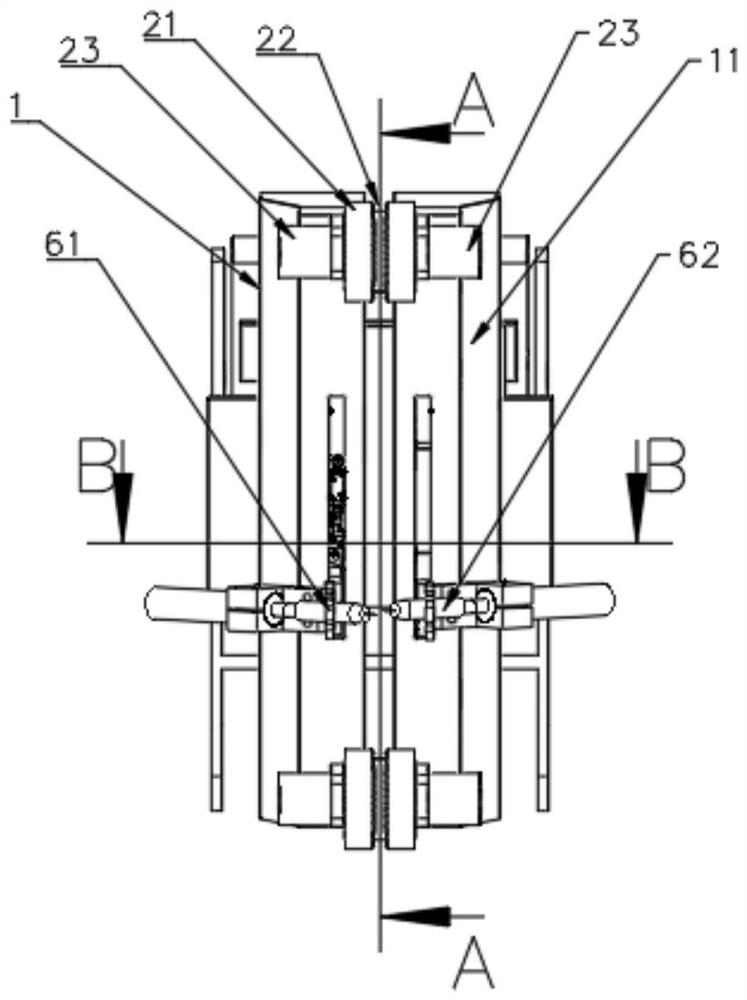

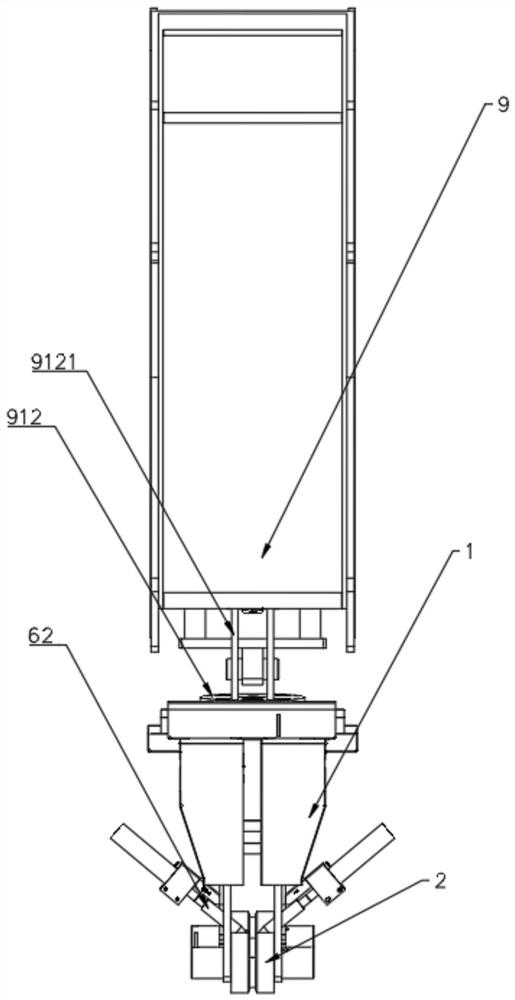

Embodiment 1

[0058] The adjustment mechanism 3 also includes a tension spring (not shown in the figure) arranged between the two mechanical arms 1 , and the direction of the tension spring is parallel to the sliding direction of the mechanical arm 1 relative to the connecting block 31 . In actual use, when the notch 22 in the tracking wheel body 21 is aligned and in contact with the rib, a forward thrust is applied to the mechanical arm 1. At this time, the tracking wheel body 21 will be subjected to a force pointing to both sides along its own axial direction. The component force of the tension spring 35 is extended by stretching (generating a restoring force in the opposite direction), and at this time, the two mechanical arms 1 will slide against each other relative to the connecting block 31, thereby realizing the adjustment of the width of the notch 22, that is, The width of the notch 22 varies freely with the diameter of the winding rib.

[0059] Further, the opening of the tracking ...

Embodiment 2

[0061] Such as Figure 6 As shown, the backs of the two mechanical arms 1 are respectively provided with nut seats 36 and through-hole seats 37 correspondingly. The through-hole seats 37 are perforated with a screw member 382 threadedly connected to the nut seats 36, and the two sides of the through-hole seats 37 are respectively pressed. Resists the first compression spring 35 sleeved on the screw member 382, and the end of the screw member 382 away from the nut seat 36 and the through hole seat 37 is fixed with a pressing plate 381 pressed against the first compression spring 35 on the right side; further Yes, one end of the screw corresponding to the pressure plate 381 is formed with a manual adjustment hole (not marked in the figure). The interaction force of the two first compression springs 35 realizes the adjustment of the distance between the mechanical arms 1 .

Embodiment 3

[0063] Such as Figure 7 As shown, the adjustment mechanism 3 also includes a first screw rod 32 and a first connecting seat 33, and a first connecting seat 33 is respectively installed on the two mechanical arms 1, and the two first connecting seats 33 are threadedly connected to the first connecting seat 33 respectively. The two ends of the screw 32, the helical directions of the threads at the two ends of the first screw 32 are opposite.

[0064] Further, the adjustment mechanism 3 also includes a first drive motor 34, the first drive motor 34 is installed on one of the mechanical arms 1, and the output shaft of the first drive motor 34 is connected to the first screw rod 32 for driving the first screw rod 32 circular rotation. In this embodiment, the end of the first screw 32 away from the first driving motor 34 is formed with a manual adjustment slot 321 , which can be manually adjusted with tools such as a wrench.

[0065] Such as Figure 4 and Figure 9 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com