Green soybean harvester

A harvester, green edamame technology, applied in harvesters, agricultural machinery and implements, solid separation and other directions, to achieve the effects of convenient operation, saving labor costs, and efficient bean picking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

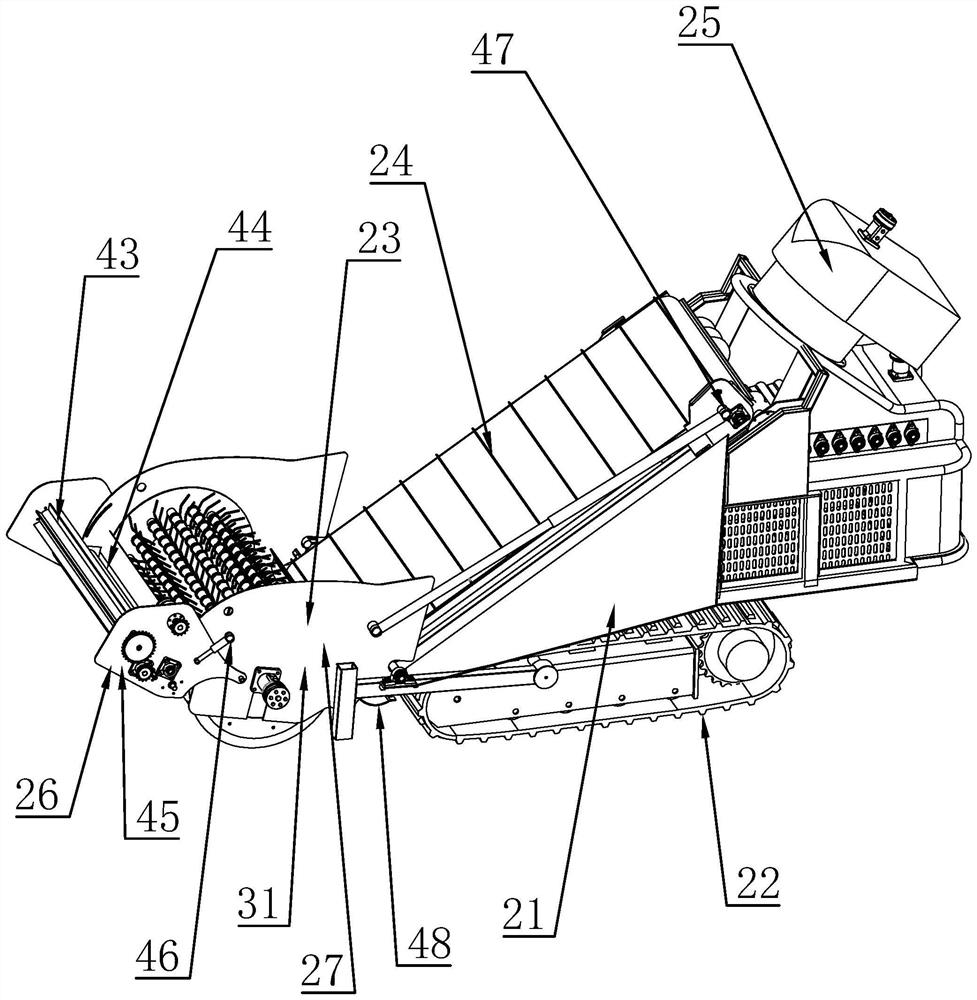

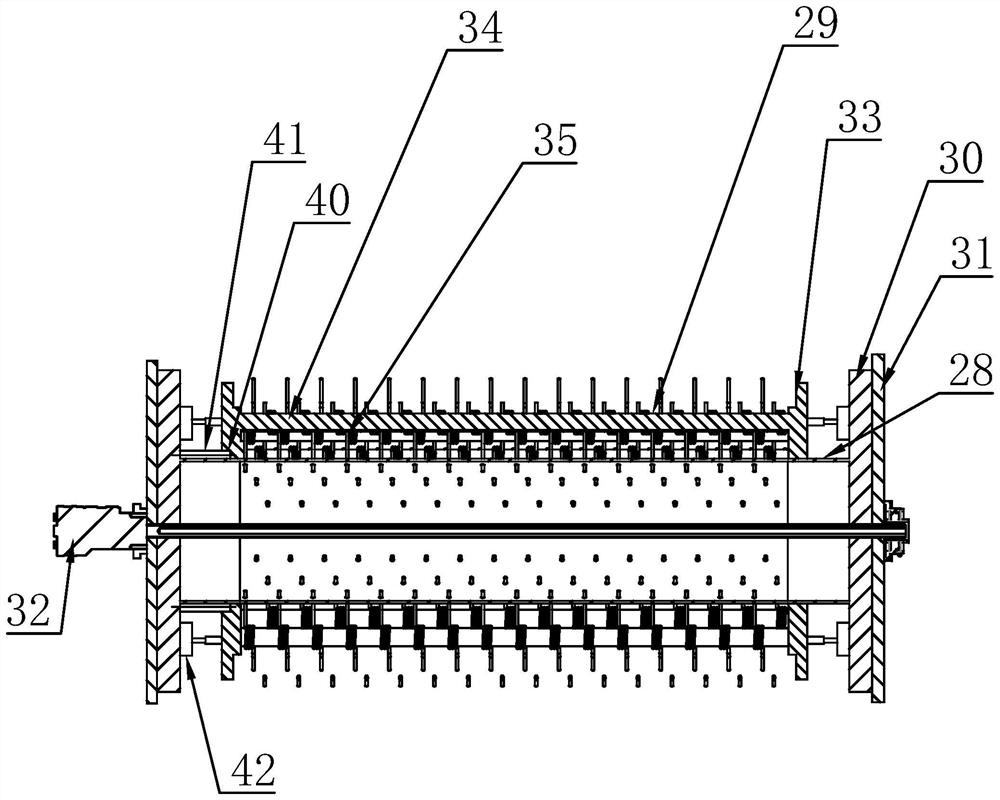

[0045] Such as figure 1 As shown, a green soybean harvester includes a machine base 21, a running mechanism 22, a picking mechanism 23, a conveyor belt 24 and a cleaning mechanism 25, the machine base 21 is located above the running mechanism 22, and the picking mechanism 23 is located on the machine base 21 The front side of the edamame is used for picking off the edamame plant, the conveyor belt 24 is arranged on the rear side of the picking mechanism 23, the input end of the conveyor belt 24 is connected with the output end of the picking mechanism 23, and the picking mechanism 23 picks up the The edamame can be transported to the input end of the conveyor belt 24, the cleaning mechanism 25 is located on the rear side of the conveyor belt 24, the input end of the cleaning mechanism 25 is connected with the output end of the conveyor belt 24, and the cleaning mechanism 25 is used To separate the edamame and sundry branches transported from the conveyor belt 24, the picking m...

Embodiment 2

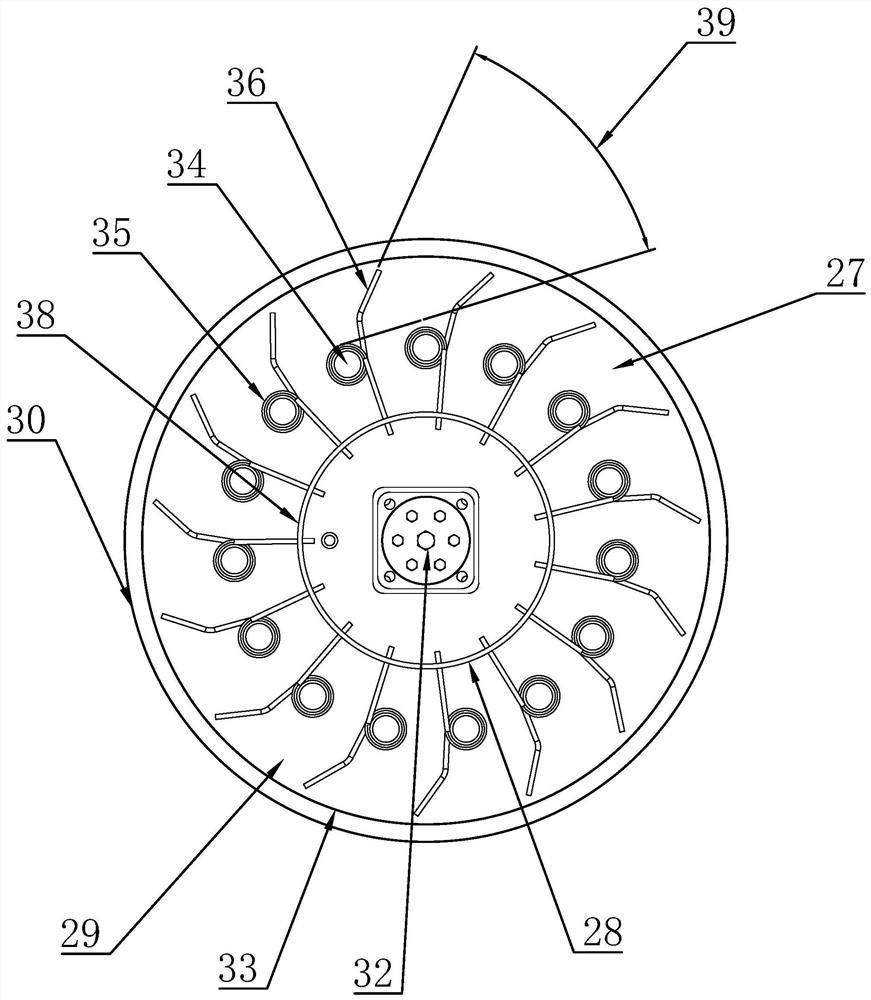

[0060] Such as Figure 4As shown, the content of embodiment 2 is basically the same as that of embodiment 1, and the difference is that the fixed connection mode between the picking bucket 29 and the rotating shaft 28 is different and the bean picking angle 39 adjustment mechanism is different. The fixed connection mode between the picking barrel and the rotating shaft in Embodiment 2 is: the fixed plate 33 of the picking barrel 29 is connected with the bolt 49 between the side plate 30 of the rotating shaft 28 . The bean-picking angle 39 adjustment mechanism includes an arc chute 50 arranged on the side plate 30 of the rotating shaft 28, the bolt 49 is arranged in the above-mentioned arc chute 50, and the bolt 49 can slide along the chute with the picking bucket 29, When it is necessary to adjust the bean-picking angle 39, you only need to loosen the bolt 49, and rotate the picking bucket 29 to the required position. When the position changes, the comb teeth 35 rotate around...

Embodiment 3

[0062] Such as Figure 5 As shown, the content is basically the same as that of Embodiment 1, except that the bean-picking angle 39 adjustment mechanisms are different. The rotating shaft 28 includes an inner sleeve 52 and an outer sleeve 53 , the outer sleeve 53 is sleeved outside the inner sleeve 52 , and the inner sleeve 52 and the outer sleeve 53 are detachably connected by a locking member 51 . Positioning hole 38 is opened on the inner sleeve 52, and the position corresponding to each positioning hole 38 on the overcoat 53 also has the elongated groove 54 that is provided with along the circumferential direction of overcoat 53, and the supporting pin 37 of the comb tooth 35 on the picking barrel 29 wears The overlong slot 54 is inserted into the positioning hole 38 . It is working state at this time. When it is necessary to adjust the bean-picking angle 39, the locking member 51 is loosened, and the fixed connection between the inner sleeve 52 and the outer cover 53 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com