Control system for spraying robot and control method

A spraying robot and control system technology, applied in the direction of program control manipulator, manipulator, spraying device, etc., can solve the problems of inability to guarantee the quality of spraying, difficult operation and implementation of high-height workers, etc., so as to improve the efficiency of spraying operation and reduce the impact on human body. damage, and the effect of improving the overall efficiency of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

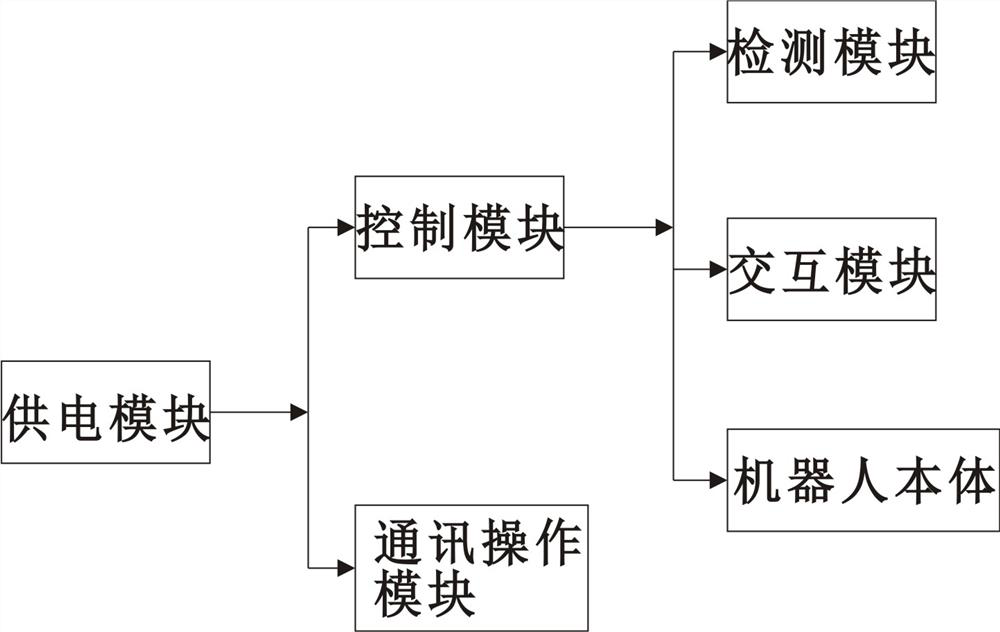

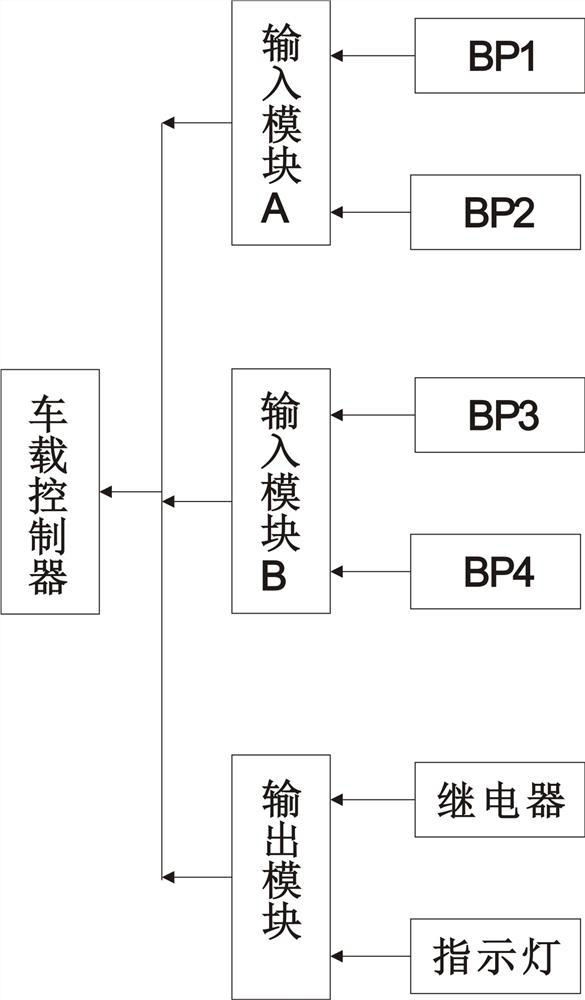

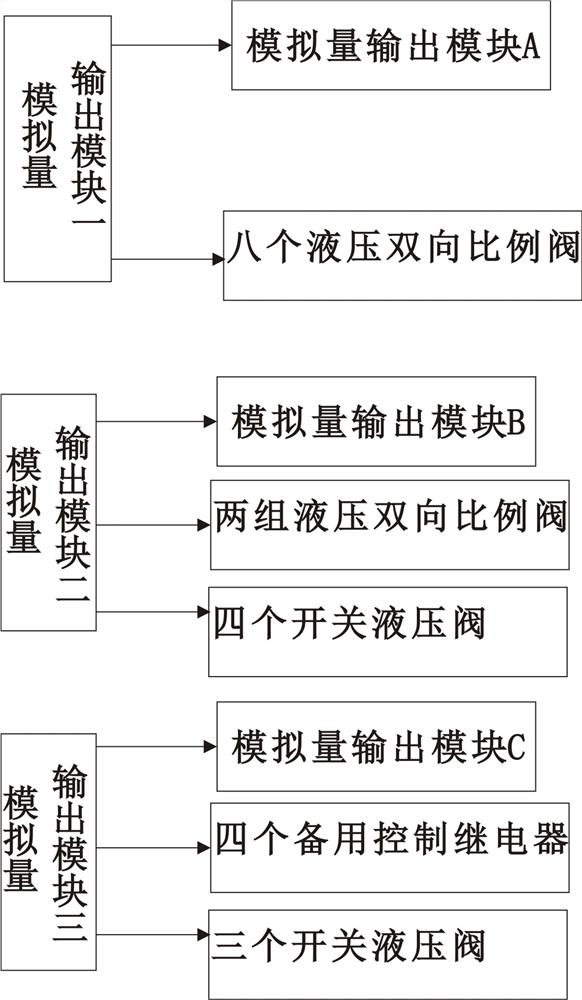

[0035] combined with Figure 1-5 The control system of the spraying robot includes a power supply module, a control module, an interaction module, a detection module and a communication operation module, the power supply module is used to supply power to the entire electrical control system and the spraying robot body, and the control module is used to control the spraying robot The main body and the output ports of the control module are respectively connected to the input ports of the interaction module and the detection module. The main body of the spraying robot includes the vehicle body and the mechanical arm installed on the vehicle body. The movement of the mechanical arm is controlled by the control module. The communication operation module and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com