A paint spraying device for the outer ring surface of an automobile wheel hub

A technology for automobile hubs and outer ring surfaces, which is applied to spraying devices, spray booths, etc., and can solve the problems of low painting efficiency and long time required for painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

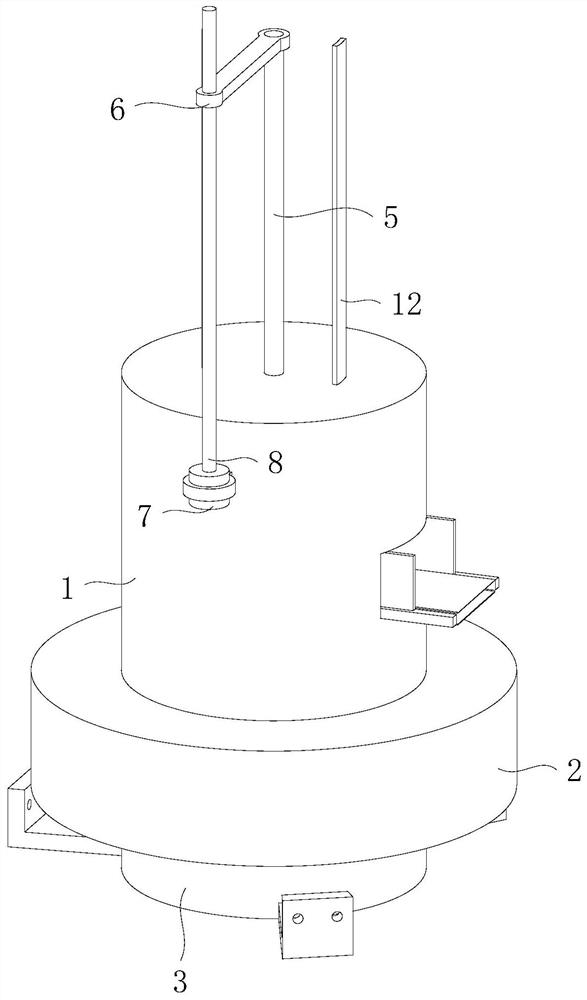

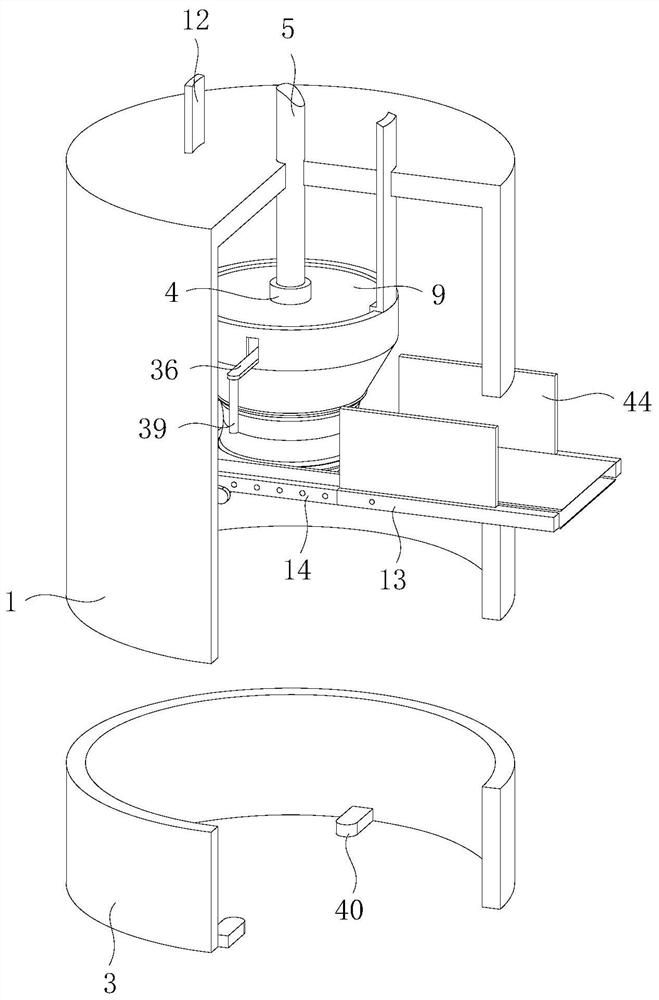

[0026] like Figure 1-7 It shows, a lacquer installation of the outer area of the car hub, including installing barrels, spraying warehouse 2 and bottom barrel 3, spray paint warehouse 2 between the installation barrel 1 and bottom barrel 3, the spray paint warehouse 2 pairs of wheels that move to the internal wheels for permanent Spray paint.

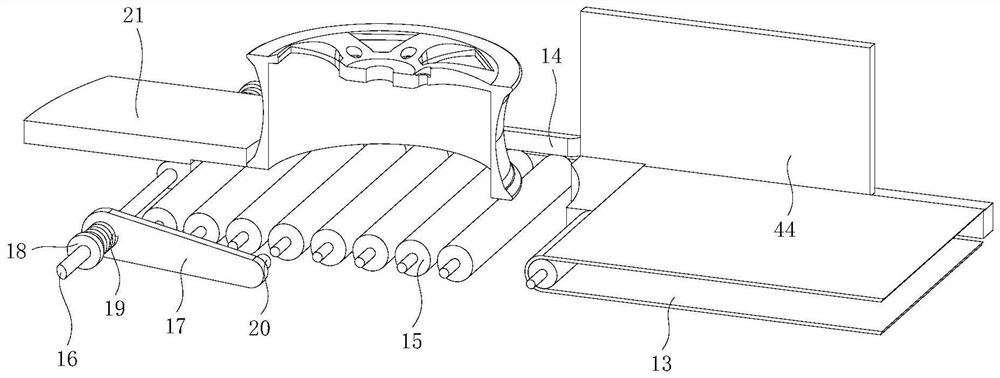

[0027] The upper and lower ends of the spray paint warehouse 2 are fixed with the installation barrel 1 and the bottom barrel 3, respectively. The inner set of the bucket 1 is set with a top plate 9, the upper surface of the top plate 9 has a vertical cylinder 4, and the upper surface of the vertical cylinder 4 is fixed. Connecting the top wall of the inner wall of the tie lever 5 and the upper end of the trolley 5 run through the inner wall of the installation barrel 1, the upper end of the trolley 5 is connected to the connection board 6, the upper end of the installation barrel 1 is fixed with an electric motor 7, the output end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com